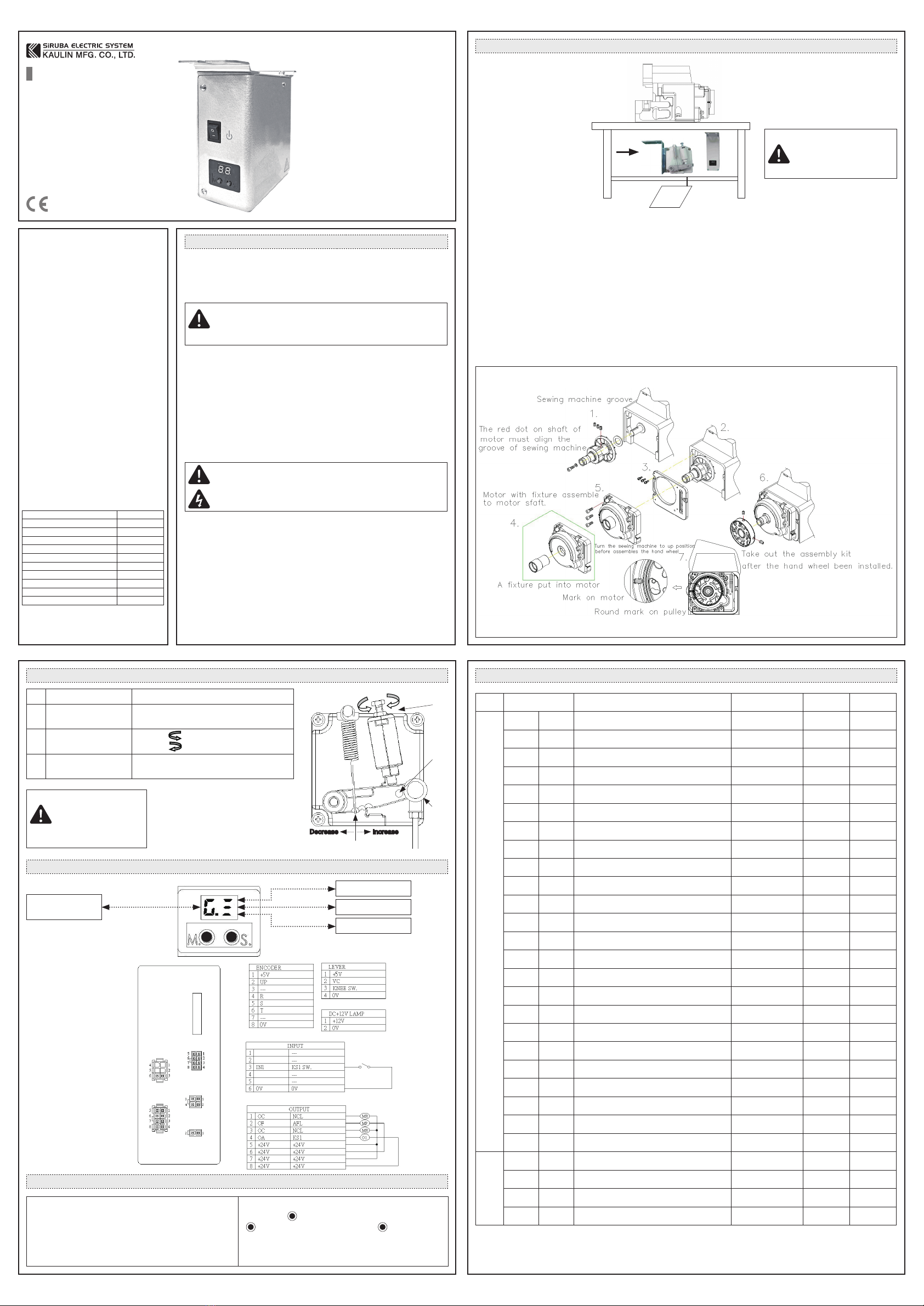

Decrease

A

B

C

D

Increase

Please read this manual with sewing machine manual thoroughly and pay attention for the following

safety precaution.

●Installation and operation must be done by the trained personnel, also turn off the power switch

and remove the plug from outlet and wait for 5 minutes before any installation.

●This product is designed for the specific sewing machines and must not be used for other purposes.

●

Only use the power voltage as described on the name plate of the motor and control box in

±

10 % ranges.

●In order to prevent abnormal operation, keep the product away from the high frequency machines.

●Don’t operate in direct sun light、outdoors area and the room temperature is 45°C above or 5°C

under.

●Don’t operate near the heater、dew area and the humidity is 30 % less or 95% more.

●Don’t operate in dusty、evaporate、combustible gas area, and stay away from corrosive material.

●

Don’t apply heavy objects or excessive force on the power cord, also don’t bend or pull the power cord.

●

In order to prevent the static interference and current leakage, all grounding works must be done properly.

●After power on the machine for the first time, use low speed to operate and check the correct

rotation direction.

●During machine operation, don’t touch any moving parts.

●All moving parts must have protective device to avoid the body contact and objects insertion.

●Maintenance and repair must be done by the properly trained technician, also all the spare parts

for repair must be approved or supplied by the manufacturer.

●Don’t use any objects or force to hit or ram the product.

Danger and caution signs

Warranty period of this product is 1 year from purchasing, or 18 months from our manufacturing date.

Warranty Detail

Any trouble found within warranty period under normal use condition in conformance with this

manual, it will be repaired free of charge. Repair will be chargeable in the following cases even if

within warranty period :

1. Inappropriate use include: wrong connecting high voltage, wrong application, disassemble, repair,

modification by incompetent personnel, or operate the product without the precaution, or operate

the products out of its specification range. Insert odd objects or liquids into the product.

2. Damage by fire, Earth quake, lighting, wind, flood, salt corrosive, moisture, abnormal power

voltage and any other damage cause by the natural disaster or by the inappropriate environments.

3. Dropping after purchase, or damage in transportation by customer himself. (or by customer’s

shipping agency)

* We put our best effort and mind in testing and manufacturing for assuring the quality and reliable

of this product. But it is possible this product can still be damaged due to external magnetic

interference and electronic static or noise or unstable power source more than expected; therefore

the grounding system of operate area must be well-connected to this product and it’s also

recommended to install a failsafe device. (such as residual current breaker)

EC Declaration of Conformity

We hereby declare that the following products:

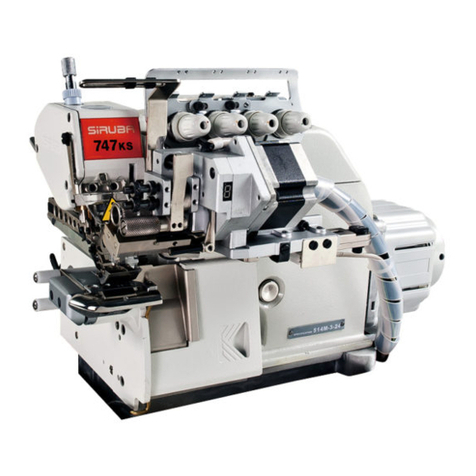

AC servo motor—747L series

are in conformity with the provision of the EC directives

as following :

-EC Low Voltage Directive (2014/35/EU)

-EC Electromagnetic Compatibility Directive (2014/30/

EU)

-EC Machinery Directive (2006/42/EC)

Applied harmonized standards :

EN 60204-31 : Electrical equipment of industrial

machines. Particular requirements for sewing

machines, sewing units and sewing system.

EN 12100 : Safety of machines.

Declaration of Conformity for Concentration Limits for

Certain Hazardous Substances

We hereby declare that the following products:

AC servo motor—747L series

are complies with the following directives and

requirements :

1. European Union RoHS Directive (2002/95/EC)

and the concentration limits for certain hazardous

substances (2005/618/EC)

2. People’s Republic of China Electronic Business

Standard : Requirements for concentration limits for

certain hazardous substances in electronic information

products (SJ/T 11363-2006)

Our product itself (motor, control box) or its packing

materials and accessories (box, screws package, user

manual, sticker, label, print…etc.) or the suppliers

of parts and raw materials are all in conformity with

the provision of the European Union RoHS Directive

and People’s Republic of China Electronic Business

Standard to conform the following concentration limits

for the ten hazardous substances :

Hazardous Substance Permissible Values

Lead (Pb) 1000

Mercury (Hg) 1000

Cadmium (Cd) 100

Hexavalent chromium (Cr VI) 1000

Polybrominated Biphenyl (PBB) 1000

Polybrominated Diphenyl ether (PBDE) 1000

Di(2-ethylhexyl)phthalate (DEHP) 1000

Butyl Benzyl Phthalate (BBP) 1000

Dibutyl phthalate (DBP) 1000

Diisobutyl phthalate (DIBP) 1000

*The concentration of lead in the lead-free process for

PCB shall be less than 800 ppm.

*For packing materials shipped with our products or parts,

the hazardous substances shall be 80 ppm or less in sum

of Pb+Hg+Cd+Cr VI.

SAFETY PRECAUTION

747L USER MANUAL

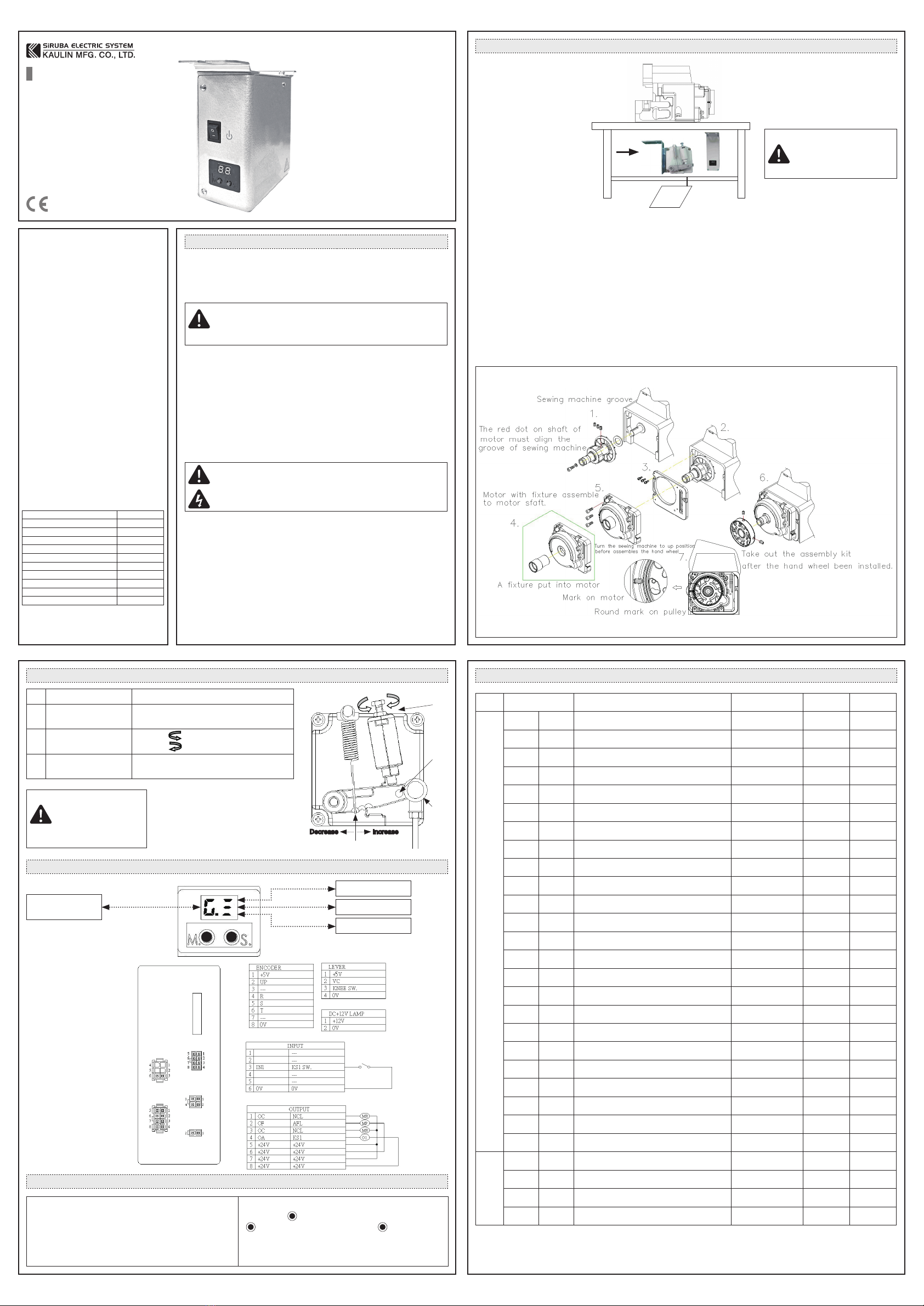

Term of adjustment Adjustment result

1Toeing forward

force adjustment

Spring A move to right = force increased

Spring A move to left = force decreased

2Heeling backward

force adjustment

Bolt B turn

= force decreased

Bolt B turn

= force increased

3Pedal stroke

adjustment

Rod D secure at right = stroke is longer

Rod D secure at left = stroke is shorter

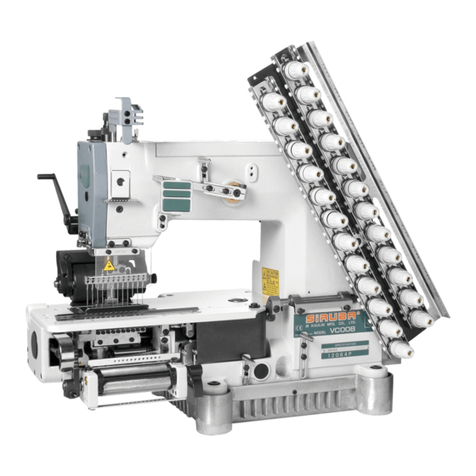

Components of speed control

unit : see figure

A: Spring for toeing forward force adjustment

B: Bolt for heeling backward force adjustment

C: Pedal arm

D: Pitman rod for pedal

NOTE: Selected machine code

Enter “PZ”PARAMETER , press S . KEY and hold it to adjust digit 0~9. Digitally accumulate until release S. key to stop accumulating.

If no key is pressed within 0.3 seconds, it will return to normal screen and auto to save.

(Note: Above 3 modes do

not display at same time )

Motor rotation

direction icon

Needle up

No position

Needle down

SPEED CONTROL UNIT ADJUSTMENT GENERAL PARAMETER LIST

PANEL KEY FUNCTIONS

ADJUST STEP AT PARAMETER ZONE

Attention : If the control box is AC 220V system, please don’t connect to the AC 380V

power outlet, otherwise the error will occur and motor is not functional. If that

happened, please turn off the power switch immediately and check the power

voltage. Continue supply the 380V power over 5 minutes might damage the fuses

and burst the electrolytic capacitors and even might endanger the person safety.

Caution :

For person safety, turn off the power

switch and remove the power plug

from outlet before any adjustment.

Risks that may cause personal injury or risk to the machine are marked with this symbol

in the instruction manual.

This symbol indicates electrical risks and warnings.

Motor Installation

1.Take off the pulley of sewing machine, remain the exhaust fan.

2. Put washer into the shaft of sewing machine then put it in the shaft of motor, to use screw to screw tight the shaft of the motor. Note: the red mark

on motor to fix on the shaft of sewing machine by set screw.

3. Fix motor on sewing machine.

4. Put a fixture to motor then set into motor shaft, push motor to sewing machine end face by a fixture.

Note: Motor shaft sticking strong magnet, pleases pay attention to powerful magnetic while force motor to sewing machine to avoid damage the

motor or hurt your finger. Pleases throw away the assemble tooling after assembled one machine. It is prohibit to use assemble tooling repeat.

5. Put motor pulley to motor shaft then tighten the screw.

Note: pleases turn the sewing machine to up position before tighten the pulley and fix the set screw on the pulley.

After that the needle at up position while motor is stop running. Pleases release the pulley to process micro adjustment on pulley if the needle stop

position is not satisfied.

Mounts speed control unit and control

box under the sewing machine table.

INSTALLATION

Caution :

For person safety, turn off the

power switch and remove the

power plug from outlet before

any adjustment.

CONNECTOR DIAGRAM

INPUT

ENCODER

MOTOR

LEVER

DC+12V

OUTPUT

How to go in the parameter content area adjustment content

Step1: Press “M.”key to enter setting mode.

Step2: Press “M.”key select the parameter you want to adjust.

Step3: Press “S.”key enter the parameter value adjustment.

Step4: Press “M.”key increase the value.

Step5: Press “SET”key to save.

How to set needle position while fixed the synchronizer:

Press the “S. ”key. Enter the setting mode , press “M.

”key To select UP / DOWN , press “S.”key to save.

Button Parameter NO. Function Name Range Ratio D0

Press

M

Key

P0 H Maximum sewing speed P1(L)-7500 spm *100 50

P1 L Low speed 200-500 spm *10 20

P2 SP Sewing speed Zero speed-Hi speed *100 0

P3 SIN Single positioning signal synchronizer 0/2 *1 0

P4 NU Define the UP positioning signal mode H/L L/H --- L

P6 POL Slow start setting for fist stitch

sewing when the power ON ON/OF --- OF

P7 SLM Slow start operation mode T/A/OF --- OF

P8 S Slow start speed 300-2000 spm *100 4

P9 SLS Stitch numbers for slow start 1-99 stitches *1 2

PA DIR Direction of motor rotation CC/CW --- CC

PB SVC Pedal start stroke positionadjustment 0-9 *1 0

PC TVC Pedal trimming stroke position adjustment 0-9 *1 0

PD HHC Cancel foot lifting at half-heeling pedal ON/OF --- OF

PE FHC Cancel trimming at full-heeling pedal ON/OF --- OF

PZ MAC Machine code D0-D1 --- D0

FL FLOAD Factory default load Y/N --- N

FS FSAVE Factory default save Y/N --- N

C1 FST Front suction stitches setting 0-99 stitches *1 0

WS WSUCM Air saving function selection ON/OF --- ON

W1 WSUC1 Setting valid stitches of suction for air saving 0-99 stitches *1 5

W2 WSUC2 Setting invalid stitches of suction for air saving 0-990 stitches *10 10

CD AFL After real section auto foot lifting mode selection 0 / 2 / 3 *1 0

CF NIKT Tape cutter link air saving off delay time 0-990 ms *10 25

CK TK3 Tape cutter action time 10-990 ms *10 10

Power

On

+

S Key

I1 IN1 IN1 Input function select NO/TK/OP --- TK

IF INF INF Input function select NO/F/TK --- F

OA OA OA Output function select NO/TK/AS/OP/OM --- TK

OC OC OC Output function select NO/NC/NW/AS --- NC

Decrease Increase

Pedal

GLOBAL SERVICE NETWORK

SERVICE HOTLINE : +886-2-2676-5203

FAX : +886-2-2689-6600, 2689-3657

WEBSITE: http: // www.hohsing.com

CHINA REGION

SERVICE HOTLINE : +86-21-64901024

FAX : +86-21-54570064

WEBSITE : http: // www.hohsing.com