Cautions, Warnings, and Regulatory Information

READ AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation manual. These instructions must be followed to avoid damage to

this product and associated equipment. Product operation and reliability depend upon proper installation.

DO NOT INSTALL ANY SIMPLEX™ PRODUCT THAT APPEARS DAMAGED Upon unpacking your Simplex product, inspect the contents

of the carton for shipping damage. If damage is apparent, immediately file a claim with the carrier and notify an authorized Simplex

product supplier.

ELECTRICAL HAZARD Disconnect electrical field power when making any internal adjustments or repairs. All repairs should be

performed by a representative or an authorized agent of your local Simplex product supplier.

STATIC HAZARD Static electricity can damage components. Handle as follows:

• Ground yourself before opening or installing components.

• Prior to installation, keep components wrapped in anti-static material at all times.

EYE SAFETY HAZARD Under certain fiber optic application conditions, the optical output of this device may exceed eye safety limits. Do

not use magnification (such as a microscope or other focusing equipment) when viewing the output of this device.

Introduction

This publication describes the installation procedure for the 4100-1293 Panel-Mounted Printer.

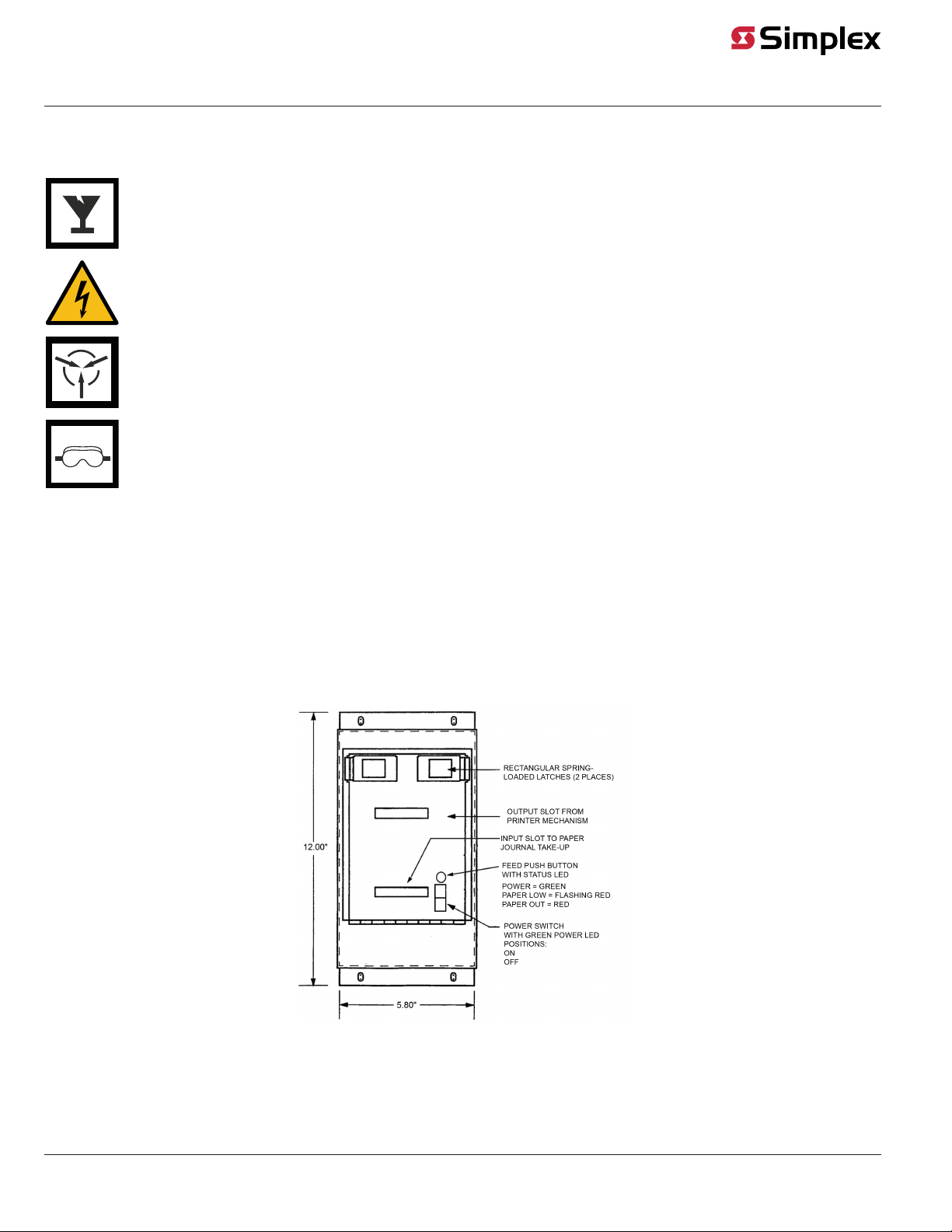

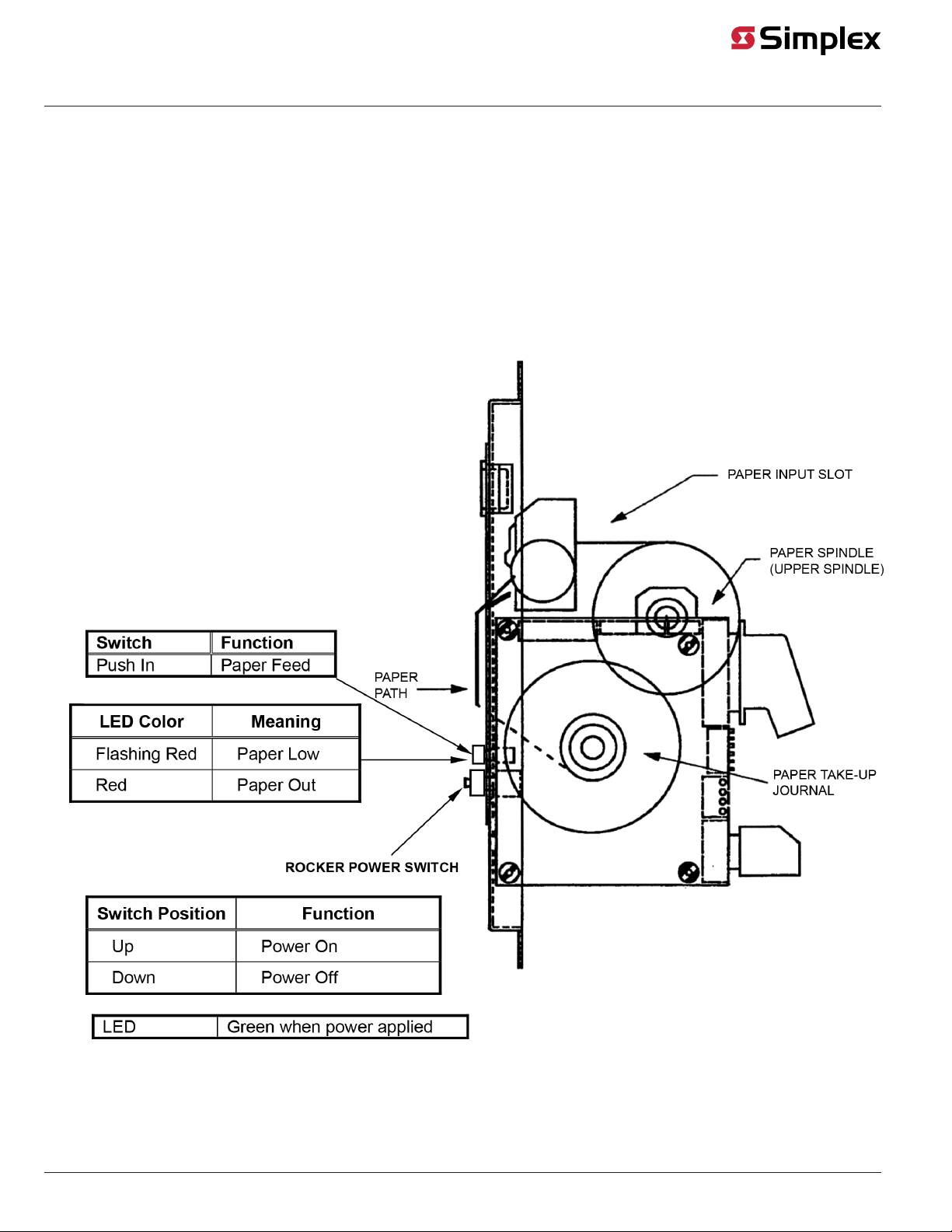

The Panel-Mounted Printer

The 4100-1293 Panel-Mounted Printer (Figure 1) is used with the 4100/4100U/4100ES Fire Alarm System. The panel-mounted printer provides hard

copy reports of the master control panel's output and provides conformance with proprietary operation (formally known as NFPA 72D). The thermal,

dot matrix panel-mounted printer displays twenty visible lines of print, has a column width of forty characters, and is capable of printing variable

output formats on standard 2.350-inch wide thermal paper.

The panel-mounted printer does not require any changes to its default switch or jumper settings. It automatically detects the interface which is

sending data and produces the appropriate output. The serial interface parameters are factory-set and stored on the printer firmware. The standard

factory settings for the serial interface parameters are: 9600 baud, no parity, 8 data bits, and 1 stop bit.

Figure 1: Panel-Mounted Printer, Front View

579-249 Rev. G

4100-1293 Panel-Mounted Printer Installation Instructions

*0579249G*