Simu MEMENTO User manual

1——

THE BRAND OF PROFESSIONALS

For over 65 years, SIMU has built on its industrial expertise and founding values in order to offer quality products

and services to its worldwide customers.

INVENTOR OF THE TUBULAR MOTOR FOR ROLLER SHUTTERS IN 1959!

In 1959, SIMU invented the tubular motor for roller shutters, a technology which has become the market standard.

Since then, we have continued to expand our knowledge and our expertise of the market and of our customers’

activities.

With over 65 years of experience, SIMU has become a reference brand in France and on the international stage!

MANUFACTURERS OF MOTORS AND AUTOMATIC CONTROLS

FOR ROLLER SHUTTERS, SUN BLINDS,

INDUSTRIAL AND COMMERCIAL CLOSURES SINCE 1952

STRONG

TECHNICAL

KNOWLEDGE

35 TECNICIANS &

ENGINEERS

HIGH

service

LEVEL

97%

DELIVERY RATE

OF OUR

MOTORS

ARE TESTED

100%

A HUMAN

ADEVENTURE WITH

260 EMPLOYEES

C

U

S

T

O

M

E

R

P

R

O

X

I

M

I

T

Y

MAXIMUM LOAD RAISED

BY OUR INDUSTRIAL

MOTORS

800

OF OUR CUSTOMERS

WOULD RECOMMEND US

100%

—— 2 3 ——

simu services

ONLINE support

services

DAILY,

OUR TECHNICIANS ANSWER

TO YOUR TECHNICAL QUESTIONS

AND ASSIST YOU WHEN

YOU NEED HELP

FOR INSTALLATION,

ADJUSTMENT OR

TROUBLESHOOTING

OF SIMU PRODUCTS.

CONTACT

CUSTOMER SERVICE

Tel. +33 3 84 64 75 00

Our technicians will answer you from Monday to Friday

from 8am to 12pm - 1.30pm to 5.15pm (4pm on Friday)

Excluding public holidays and closure periods

FOLLOW US

www.simu.com

FAQ, for immediate answers to the most frequently

asked questions about our products.

The online catalogue with all available references

available and their technical documentation;

Tutorials installation

and step-by-step adjustment

Your online ordering platform,

reserved for SIMU professional customers

(Metropolitan France). To order, consult your

prices or track your order

@

SIMU GUARANTEES

SIMU GUARANTEES ITS PRODUCTS FOR ITS PROFESSIONAL CUSTOMERS AGAINST ALL MANUFACTURING,

DESIGN OR MATERIAL FAULTS.

yOU ARE:

o A professional, a direct customer of SIMU : the full waranty applies.

o An individual or indirect customer of SIMU : please contact your installer or reseller to know the details of the

waranty applicable to you.

o

Tubular motors

o Central motors

o GM motors

o BOX and BOX SI motors

o Electronic products

o Battery and solar panel from the

AUTOSUN system sold alone

o Accessories (excluding cells and

batteries)

o LiveIn2 box.

o Plug Hz and BHz ON/OFF

o Sun sensor BHz

o Manual components

o Safety brake

o LiveIn2 Wi key

o Full solar solution AUTOSUN 2

(T3.5EHzDC motor + battery +

panel)

WARRANTY

7

M

o

t

o

r

-

B

a

t

t

e

r

y

-

S

o

l

a

r

p

a

n

e

l

PRODUCT

WARRANTY

5

PRODUCT

WARRANTY

2

PRODUCT

WARRANTY

1

AFTER-SALES SERVICE

Is a product under warranty has a failure? Contact us!

The SIMU After Sales Service will repair or replace it within 2 weeks

(as soon as we receive the defective product).

Our General Terms and Conditions of Warranty and the After Sales Service return form

are available on www.simu.com in the "Support / Warranty" section

simu formation

We accompany our professional customers through to training. Our

training department offers a programme of technical courses to help you

get to know SIMU products and understand their installation, adjustment

and programming rules.

To nd out more about our training offer, please contact your usual SIMU

sales consultant.

CONTENTS

—— 4 5 ——

INTRODUCTION

IDENTIFIFYING A MOTOR STICKER p. 6

SECURITY p. 8

- The control mode p. 9

- Installation recommendations p. 9

WIRING PRECAUTIONS p. 10

o

CENTRIS

WIRED CENTRAL MOTOR p. 11

- Installation p. 12

- Wiring with key switch p. 13

- End-limits setting p. 14

- Troubleshooting p. 15

o

CENTRIS VEOHZ

RADIO CENTRAL MOTOR p. 17

- Installation p. 18

- Wiring p. 19

- Compatible transmitters p. 19

- End-limits setting p. 20

- Command mode p. 21

- Validation of the rst command point p. 21

- Control of the visual command p. 22

- Use p. 22

- Optionnal settings p. 23

- Troubleshooting p. 25

o

T8, T8M, T8S, T8S DMI

SINGLE-PHASE MOTOR p. 27

- Installation tubular motors T8 and T8M p. 28

- Installation tubular motors T8S and T8S DMI p. 29

- Wiring with key switch p. 30

- End-limits setting p. 32

- Troubleshooting p. 33

o

T9, T9M

THREE-PHASE MOTOR p. 35

- Installation p. 36

- Examples of installation p. 37

- Wiring three-phase motor with SD350 - with manual override - 400V p. 38

- Wiring three-phase motor with SD350 - without manual override - 400V p. 40

- Wiring three-phase motor with SD350 - with manual override - 230V p. 42

- Wiring three-phase motor with SD350 - without manual override - 230V p. 44

- Wiring three-phase motor with SD510 - with manual override - 400V p. 46

- Wiring three-phase motor with SD510 - without manual override - 400V p. 48

- Wiring three-phase motor with SD510 - with manual override - 230V p. 50

- Wiring three-phase motor with SD510 - without manual override - 230V p. 52

- End-limit settings p. 54

- Troubleshooting p. 55

o

SIMUBOX

EXTERNAL MOTOR p. 57

- Installation p. 58

- Single-phase SIMUBOX motor wiring with key switch p. 60

- Three-phase SIMUBOX motor wiring with key switch p. 62

- Three-phase SIMUBOX smotor (no EI) wiring with SD510- 400 V p. 64

- End-limits setting p. 66

- Troubleshooting p. 69

o

SIMUBOX SI

EXTERNAL MOTOR p. 71

- Installation p. 72

- SIMUBOX SI motor wiring with key switch p. 74

- End-limits setting p. 76

- Troubleshooting p. 77

o

SD100HZ

RADIO CONTROL BOARD p. 79

- Installation p. 80

- Installation and wiring p. 81

- Box setting p. 86

- Troubleshooting p. 90

o

SD350

CONTROL BOARD p. 93

- Installation p. 95

- Wiring of three-phase motor with SD350 - with manual override - 400 V p. 96

- Troubleshooting p. 98

o

SD510

CONTROL BOARD p. 99

- Presentation p. 101

- Power wiring p. 103

- Three-phase tubular motor wiring with SD510 - with manual override - 400 V p 104

- SIMUBOX three-phase motor (no EI) with SD510 - 400 V p 106

- End-limits setting p. 108

- Key switch connection p. 108

- Safety device connection (for a shutter which cannot lift a person) p. 109

- Safety device connection (for a shutter which can lift a person) p. 112

- First power on p. 115

- Expert level parameters p. 123

- Consulting and programming maintenance p. 127

- Troubleshooting p. 132

7——

MOTOR STICKER

—— 6

Each SIMU motor has an identication sticker with a unique registration number, stuck on the tube, useful to have

its technical information and ensure its traceability.

IDENTIFYING A MOTOR STICKER

In case of repairing or of after-sales service, you may encounter motors with different stickers: there are older sticker models.

However, the information given will be the same as those presented above.

STICKER FOR UNIQUE REGISTRATION WITH DATAMATRIX & BARCODE

STICKER FOR UNIQUE REGISTRATION WITH DATAMATRIX

STICKER FOR UNIQUE REGISTRATION WITH DATAMATRIX

Technical reference + index

Production code (PPP)

Production year (YY)

Production day (DDD)

Production hour (HH)

Production minute (MM)

Production second (SS)

Technical reference + index

Torque (Nm)

Origin

Standards &

Homologations

Product

reference Current (A)

Cycles number per hour

Waste

treatment

Power supply (V)

Speed of the motor (rpm)

Frequency (Hz)

Operating

temperature

Description (reference only for internal use)

Protection

index against

solid and

liquid parts

Power of the motor (W)

NEW

2 detachable parts to stick on the outside

of the tube

Continuous operating time

The datamatrix and the barcode provide a code enabling the traceability of the motor:

Unique traceability with datamatrix (16x16mm)

Technical reference

+ index

Origin

Origin

Product name

Product name

Traceability: datamatrix

Traceability: datamatrix

Unique production code

Waste treatment

Waste treatment (battery)

Technical reference + index

Unique production code

Standards & Homologations

Operating temperature

Standards & Homologations

SIMU address

SIMU address

Technical reference + index

Production code (PPP)

Production year (YY)

Production day (DDD)

Production day (DD)

Production minute (MM)

Production second (SS)

—— 8 9 ——

NORMS SECURITY

SECURITY THE CONTROL MODE

FROM MAY 1ST 2005,

ALL THE STATE MEMBERS OF THE EUROPEAN UNION

ARE REQUIRED TO APPLY EUROPEAN STANDARD EN 13241-1

FOR THE CERTIFICATION

OF ALL INDUSTRIAL, COMMERCIAL AND GARAGE DOORS.

The main requirements are:

Solution to avoid shutter curtain fall (safety brake)

Solution to avoid closing risks

Solution to avoid opening risks

The marking is the compliance of the manufacturer with the EN 13241-1 standard.

The manufacturer must supply to installers:

Installation and removal instructions

User's manual

Maintenance manual

Declaration of conformity

Declaration of performance

APPLICABLE STANDARDS

EUROPEAN DIRECTIVES AND STANDARDS

All European countries are required to comply with European directives for products placed on the market. Compliance

with harmonised standards provides a presumption of conformity with the essential health and safety requirements

of the European directives that reference them. One of the major changes linked to the transition to the new European

standards and directives is the notion of responsibility: if the product is the result of the assembly of components

from several suppliers, the installer is considered, in fact, responsible for the whole installation.

SCOPE AND RESPONSIBILITIES

The motorised product must be installed by a professional in the eld of motorisation and home automation. The

installer must ensure that the installation of the drive complies with the relevant standards in the intended area of

application and the electrical installation regulations in force in the country of use. Before installing and using the

motorization, carefully follow the instructions in the manual supplied with the product and the safety instructions. All

use of the motorization outside of the eld of application is strictly prohibited. Wrongful use or other failure to comply

with the instructions in the manual would dismiss SIMU from any liability and guarantee. The installer must inform

his customers of the conditions of use and maintenance of the motorization and must give them the instructions for

use and maintenance, as well as the document enclosed with the product (instructions and safety). Any after-sales

service operation on the operator requires the intervention of an operator and home automation professional. If you

have any doubts about the installation of the operator or if you need further information, please contact a SIMU

representative or visit www.simu.com

INSTALLATION RECOMMENDATIONS

DEADMAN

with permanent visual control

You have to HOLD the button or

the key to OPEN or CLOSE the door.

You have always a view during the

movement of the door.

You don’t need safety accessories.

MIXED MODE

with permanent visual control

You have to HOLD the button

or the key to CLOSE the door.

You have always a view on the door

during the down command.

You don’t need safety accessories.

This mode is forbidden for grills.

IMPULSE MODE

stable mode

You OPEN and CLOSE the door by

IMPULSE command.

You have to install safety

accessories to secure the closing

in all cases.

You have to put safety accessories

to secure the opening if you have

crushing, shearing, lifting or

drawing-in point (ie grills)

THE RESPONSABILITIES

OF THE INSTALLER AND THE

MANUFACTURER ARE ENGAGED

WARNING: This document does not exempt the installer from carrying out a risk analysis of the installation, as he

is fully responsible for it; The recommendations below are given for information purposes only and SIMU cannot

be held responsible for any failure to comply with the requirements of the applicable standards.

Automatic control

(automatic door closure)

Pulse control

Control maintained within sight

THAT OPEN ONTO ON PUBLIC ROAD (INCLUDE COLLECTIVE HOUSING)

THAT OPEN ONTO ON PUBLIC ROAD

Safety brake

YES YES YES

NO NO

OUI OUI OUINON NON

OUI OUI OUINON NON

Safety edge Cell kits Signal light Area lighting

YES YES NO

YES YES *

YES YES NO

YES YES *

Automatic control

(automatic door closure)

Pulse control

Control maintained within sight YES NO YES

NO NO

OUI OUI OUINON NON

OUI OUI OUINON NON

YES NO NO

YES YES *

* for the roller grills, cell sets at the top are also needed

YES YES NO

YES YES *

The following table shows SIMU's recom-

mendations on the safety elements to be

integrated according to its situation and

operating mode.

THE STANDARD EN 13241-1

IS MAINLY AIMED AT HEIGHTENING

THE SAFETY OF PEOPLE

AND PROPERTIES

CENTRIS

11 ———— 10 11 ——

WIRING PRECAUTIONS

2 switches on same motor :

NOT ALLOWED

Mandatory use of sequence

switch or control device.

Mandatory use of double

pole switch or control

device

The yellow and green

wire is used for earth

connection only.

2 motors on single

pole switch :

NOT ALLOWED

only electronic motors allow this type of

wiring : please contact us.

—— 12 13 ——

CENTRIS WIRED CENTRAL MOTOR

INSTALLATION WIRING WITH KEY SWITCH

➊CENTRIS motor

➋Spring boxes

➌Tube Ø60 or 76 mm

➍Curtain or rolling grill

➋

Neutral

blue

brown Direction 1

Direction 2

Phase

black

red

Earth

yellow/

green

CENTRIS

motor

POWER SUPPLY 230V 50Hz

Universal key switch

or or

D

➊

➌

➍

➋

SD100Hz radio control board + remote control

Key switch + declutching handle

Key switch with built-in declutching system

DDeclutching security box + switch

with safety

accessories

FUNCTIONING MODE CONFIGURATION

Up

Universal key

switch connec-

tor block

direction

Down

Unstable mode

The position of the buttons must

be as indicated position to ensure

the applying of deadman operating

mode.

JUNCTION BOX

(NOT PROVIDED) KEY SWITCH

- DEADMAN OPERATING MODE IS MANDATORY

TO CLOSE THE CURTAIN WITH A KEY SWITCH.

- DEADMAN OPERATING MODE IS MANDATORY

TO OPEN THE CURTAIN IF A PERSON COULD BE LIFTED.

- MIXED OPERATING MODE IS ALLOWED

IF THE CURTAIN COULDN'T LIFT A PERSON.

direction

—— 14 15 ——

CENTRIS WIRED CENTRAL MOTOR

END LIMITS SETTING TROUBLESHOOTING

Sliding end limits box cover

and Removable memory rings

Dand Rotary adjusting wheels

and Electric switches

Motor crown.

Guiding blades.

1 - Put electrically the shutter to the DOWN wished position

2 - Remove the memory ring of the right side .

3 - Turn the right adjusting ring in the “-” direction until to activate the

switch .

1 - Put electrically the shutter to the UP wished position (noise of the blades).

2 - Move the shutter down up to the oor.

3 - Remove the memory ring of the left side .

4 - Turn the left adjusting ring Dturns in the “-” direction

(tip: mark the wheel with a pencil).

Move the shutter up and down to check the end limits positions. If necessary, turn the adjusting wheels in

the “+” direction to increase shutter run or in the “-” direction to decrease shutter run.

screw CBL Z 3x12

IDENTIFYING THE END LIMITS

DOWN END-LIMIT ADJUSTMENT

UP END-LIMIT ADJUSTMENT

DO NOT FORGET TO RETIGHTEN THE

PROTECTIVE RAIL AFTER ADJUSTMENT

==

1 2,5°

x 5 x 1

D

PROBLEMS POSSIBLES CAUSES SOLUTIONS

The motorized product is not

working The motor is on thermal cut

Wait until the motor cools down

The motorized product

is running without driving

the curtain

The declutching system is active

Check that the declutch cable is not

wound up or that the clutch lever is

deactivated

The curtain doesn't go up

and down

The motor is disengaged

and doesn't move the curtain

- Cut the power off

- Re-engage the motor by the clutch

handle

- Operate the curtain

The motor is operating in one

direction only

Key switch not properly wired Check the operating of the motor with

direct power supply

Wrong balancing Check the balancing of the curtain

The motor stops before

its end-limits

Wrong end limit setting Set the end-limit on the good position

Wrong balancing Check the balancing of the curtain

The motor losts its end-limits

No end-limit setting Set the end-limit on the good position

Dismantling of the teeth

on the end-limit unit system Check the teeth condition and align them

19 ——

CENTRIS VEOHZ RADIO CENTRAL MOTOR

—— 18

INSTALLATION WIRING DIAGRAM

COMPATIBLE TRANSMITTERS

➊Centris veoHz central motor

➋Spring boxes

➌Tube Ø60 or 76 mm

➍Curtain or rolling grill

The CENTRIS veoHz motor is compatible with Simu veoHz transmitters only.

Refer to the corresponding instruction manuals.

- Max. 12 transmitters per motor in total

➊

➌

➋

➍

➋

Remote control

Declutching handle

Control box veoHz with declutching system

The installation of the power supply must comply with the standards in force in the country where it is

installed; the power line must be reserved exclusively for the motor and provided with adequate protection.

An all-pole disconnection device must be provided:

- Either via a power cable with a plug.

- Or by a switch providing a contact separation distance of at least 3 mm on each pole

(see EN60335-1 standard).

- Make the connections when the equipment is not live.

- Do not connect the motor to a power source (mains) before completing the installation.

or

12

1

2

OFF

Blue

Brown

Green/Yellow

N

L1

PE

230V 50Hz power supply

Control box veoHZTSA 3B veoHz

Move the transmitter away from any metal surface which may prevent it from operating correctly

(loss of range)

—— 20 21 ——

CENTRIS VEOHZ RADIO CENTRAL MOTOR

LIMIT SWITCH SETTINGS COMMAND MODE

VALIDATION OF THE FIRST COMMAND POINT

PROG

>>>

Please identify the prog button to start setting.

This button is necessary to set end-limits.

Perform all the programming with the transmitter

that will control the closing.

The upper and lower stop points are mandatory

(mounting with at least 2 M5 screws per stop point).

ON

3 s.

OK

no OK

- Switch on the motor.

- Simultaneously press the keys ▲ and ▼ on a veoHz transmitter

—> The motor responds with a “short rotation”.

This transmitter controls the motor with a press and hold

mechanism (by default).

Press the ▲key on the transmitter:

➊If the shaft rotates in an upward direction, the direction

is correct and you can proceed to step 3.

➋If the shaft rotates in a downward direction, the

direction is wrong and you must reverse the rotation

direction by the ●STOP key for at least 3 seconds

The motor conrms the setting by a “short rotation”.

X > 30 mm

1. 1.2. 2.

3 s.

=

➊Lower hold point

1. Position the motor on the wanted lower hold point.

2. Simultaneously press the keys ●STOP et ▼to set the lower hold point

—> The motor conrms the setting by a “short rotation”.

➋Upper hold point

1. Position the motor on the wanted upper hold point.The upper hold point must be located at a distance greater

than 30 mm from the upper stop point.

2. Simultaneously press the keys STOP et ▼ to set the upper hold point

The motor conrms the setting by a “short rotation”.

After saving the upper and lower stop points, conrm the settings:

- Press ●STOP for 3 seconds.The motor rotates 0.5 second in the downward direction and then automatically rises

to force the upper stop points and “de-compresses”.

At this step, you can modify the motor command mode, before completing the programming by validating the rst

command point.

Do not do any

command with

the remote control

while the curtain

is moving.

MODE 1 (default)

press and hold

inactive

press and hold

pulse

STOP / partial opening

press and hold

MODE 2

5 s.

If you are not satised with this mode or you feel that it may have any danger to people and property, go back to

MODE 1:

- To go back to MODE 1, simultaneously press the keys ● STOP, ▲and ▼for 5 seconds

The motor conrms the setting by a “short rotation”.

Note that the command mode cannot be changed once the rst transmitter is validated. In this case,

a complete reset of the motor is required.

by default, command by press and hold to raise and lower.

command by pulse press to raise and press and hold to lower.

MODE 2 is authorised only if there is no crushing, shearing, lifting or drawing-in point as defined in

EN12453:2001 standard §4.1.1and §4.1.2.(e.g.: grilles and curtains with projections that may be used to lift a

person are not authorised with MODE 2).Failure to follow these instructions will result in a hazardous situation

that could result in death or serious injury. Choosing this mode engages the full liability of the installer.

If the default command mode MODE 1 is appropriate, do not perform this step and skip to the next chapter.

To enter MODE 2 :

- Position the curtain outside the limit switch positions.

- Simultaneously press the keys ● STOP, ▲and ▼for 5 seconds

—> The motor conrms the setting by a “short rotation”.

You now control the motor by pulse to raise and by press and hold to lower.

1- ENTER THE SETTINGS MODE

MODE 1

MODE 2

CHANGE OF MODE

2- SETTING THE ROTATION DIRECTION

3- LIMIT SWITCH SETTINGS

4- VALIDATION OF SETTING

➊

➊

➋

➋

1 s.

At this step, you need to validate the 1st command point.

- Press the PROG key of the transmitter for 1 second.

The motor conrms the setting by a “short rotation”.

Your transmitter is now set and controls the motor according to the mode

dened before.

—— 22 23 ——

CENTRIS VEOHZ RADIO CENTRAL MOTOR

CONTROL OF THE VISUAL COMMAND OPTIONAL SETTINGS

USE

The EN12453:2001 standard §5.1.1.4 stipulates that the person operating

the door must always have a direct view of the door, be close to the door

when the shutter is moving and not remain in a dangerous position.

By default, the VEO Hz mobile transmitters have a very short radio

range (setting on threshold 2).

It is the responsibility of the installer to ensure that the dened radio

range guarantees a visual command.

If the power supply is disconnected for over 30 seconds, the next radio command

authorised will only be to raise the curtain to the upper stop points (resetting).

The motor forces the stop points before “decompressing”.

threshold

1

threshold

3

threshold

2

threshold

4

- If you feel that this very short range does not allow controlling the product appropriately, you can increase it

(threshold 3 - threshold 4), provided that the new radio range guarantees an exclusively visual command.

- If you feel that this very short range does not allow visually controlling the product, you can decrease it (threshold 1).

If the transmitter's default range is appropriate (threshold 2), do not perform this step. .

First remove the rear screw on the transmitter to quickly access the PROG button (as you will have 15 seconds

to conrm the threshold selection).

- Put the curtain outside the limit switch positions.

- Simultaneously press the keys ▲and ▼on the VEO Hz transmitter for 5 seconds —> The motor responds with

a “short rotation”.

To increase the range, press▲. To decrease the range, press ▼.

The motor performs a “short rotation” corresponding to the selected threshold:

- Threshold 1: a rotation of 0.5 s.

- Threshold 2: two rotations of 0.5 s.

- Threshold 3: three rotations of 0.5 s.

- Threshold 4: four rotations of 0.5 s.

After selecting your threshold, conrm the setting within 15 seconds by pressing

“Prog” for 1 second

—> The motor conrms the setting by a “short rotation”.

Ensure that the new range ensures an exclusively visual command.

This new radio range is valid for all mobile transmitters that will be programmed later.

When the transmitter is out of the dened range, its orders are ignored.

1 s.

CHANGING THE RADIO RANGE (THRESHOLDS 1 - 2 - 3 - 4)

- Instructions for use: refer to the command point manuals and the clutch system manual.

- The motor does not require any maintenance operations. Change the batteries of your command points after 2 years or before

that, depending on how frequently it is used.

1

2

Control via

the radio command

Manual operation

using the clutch

handle provided

1- Open the motor’s memory from the previously programmed transmitter : Press the PROG key of the transmitter for 3 seconds

The motor responds with a “short rotation”.

2- Validate the operation from the new transmitter : Press the PROG key of the new transmitter for about 1 second

The motor responds with a “short rotation”.

- If the new command point is mobile, its range will be equal to that dened before. All mobile or wall-mounted

transmitters control the motor according to the command mode selected before.

- With respect to a xed command point, it is the responsibility of the installer to mount this command point where it is visible from the curtain

- To delete a transmitter from the motor memory: perform operation 1- from a transmitter that was previously programmed and

operation 2- from the transmitter to be deleted.

3 s.

1 s.

A- PROGRAMMING A NEW MOBILE OR FIXED COMMAND POINT

B- PARTIAL OPENING

C- CHANGING THE POSITION OF THE UPPER LIMIT SWITCH

1-

1- 2-

2-

This function is provided only for MODE 2 (raise by pulse press) and for upward movement

1- CHECK if the default “partial opening” position is suitable.

a- To do this, position the curtain in the lower position.

b- Press the STOP key for 0.5 S.

c- The curtain goes back to its “partial opening” position.

2- CHANGE THE “PARTIAL OPENING” POSITION if the default position is not suitable

a- For this, position the curtain at the desired “partial opening” position.

b- Press the STOP key for 6 seconds —> The motor conrms the setting by a “short rotation”.

c- The new position of the partial opening is saved.

0,5 s.

6 s.

OK

a- a- b- c-b- c-

6 s. 3 s.

1- Put the motor on the current upper end-limit position by using the key ▲.

2- Simultaneously press the keys ▲and ▼for 6 seconds —> The motor responds with a “short rotation”.

3- Put the curtain on the wanted limit switch using the keys ▲and ▼.

4- Press the STOP key for 3 seconds —> The motor conrms the setting by a “short rotation”.

The new end-limit position is saved.

1- 2- 3- 4-

—— 24 25 ——

CENTRIS VEOHZ RADIO CENTRAL MOTOR

E- CANCELLATION OF THE PROGRAMMING AND LIMIT SWITCH SETTINGS

F- CANCELLATION OF THE PROGRAMMING AND LIMIT SWITCH SETTINGS

1- Cut the power supply of the motor for 2 seconds.

2- Power on the power supply of the motor for 7 seconds.

3- Cut the power supply of the motor for 2 seconds.

4- Power on the power supply of the motor.

—> The motor responds with a “short rotation”

1 s.

1 s.

OFF

2 s. 7 s. 2 s.

ON ONOFF

OFF

2 s. 7 s. 2 s.

ON ONOFF

1-

1-

2-

2-

3-

3-

4-

4-

Take a transmitter previously programmed or not on the motor.

Press the PROG key of this transmitter for 1 second until the motor responds with a “short rotation”.

This transmitter is now the only one programmed on the motor, all other transmitters are erased.

However, the motor settings are not changed.

1 s.

1- Cut the power supply of the motor for 2 seconds.

2- Power on the power supply of the motor for 7 seconds.

3- Cut the power supply of the motor for 2 seconds.

4- Power on the power supply of the motor.

—> The motor responds with a “short rotation”

Press the PROG key of the transmitter for more than 7 seconds.

Press and hold until the motor responds with a “short rotation” and then a few seconds later

—> the motor again responds with a “short rotation”.

The motor memory is now completely empty.

Fully set the motor again.

The motor is now in “programming cancellation” mode

If you change the power supply of multiple motors, they will all be ready for cancellation. It is therefore appropriate

to “eject” from this mode all motors not concerned by this modication, by pressing a command key of a transmitte

programmed with the motors to be ejected.

Now validate the “programming cancellation” of the motor:

> 7 s. 2s. 7s.

D- CHANGING THE POSITION OF THE LOWER LIMIT SWITCH

6 s. 3 s.

1- 2- 3- 4-

1- Put the motor on the current lower end-limit position by using the key ▼.

2- Simultaneously press the keys ▲and ▼for 6 seconds —> The motor responds with a “short rotation”.

3- Put the curtain on the wanted limit switch using the keys ▲and ▼.

4- Press the ● STOP key for 3 seconds —> The motor conrms the setting by a “short rotation”.

The new end-limit position is saved.

TROUBLESHOOTING

PROBLEMS POSSIBLES CAUSES SOLUTIONS

The motorised product

is not working

The motor is thermally protected

Wait for the motor to cool down. If the mo-

torised product still does not work, use the

clutch device and contact a motor and

building automation professional

The motor is disengaged Re-engage the motor by re-screwing the

clutch handle

Out-of-range command point Get closer to the motor

The product does not work

properly Command point at range limit Get closer to the motor

The down command

is ignored

The motor suffered a power

failure > 30s or a disengagement

during a failure < 30s

Raise the curtain up to the upper stop

points; the product will then make a

short downward movement

Transmitter LED ashing

very fast or jerky movement

of the product (need to restart

every 3 sec.)

Low battery Replace the battery, otherwise the

curtain cannot be moved

I cannot pair

my mobile transmitter

Command point not compatible

with VEO Hz Get a VEO Hz command point

No more channels available

(12 max) Delete an existing transmitter

Out-of-range command point Get closer to the motor

—— 28 29 ——

SINGLE-PHASE MOTOR T8, T8M, T8S, T8S DMI

INSTALLATION

➊ Tubular motor with or without manual override

➋ Plates for motor side (double plates + angle bracket + motor bracket)

➌ Adjustable bobbin with shaft

➍ Plates opposite side (double plates + angle bracket + safety brake bracket)

➎ Safety brake

➏ Wheel

➐ Tube

➊ Tubular motor with or without manual override

➋ Plates for motor side (double plates + angle bracket + motor bracket)

➌ Adjustable bobbin with shaft

➍ Plates opposite side (double plates + angle bracket + safety brake bracket)

➎ Safety brake

➏ Wheel

➐ Tube

T

U

BE

➋

➋

➊

➏

➊

➐➏

➌➌

➐

➍

➍

➎

➎

TUBULAR MOTOR T8 - T8M TUBULAR MOTOR T8S - T8S DMI

—— 30 31 ——

SINGLE-PHASE MOTOR T8, T8M, T8S, T8S DMI

WIRING WITH KEY SWITCH

1

2

3

1

2

3

Neutral

blue

brown Direction1

Direction 2

Phase

black

red

Earth

yellow/green

TUBULAR MOTOR T8 - T8M

TUBULAR MOTOR T8S - T8S DMI

FOR WIRING WITH SD100HZ CONTROL BOARD,

PLEASE REFER TO PAGE 81

JUNCTION BOX

(NOT PROVIDED)

Power supply 230V 50Hz

- DEADMAN OPERATING MODE IS MANDATORY TO CLOSE THE

CURTAIN WITH A KEY SWITCH.

- DEADMAN OPERATING MODE IS MANDATORY TO OPEN THE

CURTAIN IF A PERSON COULD BE LIFTED.

- MIXED OPERATING MODE IS ALLOWED IF THE CURTAIN

COULDN'T LIFT A PERSON.

Universal key switch

FUNCTIONING MODE CONFIGURATION

Up

Universal key

switch connec-

tor block

direction direction

Down

Unstable mode

the position of the buttons must

be as indicated position to ensure

the applying of deadman

operating mode.

KEY SWITCH

—— 32 33 ——

SINGLE-PHASE MOTOR T8, T8M, T8S, T8S DMI

END-LIMITS SETTINGS

TUBULAR MOTOR T8 - T8M

TUBULAR MOTOR T8 - T8M

T8S - T8S DMI

T8S - T8S DMI

T8S - T8S DMIT8 - T8M

IDENTIFICATION OF THE SETTING SCREW.

SETTING THE END-LIMITS

- Identify the setting screw by arrows I and II on the head of motor, corresponding to the rotation of

the winding. These will be used to modify the end-limits positions of both directions of rotation.

- Turn setting screw on clockwise direction (+) to increase the number of turns

- Turn setting screw on anticlockwise direction (-) to decrease the number of turns

Setting the upper end limit:

Press the ▲ key on the command point and adjust the position of the end limit by turning the corresponding

adjustment screw.

Setting the lower end limit: Press the ▼key on the command point and adjust the position of the end limit

by turning the corresponding adjustment screw

TROUBLESHOOTING

PROBLEMS POSSIBLES CAUSES SOLUTIONS

The end-limits are lost

The adaptor crown is not xed

correctly (with the basic crown or

with the tube)

Check that the end ring xing screws

are present on the base ring and on the

roller tube.

The motor is operating in one

direction only. Connection problem

Please check the wiring of the command

point (brown wire, black wire) and check

the operating of the motor.

The motor doesn't operate.

The security end limit switch

is activated (in case of use of

manual override, don't cross up or

down end-limit position)

Turn back few rounds with the manual

override to operate the motor

by command order again.

The manual override system is

active.

The microswitch puts the power

off.

Deactivate the manual override system

The crank is hinged on the eye

crank of the manual override. Due

to its weight (very long and very

heavy shaft), the microswitch

cuts the power.

Remove the crank of the manual override

when you don't use it

The safety brake switch is active Please check the continuity of the safety

brake switch

The motorised product does

not work.

The motorization is in thermal

cut-off Wait for the motorization to cool down

—— 36 37 ——

THREE-PHASE MOTOR T9, T9M

INSTALLATION

➊ Tubular motor with or without manual override

➋ Plates for motor side (double plates + angle bracket + motor bracket)

➌ Adjustable bobbin with shaft

➍ Plates for opposite side (double plates + angle bracket + safety brake bracket)

➎ Safety brake

➏ Wheel

➐ Tube

ôté moteur

T

U

B

E

➋

➊

➏

➐

➌

➍

➎

MOTOR TUBULAR T9 - T9M WITH SD350 CONTROL BOARD

WITH SD510 CONTROL BOARD

INSTALLATION EXAMPLES

Other Simu Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

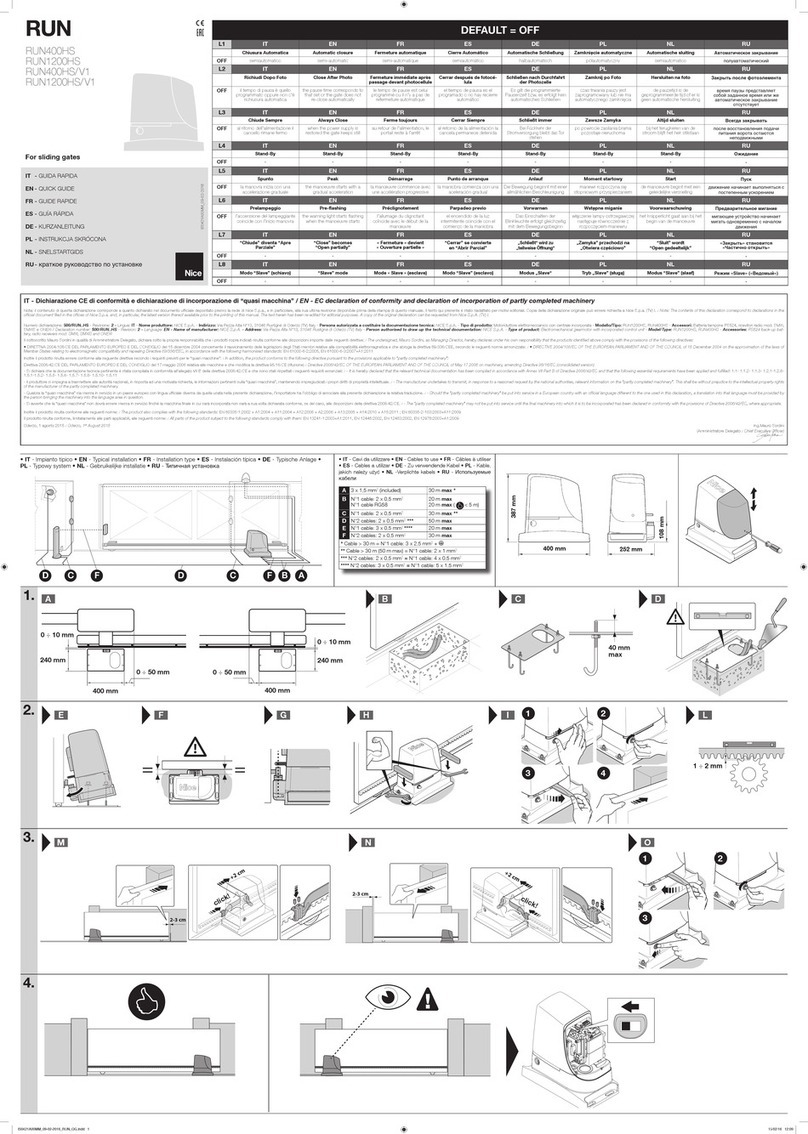

Nice

Nice RUN1200HS quick guide

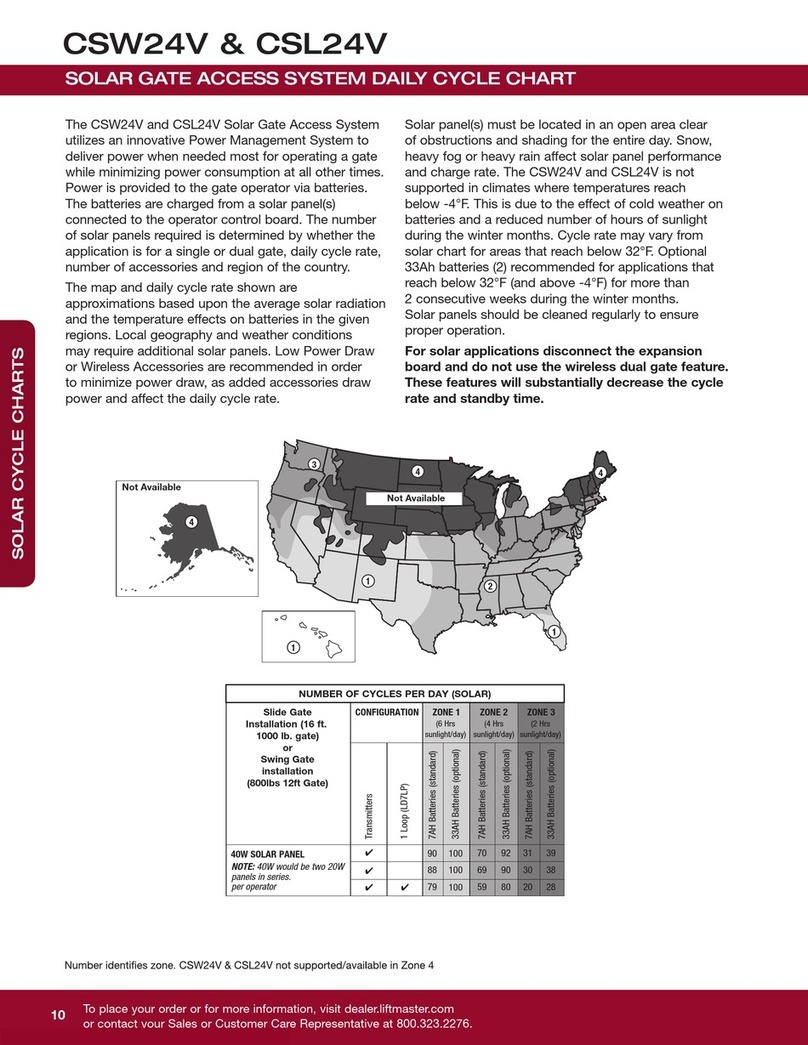

Chamberlain

Chamberlain LiftMaster CSL24V manual

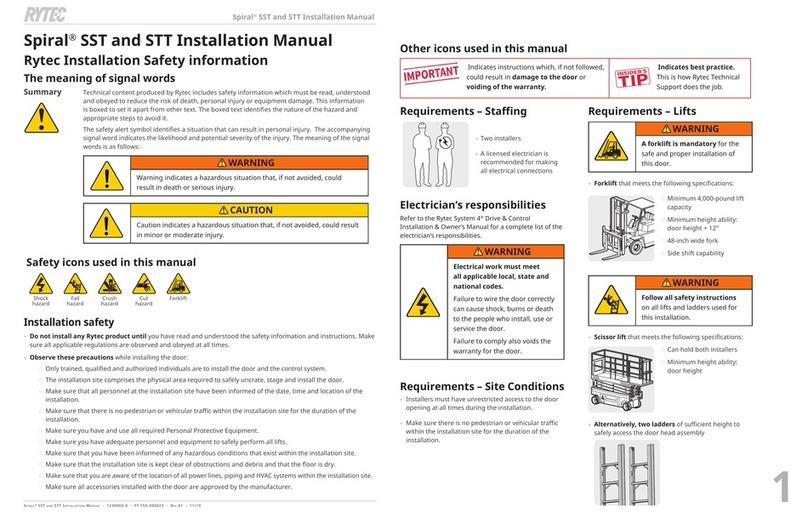

RYTEC

RYTEC Spiral SST installation manual

Wayne-Dalton

Wayne-Dalton Prodrive 3220C Installation instructions and owner's manual

BFT

BFT DEIMOS 300 BT Installation and user manual

Wayne-Dalton

Wayne-Dalton 6600 Installation instruction and owenrs manual

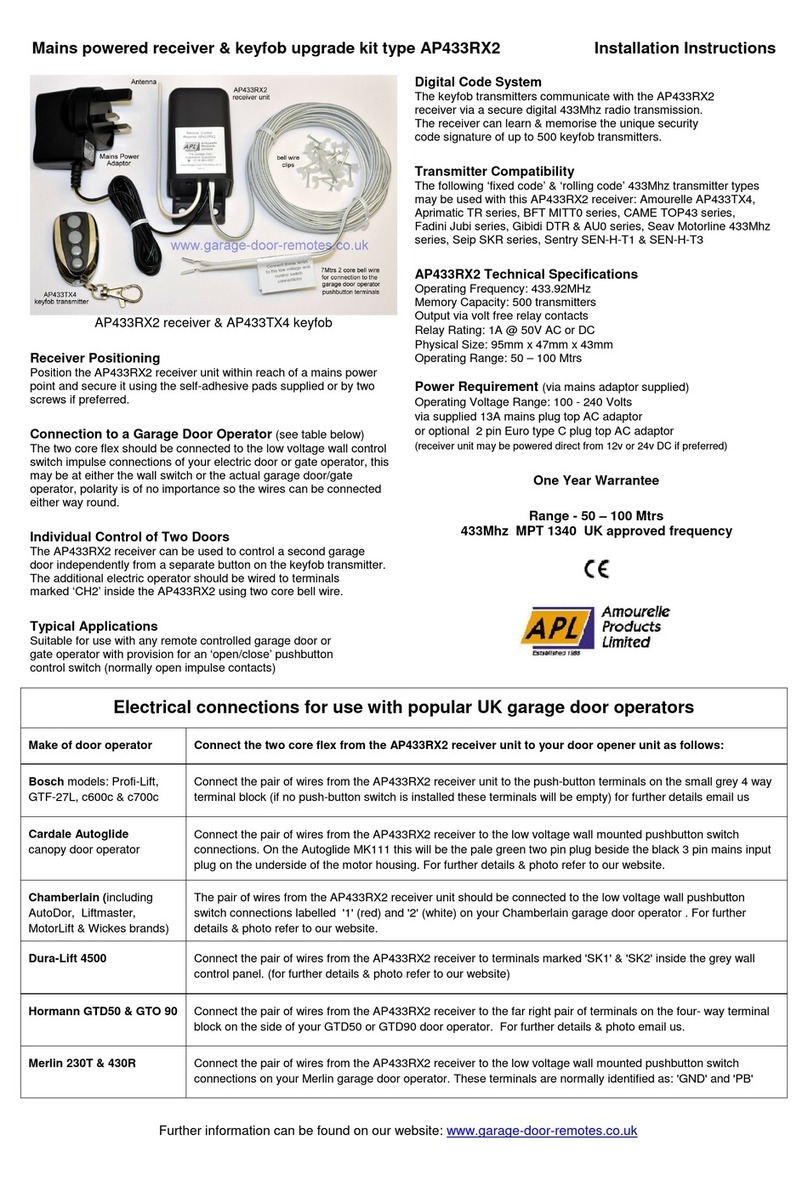

Amourelle

Amourelle AP433RX2 installation instructions

Cardale

Cardale DC-650N Owners and installation manual

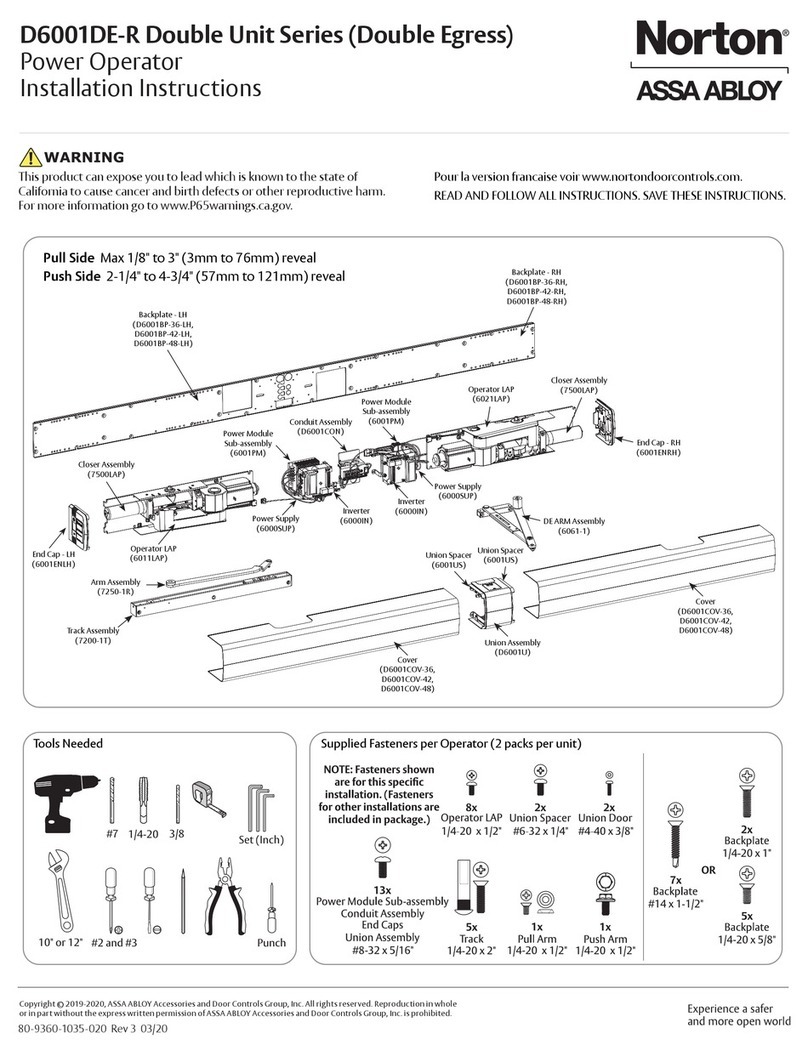

Assa Abloy

Assa Abloy Norton D6001DE-R Double Unit Series installation instructions

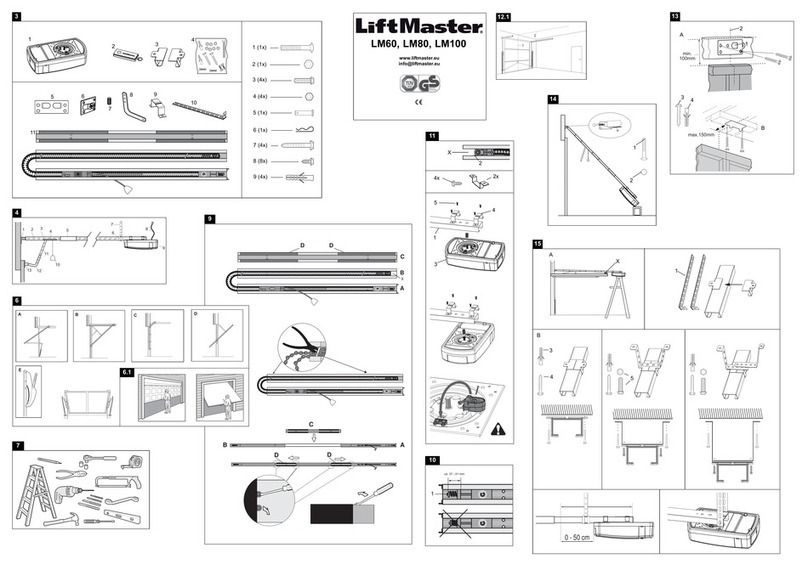

Chamberlain

Chamberlain LiftMaster LM60 quick start guide

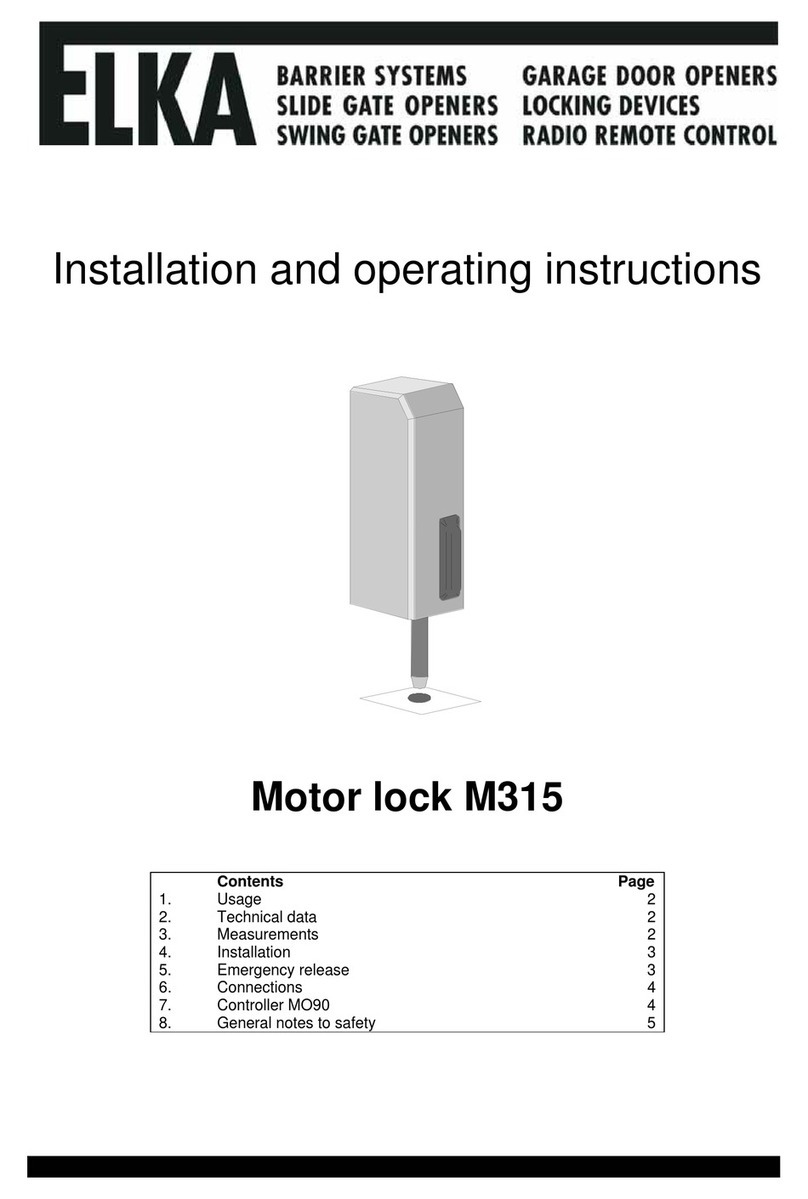

Elka

Elka M315 Installation and operating instructions

Chamberlain

Chamberlain 882LMW quick start guide