Simex TRS-09a User manual

User manual - POWER SUPPLY TRS-09a

CONTENTS

1. BASIC REQUIREMENTS AND USER SAFETY.........................................................................................3

2. GENERAL CHARACTERISTICS................................................................................................................4

3. TECHNICAL DATA......................................................................................................................................4

4. DEVICE INSTALLATION............................................................................................................................5

4.1. UNPACKING.......................................................................................................................................5

4.2. ASSEMBLY.........................................................................................................................................5

4.3. CONNECTION METHOD...................................................................................................................6

4.4. MAINTENANCE................................................................................................................................10

5. SELECTION OF OPERATION MODE......................................................................................................10

Exp anation of symbo s used in the manua :

- This s mbol denotes especiall important guidelines concerning the installation and

operation of the device. Not compl ing with the guidelines denoted b this s mbol

ma cause an accident, damage or equipment destruction.

IF THE DEVICE IS NOT USED ACCORDING TO THE MANUAL THE USER IS

RESPONSIBLE FOR POSSIBLE DAMAGES.

- This s mbol denotes especiall important characteristics of the unit.

Read an information regarding this s mbol carefull

2

User manual - POWER SUPPLY TRS-09a

1. BASIC REQUIREMENTS AND USER SAFETY

- The manufacturer is not responsible for any damages caused by

inappropriate installation, not maintaining the proper technical condition

and using the unit against its destination .

- Installation should be conducted by qualified personnel . During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and EMC

regulations.

- The unit must be properly set-up, according to the application. Incorrect

configuration can cause defective operation, which can lead to unit damage or

an accident.

- If in the case of a defect of unit operation there is a risk of a serious threat

to the safety of people or property additional, independent systems and

solutions to prevent such a threat must be used.

- The unit uses dangerous voltage that can cause a lethal accident. The unit

must be switched off and disconnected from the power supply prior to

starting installation of troubleshooting (in the case of malfunction).

- Neighbouring and mating equipment must meet the requirements of appropriate

standards and regulations concerning safety and be equipped with adequate

anti-overvoltage and anti-interference filters.

- Do not attempt to disassemble, repair or modify the unit yourself. The unit

has no user serviceable parts. Units, in which a defect was stated must be

disconnected and submitted for repairs at an authori ed service centre.

- Do not use the unit in areas threatened with excessive shocks, vibrations,

corrosive gasses and oils.

- Do not use the unit in explosion hazard areas.

- Do not use the unit in areas with significant temperature variations, exposed to

icing.

- Do not use the unit in areas exposed to direct sunlight.

- Make sure that the ambient temperature (e.g. inside the control box) does not

exceed the recommended values. In such cases forced cooling of the unit must

be considered (e.g. by using a ventilator).

The unit is designed for operation in an industrial environment and must

not be used in a household environment or similar.

3

User manual - POWER SUPPLY TRS-09a

2. GENERAL CHARACTERISTICS

TRS-09a is a supporting power supply for the TRS System which supplies stabilized

direct voltage 11.5V. It can work in two modes: as a controlled supply (switched on with

external voltage 7 ÷ 12V) or a non-controlled supply. The configuration is selected by means of

a link. Current efficiency is 200 mA. The supply is resistant to output voltage short circuit. The

device is located in a casing that completely protects it against dust or low pressure streams of

water.

3. TECHNICAL DATA

Power supply voltage 230V AC +10%, -5%, 50 ÷ 60 Hz

External fuse (required) T - type, max. 2 A

Power consumption max. 6 VA

Output voltage 11.5 V ±5% DC

Current efficiency max. 200 mA

Control voltage 7V ÷ 12V DC, max. 2mA

Protection level IP 65 (ABS casing)

Housing type

Housing material

Housing dimensions (L x W x D)

without glands

with glands

wall mounted

ABS

110 x 0 x 67 mm

133 x 130 x 67 mm

Operating temperature

(depending on version)

0°C to +50°C

or -20°C to +50°C

Storage temperature

(depending on version)

-10°C to +70°C

or -20°C to +70°C

Altitude up to 2000 meters above sea level

Fastening to wall, 2 M3 bolts

Connection cable 4 conductors (2 supply conductors

+ 2 data transmission conductors)

Screws tightening max. torque 0,5 Nm

Max. connection leads diameter 2,5 mm2

Safety requirements according to:

PN-EN 61010-1:1999 + PN-EN 61010-1/A2:1999

installation category: II

pollution degree: 2

voltage in relation to ground: 300V AC

insulation resistance: >20MΩ

insulation strength between power supply and input/output

terminal: 1min. @ 2300V

EMC PN-EN 61326:2003

4

User manual - POWER SUPPLY TRS-09a

This is a class A unit. In housing or a similar area it can cause radio

frequency interference. In such cases the user can be requested to use

appropriate preventive measures.

Detailed informations about installation of TRS system user can find in:

“User manual for Temperature and Humidity Recording System”.

4. DEVICE INSTALLATION

The unit has been designed and manufactured in a way assuring a high level of user

safety and resistance to interference occurring in a typical industrial environment. In order to

take full advantage of these characteristics installation of the unit must be conducted correctly

and according to the local regulations.

- Read the basic safety requirements on page 3 prior to starting the installation.

- Ensure that the power supply network voltage corresponds to the nominal

voltage stated on the unit’s identification label.

- The load must correspond to the requirements listed in the technical data.

- All installation works must be conducted with a disconnected power supply.

- Protecting the power supply clamps against unauthorized persons must be

taken into consideration.

4.1. UNPACKING

After removing the unit from the protective packaging, check for transportation damage.

Any transportation damage must be immediately reported to the carrier. Also, write down the

unit serial number on the housing and report the damage to the manufacturer.

Attached with the unit please find:

- warranty,

- user’s manual for TRS-09a unit (device)

4.2. ASSEMBLY

- Disconnect the power supply prior to starting assembly.

- Check the correctness of the performed connections prior to switching the unit on.

To install the device prepare pinholes accordingly to Figure 4.1. Back side of the

case (with mounting holes) should be mounted to a wall using screws.

5

User manual - POWER SUPPLY TRS-09a

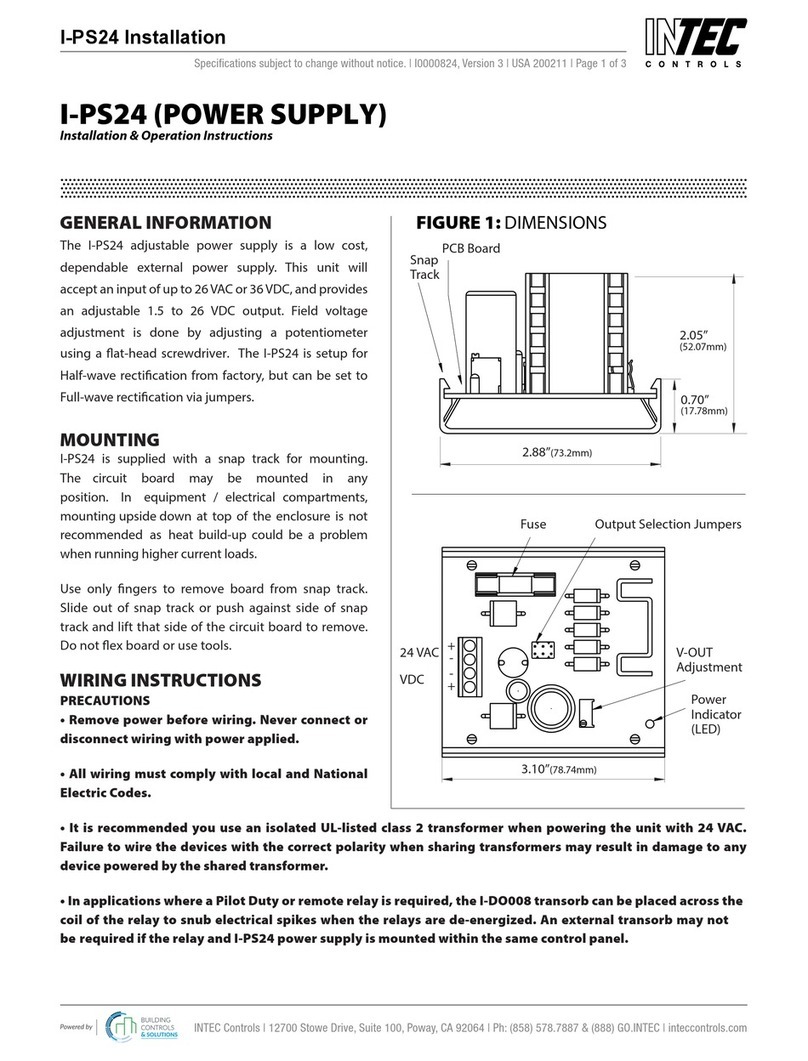

Figure 4.1. Distances between pinholes

4.3. CONNECTION METHOD

Caution

- Installation should be conducted by qualified personnel . During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and EMC

regulations.

- The unit is not equipped with an internal fuse or power supply circuit breaker.

Because of this an external time-delay cut-out fuse with minimal possible nominal

current value must be used (recommended bipolar, max. 2A) and a power supply

circuit-breaker located near the unit. In the case of using a monopolar fuse it must

be mounted on the phase cable (L).

- The power supply network cable diameter must be selected in such a way that in

the case of a short circuit of the cable from the side of the unit the cable shall be

protected against destruction with an electrical installation fuse.

- Wiring must meet appropriate standards and local regulations and laws.

- In order to secure against accidental short circuit the connection cables must be

terminated with appropriate insulated cable tips.

- Tighten the clamping screws. The recommended tightening torque is 0.5 Nm.

Loose screws can cause fire or defective operation. Over tightening can lead to

damaging the connections inside the units and breaking the thread.

6

60 mm

90 mm

User manual - POWER SUPPLY TRS-09a

- In the case of the unit being fitted with separable clamps they should be inserted

into appropriate connectors in the unit, even if they are not used for any

connections.

- Unused clamps (marked as n.c.) must not be used for connecting any connecting

cables (e.g. as bridges), because this can cause damage to the equipment or

electric shock.

- If the unit is equipped with housing, covers and sealing packing, protecting

against water intrusion, pay special attention to their correct tightening or clamping.

In the case of any doubt consider using additional preventive measures (covers,

roofing, seals, etc.). Carelessly executed assembly can increase the risk of electric

shock.

- After the installation is completed do not touch the unit’s connections when it is

switched on, because it carries the risk of electrical shock.

Due to possible significant interference in industrial installations appropriate measures

assuring correct operation of the unit must be applied. To avoid the unit of improper

indications keep recommendations listed below.

-Avoid common (parallel) leading of signal cables and transmission cables together with

power supply cables and cables controlling induction loads (e.g. contactors). Such cables

should cross at a right angle.

-Contactor coils and induction loads should be equipped with anti-interference protection

systems, e.g. RC-type.

-Use of screened signal cables is recommended. Signal cable screens should be

connected to the earthing only at one of the ends of the screened cable.

-In the case of magnetically induced interference the use of twisted couples of signal cables

(so-called “spirals”) is recommended. The spiral (best if shielded) must be used with RS-

4 5 serial transmission connections.

-In the case of interference from the power supply side the use of appropriate anti-

interference filters is recommended. Bear in mind that the connection between the filter

and the unit should be as short as possible and the metal housing of the filter must be

connected to the earthing with largest possible surface. The cables connected to the filter

output must not run in parallel with cables with interference (e.g. circuits controlling relays

or contactors).

Connections of power supply voltage and measurement signals are executed using the

screw connections inside of the unit’s housing (Figure 4.2 - 4.4).

Figure 4.2. Method of cable insulation replacing and cable terminals

7

max. 2 mm

6-7 mm

User manual - POWER SUPPLY TRS-09a

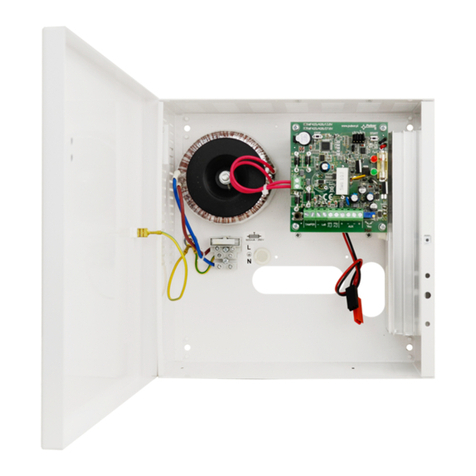

Figure 4.3. Location of elements inside the module case

Connectors description

{ +12V out} - network supply voltage output (+)

{ ctrl } - control voltage input

{ DATA } - RS 4 5 lines connectors

{ GND } - GND of supply output and control input.

Figure 4.4. Connection of TRS-09a module to the network

8

58 7 6 4 3

1 2

DATA-

DATA+

RS - 485

ctrl

GND

+12V

out

shield

230V AC

J1

J2

LED indicator

Power output and

RS-485 connector

Power suppl

input connector

Output voltage

11.5 V ±5% DC

GND

DATA -

DATA+

ctrl

58 7 6 4 3

+12V out

GND

Control voltage

7V ÷ 12V DC

RS-485 bus

RS-485 bus

DATA -

DATA+

User manual - POWER SUPPLY TRS-09a

Figure 4.5. Connection of power suppl

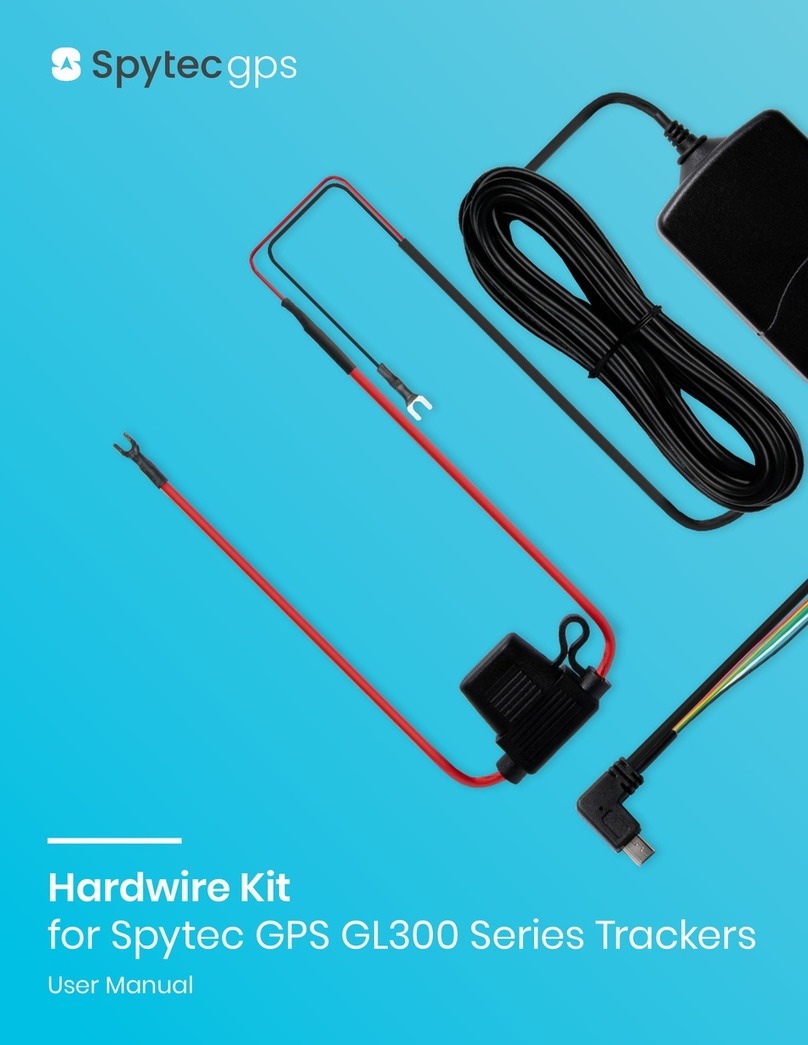

Serial connection of power supply modules TRS-09a (while power output of one module

drives control input of the next one, Figure 4.6), allows turn off all modules connected to the

network at the same time. When power supply of first TRS-09a module is turned off, then

following power supply modules will be turned off sequentially.

Figure 4.6. Cascade of power suppl modules TRS-09a.

RS-485 bus should be equipped with termination resistors (100-150 ohm) on

both ends. The bus must not be ramified, and longer than 1 km.

9

FUSE

L N

N

L

1 2

A+

B-

terminator

(120 ohm)

ctrl ...

Measurement modules of TRS s stem

TRS- 09a modules

SRS-2/4-Z16-B1a

User manual - POWER SUPPLY TRS-09a

4.4. MAINTENANCE

The unit does not have any internal replaceable or adjustable components available to the

user. Pay attention to the ambient temperature in the room where the unit is operating.

Excessively high temperatures cause faster ageing of the internal components and shorten the

fault-free time of unit operation.

In cases where the unit gets dirty do not clean with solvents. For cleaning use warm water with

small amount of detergent or in the case of more significant contamination ethyl or isopropyl

alcohol.

Using any other agents can cause permanent damage to the housing.

Product marked with this symbol should not be placed in municipal waste. Please

check local regulations for disposal and electronic products.

5. SELECTION OF OPERATION MODE

The selection of operation mode can be done by proper jumper settings (see Figure 5.1):

•externa y contro ed mode : {J1} open , {J2} open or short

This configuration allows to remote control of the module using it's control input (voltage

7÷12V connected to { ctrl } terminal). If control input is not connected, or it's voltage is to low,

module output voltage is turned off - voltage between terminals { +12V out } and { GND } will

drop to 0V.

•Stand a one mode : {J1} short, {J2} open

This configuration allows stand alone mode of module operation. Module is independent

of external signal { ctrl }. Power supply module is permanently turned on - voltage between

terminals { +12V out } and { GND } is about 11.5 V.

10

SIMEX Sp. o.o.

ul. Wielopole 7

80-556 Gdańsk

Poland

tel.: (+48 58) 762-07-77

fax: (+48 58) 762-07-70

http://www.simex.pl

e-mail: info@simex.pl

Table of contents

Popular Power Supply manuals by other brands

Aktakom

Aktakom ATH-2235 user manual

Delta Elektronika

Delta Elektronika SM 15-100 product manual

Niko

Niko 10-805-01 manual

Siemens

Siemens SITOP PSU100S operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley Bulletin 1609 Installation and operation

Thermo Scientific

Thermo Scientific EC300XL Operating and maintenance manual