Simpson Electric 14510-2 User manual

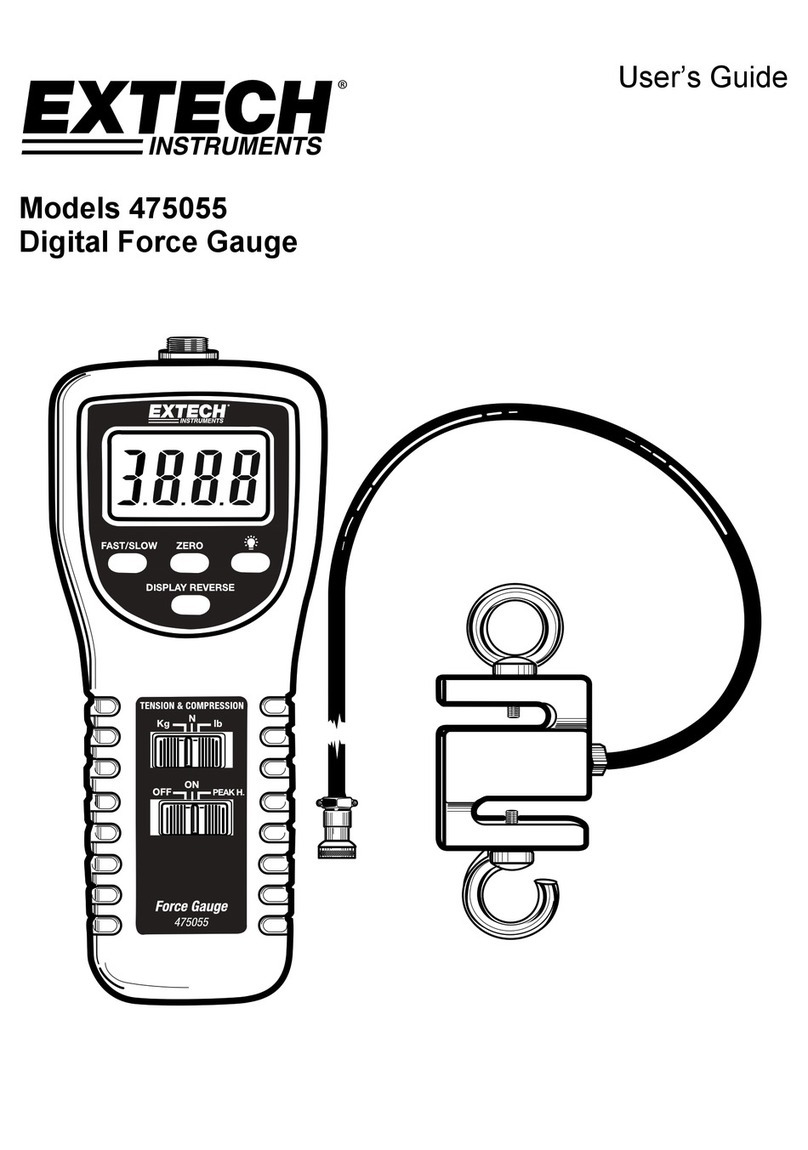

Simpson 14510-2

Volt-Ohm-Milliammeter

OPERATOR’S MANUAL

2

About this Manual

To the best of our knowledge and at the time written, the information con-

tained in this document is technically correct and the procedures accurate

and adequate to operate this instrument in compliance with its original ad-

vertised specifications.

Notes and Safety Information

This Operator’s Manual contains warning symbols which alert the user to

check for hazardous conditions.These appear throughout this manual where

applicable, and are defined below. To ensure the safety of operating perfor-

mance of this instrument, these instructions must be adhered to.

!

Warning, refer to accompanying documents.

Caution, risk of electric shock.

This instrument is designed to prevent accidental shock to the operator when

properly used. However, no engineering design can render safe an instru-

ment which is used carelessly. Therefore, this manual must be read carefully

and completely before making any measurements. Failure to follow direc-

tions can result in a serious or fatal accident.

!

Technical Assistance

SIMPSON ELECTRIC COMPANY offers assistance Monday through Friday

7:30 am to 5:00 pm Central Time. To receive assistance contact Technical

Support or Customer Service at (847) 697-2260.

Internet: http://www.simpsonelectric.com

Warranty and Returns

SIMPSON ELECTRIC COMPANY warrants each instrument and other articles

manufactured by it to be free from defects in material and workmanship un-

der normal use and service, its obligation under this warranty being limited to

making good at its factory or other article of equipment which shall within one

(1) year after delivery of such instrument or other article of equipment to the

original purchaser be returned intact to it, or to one of its authorized service

centers, with transportation charges prepaid, and which its examination shall

disclose to its satisfaction to have been thus defective; this warranty being

expressly in lieu of all other warranties expressed or implied and of all other

obligations or liabilities on its part, and SIMPSON ELECTRIC COMPANY nei-

ther assumes nor authorizes any other persons to assume for it any other

liability in connection with the sales of its products.

SHOCK HAZARD:

As defined in American National Standard, C39.5,

Safety

Requirements for Electrical & Electronic Measuring & Controlling Instrumen-

tation

, a shock hazard shall be considered to exist at any part involving a

potential in excess of 30 volts RMS (sine wave) or 42.4 volts DC or peak and

where a leakage current from that part to ground exceeds 0.5 milliampere,

3

when measured with an appropriate measuring instrument defined in Sec-

tion 11.6.1 of ANSI C39.5.

NOTE: The proper measuring instrument for the measurement of leakage

current consists essentially of a network of a 1500 ohm non-inductive resistor

shunted by a 0.15 microfarad capacitor connected between the terminals of

the measuring instrument. The leakage current is that portion of the current

that flows through the resistor. The Simpson Model 229-Series 2 AC Leak-

age Current Tester meets the ANSI C39.5 requirements for the measurement

of AC leakage current and can be used for this purpose. To measure DC

Leakage current, connect a 1500 ohm non-inductive resistor in series with a

Simpson 0-500 DC microammeter and use this as the measuring instrument.

Multi-function instruments such as the 14510-2 are intended as general pur-

pose measuring instruments for use in relatively low power 120/240 V AC or

dry battery operated circuits such as found in consumer appliances, home

entertainment equipment or general laboratory applications.Some high power

circuits, however, are within its measurement range and present an arcing/

explosion hazard in the event of an unanticipated circuit behavior, a defective

measuring instrument or of an operator error if the operator has not recog-

nized the hazard and observed appropriate personal protective measures.

Such high power circuits that would be within the measuring range of this

Instrument would be found in commercial or industrial equipment operating

from AC and DC supply circuits above 240 V, storage battery banks, or cir-

cuits containing large capacitors. Measurements in such circuits should only

be performed by personnel trained to recognize the hazards and using ap-

propriate safety measures.The Safety Precautions in Section IV are intended

to alert the operator to the more commonly encountered hazards and protec-

tive measures to avoid them.The dangers in high power circuits are serious.

Do not take safety precautions lightly.

NOTE: Any circuit containing voltages exceeding 30 V AC or 60 V DC should

be considered to be a possible shock hazard, and contact with the circuit

should be avoided while the circuit is energized.

4

NOTES

5

NOTES

6

Contents

1. INTRODUCTION................................................................................ 7

1.1 General ...............................................................................................7

1.2 Description .........................................................................................7

1.3 Items And Accessories .......................................................................7

1.4 Technical Data ....................................................................................8

1.5 Definition Of Accuracy ........................................................................9

1.6 Safety Consideration ..........................................................................9

2. PREPARATION FORUSE............................................................... 10

2.1 Unpacking And Inspection ...............................................................10

2.2 Warranty............................................................................................10

2.3 Shipping ...........................................................................................10

2.4 Power Source Requirements ...........................................................10

3. CONTROLS,JACKSANDINDICATOR............................................ 11

3.1 Front Panel .......................................................................................11

4. OPERATION.................................................................................... 12

4.1 Safety Precautions............................................................................12

4.2 Measuring DC Voltages ...................................................................14

4.3 Measuring AC Voltages ....................................................................14

4.4 Measuring Direct Current .................................................................15

4.5 Measuring Resistances....................................................................16

5. OPERATOR MAINTENANCE .......................................................... 17

5.1 Inspection .........................................................................................17

5.2 Battery And Fuse Access .................................................................17

5.3 Battery Replacement........................................................................18

5.4 Fuse Replacement ...........................................................................18

5.5 Care ..................................................................................................19

6. SERVICING INSTRUCTIONS.......................................................... 20

6.1 Replacement Part Table for 14510-2 ...............................................20

6.2 Schematic Diagram, 14510-2 Volt-Ohm-Milliammeter.....................22

7

1. INTRODUCTION

1.1 General

The Simpson 14510-2 Volt-Ohm-Milliammeter (hereinafter referred to as the

14510-2 or the Instrument) is a portable instrument, suitable for the telephone

industries.This instrument is designed for the service person who values true

portability, reliability, simplicity and ruggedness. The Instrument can be ap-

plied in both permanent and mobile installations.

The 14510-2 features reverse safety-style jacks, an easy-to-read dial, a large

range switch knob and an attractive color clutter-free panel.

1.2 Description

The case is made of high-impact (ABS) plastic and is contemporarily styled.

The Instrument is battery operated for the resistance ranges, and fuse and

diode overload protected, with a self-shielded taut-band movement.The taut-

band suspension provides a high degree of repeatability and is highly resis-

tant to shock and vibrations helping to ensure the accuracy and life of the

Instrument. A handle, attached to the sides of the case, allows the Instrument

to be used in either a vertical or horizontal position.The horizontal position is

preferred for greater accuracy since the Instrument is calibrated in that posi-

tion.

1.3 Items And Accessories

All applicable items and accessories required to operate the 14510-2 are

furnished with the Instrument and are listed in Table 1-1. Additional accesso-

ries are listed in Table 1-2.Available replacement parts are listed in Table 6-1.

Table 1-1. Accessories furnished with the Instrument

Quantity Description Number

1 Test Lead Set 00043

*2 15 Volt Cell, NEDA 208 1-111010

*1 1.5 Volt, D Cell, NEDA 13F 1-111798

1 Operator’s Manual 6-114022

* Readily available through local retail stores.

Table 1-2. Additional Accessories

Description Number

Utility Vinyl Carrying Case 00549

Vinyl Carrying Case 01818

Ever-Redy Vinyl Carrying Case 00805

Deluxe Carrying Case 00812

There are three batteries in the ohmmeter circuits. One is a NEDA 13F cell

that furnishes 1.5 volts for the RX1, RX10, RX100 and RX1000 ranges.Two

are NEDA 208 cells that furnish 30 volts required for the RX10,000 range.

The batteries are readily available and replacement is accomplished easily.

Most of the component parts are mounted on a printed circuit board which

8

simplifies assembly and maintenance, thus extending the useful life of the

Instrument.

Each Instrument is furnished with one pair of probe type test leads (one red

and one black, each 48 inches long, Catalog No. 00043) for all Instrument

applications. These test leads have elbow plugs on one end to connect the

leads to the recessed jacks on the Instrument front panel. The probe tips at

the opposite end have threaded shoulders to accept the screw-on insulated

alligator clips (furnished with the test leads).The test leads and the insulated

alligator clips are rated for the voltage and current ranges available on the

14510-2. Maximum ratings are 100 V AC or DC or 10 DC amperes.

These ratings for the test leads must not be exceeded in any application.

1.4 Technical Data

Table 1-3 lists the Technical Data for the 14510-2

Table 1-3

1. DCVOLTS

Ranges: 0.3 V, 3 V, 12 V, 60 V, 300 V, 600 V

Sensitivity: 20 k⍀/volt ranges except on the 0.3 V range, 16 k⍀/volt.

Accuracy: ⫾2% of full scale (FS) all ranges, except on the 0.3 V range,

which on the 0.275 V mark (red line) is ⫾0.5% of FS.

2. ACVOLTS

Range Frequency Response (Hz) Accuracy % of FS

3 V 20 Hz - 100 kHz ⫾1% ⫾3

12 V 20 Hz - 100 kHz ⫾1% ⫾3

60 V 20 Hz - 40 kHz ⫾1% ⫾3

300 V 20 Hz - 10 kHz ⫾2% ⫾3

600 V 20 Hz - 5 kHz ⫾1% ⫾3

Sensitivity: 3 k⍀/volt

Indication: Full wave average responding. Calibrated in rms for

sinusoidal wave forms.

3. DC CURRENT

Range Accuracy % of FS Voltage Drop

0.06 mA ⫾2 300 mV ⫾2%

1.2 mA ⫾2 149 mV nominal

12 mA ⫾2 166 mV nominal

120 mA ⫾2 341 mV nominal

!

9

4. RESISTANCE Battery Voltage Battery Current

Range Midscale Reading (Nominal) (Nominal)

RX1 20 ⍀1.5 V 75 mA

RX10 200 ⍀1.5 V 7.5 mA

RX100 2 k ⍀1.5 V 0.75 mA

RX1000 20 k ⍀1.5 V 0.075 mA

RX10,000 200 k ⍀30 V 0.15 mA

Accuracy: ⫾2% of FS angular deflection at midscale.

5. Reference Conditions: 25°C ⫾2°C, 45 to 75% relative humidity

6. Movement: Taut-band 100° arc, 50 µA FS

7. Dial Arcs: One arc each for ⍀and DC, two arcs for AC

8. Overload Protection: Meter movement by varistor, ranges fused

1/2 A, 250 V in series with 2 A, 600 V

9. Operating Temperature

Ranges (to maintain

rated accuracy): 57°F - 97°F

10. Size: 7" H x 4-1/4" W x 3-1/8" D

11. Weight: Approximately 2-1/2 lbs. with batteries

(1.133 kg)

12. Rated Circuit-to-

Ground*: 600 V AC/DC maximum

* Per ANSI C39.5 April1974:“The maximum voltage,withrespecttoground,

which may safely and continuously be applied to the circuits of an instru-

ment.”

1.5 Definition Of Accuracy

The voltage and current accuracy of the Instrument is commonly expressed

as a percent of full scale.This should not be confused with accuracy of read-

ing (indication).For example, ⫾2% of full scale on the 10 volt range allows an

error of ⫾0.20 V at any point on the dial. This means that at full scale, the

accuracy of reading would be ⫾2%, but at half scale it would be ⫾4%.There-

fore, it is advantageous to select a range which gives an indication as near as

possible to full scale.

1.6 Safety Consideration

This Operator’s Manual contains special caution and warning symbols to alert

the user to hazardous operating and servicing conditions. These symbols

appear throughout this publication where applicable and are defined on the

inside front cover of this manual under SAFETY SYMBOLS. Adhere to these

instructions in order to ensure the safety of operating and servicing person-

nel and to retain the operating performance of this Instrument.

10

2. PREPARATION FOR USE

This section contains instructions for preparing the new Instrument for use.

Also included are unpacking and inspection procedures, warranty, shipping,

and power source requirements.

2.1 Unpacking And Inspection

Examine the shipping carton for signs of damage before unpacking. If the

carton is in good condition, unpack and inspect the Instrument and packing

materials for possible damage incurred during shipment. If damage is noted,

notify the carrier and supplier and do not attempt further use of the Instru-

ment. If the Instrument appears to be in good condition, read the Operator’s

Manual in its entirety. Become familiar with the Instrument as instructed in the

manual, then check the electrical performance. Also check to see that all fur-

nished items and accessories are included (Table 1-1). Save the shipping

carton and packing material for future storing or shipping of the Instrument.

After unpacking the Instrument, a 1.5V battery and two 15V batteries may be

found in separate envelopes in the box with the Instrument and test leads.

Two alligator clips for the test leads are in a polyethylene bag. (See Section 5

for instructions on how to open the battery compartment and install the bat-

teries.)

2.2 Warranty

The Simpson Electric Company warranty policy is printed on the inside front

cover of this manual.Read it carefully before requesting any warranty repairs.

NOTE: For all assistance, including help with the Instrument under warranty,

contact the nearest Authorized Service Center for instructions. If necessary,

contact the factory directly. Give full details of any difficulty, the Instrument

model number, series number and date of purchase. Service data or ship-

ping instructions will be mailed promptly. If an estimate of charges for non-

warranty or other service work is required, a maximum charge estimate will

be quoted. This charge will not be exceeded without prior approval.

2.3 Shipping

Pack the Instrument carefully and ship it prepaid and insured.

2.4 Power Source Requirements

There are three batteries in the ohmmeter circuits. One is a NEDA 13F cell

that furnishes 1.5 volts for all ranges except RX10,000 range.Two NEDA 208

cells furnish 30 volts for the RX10,000 range. Weak batteries should be re-

placed promptly . Replace with the same type batteries as supplied with the

Instrument. (See Table 1-1.)

11

3. CONTROLS, JACKS AND INDICATOR

The purpose and use of the 14510-2 front panel controls and its features are

described below. Become familiar with each control and its function before

using the Instrument.

3.1 Front Panel

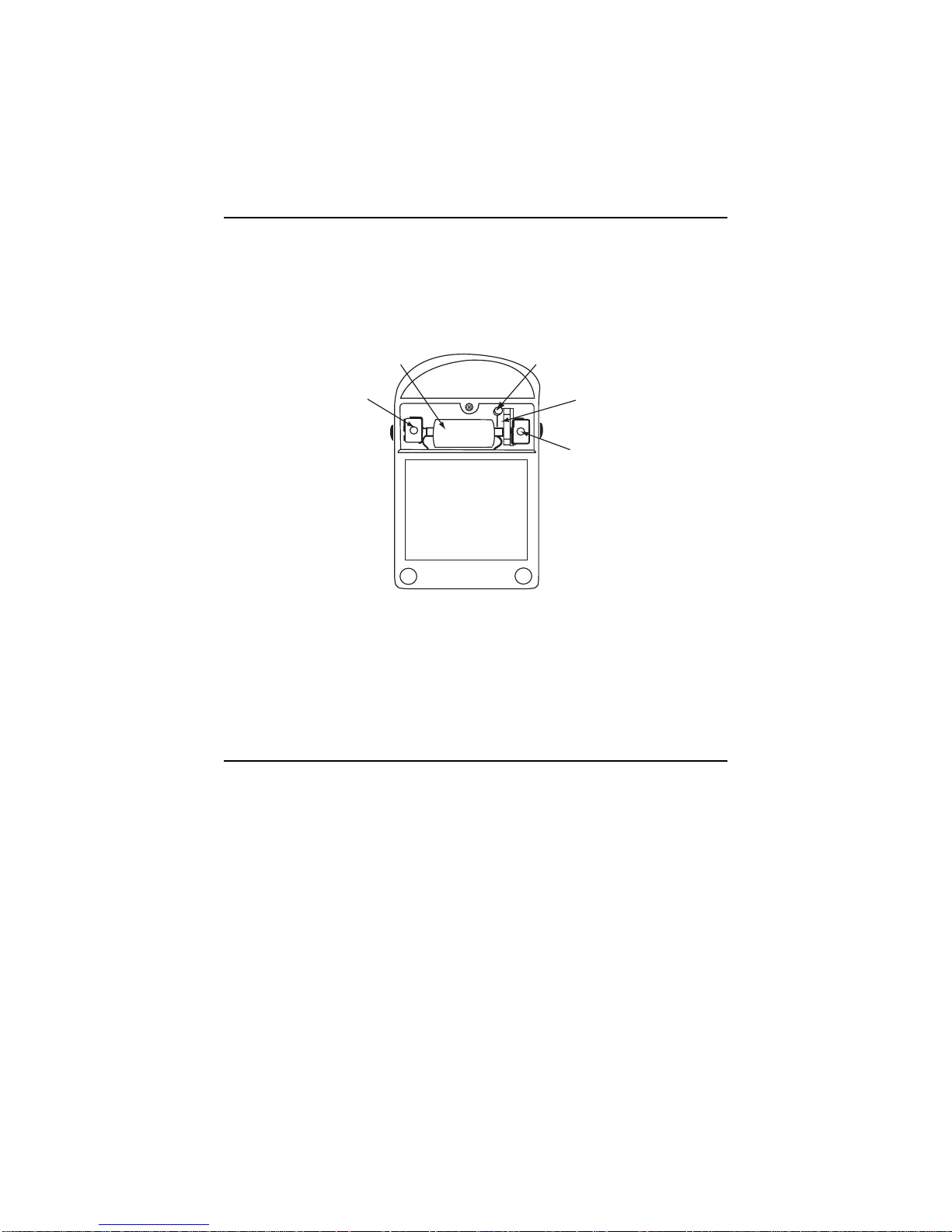

Item numbers in Table 3-1 correspond with identifying numbers in Figure 3-1.

Table 3-1. Controls, Jacks and Indicator

1. Meter: ThismeteriscalibratedforACvoltage(rms), DC volt-

age, current and resistance. Some scales are read

directly while others require a multiplying factor.

2. Range Switch: The range switch has 21 positions. It may be turned

to any position from either direction.There are eleven

voltage positions, four direct current positions, five

resistance positions and an OFF position.

3. Ohms Adjust: The ohms adjust control is a variable resistor in the

ohmmeter circuit, which permits adjustment to “0”for

the ohms ranges.

4. Circuit Jacks: There are two jacks located on the front panel.These

are the connections for the test leads. The elbow

prods of the test leads are plugged into the proper

jacks. Negative (–) black to (⍀) jack, positive (+) red

lead to (+) jack.

Figure 3-1. Simpson 14510-2 Front Panel

12

5. Pointer Adjust for

Zero With the Instrument in an operating position, check

that the pointer indicates zero at the left end of the

scale when there is no input. If pointer is off zero,

adjust the screw located in the cover below the cen-

ter of the dial. Use a small screwdriver to turn the

screw slowly clockwise or counterclockwise until the

pointer is exactly over the zero mark at the left end of

the scale.With the indicating pointer set on the zero

mark, reverse the direction of rotation of the zero

adjuster a sufficient amount to introduce mechani-

cal freedom or “play” but an insufficient amount to

disturb the position of the indicating pointer.This pro-

cedure will avoid disturbances to the zero setting by

subsequent changes in temperature, humidity, vibra-

tion and other environmental conditions.

4. OPERATION

Beforeattempting tooperatethisInstrument, refertoWARNINGoninside front

cover of this manual.

Information required to use and operate the 14510-2 in the proper manner

follows below:

The test leads are provided with accessory screw-on alligator clips which

may be attached to the probe tips. Eliminating the need to hand-hold test

probes to a circuit for extended periods, the test clips also reduce hand prox-

imity to a high voltage circuit while energized. Circuit power must, of course,

be turned off and any charged capacitors discharged before connecting or

disconnecting clips to or from the circuit. Replacement of test leads, when

necessary, should be of the exact style supplied with the Instrument.

NOTE: All measurements are made with the black test lead connected to the

(⍀) jack and the red test lead to the (+) jack.

Before making any measurements, check to see that the pointer indicates

zero, when the Instrument is in the operating position.If the pointer is off zero,

use a small screwdriver to turn the screw located directly above the range

switch in either direction until the pointer rests at zero. (See Section 3, Con-

trols, Jack and Indicator.)

4.1 Safety Precautions

NOTE: The following precautions are suggestions and reminders of com-

monly recognized safe practices to be used and specific hazards to be avoided

and are not implied to be sufficient to ensure the safety of untrained person-

nel in all circumstances.Neither is this manual a substitute for technical manu-

als covering the equipment in which measurements are to be made. Always

!

13

refer to the equipment manual and its specific warnings and instructions, and

observe them as well as those contained herein.

1. The 14510-2 should only be used by personnel qualified to recognize

shock hazards and trained in the safety precautions required to avoid

possible injury.

2. Do not connect any terminal of this Instrument to a circuit point at which a

voltage exceeding 600 volts AC or DC may exist with respect to earth

ground. (Refer to Table 1-3, item 12.)

3. This Instrument is intended only for use indoors or in sheltered locations.

To prevent fire or shock hazards, do not expose it to rain or moisture.

Condensation may occur when the Instrument is moved from a cold area

to a warm area. DO NOT ATTEMPT HIGHVOLTAGE MEASUREMENTS

UNTIL CERTAINTHAT THE INSTRUMENT HAS DRIEDTHOROUGHLY.

4. Turn off power and discharge any capacitors in the circuit to be mea-

sured before connecting to or disconnecting from it.

5. Before using this Instrument, check accessories (if any) and test leads

for missing, damaged, deteriorated or otherwise faulty insulating parts.

Do not use, or permit the use of, equipment with faulty insulation until it

has been properly repaired.

IMPORTANT:

6. Always wear safety glasses when working with electrical circuitry.

7. Do not work alone on high voltage circuits. Make certain that someone

capable of rendering aid is nearby and aware.

8. Do not handle the Instrument, its test leads or the circuitry while taking

any measurements.

9. Be sure to reset the range switch to the OFF position after completing

resistance or current measurements.This is to prevent inadvertent appli-

cation of high voltage to the resistance or current ranges when the In-

strument is next used.

10. Hands, shoes, floor and workbench must be dry. Avoid measurements

under humid, damp or other environmental conditions that could affect

the dielectric withstanding voltage of the test leads of the Instrument.

11. Do not change switch settings or test lead connectionswhile the circuit is

energized. A mistake could result in damage to the Instrument and pos-

sible personal injury.

12. Locate all voltage sources and accessible current paths before making

connections to circuitry.

NOTE: Voltage may appear unexpectedly or in unexpected locations in faulty

equipment. An open bleeder resistor, for example, may result in a capacitor

retaining a dangerous charge.

13. Make certain that the equipment being worked upon is properly grounded

and fuses are of the proper type and rating.

14. Check and double check switch positions and jack connections before

applying power to the Instrument.

15. Always remain alert for low voltage circuits which may be floating at high

voltage with respect to earth ground and for composite voltages (AC +

DC) such as are found in rf amplifiers.The floating voltage or composite

14

voltagemustnotexceedtheInstrument’s rated maximum circuit-to-ground

voltage. (See Table 1-3, item 12.)

16. Do not make electrical measurements where the air may contain explo-

sive concentrations of gas or dust such as in mines, grain elevators, gaso-

line stations or in the presence of charging batteries, until determined to

be safe by qualified personnel. Note that even metallic dust can be ex-

plosive.

17. No general purpose VOM is to be used to make measurements on blast-

ing circuits or blasting caps. Use only designated instruments.

Be extremely careful when working with high voltage circuits. Even though

the Instrument and test leads are well insulated for protection of the operator,

it is not advisable to handle either when power is on in the circuit.

4.2 Measuring DC Voltages

1. Set the range switch at one of the six voltage range positions marked 0.3

V, 3 V, 12 V, 60 V, 300 V or 600 V. When in doubt about the approximate

voltage present, start with the highest voltage range to protect the Instru-

ment.If the voltage reading is within the limits of a lower range, the switch

then may be set to that range to obtain a more accurate reading.

2. Be sure the power is off in the circuit to be measured and all capacitors

have been discharged.

3. Connect the black test lead to the negative side of the circuit being mea-

sured and the red test lead to the positive side of the circuit.

4. Turn on the power of the circuit and read the voltage on the black scale

marked AC-DC. For the 0.3 V and the 3 V ranges, use the 0-300 figures

and divide the reading by 1000 and 100 respectively. For the 12 V, 60 V

and 300 V ranges read the figures directly. For the 600 V range, use the

0-60 figures and multiply the reading by 10.

5. Turn the power off, disconnect the test leads and return the range switch

to the OFF position.

4.3 Measuring AC Voltages

NOTE: The rectifier circuit in the 14510-2 responds to the full-wave rectified

average value of an AC waveform.The Instrument is calibrated in terms of the

rms value of a pure sine wave which will be correct for all sinusoidal wave-

forms. If the waveform is non-sinusoidal, the reading could result in a sub-

stantial error. Also, accuracy is lessened at higher input frequencies.

NOTE: Since the VOM will respond to DC voltage when set on any AC volt-

age range, an external blocking capacitor must be employed where mea-

surements of AC superimposed on DC are encountered.

1. Set the range switch at one of the five voltage range positions marked 3

V, 12 V, 60 V, 300 V or 600 V. When in doubt about the approximate volt-

age in the circuit being measured, start with the highest voltage range as

!

15

a protection to the Instrument. If the voltage is within a lower range, the

switch then may be set at a lower range to obtain a more accurate read-

ing.

2. Be sure the power is off in the circuit being measured and all the capaci-

tors have been discharged.

3. Connect the test lead across the voltage source with the black lead on

the ground side.

4. Turn on the power in the circuit being measured and read the voltage on

the red scale marked AC.

5. For the 3V range, read the value directly on the red scale marked 3V AC.

Forthe12V, 60V, 300 V and 600V ranges,readontheblackscale marked

AC-DC. For the 12V, 60V and 300V ranges, read the figures directly. For

the 600 V range, use the 0-60 figures and multiply the reading by 10.

6. Turn power off, disconnect the test leads and return the range switch to

the OFF position.

4.4 Measuring Direct Current

Never connect the test leads of this Instrument directly across any source of

voltage when it is used for current measurements. This will damage the In-

strument.

NOTE: The voltage drop will not significantly affect most circuits whose cur-

rent is being measured. In some low voltage circuits, such as transistor cir-

cuits, it may be necessary to take the voltage drop into account when making

current measurements. (See Table 1-3, Current Ranges.)

Do not switch any range or function settings on the Instrument and never

disconnect the test leads from the circuit while the circuit under measurement

is energized. When the circuit is de-energized, discharge all the capacitors.

Never exceed the circuit-to-ground voltage of the Instrument, 600V max.(See

Table 1-3, item 4.12.)

In all current measurements, be certain that the power to the circuit under test

has been turned off before restoring circuit continuity.

1. Set the range switch at one of the four range positions marked 0.06 mA,

1.2 mA, 12 mA or 120 mA. Always start with the highest range first.

2. Turn the power off, discharge all capacitors and open the circuit in which

the current is to be measured. Connect the Instrument in series with the

circuit. Connect the red test lead to the positive side and the black test

lead to the negative side of the circuit.

3. Turn on the power to the circuit under test.

!

!

16

4. Read the current in milliamperes on the black AC-DC scales. For the

0.06 mA range, use the 0-60 scale and divide the reading by 1000. For

the 1.2 mA range, use the 0-12 scale and divide the reading by 10. For

12 mA range, use 0-12 scale and read directly. For the 120 mA range,

use 0-12 scale and multiply readings by 10.

5. Upon completion of all readings, turn off power to the circuit and remove

test leads from circuit.

6. IMPORTANT:Return range switch to the OFF position when current mea-

surements are completed.

4.5 Measuring Resistances

Before making resistance measurements, remove all power to the circuit un-

der test and discharge all capacitors.

When DC resistances are measured, the internal batteries of the Instrument

furnish power for the measuring circuit.The zero adjust control provides cor-

rection for battery deterioration over long periods of time.

1. Set the range switch to the desired resistance range position.

2. Connect the probe ends of the test leads together (short tips together).

3. Observe the Instrument indication. It should read “0” on the ohms arc,

which is at the top of the dial.

4. If the pointer does not read “0”, rotate the V Adj. (Zero Adjust Control)

knob either direction until it does read “0”.If the pointer cannot be brought

up to the “0” mark, replace the appropriate battery (1.5 V for low ranges

and two 15 V for the high range — refer to paragraph 5.3 for battery re-

placement).

Do not apply any power to the circuit before measurements are completed

and the test leads are disconnected.

5. Connect the test leads across the resistance which is to be measured. If

there is a “forward” and “backward” resistance, such as with diodes, ob-

serve the polarity in the lead connections to control each test.The resis-

tance should be relatively low when the diode is forward biased by the

battery potential and higher in the opposite direction.

When checking diodes and semiconductors do not use the RX1000 or

RX10,000 ranges. Using these ranges may result in permanent damage to

component being checked.

6. Read the indication of the OHMS arc at the top of the dial. Note that the

arc reads from right to left for increasing values.

7. Multiply the reading by the multiplier factor indicated at the switch posi-

!

17

tion; the result is the resistance value in ohms. (“K” on the dial and panel

stands for “one thousand.”)

NOTE: The resistance of nonlinear components will measure differently from

one resistance range to another. For example: a diode could measure 80

ohms on the RX1 range and 300 ohms on the RX10 range.The difference in

the reading is a result of the non-linear diode characteristic and does not

indicate faulty operation of the ohmmeter circuit.

8. Disconnect ends of test leads and return the range switch to the OFF

position after resistance measurements are completed.

5. OPERATOR MAINTENANCE

This section describes those functions necessary to maintain the Instrument

in an operating condition and which may be performed by the operator or

user. This Instrument is carefully designed and constructed with high quality

components. By providing reasonable care and following instructions in this

manual, the user can expect a long, useful service life of the Instrument.

Servicing, other than that which is described in this Section, should be per-

formed only by qualified personnel, by one of the Authorized Service Centers

or by the factory.

5.1 Inspection

The user is protected from electrical shock by the insulation of the Instrument

and the test leads. Frequent examination of each should be made for any

insulation damage, such as cracks, cuts, chips, burns or deterioration that

expose internal metal parts or conductors, or any reduction in spacing be-

tween such metal and hand contact by the user. Replacement leads should

be the same as those originally supplied with the Instrument and can be ob-

tained from one of the Authorized Service Centers or the factory.

To avoid electrical shock, disconnect test leads from live circuits and from the

Instrument before opening the battery compartment cover.

5.2 Battery And Fuse Access

The batteries and 1/2-ampere fuse are located inside an isolated compart-

ment at the top-rear of the Instrument case. To open the compartment, pro-

ceed as follows:

Place the Instrument face down on a soft padded surface and unscrew the

single captivated screw on the compartment cover. Remove the cover from

the case and set it aside. Batteries and fuse now can be replaced.

NOTE: If replacement of the 2-amp high current interrupting fuse is neces-

sary, the Instrument case must also be removed (see paragraph 5.5 and Fig-

ure 5-2).

!

18

5.3 Battery Replacement

Battery replacement is indicated when the pointer cannot be adjusted to zero

on a resistance range.

Remove the battery compartment cover (paragraph 5.3). If zero cannot be

adjustedontheRX1, RX10, RX100 or RX1000 ranges,the1.5V battery needs

replacement. Replace with a 1.5 V, NEDA 13F, “D” size cell. If zero cannot be

adjusted on the RX10,000 range, one or both 15 V batteries need replace-

ment. (It is suggested that both batteries be replaced at the same time.) Re-

place with 15 V NEDA 208 battery, Burgess U10, Eveready 411, Ray-O-Vac

208, or equivalent.

Replace the battery compartment cover.

5.4 Fuse Replacement

Fuse replacement is indicated when the Instrument is completely inoperative

in all functions.

The 1/2 A, 250 V fuse is accessible inside the battery compartment. Remove

the battery compartment cover (paragraph 5.3).Carefully pry the fuse from its

clips and replace with an exact replacement.Do not substitute a different type

fuse or rating.It may not serve its purpose and may cause the internal fuse to

blow unnecessarily next time. Replace with a 1/2 A, 250 V Quick Acting

Littlefuse Type 3AG, Catalog No. 312.500, or equivalent.

NOTE: A spare has been provided in the compartment adjacent to the work-

ing fuse as an emergency replacement. If the spare is used, replace it as

soon as possible to assure that it will again be available in an emergency.

If the Instrument now operates (check it in a resistance range by shorting the

testleads together), replace the compartment cover.If the Instrumentstill does

not operate, the internal fuse may be open. For access to this fuse, the case

back must be removed.

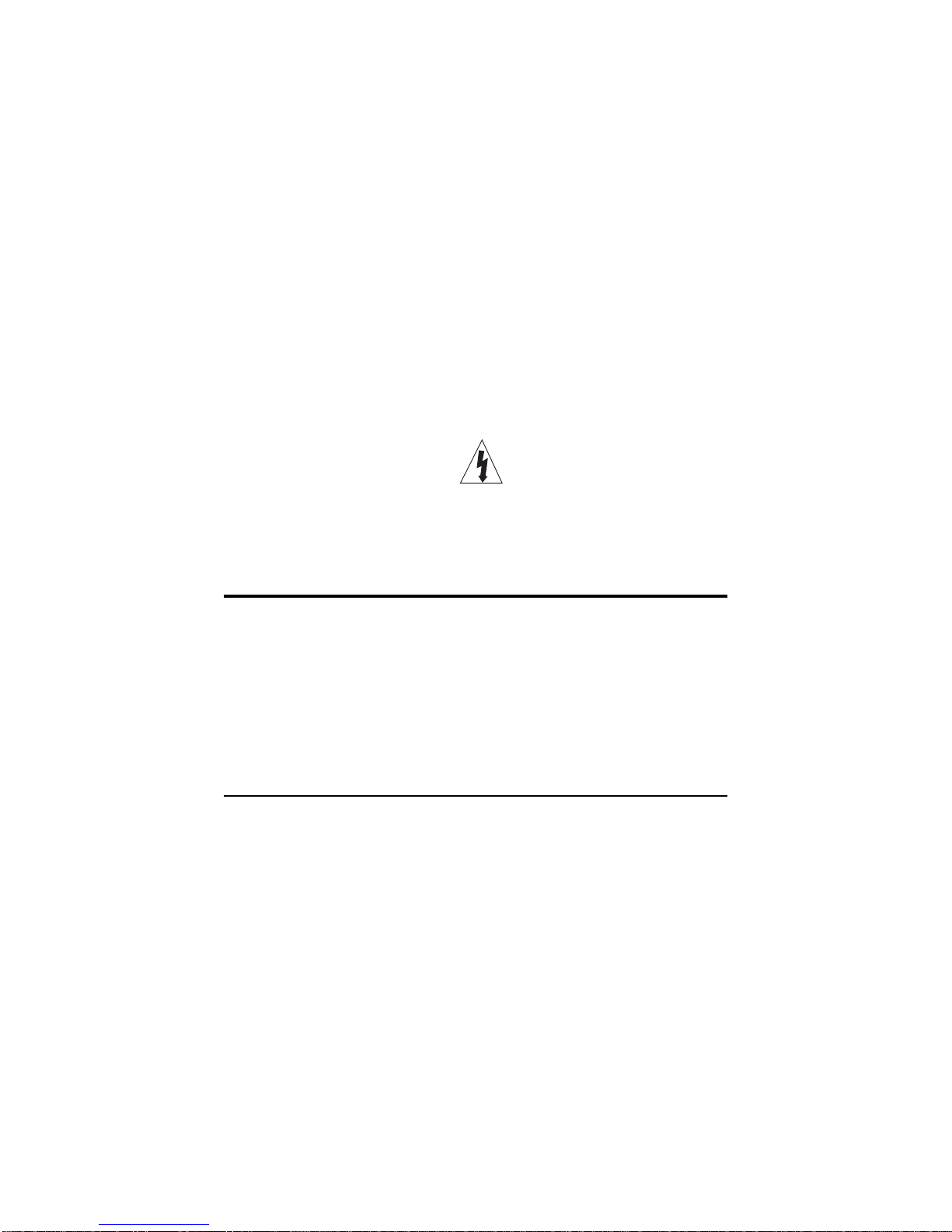

++

WARNING

To avoid electrical shock, make certain that test leads are disconnected from any circuits

before removing covers.

NOTE: If instrument fails to operate after replacing fuse (F1) check and replace (F2) inside

case, if required, before returning for repair.See Operator's Manual.No other user serviceable

parts inside. Refer servicing to qualified personnel only.

CARELESSNESS AND MISUSE OF THIS INSTRUMENT CAN BE DANGEROUS

Before connecting this instrument, carefully read the instructions and precautions in the

Operator's Manual. Failure to do so can result in a serious or fatal injury.

SAFETYTIPS

1. Do not attempt any measurements unless trained, qualified and authorized to do so.

2. Do not connect to any circuit where the voltage with respect to ground earth may exceed

1000 volts.

Whenever making measurements with this instrument:

a. Turn off circuit power and discharge any capacitance in the circuit before connectin

or disconnecting test leads or changing switch settings.

b. Double-check for correct swtich settings and test lead connections before applying

power.

c. Do not touch the instrument, test leads or the circuit while power is ON.

d. Do not use any instrument or test leads that are damaged, contaminated, deteriorated,

moist, or which have missing parts.

4. Voltages as low as 30 volts r.m.s. or 42.4 volts peak can render an electric shock.

5. Read the Operator's Manual for additional precautions and instructions.

¯¯

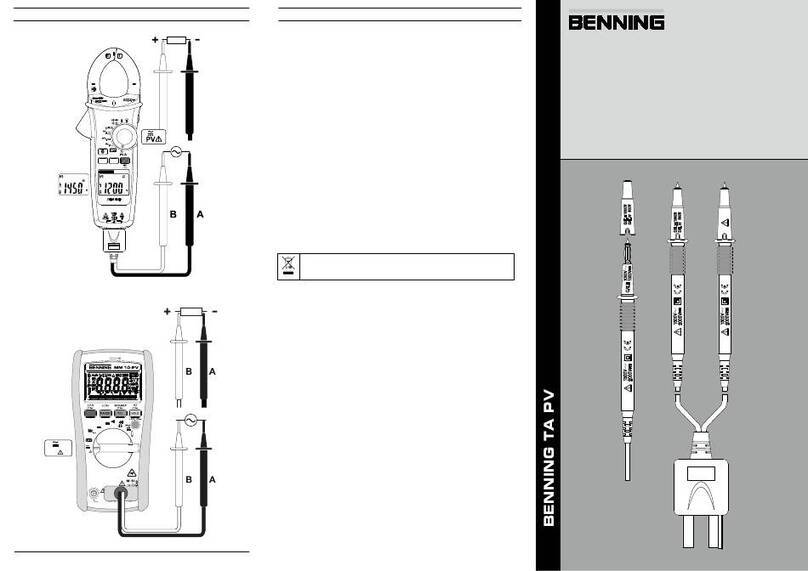

1.5V

Battery

15V

Battery

Spare Fuse

1/2 A, 250V

Fuse (F1)

15V

Battery

Figure 5-1. Battery and Fuse Compartment

19

1. Remove the battery compartment cover. Place the Instrument face-down

on a soft, padded surface. Loosen the four screws at the four corners of

the case back and lift the case back off of the Instrument.

Figure 5-2. Location of 2 Amp Fuse

2. Take care not to disturb any internal components or wiring. Do not at-

tempt any servicing beyond fuse replacement unless qualified to do so.

Improper repairs may endanger the user of this Instrument.Refer to sec-

tion 5, SERVICING INSTRUCTIONS.

3. Carefully pry the fuse from its clips and replace it with an exact replace-

ment. Do not substitute a different type fuse or rating as it may not serve

its special purpose. Replace only with a Littlefuse Type BLS or Bussman

type BBS, 2 A, 600V.

4 Shake the unit gently to make certain that no loose debris is left inside.

Replace the case back and tighten the four screws. Replace the battery

compartment cover.

5.5 Care

1. For insulation to remain effective, keep clean and dry at all times. For

normal grime, use a mild detergent and a damp cloth to clean the Instru-

ment and dry thoroughly before use.DO NOT PERMIT LIQUIDSTO EN-

TERTHE CASE.

2. Immediately clean all spilled materials from the surface of the Instrument

and wipe dry. If the spillage is corrosive, use a suitable cleaner to neu-

tralize the corrosive action.

3. When the Instrument is not in use, rotate the function switch to the OFF

position.

4. Whenever possible, avoid prolonged exposure or usage in areas which

15V Battery

Front Panel

2 Amp Fuse

!

20

are subject to temperature and humidity extremes, vibration or mechani-

cal shock, dust or corrosive fumes, or strong electrical or electromag-

netic interferences.

5. On a monthly basis, verify Instrument accuracy by performing operational

checks using known, accurate and stable sources. If proper calibration

equipment is not available, contact the nearest Authorized Service Cen-

ter. If the Instrument has not been used for 30 days, check the batteries

for leakage and replace if necessary.

6. It is recommended that the Instrument be returned annually to the near-

est Authorized Service Center, or to the factory for an overall check, ad-

justment and calibration.

7. When the Instrument is not in use, store in a room free from temperature

extremes,dust,corrosivefumesandmechanicalvibrationorshock.If stor-

age time is expected to exceed 30 days, remove batteries.

8. When an Instrument must be stored and/or transported in a vehicle in

very cold weather, it will be subject to condensation when brought into a

warm building.Therefore, do not attempt high voltage measurements until

the Instrument has had time to dry completely.

6. SERVICING INSTRUCTIONS

An improperly repaired instrument may be dangerous to the user.This Instru-

ment contains no user-serviceable parts other than the batteries and fuses.

Do not attempt any other repairs or parts replacement unless trained and

qualified to do so. The contents of this section are provided only for use by

such qualified repairmen. Refer repairs to the factory or to one of the Autho-

rized Service Centers.

Table 6-1 lists the replacement parts for the 14510-2 and the ordering part

numbers. Replacement parts and accessory items may be ordered from the

factory or from any Authorized Service Center.

6.1 Replacement PartTable for 14510-2

Table 6.1. Replacement Parts for 14510-2

Symbol Description Part No.

B1, B2 15 V Battery 1-111010

B3 1.5 V Battery 1-111798

D1, D2 Diode, Germanium, 1N100 1-115970

R2 Resistor, 27 k⍀, 1%, 1/2 W 1-110282

R3 Rheostat, 100 k⍀, 10%, 1/2 W 5-119020

R4, R5 Rheostat, 1 k⍀, 10%, 1.5W,W.W. 5-117967

R6 Resistor, 1.3 ⍀V, 1%, 1/2 W 5-118990

R9 Rheostat, 2 k⍀, 10%, 1.5W, W.W. 5-116716

R10 Resistor, 4.5 k⍀, 1%, 1/2 W 5-118983

R11 Resistor, 27 k⍀, 1%, 1/2 W 1-110282

Table of contents

Other Simpson Electric Measuring Instrument manuals