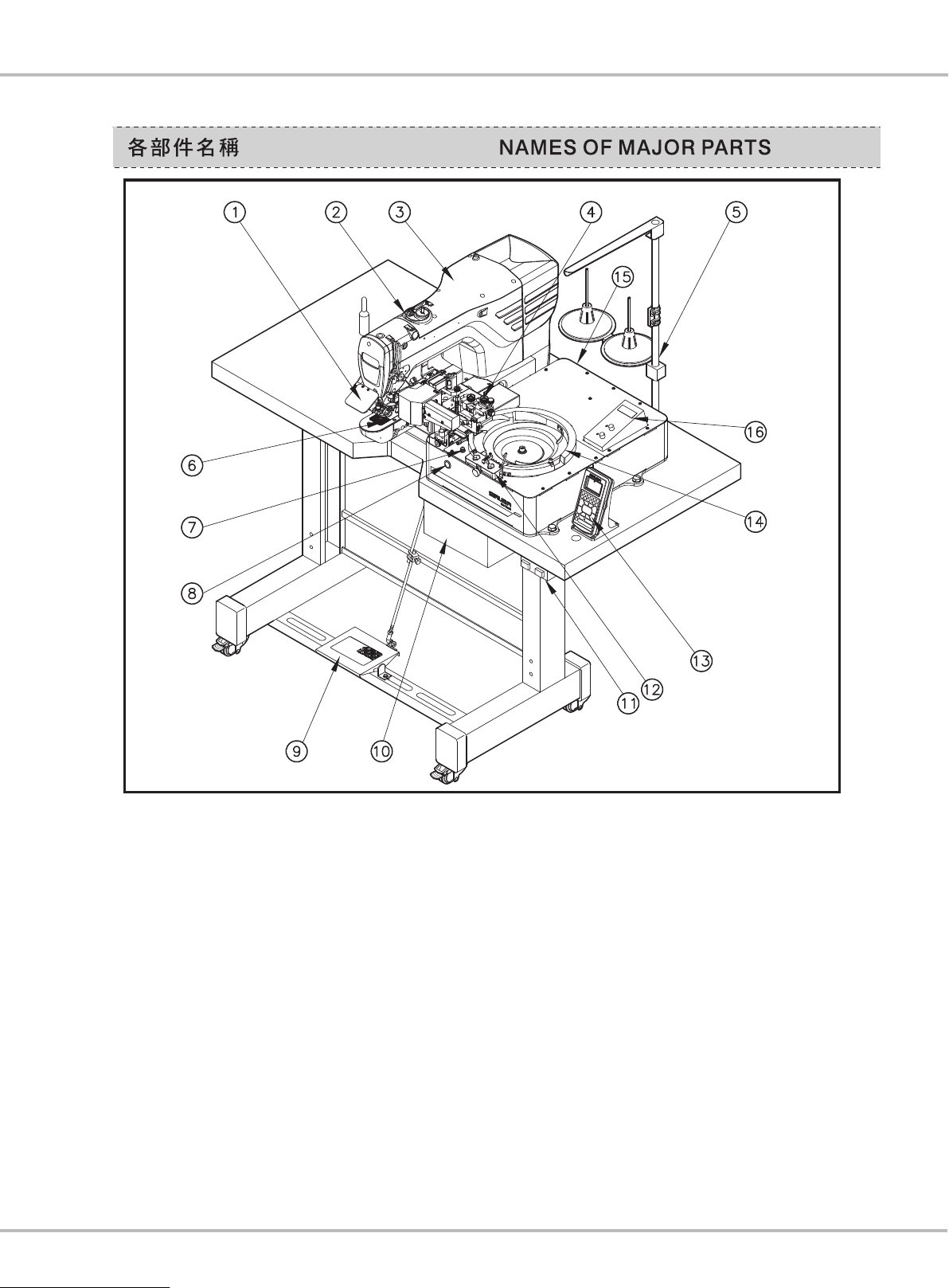

Siruba Sew Reach ABF Series User manual

Other Siruba Sewing Machine manuals

Siruba

Siruba 700K UT-3 User manual

Siruba

Siruba 700L-BKF1 User manual

Siruba

Siruba DL7200B User manual

Siruba

Siruba DL3880 Series User manual

Siruba

Siruba BH9820 User manual

Siruba

Siruba LBHS-1790S User manual

Siruba

Siruba BH780 Datasheet

Siruba

Siruba DL720 User manual

Siruba

Siruba DL7200D-NM1 User manual

Siruba

Siruba AA-6 User manual

Siruba

Siruba DL7200 User manual

Siruba

Siruba ASP-EBJ100 User manual

Siruba

Siruba AA-6 User manual

Siruba

Siruba C007KP User manual

Siruba

Siruba 700F User manual

Siruba

Siruba C007K User manual

Siruba

Siruba 700K User manual

Siruba

Siruba LKS-1900AN User manual

Siruba

Siruba L818F User manual

Siruba

Siruba 747L User manual