SimpliVity OmniCube CN-2000 Operating manual

www.SimpliVity.com

SimpliVity OmniCube CN-2000, CN-2200,

CN-3000, and CN-5000 Hardware

Installation and Maintenance Guide

2

Trademarks

SimpliVity®, ®, SimpliVity cube logo®, SimpliVity The Data Virtualization Company®,

OmniCube®, OmniStack®, Global Federated Architecture®, Data Virtualization Platform™, SVT™, and

RapidDR™ are trademarks or registered trademarks of SimpliVity® Corporation in the United States

and certain other countries.

All other trademarks are the property of their respective owners.

Patents

SimpliVity OmniCube® and OmniStack® products are covered by various United States and foreign

patents and pending patent applications.

Patents include:

US8478799; US9032183; US9367551; US9436748; US2013/0290263; US2013/0024615;

US2012/0331029; US2015/0242315; US2016/0200927; CNZL201080033630.9; CA 2,840,178;

JP 2014-517025; DK2433226; EP2433226; FI2433226; FR2433226; DE2433226; IT2433226;

JP5902323; JP5695040; NO2433226; ES2433226; SE2433226; GB2433226; AU33222325; AU

WO2010/151813; BR WO2010/151813; CA WO2010/151813; IN679/CHENP/2012A; EP2734933;

HK1196886; AU WO2012/177461; BR WO2012/177461; CA WO2012/177461; CN103703464A;

EP2724263; HK1197696; IN368/ CHENP/2014A; JP2014-524078; BR WO2013/126680; BR

WO2016/115219; CA WO2013/126680; CA WO2016/115219; CN104221014A; EP2817743;

HK WO2013/126680; HK WO2016/115219; IN WO2013/126680; IN WO2016/115219; JP

WO2013/126680; JP WO2016/115219

Copyright

Information in this document is subject to change without notification. Reproduction in any manner

whatsoever without the written permission of SimpliVity Corporation is strictly forbidden.

© SimpliVity Corporation 2017

Customer support

To contact SimpliVity Customer Support, visit https://support.simplivity.com. When contacting a

representative, you need to know the serial number of your OmniStack server to verify your service

subscription.

SimpliVity uses OmniWatch to automatically monitor the health of your OmniStack equipment and

have it send us notifications of any alerts or errors.

January 2017

760-000194 Rev A

Intended audience 3

Intended audience

This document is intended for users of SimpliVity OmniStack products who want to install, manage, and

monitor their hyperconverged IT infrastructure. This information is intended for system administrators

experienced in hypervisor technology, virtual machine management, and data center operations.

SimpliVity documentation conventions 4

SimpliVity documentation conventions

SimpliVity documentation uses the following conventions to assist your reading.

General formatting

Monospace font represents a command line syntax, file path, system output, or similar code.

Italic font represents a user-defined name or variable.

Bold font represents a user interface element, such as a button or tab, with which a user interacts.

Command Line formatting

SimpliVity documentation uses the following format for CLI commands:

command --option variable

where

■command is the name of the command and should be typed exactly as shown.

■--option is a command option and should be typed exactly as shown.

■variable is an option variable and should be replaced with the required value.

SimpliVity documentation feedback 5

SimpliVity documentation feedback

We welcome your feedback, suggestions, and comments to help us continue to improve the quality of

our documentation.

Send your comments to Documentation-Feedback@SimpliVity.com and include as much detail as

possible to help us identify the affected area.

Contents 6

Contents

Chapter 1: Hardware overview................................................................................................. 8

Hardware components........................................................................................................................ 8

About the front panel components................................................................................................8

About the back panel components............................................................................................. 10

Environmental and technical specifications...................................................................................... 12

Enclosure size and weights........................................................................................................ 12

Power and thermal...................................................................................................................... 13

Temperature and humidity...........................................................................................................14

Vibration and shock.....................................................................................................................14

Altitude and airborne contaminants............................................................................................ 14

Agency compliance standards.................................................................................................... 14

About hardware upgrades.................................................................................................................15

About firmware revisions...................................................................................................................15

Chapter 2: Install the server hardware..................................................................................16

About electrostatic discharge............................................................................................................ 16

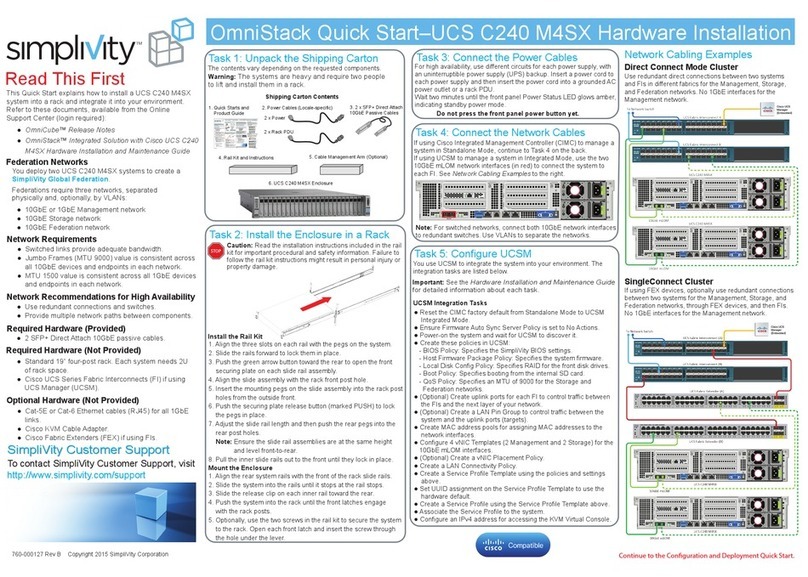

Unpack the shipping carton.............................................................................................................. 16

Shipping carton contents.............................................................................................................18

Hardware not supplied in the shipping carton............................................................................ 18

Install the server enclosure in a rack............................................................................................... 20

Mount the enclosure in the rails....................................................................................................... 21

Connect the network cables............................................................................................................. 22

Connect the power cables................................................................................................................ 23

Organize the cables.......................................................................................................................... 24

Power on the system........................................................................................................................ 24

Attach the OmniCube bezel..............................................................................................................24

Detach the OmniCube bezel.......................................................................................................26

Chapter 3: Configure the IPMI port for remote management............................................. 27

Connect to IPMI and launch the Virtual Console............................................................................. 28

IPMI configuration requirements....................................................................................................... 29

Chapter 4: Server troubleshooting........................................................................................ 30

About diagnostic indicators............................................................................................................... 30

About drive monitoring...................................................................................................................... 31

About front drive numbering....................................................................................................... 32

About power supply monitoring........................................................................................................ 33

About Accelerator card monitoring................................................................................................... 34

Accelerator card is not detected................................................................................................. 35

Revert an Accelerator card to its backup firmware.................................................................... 36

About network interface monitoring.................................................................................................. 36

Contents 7

Chapter 5: Drive maintenance................................................................................................39

Drive maintenance guidelines........................................................................................................... 39

Remove a drive................................................................................................................................. 40

Install a drive.....................................................................................................................................41

Chapter 6: Power supply maintenance................................................................................. 43

About power supply maintenance guidelines................................................................................... 43

Remove a power supply................................................................................................................... 43

Install a power supply....................................................................................................................... 44

Chapter 7: About network cabling options...........................................................................46

About the 10GbE-only network configuration................................................................................... 46

About the direct-connected network configuration............................................................................47

About the switch-connected network configuration.......................................................................... 48

Appendix A: SimpliVity terminology......................................................................................50

Chapter 1: Hardware overview 8

Chapter 1: Hardware overview

This section contains the following topics:

•Hardware components

•Environmental and technical specifications

•About hardware upgrades

•About firmware revisions

The foundation of the SimpliVity architecture is two or more high-performance and highly-available

OmniCube servers. An OmniCube server provides computing, storage, networking, and other

resources to the virtual machines (VM) in the Federation.

After installing the hardware in a rack and connecting power and network cables, you can deploy each

OmniCube server into a SimpliVity Federation. As your capacity and performance needs increase, you

can add more OmniCube servers for easy, on-demand scalability, with no disruption to users.

Hardware components

Each OmniCube model provides different hardware configurations for storage, compute, and memory.

About the front panel components

The front panel of each OmniCube server provides system controls, diagnostic indicators, USB and

video ports, and contains a different number of solid state drives (SSD) and hard disk drives (HDD).

Figure 1: OmniCube CN-5000 front panel

Chapter 1: Hardware overview 9

Figure 2: OmniCube CN-2000 and CN-3000 front panel

Figure 3: OmniCube CN-2200 front panel

Table 1: Front panel component descriptions

Callout Component Description

1 Power button Controls power to the system and indicates whether

there is power to the system. If the indicator is green, the

system is receiving power.

2 Diagnostic indicators Shows hardware error conditions.

3 System identification button System identification button and system identification

connector.

The system identification button helps you locate a

system within a rack. If you push the system identification

button on the back panel or the front panel, the system

identification buttons on the front panel and the back

panel flash blue. Push a system identification button a

second time to stop it from flashing.

The system identification connector, located to the right

of the system identification button, connects the optional

system status indicator assembly through the optional

cable management arm.

4 Retention latches Locks the enclosure in the rack. You can push a latch to

release the enclosure and slide it out.

Chapter 1: Hardware overview 10

Callout Component Description

5 Storage The disk drives have power (top) and activity (bottom)

LED indicators. Labels indicate the type (SAS or SATA)

and capacity of each drive. For rotational drives, the

rotation speed (rpm) is indicated.

The system models contain different drive configurations:

■ CN-5000: Contains 24 2.5" drives. Drives 0 to 5 are

SSDs. Disks 6 to 23 are HDDs.

■ CN-2000 and CN-3000: Contains 12 3.5" drives.

Drives 0 to 3 are SSDs and drives 4 to 11 are HDDs.

■ CN-2200: Contains 10 3.5" drives. Drives 0 and 1 are

SSDs and drives 2 to 9 are HDDs. Drives 10 and 11

are empty.

If you pull the system enclosure from the rack, the drive

numbering scheme is described on a label attached to

the top of the enclosure.

6 Video input Enables you to connect a monitor as part of a keyboard,

video, and mouse (KVM) setup, for local administration.

7 USB connector USB 2.0-compliant connector. Enables you to connect

a USB device, such as a keyboard, as part of a KVM for

local administration.

8 Service tag Provides identification information that you can use when

contacting Customer Support.

About the back panel components

The back panel of an OmniCube server contains the Accelerator, network ports, rear boot drives, and

the power supplies.

Figure 4: Back panel of an OmniCube server with a single CPU

Chapter 1: Hardware overview 11

Figure 5: Back panel of an OmniCube server with two CPUs

Table 2: Back panel component descriptions

Callout Component Description

1 Riser 1 Contains PCIe slots 1-3. You can install optional

2x10GbE or 2x1GbE network cards in these slots, as

shown in slot 2, used by guest VMs only.

A system with a single CPU does not contain riser 1. A

plate is installed in place of riser 1.

2 Accelerator Installed in PCIe slot 5 of riser 2, but also occupies slot 4.

The card has two LEDs that continuously glow green to

indicate normal operation.

3 RAID controller RAID Controller for the rear boot drives installed in PCIe

slot 6 of riser 3. The RAID Controller for the front data

disks is a mezzanine card.

4 System identification button System identification button and system identification

connector.

The system identification button helps you locate a

system within a rack. If you push the system identification

button on the back panel or the front panel, the system

identification buttons on the front panel and the back

panel flash blue. Push a system identification button a

second time to stop it from flashing.

The system identification connector, located to the right

of the system identification button, connects the optional

system status indicator assembly through the optional

cable management arm.

5 IPMI port Dedicated IPMI port for remote, out-of-band, web-based

management.

Chapter 1: Hardware overview 12

Callout Component Description

6 Serial port Serial port that you can use to connect a serial device.

7 Video connector Video connector that enables you to connect a monitor or

keyboard, video, monitor (KVM) device.

8 USB connectors Two USB 3.0 compliant ports for connecting USB devices

to the system.

9 10GbE ports Two 10GbE network interfaces, numbered 1 and 2.

Each 10GbE interface has link (top) and activity (bottom)

round LEDs. These interfaces are dedicated to SimpliVity

Storage and Federation networks.

10 1GbE ports Two 1GbE network interfaces, numbered 3 and 4,

from left to right. Each 1GbE interface has link (left)

and activity (right) square LEDs. These interfaces are

dedicated to the Management network and, optionally,

VM traffic.

11 Power supplies Two redundant, 750W or 1100W power supplies

with fans, numbered 1 and 2, from left to right. Each

power supply has a status indicator light in the handle.

Disconnect the power cords before removing a power

supply. Wattage depends on the CPU requirements

(number of cores).

12 Boot drives Two hot-swappable 2.5" hard drives. Reserved for system

use and are not available for user data storage.

Environmental and technical specifications

There are specific environmental and technical specifications for each hardare platform. The

specifications help you when planning the appropriate installation location, environmental conditions,

and resources, such as power and cooling.

Enclosure size and weights

OmniCube servers have specific size dimensions and weights. This information helps you when

planning to install the enclosure in a rack.

Dimension Centimeters Inches

Enclosure width 48.2 17.5

Maximum height 8.73 3.44

Chapter 1: Hardware overview 13

Dimension Centimeters Inches

Maximum depth (from rack

flange)

75.58 29.75

System Model Kilograms Pounds

CN-2000, CN-2200, CN-3000 32.5 71.5

CN-5000 29.5 65

Power and thermal

OmniCube servers have two redundant power supplies with specific power and thermal specifications.

Specification CN-2000 and CN-3000 CN-2200 CN-5000

Current consumption 10A-5A ■ 750W: 10A-5A

■ 1100W: 12A-6.5A

12A-6.5A

Supply voltage 100–240VAC

(autoranging). Make

sure each power source

has sufficient electrical

overload protection.

100–220VAC

(autoranging). Make

sure each power source

has sufficient electrical

overload protection.

100–240VAC

(autoranging). Make

sure each power source

has sufficient electrical

overload protection.

Frequency 50/60Hz 50/60Hz 50/60Hz

Heat dissipation 2843/2891 BTU/hr max ■ 750W: 2843/2891

BTU/hr max

■ 1100W: 4100 BTU/hr

max

4100 BTU/hr max

Maximum inrush current 55A 55A 55A

Energy efficiency Energy Star, spec

version 1.0

Energy Star, spec

version 1.0

Energy Star, spec

version 1.0

Power supply efficiency 90-96% efficient (load

dependent)

■ 750W: 82-91%

efficient (load

dependent)

■ 1100W: 89-92%

efficient (load

dependent)

89-92% efficient (load

dependent)

Chapter 1: Hardware overview 14

Temperature and humidity

OmniCube servers have limits for temperature and humidity under operating and storage conditions.

Specification Description

Humidity and

Temperature

(continuous

operation)

10°C to 35°C (50°F to 95°F) at 10% to 80% relative humidity with 26°C (78.8°F)

maximum dew point (maximum wet bulb temperature). De-rate maximum

allowable dry bulb temperature at 1°C per 300m above 950m (1°F per 547 ft

above 3117 ft).

Temperature

(storage)

-40°C to 65°C (-40°F to 149°F) with a maximum temperature gradation of 20°C

per hour.

Vibration and shock

OmniCube servers have limits for vibration and shock under operating and storage conditions.

Specification Description

Vibration

(operating)

0.26Grms at 5-350Hz in all orientations.

Vibration

(storage)

1.87Grms at 10-500Hz for 15 minutes (all six sides tested).

Shock

(operating)

One shock pulse in the positive z axis (one pulse on each side of the system) of 31G

+/– 5% for +/–10%; in the operational orientation.

Shock

(storage)

Half sine shock on all six sides of 71G +/– 5% with a pulse duration of 2ms +/–10%;

square wave shock on all six sides of 27G with velocity change at 235 in/sec or greater.

Altitude and airborne contaminants

OmniCube servers have limits for altitude and airborne contaminants under operating and storage

conditions.

Specification Description

Altitude (operating) -15.2m to 3048m (–50 ft to 10,000 ft)

Altitude (storage) -15.2m to 12,000m (–50 ft to 39,370 ft)

Contaminant level (operating) Class G1 or lower as defined by ISA-S71.04-1985

Agency compliance standards

OmniCube servers meet agency compliance standards.

An OmniCube host complies with the following standards:

Chapter 1: Hardware overview 15

■ FCC 47 CFR Part 15 Subpart B: 2012

■ EN 55022:2010 COR 2011

■ CISPR 22:2008

■ EN 55024:2010

■ CISPR 24:2010

■ COR 2011

■ VCCIV3:2009

■ ANSI/UL 60950-1, 2nd Edition (2007)

■ CSA C22.2 No. 60950-1 2nd Edition (2007)

■ IEC 60950-1:2005 (2nd Edition); Am 1:2009

■ RoHS EU Directive 2002/95/EC

About hardware upgrades

If you would like to upgrade the server hardware components, contact Customer Support.

Note:

Never install additional options other than those approved for installation by Customer Support. Doing

so will void your warranty and might cause serious server instability and potential data loss.

About firmware revisions

The OmniStack software requires that each supported platform is running a specific firmware revision.

To avoid compatibility issues, contact Customer Support before making any firmware changes.

Note:

If your server, or any management software, has automatic software updates enabled, disable this

feature to avoid installing unsupported firmware revisions.

Chapter 2: Install the server hardware 16

Chapter 2: Install the server hardware

This section contains the following topics:

•About electrostatic discharge

•Unpack the shipping carton

•Install the server enclosure in a rack

•Mount the enclosure in the rails

•Connect the network cables

•Connect the power cables

•Organize the cables

•Power on the system

•Attach the OmniCube bezel

Installing the server hardware involves unpacking all hardware components, installing the enclosure in

a rack, connecting the power and network cables, and powering on the server.

About electrostatic discharge

You must protect sensitive hardware from electrostatic discharge (ESD), which can damage electronic

components.

■ Ensure the server hardware is fully grounded at all times to prevent damage from electrostatic

discharge.

■ When not installed in a rack, server hardware must be stored in its original packaging or placed on a

sturdy surface that is protected from electrostatic discharge.

■ When handling server hardware components, always use the electrostatic wrist strap provided, or

use a similar form of ESD protection.

Unpack the shipping carton

You unpack the shipping carton to prepare the system hardware components for installation.

Before you begin

■ The OmniCube servers are heavy. You must have at least one other person to help you lift and

unpack the carton, and SimpliVity recommends the use of a datacenter equipment lift.

■ You have cut the pallet shipping straps, which might have considerable tension, using an appropriate

tool and safety wear.

Chapter 2: Install the server hardware 17

Procedure

1. Remove the shrink wrap from the palleted cartons and carefully cut any straps that hold the cartons

to the pallet.

2. To orient the carton for ease of unpacking and racking, locate the black circle printed on the side of

the carton. This is the front of the system enclosure.

3. Use a boxcutter to cut the sealing tape. Be careful that you do not cut into the carton. Retain the

carton and packaging in case you need to return the system.

4. Remove the rail kit (callout 1), which contains the rails and the installation instructions.

Figure 6: OmniCube Shipping Carton Contents

5. Remove the cable management arm (CMA) kit, (callout 2) which contains the CMA assembly, a

signal LED extension cable, and the installation instructions. Do not open this box until the end of

the installation procedure, when you are ready to organize the system cables.

6. Remove the accessory pack (callout 3), which contains:

■ SimpliVity bezel.

■ Power and network cables.

■ Software and documentation flash drive.

■Quick Start posters and international Product Information Guide.

Chapter 2: Install the server hardware 18

7. If you are not ready to install the system in a rack, keep it in the shipping box or place it on a sturdy

surface that is protected from electrostatic discharge.

Shipping carton contents

The shipping carton contains some standard items while other items are included based on your

configuration.

Part Description

Server enclosure Provides processing power and storage capacity.

Bezel Protects the SSD and HDD drives in the front panel.

Power cords (locale specific) ■ Two standard power cords.

■ Two rack power distribution unit (PDU) cords.

1 SFP+ Direct Attach (Twinax) cable Connects a 10GbE interface on one server directly to a

10GbE interface on another server. Depending on your

network configuration and the distance between the

server, you might need different or additional cables.

Sliding rail kit Contains the left and the right rails, two hook and loop

straps, and detailed installation documentation.

Cable Management Arm kit (optional) Contains the CMA assembly and installation

documentation.

Printed documentation ■Hardware Installation Quick Start

■Configuration and Deployment Quick Start

■Product Information Guide (safety and regulatory

notices)

■End User License Agreement

Hardware not supplied in the shipping carton

Your network environment might require additional hardware components not supplied in the shipping

carton.

Hardware Description Application

Rack 19 inch (48.3 cm), four-post,

toolless rack.

Provides easy access to

the server hardware in your

computing environment.

1GbE data cables Two Category 5E or Category 6

cables with RJ45 connectors.

Connects the 1GbE network

interfaces on each server to a

1GbE switch. This is required

Chapter 2: Install the server hardware 19

Hardware Description Application

An optional third cable is

required to use the IPMI port for

remote console access.

only if you are connecting the

1GbE network interfaces on

each server to a switch, such as

in a direct connected or switch-

connected network configuration,

for example.

10GbE data cables 2SFP+ Direct Attach active

cables.

Connects the 10GbE interfaces

on one server to a 10GbE

switch.

Redundant network switches Required number of switches. Connects devices to a network.

The number of switches depends

on your network configuration.

Redundant Uninterruptible

Power Supply (UPS)

Required number of UPS

devices.

Provides temporary power to the

server in the event of a complete

power outage.

Rack requirements

Each server ships with a sliding rail kit. The sliding rails allow you to fully extend the enclosure out of

the rack for service.

CAUTION:

See the Rack Installation Instructions supplied with the rail kit for safety and installation

instructions.

The racks you use for each server must meet these requirements:

■ The sliding rails support tool-free mounting in 19-inch, EIA-310-E compliant square-hole, 4-post

racks, and also support tooled mounting in threaded 4-post racks.

■ Each enclosure is 2U. Ensure the rack has sufficient space for all enclosures.

■ For full power redundancy across all servers, you need a rack with two power distribution units

(PDU) feeding separate outlet strips, with sufficient vacant outlets on each strip.

■ Ensure the rack is installed and stabilized or bayed according to the manufacturer's instructions.

■ When servicing an enclosure in a rack, extend only one enclosure at a time to prevent the rack from

tipping.

Rack installation guidelines

There are guidelines to help you successfully install each server in a rack.

■ Follow all safety guidelines stated in the documentation that came with the rack, particularly when

installing components into the locations at the top of the rack.

■ Ensure the rack meets the requirements.

■ Install the servers in the same rack when possible.

Chapter 2: Install the server hardware 20

■ Install the servers in a rack starting from the bottom of the rack.

■ Always install the servers in a horizontal position, or you void your warranty and support contract.

Install the server enclosure in a rack

You install the rails, which are included in the shipping carton, at the lowest available U space in the

rack enclosure. You then work up from the bottom of the rack to add additional rails.

Before you begin

■ You have read the safety instructions in the Product Information Guide supplied with your system.

■ For first time installers, you have read the instructions included in the rail kit. The rail kit instructions

also explain stabilizing the rack, installing devices, and power distribution.

■ You have identified the rack location for the right rail. The system requires 2U of rack space.

CAUTION:

Two people are required to safely install the system hardware in a rack. The Rack Installation

instructions included in the rail kit box contain important safety and procedural information.

Procedure

1. Pull apart the front and rear rail brackets, lengthening the rails to the correct distance for your rack.

2. Align the top of the rail brackets with the U space markers on the front and rear rack columns

(callouts 1 and 2).

Figure 7: Rail kit installation

3. Firmly push the brackets onto the rack columns so that the blue latches (callout 4) engage and lock.

4. Make sure that both the front and rear bracket latches are closed and the rails are secure.

5. Repeat Step 1 through Step 4 for the left rail.

Other manuals for OmniCube CN-2000

1

This manual suits for next models

8

Table of contents

Other SimpliVity Server manuals

Popular Server manuals by other brands

Xerox

Xerox 701P21110 Guide manual

Gigabyte

Gigabyte GS-SR101T System installation guide

Huawei

Huawei FusionModule2000 V500R003C10 installation guide

Avaya

Avaya S8730 Installing and configuring

Lenovo

Lenovo ThinkSystem SR860 V3 user guide

SMC Sierra Monitor

SMC Sierra Monitor FieldServer FS-8700-122 PROFIBUS DP Master Driver manual