l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Sequential order of adjustment procedures ...............................................

Vertical shaft end play .........................................................................

Bevel gear mesh and arm shaft end play ..................................................

Disc and disc follower clearance ........................................................

Cam stack radial play .....................................................................

Take-up lever and needle bar connecting link lost motion .............................

Needle bar bearings ...........................................................................

Needle bar height ..............................................................................

Needle bar pendulum timing ...............................................................

Zig-zag centralizing procedure ..............................................................

Needle location in the needle plate slot ..................................................

Needle to hook relationship ..................................................................

Maximum width zig-zag lever stop.........................................................

Needle bar safety bight stop (left side) ..................................................

Presser bar height and alignment ...........................................................

Hook drive belt tension .....................................................................

Hook timing (hook and needle synchronism) ............................................

Bobbin case position finger .................................................................

Bobbin case position plate .................................................................

Bobbin case clearance .......................................................................

Needle Thread tension .......................................................................

Bobbin winder .................................................................................

Feed rock shaft end play ....................................................................

Feed dog centralization .....................................................................

Feed dog height ..............................................................................

Feed dog throw ...............................................................................

Stitch length regulator spring tension...................................................

Motor belt tension ...........................................................................

Zero feed ....................................................................................

Lubrication....................................................................................

Flexi stitch zeroing..........................................................................

Buttonhole cutting space..................................................................

51

52-53

54-55

56-57

56-57

58-59

60-61

62-63

64-65

66-67

68-69

70-71

72-73

74-75

76-77

78-79

80-81

82-83

82-83

84-85

86-87

88-89

90-91

92-93

92-93

94-95

96-97

98-99

100-103

104-108

109-110

111-112

PAGE

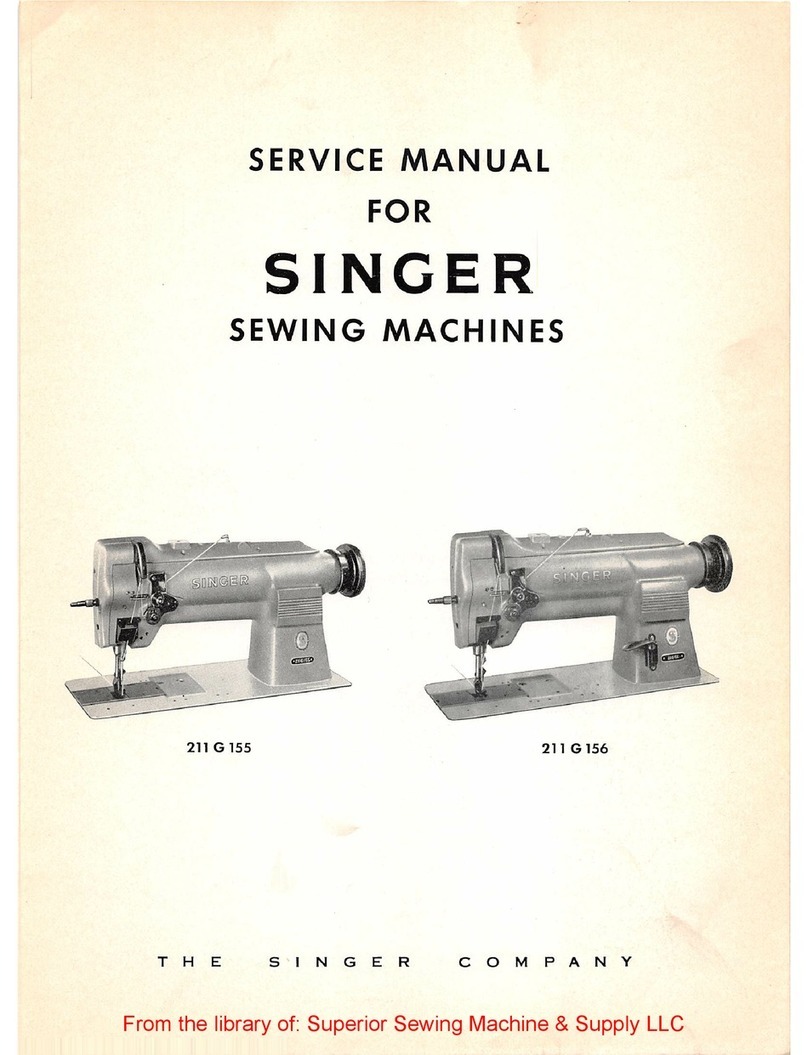

Service Manual

Table of Contents

Section 2

05

Rev. n .

o

358487-001 Mar./2005