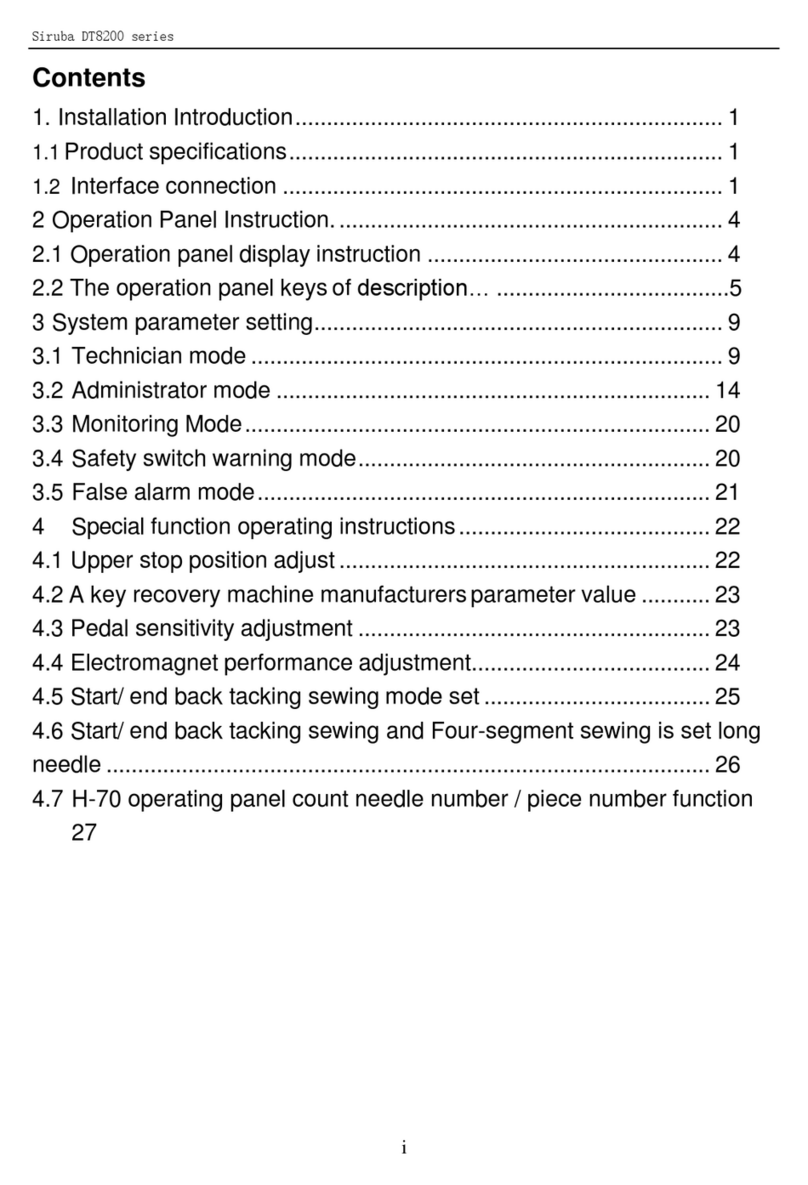

CONTENT

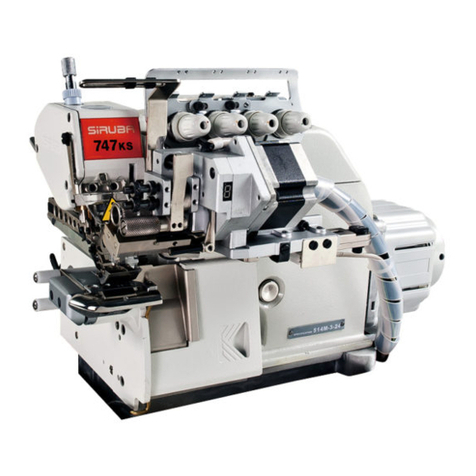

Principal parts of the machine .............................................................................................................................3

Accessories ......................................................................................................................................................... 4

Power, switch ...................................................................................................................................................... 5

Removing extension table ................................................................................................................................... 5

Accessory box ..................................................................................................................................................... 5

Levelling the machine.......................................................................................................................................... 6

Replacing needle................................................................................................................................................. 6

How to remove and attach the shank.................................................................................................................. 7

Replacing presser foot ........................................................................................................................................ 7

Winding the bobbin........................................................................................................................................... 8-9

Inserting and remove the bobbin...................................................................................................................10-11

Threading upper thread...................................................................................................................................... 12

Automatic needle threader ................................................................................................................................. 13

Drawing up bobbin thread .................................................................................................................................. 14

Adjusting thread tension..................................................................................................................................... 15

Bobbin thread adjustment .................................................................................................................................. 16

Adjusting tension for zigzag and embroidery ..................................................................................................... 16

Fabric -Thread - Needle - Table ......................................................................................................................... 17

Sewing (pattern selector) and operation table .............................................................................................. 18-20

Operation buttons............................................................................................................................................... 21

Reverse button ................................................................................................................................................... 22

Pattern operation instruction .............................................................................................................................. 22

Twin needle operation instruction....................................................................................................................... 22

Zigzag non-section operation instruction ........................................................................................................... 23

Stitch length non-section operation instruction .................................................................................................. 24

Display the zigzag width operation instruction ................................................................................................... 25

Display the stitch length operation instruction.................................................................................................... 25

Start to sewing.................................................................................................................................................... 26

Error correction................................................................................................................................................... 26

Straight stitches .................................................................................................................................................. 27

Zig-zag stitch ...................................................................................................................................................... 27

Free arm sewing................................................................................................................................................. 27

Seam finishing.................................................................................................................................................... 27

Transfer sewing direction ................................................................................................................................... 28

Stitch balance dial .............................................................................................................................................. 28

Overcasting sewing ............................................................................................................................................ 29

Straight stretch stitch .......................................................................................................................................... 29

Three step zig-zag stitch .................................................................................................................................... 29

Blind stitch ...........................................................................................................................................................30

Buttonhole sewing ...............................................................................................................................................31

Zipper sewing ......................................................................................................................................................32

Hemming .............................................................................................................................................................33

Quilter guide ........................................................................................................................................................33

Button sewing......................................................................................................................................................33

Cleaning and oiling..............................................................................................................................................34

Oil inside of the face cover..................................................................................................................................35

Removing and replacing the bulb........................................................................................................................35

Fault finding chart...........................................................................................................................................36-37