SimworX Pro Series User manual

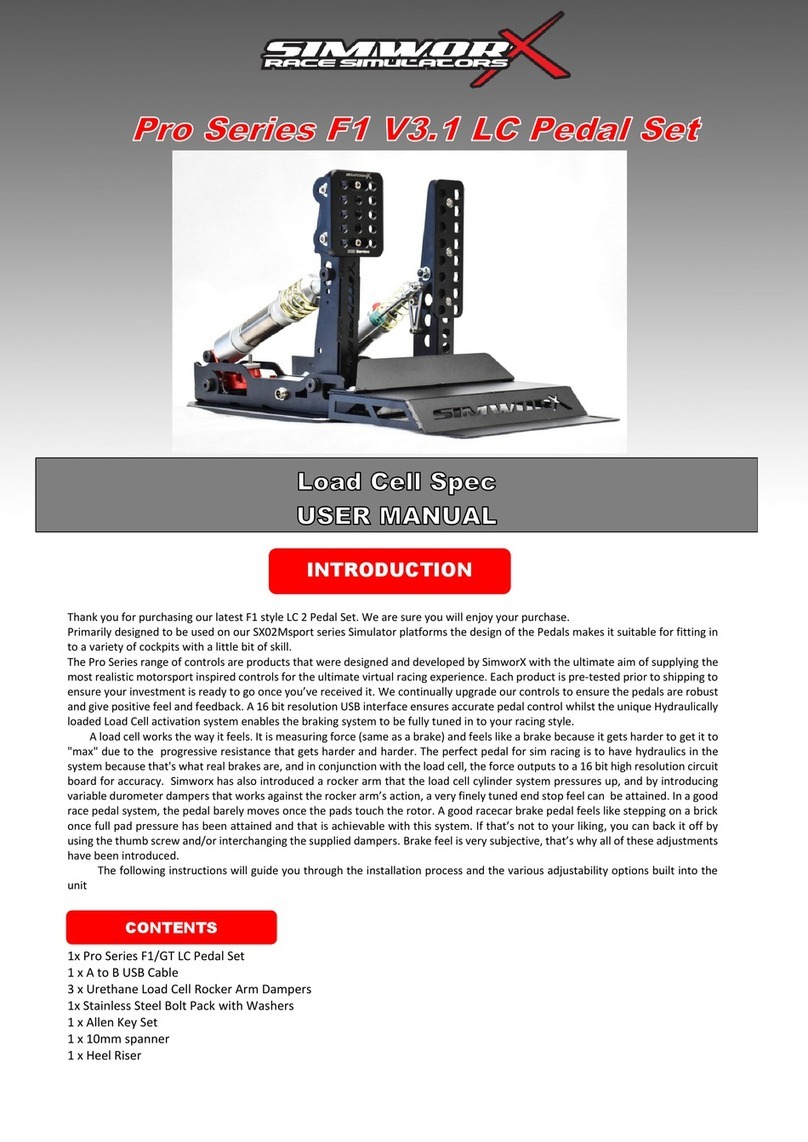

Pro Series F1 LC Pedal Set

USER MANUAL

Load Cell Spec

Thank you for purchasing our F1 LC Pedal Set. We are sure you will enjoy your purchase.

The compact design of the F1 LC Pedals makes it suitable for fitting in to compact F1 style cockpits where footwell

space is limited.

The Pro Series range of controls are products that were designed and developed by SimworX with the ultimate aim of

supplying the most realistic motorsport inspired controls for the ultimate virtual racing experience. Each product is

pre-tested prior to shipping to ensure your investment is ready to go once you’ve received it. We continually upgrade

our controls to ensure the pedals are robust and give positive feel and feedback. A 12 bit resolution USB interface

ensures accurate pedal control whilst the unique Hydraulically loaded Load Cell activation system enables the braking

system to be fully tuned in to your racing style.

A load cell works the way it feels. It is measuring force (same as a brake) and feels like a brake because it gets

harder to get it to "max" due to the progressive resistance that gets harder and harder. The perfect pedal for sim

racing is to have hydraulics in the system because that's what real brakes are, and in conjunction with the load cell,

the force outputs to a 12 bit resolution circuit board for accuracy. Simworx has also introduced a rocker arm that the

load cell cylinder system pressures up, and by introducing variable durometer dampers that works against the rocker

arm’s action, a very finely tuned end stop feel can easily be attained. In a good race pedal system, the pedal barely

moves once the pads touch the rotor. A good racecar brake pedal feels like stepping on a brick once full pad pressure

has been attained and that is achievable with this system. If that’s not to your liking, you can back it off by using the

thumb screw and/or interchanging the supplied dampers. Brake feel is very subjective, that’s why all of these

adjustments have been introduced.

The following instructions will guide you through the installation process and the various adjustability options

built into the unit

1x Pro F1 LC Pedal Set

1x 3M USB Cable

3 x Urethane Load Cell Rocker Arm Bushes

1x Stainless Steel Bolt Pack with Alloy Washers

1 x Allen Key Set

For owners of existing Simworx simulators and/or chassis units, the mounting points for the pedals are already in

place. Locate the pedals and with the supplied bolt set insert them in to the pre-tapped bolt holes. .

For fitting to other simulators, make sure the frame is strong enough to withstand the forces you can exert on the

brake pedal. On the next page you will find a drilling guide for your Pedals base plate. Position the pedal set plate at

your preferred location and using the rear slots either side of the base plate, carefully mark the hole position through

the rear base slot onto your mounting surface. As a rule we usually recommend marking the mounting bolt holes

halfway in the slots so you can move its position backwards and forwards to your requirements.

Once you are satisfied with its location, drill a small pilot hole at each bolt location. Finish the hole size for the

forward slots at 8.5mm

Bolt the pedal set in place using two of the supplied bolts and alloy cup washers in the bolt pack. Loosely fasten the

slot bolts and adjust the pedal position incrementally until you are satisfied with its final position. Once satisfied mark

through the two bolt holes on the front slots, take the pedal set off again and drill the final two 8.5mm holes where

you marked them.

For final permanent mounting, push in the four slot bolts and tighten securely. Please make sure they are secured

tightly to ensure that the pedal set doesn’t flex under the pressure. The mounting surface needs to be strong enough

to withstand the 120kgs+ of pressure that can be exerted on the brake pedal. Any flex in the mount plate will affect

the pressure exerted on the Load cell.

INTRODUCTION

PACKAGE CONTENTS

FITTING

Drill and locate these holes first

If satisfied with positioning of your pedals mark and drill the remaining front 2 holes

90

70 275

90

Slot Centres

232mm

10

195

260

275

Plug in the supplied USB A to B cable into the rear of the pedal set and then into a spare USB port

on your computer. The pedal set should be automatically be detected by Windows and self-install.

You can confirm this by going to the ‘devices and printers” and confirming that “Simworx Pro

Series” is listed there. If its not listed, try another USB port on the computer end.

This procedure is based on the windows 7/8.1/10 operating system, older systems may vary.

1. Once you have connected your pedals and the “Simworx Pro Series” device is visible in windows “Devices and

Printers”, right click on the “Simworx Pro Series” and select “Game Controller Settings

2. From the next list, select “Simworx Pro Series” and click the “Properties” button.

3. Click the “Settings” tab in the next window.

4. Click “Reset to default”

5. Click “Calibrate”

6. Follow the on screen prompts to calibrate your device

7. Once completed, you will be taken to the testing window, press all the pedals and watch the

visible red sliders to confirm calibration, if the red sliders do not travel the full extent, repeat from step 3.

Once correctly calibrated in Windows you can run your game and configure your in game controls.

You may find that when assigning the brake pedal in the game, you may notice a flickering on the calibration bar due

to a slight pre-load tension on the load cell. This is related to what you have set the pedal position and rocker arm

damper tension to. Adding a touch of Dead Zone to the brakes will eliminate that initial static pre-load.

As we use the Leo Bodnar BUO836-LC interface for our pedals there is a handy Leo Bodnar Calibration exe file

DIView.exe - For Accurate Calibration that is available for download from his website to assist in the calibration:

CONNECTION

CALIBRATION

BU0836-LC Load Cell Joystick Controller

Click Here to DIView.exe download

Product Description More Details How to Use Product Downloads Additional Images

Pedal Face Angle

The pedal face on the brake pedal is fitted with angle and height

adjustments. To adjust, using a 5mm allen key and 10mm

spanner, loosen off the two nuts (pointed out by the red

arrows) a few turns to loosen the pad assembly. Once loose,

you will be able to adjust the pad upwards & down, as well as

tilt the pedal face backward and forwards until you’re

comfortable with the position.

Once you’re satisfied with the position, tighten up the bolts

firmly to ensure that the pad does not move under load.

Brake Tensioner Ring

ADJUSTMENTS

The brake assembly can be adjusted for brake

stroke / tension. With four settings. Soft, Medium

Soft, Hard & Medium Hard. Each setting changes

the amount of braking force & travel of the pedal.

You will be supplied with 4 Urethane dampers. Our

default damper is the soft (RED) which is fitted as

standard and the medium soft (Short red) and the

two Black hard dampers are supplied in a box with

your pedals. The softest damper is the Red colour

Damper as it gives more squash, the medium soft

is the short Red damper and the hardest is the

Black colour capped Dampers. The softest damper

set provides the most travel and softest feel,

whereas the hard damper setting provides a short

travel with a very firm pedal. You can also adjust

the feel with the thumb wheel by screwing it in and

out. To fit the alternative damper, unscrew the

thumb wheel and replace the damper. Replace the

thumbwheel and screw down to the required feel..

Thumbwheel

Loosen Tighten

Brake Pedal Feel

The pedals come with four urethane dampers which have different durometers and heights that act on the Load

Cell Cylinder Rocker Arm. The Red is the “soft” damper and the Black is the “Hard” damper. The thumbwheel

enables the pedal feel to be infinitely adjustable. As standard, the soft grade damper (RED) is fitted. The short red

damper will give you a more solid feel, the short and long black dampers will give you a much harder pedal end

feel. To change the dampers, if needed, is a very simple process as outlined below..

Rocker Arm

Damper

Various dampers

as supplied with

your pedals

The brake cylinder is fitted with a

dedicated spring tensioner for adjusting

the initial preload to the brake pedal to

mimic the initial pad travel to the rotor.

This is useful for fine tuning that initial

pedal travel. If required, to adjust, hold

the brake cylinder and spin the

tensioner ring at the base of the brake

spring. Once the tensioner ring starts to

feel tight to turn, you have reached the

maximum tension point. Do not try and

force the tensioner ring further .

Adjustable

Tensioner Ring

Pedal Rebound Adjust

After any adjustment, you may need to alter the pedal rebound to get the

pedal sitting nicely again. To do this, use an 8mm spanner to loosen the

locking nut (pointed out by the red arrow) then use a 3mm allen key to

adjust up or down the stop until the pedal is in your desired position. Once

you’re happy with the position, tighten the locking nut firmly.

Pedal Rebound Adjustment

If required, your pedals are fitted with an adjustable set point that can be changed using a

3mm allen key and an 8mm spanner.

ADJUSTMENTS

Pedal Set Points are adjusted via the screw stops at the base of the pedals

Accelerator Pedal Stroke Adjust

The accelerator pedal stroke can be adjusted for a

shorter stroke by rotating the alloy adjuster at the top

of the cylinder. Undo the thumbscrew on the adjuster,

rotate the adjuster to your desired position.

Once satisfied re-tighten the thumbscrew.

Once you’re totally satisfied with it’s stroke length don’t

forget to recalibrate the accelerator axis.

Please Note:

After any of these adjustments, you will need to go through the calibration process again.

Problem: ‘In the game, my car doesn’t brake / accelerate effectively’

Solution: Recalibrate the pedal set in the windows game devices and re assign them in game.

Problem: ‘My pedal set is not detected by windows’

Solution: Try an alternative USB port on the computer, Listen for the audible ‘connect/disconnect’ noise

from windows. Alternatively try a different USB cable.

If you have any problems installing/calibrating or setting up your Pro GT pedal set, contact SimworX

support on the below email or give us a call and are more than happy to assist.

We appreciate your feedback, any feedback relayed via Facebook or email is greatly appreciated.

SimworX Simulators

2/29 Hightech Place, Lilydale

Victoria, Australia 3140

PH: +61 3 9739 5111

Sales: sales@simworx.com.au

Web: www.simworx.com.au

TROUBLESHOOTING

This manual suits for next models

1

Table of contents

Other SimworX Video Gaming Accessories manuals