SimTech WeldTech User manual

www.SimtechUSA.com

Corrosion Resistant Fluid and

Air Handling Systems.

WeldTech

Socket Hand Held Tool

Operation Manual

2

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

1.081210

WeldTech - Hand Held Socket Tool

Safety Rules

The use of electrical components is always a potential danger. In order to avoid any kind of accident

caused by electrical sources it’s strongly suggested to read and follow carefully the following safety

rules before operating the machine.

The working area must be clean.•

Do not use machine in rain, inclement weather or close to flammable liquids.•

Always use the machine in a fixed and safe position.•

The machine is operated by 110 Volts therefore be sure that the power supply plug is•

supplied with the safety devices according to the standard requirements also check

that the power supply will be on the range of maximum 10% of the machine’s nominal

tension.

Regularly check the cables and the plug. If the cable needs to be replaced, please contact•

factory.

Never unplug the power supply by pulling the cable.•

Never carry the machine by the cable.•

Before using the machine, always check that the handle is dry.•

The heater is extremely hot, it’s strongly suggested to use suitable gloves.•

Before packing away the machine, wait for the complete cooling of the heating surface.•

Description

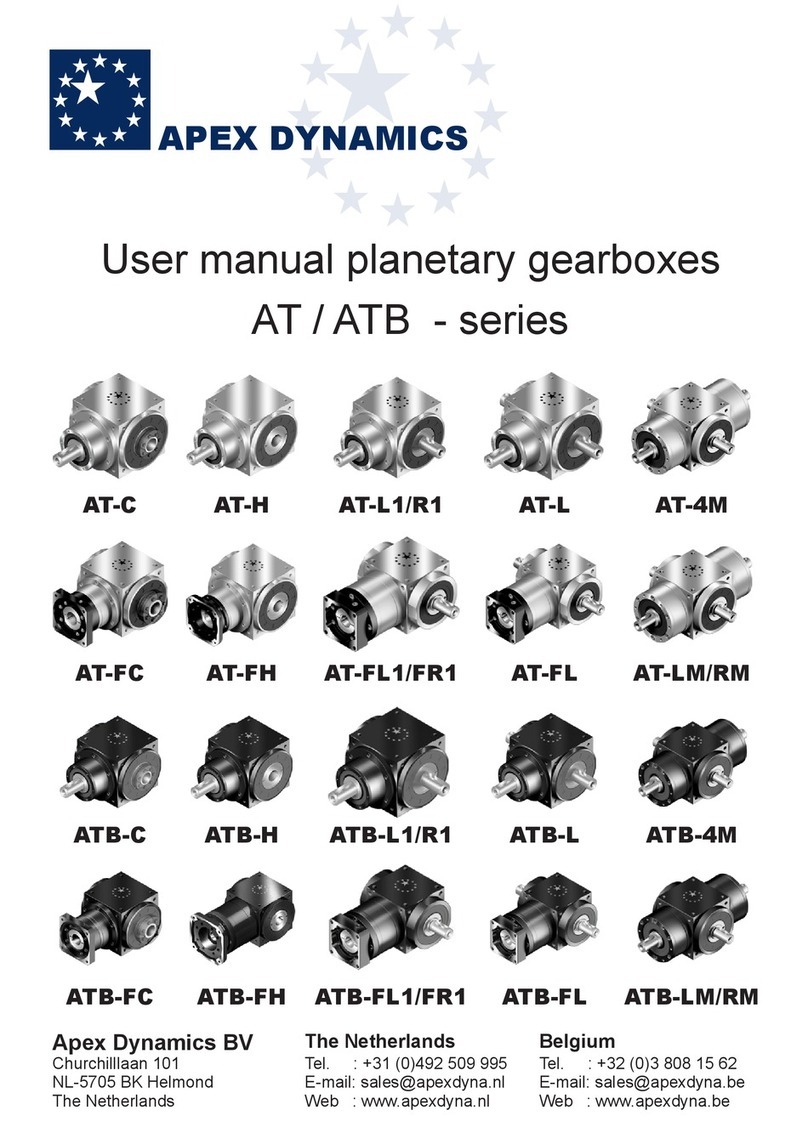

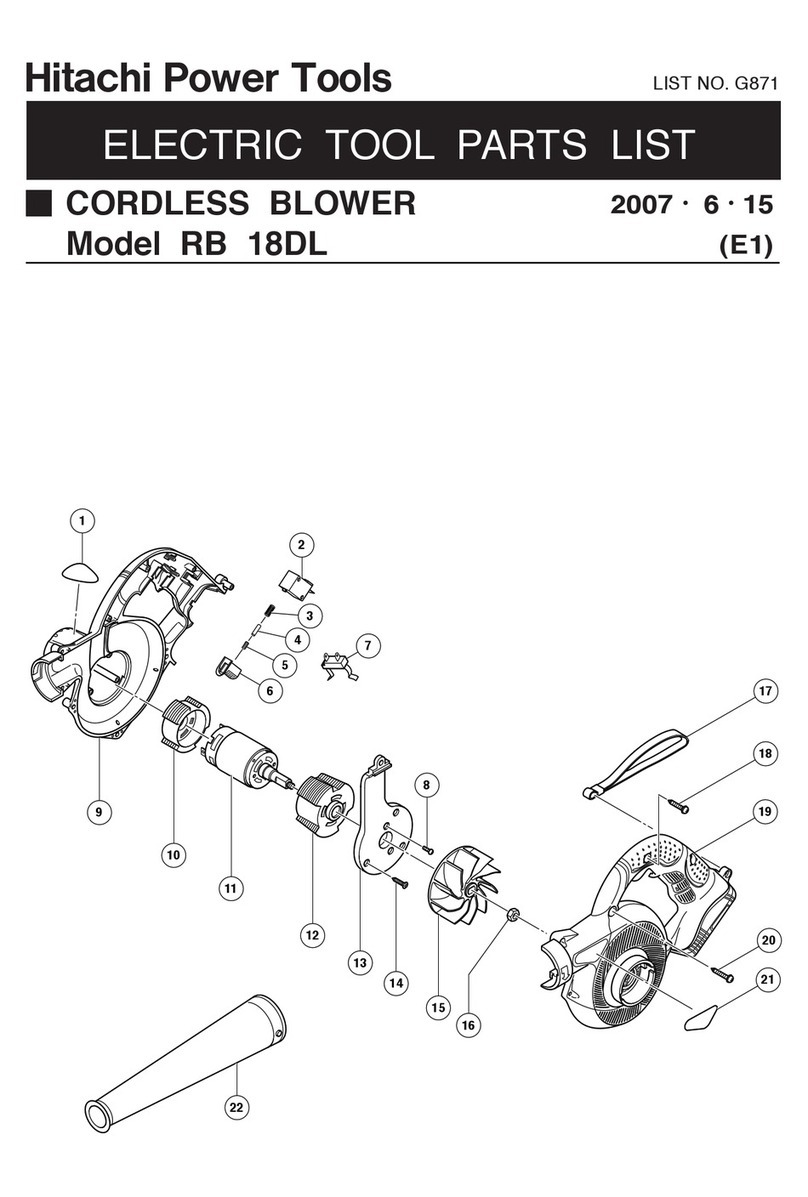

The Simtech portable socket fusion machines are available in two size ranges ½”-2” (20mm to

63mm) and ½” – 4” (20mm to 110mm) in both IPS and metric sizes. Each unit come completes with

an electric heating plate, digital temperature controller, durable plastic handle, two position metal

bench mounting bracket and heater stand. The unit also includes a side handle handle attachment

and heater bushing tools. A convenient carry case provides protection and safety while not in use.

½”-2” Tool is 110v / 800 w

½”-4” Tool is 110v / 1200 w

220v Avaliable upon request

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

3

1.081210

WeldTech - Hand Held Socket Tool

20mm through 110mm:

Complete Unit includes: Metal carrying case, Table stand, Table clamp stand, PTFE heater bushings: 20mm,

25mm, 32mm, 40mm 50mm, 63mm, 75mm, 90mm and 110mm, Adjusting tools and fasteners. Electrical

requirements: 110 /1Ph/60Hz

20mm through 63mm:

Complete Unit includes: Metal carrying case, Table stand, Table clamp stand, PTFE heater bushings

20mm, 25mm, 32mm, 40mm 50mm and 63mm, Adjusting tools and fasteners. Electrical requirements:

110/1Ph/60Hz

4

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

1.081210

WeldTech - Hand Held Socket Tool

•Unpackthemachine,putitinthesupport,and

assemble the PTFE coated bushes of the required

diameter. ( The diameter is clearly stamped on

the bushes themselves)

•MakesuretheTableviceisrmlymountedon

the work bench and insert and secure the Hand

Tool.

•ShouldsuppliedCordlengthbeinsufcient,a

standard 110V extension should be used.

•Selecttherightsizebushing,correspondingto

the size of the pipe and fitting to be welded.

•Whenfacingthetool,positionthefemale

bushing on the right side of the tool and the

male bushing on the left side.

•Lineuptheholesinthecenterofthebushing

with the hole in the center of the heat plate.

•Puttheallenboltthroughthefemalebushing

first then the heat plate and finally thread it into

the male bushing.

•Useanallenwrenchtoensurethatboth

bushings are securely fastened to the heat plate.

•Plugthehandtoolintoa110Vsocket;the

green power light and the yellow temperature

indicator light will go on.

•Selecttheappropriatetemperature(260C)You

can set the required temperature by pushing the

up/down arrows.

•Waituntiltheyellowtemperatureindicator

light goes off before proceeding with the weld.

•Pipemustbecutsquareandtheendmust

be chamfered. The fitting interior should be

thoroughly cleaned using a cleaning agent. The

pipe end should be chamfered on the outside.

•Pipeinsertiondepthmustbemarkedfrom

chamfered end as follow:

•Fittingandpipeshouldbepushedaxially

against the abutment (fitting) or the marking

(pipe) and should be held there.

•Thepartstobeweldedshouldbeheatedin

accordance with the information and time given

intheSocketWeldReferenceValuechart.

•Aftertheheatingtime,thettingandpipes

should be withdrawn from the heater element

abruptly and without twisting. They should be

pushed together right up to the mark or the

abutment.

•Afterobservingthe“TotalCoolingTime”your

joint is now ready to take on full pressure (equal

to the rating of the pipe and fitting).

•Cleantheinternalpartofthettingandthe

external part of the pipe with acetone or alcohol.

( Dirt or grease damage the weld)

DO NOT USE ACETONE OR ANY OTHER

CLEANING AGENTS ON THE BUSHINGS.

Pipe OD Insert Depth

20mm / ½” 0.63

25mm / ¾” 0.7

32mm / 1” 0.78

40mm 1¼” 0.86

50mm / 1½” 0.94

63mm / 2” 1.14

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

5

1.081210

WeldTech - Hand Held Socket Tool

Standard values for socket welding of pipe and fittings at an ambient temperature of 20°C and at a

moderate air flow.

Weldingtemperatureforallmethods:255°C-270°C

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

16

20

25

32

40

50

63

75

90

110

4

8

8

12

12

16

16

21

25

32

3

3

3

5

5

5

5

7

7

7

6

12

12

18

18

24

24

30

40

50

2

2

2

4

4

4

6

6

6

8

Clamped

(sec)

(sec)

(sec)

OD

(MM)

OD

(Inches)

Total

(min)

Pipe Insertion Time Cooling Time

Maximum

Changeover

Time

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

16

20

25

32

40

50

63

75

90

110

8

10

15

18

22

35

45

60

75

80

4

4

4

6

6

6

8

8

8

10

8

10

15

15

20

20

30

30

40

50

2

2

2

4

4

4

6

6

6

8

Pipe Insertion Time Cooling Time

Clamped

(sec)

(sec)

PN10/SR150

(sec)

OD

(MM)

OD

(Inches)

Cooling Time

(min)

Maximum

Changeover

Time

PP Socket Welding Times

PVDF Socket Welding Times

6

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

1.081210

WeldTech - Hand Held Socket Tool

Notes

•Althoughtheindicatorlightisoffwhenyou

first insert pipe and fittings into the bushings, it

will probably light as soon as the ‘cold’ pipe and

fitting touch the bushings. This is natural and you

can proceed with your weld. Just make sure that

light is off before inserting.

•Ifattheendofanyweldthereisanymaterial

left onto the bushing just use a clean wipe to

remove it from the Teflon coated surface of the

bushing.

•Ifthematerialisleftontothebushingafterall

welds performed check the following:

a)Yourpre-heatingtime(youareheatingtoo

long);

b)Yourtemperaturesettingmaybetoohigh

(you have a ±10°C window to adjust your

temperature)

WARNING:

This tool operates at elevated temperature.

Direct contact, even brief, with any heated parts

(plates or bushings) can result in severe burns to

unprotected skin.

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

7

1.081210

WeldTech - Hand Held Socket Tool

Notes

8

SIMTECH

Phone: 877-777-2467 • Fax: 215-547-9129

www.SimtechUSA.com

1.081210

WeldTech - Hand Held Socket Tool

Simtech Industrial Products, Inc.

47-A Runway Road, Levittown, PA 19057

Phone: 215-547-0444 Fax: 215-547-9129

Web site: www.SimtechUSA.com

WARRANTY

Simtech Industrial Products, Inc. products are warranted to be free from defects in materials and workmanship for one (1) year from date of

shipment. No claim shall be permitted under this warranty unless Buyer gives Simtech Industrial Products, Inc. written notice of all respects

in which Buyer claims the product to be defective. Notice must be received within ten (10) days from the date which the Buyer discovers, or

should have discovered the defect. Buyer shall give Simtech Industrial Products, Inc. a reasonable opportunity to inspect the product after

notice has been given. This warranty shall not apply to any products or components, which have been subjected to abnormal use, negligence

or accident.

Seller’s sole obligation under this warranty shall be limited solely on the repair or replacement, as elected by Simtech Industrial Products, Inc.,

of defective or nonconforming material. To the maximum extent permitted by law, Buyer irrevocably waives all claims for money damages

relating to the condition, use and performance of the goods purchased. In no event shall Simtech Industrial Products, Inc. liability exceed the

purchase price of the product sold by Simtech Industrial Products, Inc.

In no event, whether because of a breach of warranty or representation or any other cause, whether based upon contract, tort, warranty or

otherwise, arising out of the performance or nonperformance by seller of its obligations under this agreement or with respect to the products

sold pursuant here to; shall seller be liable for lost earnings, income or profits or indirect, incidental, liquidated or consequential damages.

The implied warranties of merchantability and fitness for a particular purpose except as set forth in this warranty, express or implied, are

hereby disclaimed and excluded. Nothing shall be construed as an additional warranty unless specifically designated as such in writing and

signed by Simtech Industrial Products, Inc.

Simtech Industrial Products, Inc. reserves the right, in its discretion, at any time and from time to time, to make changes to any specification,

data or information contained herein.

Other manuals for WeldTech

1

Table of contents