9 10

Assemble And Disassemble Assemble And Disassemble Operating Instructions Operating Instructions

3.Push upward the front shroud and then forward, then remove it;

4.Sew on the screw st5x8 and fix it;

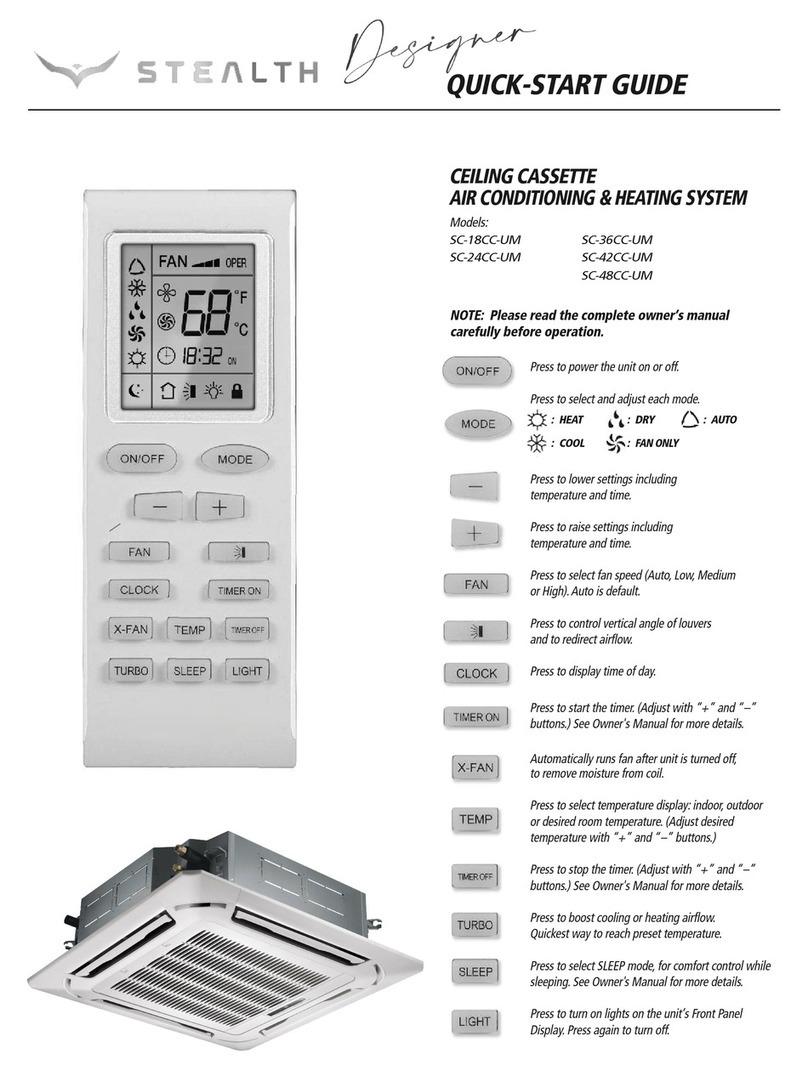

●OPERATION BUTTION SPECIFICATION: (the buzzer will make a “D”sound when pressing

The button and the operation is effective.)

1.When the electricity is on ,the machine Will make two “D D”Short Sound, press the button ,

the machine is on; press again , the machine is Off; turn on the machine after the machine

halts, 3 minutes automatic protection will be on.

2.For setting the operation mode, in accordance with the following order:

4.TEMP/UP AND TEMP/DOW N:to set temperature and timing

(1)Set the temperature, once pressing the button TEMP/UP TEMP/DOWN, the

temperature climbs or falls 1℃; when the indoor temperature is displayed on LED,

when first pressing the button, it will switch to the display of setting temperature, after

that, every time when pressing the button, the temperature climbs or falls 1℃;5 seconds

after the operation, LED will re-display the indoor temperature;

(2)When in the time setting position, every time when pressing TIME/UP TIME/DOWN,

the time gains or looses 1 hour, the time being 0-12 hour circulating setting,5 seconds

after the time setting, it will fall into timer position; if the current setting is 0 hour,5seconds

after the time setting ,it will quit the timing position.

5. TIMER:

(1)To set the machine on, pressing the button can set timing shutdown, pressing the

TEMP/UP TEMP/DOWN can set timing shutdown;re-pressing the button when the timing

is not determined will cancel timing shutdown; during timing shutdown, the customer can

shutdown the machine manually to cancel the timing shutdown;

(2 To set the machine off, pressing the button can set the timing start, pressing the)

TEMP/UP TEMP/DOWN can set the on time; press the button again when the timing is not

determined can cancel the timing shutdown, the customer can shutdown the machine

manually to cancel the timing shutdown;

6.SWING:

Press the button will switch between automatic swing and swing halt, the swing angle being

120°;The swing wind is simultaneous with the internal wind machine switch.

7.SLEEP:

(Sleep can only work when the cooling and heating mode is on, sleep will automatically cancels

when restart) when the sleep is on, the internal wind machine will automatically switch to low wind.

A.When the cooling is on: after 1hour,the set temperature climbs 1℃;2 hour later, it climbs

another 1℃;6 hours later, off;

b.When the heating is on; after 1hour,the set temperature falls 1℃;2 hour later, it falls another

1℃;6 hours later, off;

5. Assemb le the disassemb led parts following the compleme ntary procedures.

Disassemb le

1.If the machine is fixed on the wall, disassemble the air-inlet frame and front cover, then

wrench the screw;

2.Remo ve the ma chine;

3.Loose the screw, and remo ve the fixed connecting rod cover and drainpipe internal joint

4.Loose the drainpipe connecting rod and rotate 90°,remove alon the rail alongside the drainpipe;

5.Remo ve the drainpipe from the drainpipe;

6.Remo ve the drainpipe.

AIr-inlet

Scre

low speed wind

edium speed wind

igh speed wind

auto

cooling

ehumidification entilation eating

3.3.

d v h

h

m