SIS M200 User manual

SIS MACHINES

TECHNICAL OPERATING MANUAL_v7.5_M200

This operating manual is downloadable from http://www.siselectromed.com/

CAUTION: Due to periodic revisions, always check that you are reading the

most up to date version of this manual.

Please read t is manual carefully before using t e SIS equipment.

Page 1. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

CONTENTS

DELIVERY AND UNPACKING _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _3

WARNING FOR BIOLOGICAL APPLICATIONS _ _ _ _ _ _ _ _ _ 3

DEVICE DESCRIPTION _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 3

OPERATIONAL MODE_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _4

POWER SOURCE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

Inserting AAA Batteries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

ELECTRODE HARNESS CONNECTION _ _ _ _ _ _ _ _ _ _ _ _ 4-5

KEYPAD CONTROLS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 5-6

APPLICATION INSTRUCTIONS

Internal Organ and Tissue Infections_ _ _ _ _ _ _ _ _ _ _6-8

Constant Ultra-Low Output Current _ _ _ _ _ _ _ _ _ _ _ _ 9

Water Treatment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

AUDIO AND VISUAL ALERTS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11-14

Electrode Contact Monitoring Setting_ _ _ _ _ _ _ _ _ _ _15

Electrode Harness C eck _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

CONTRAINDICATIONS AND SAFETY_ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

MEDICAL DISCLAIMER _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

MAINTENANCE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

WARRANTY _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

Returns, Disposal _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _21

DEVICE SPECIFICATIONS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _22

MANUFACTURER'S DECLARATION _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

Page 2. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

DELIVERY AND UNPACKING

Please unpack the shipping package carefully and inspect contents

immediately on receipt. You must check that all ordered equipment is

included in the shipping box and notify SIS anufacturing Ltd New Zealand

immediately of any missing items from your order.

Visible damage or tampering to shipping boxes must be recorded before

signing the delivery receipt. Please take photographs of any received

damaged items. Report the damage or tampering immediately to the shipping

carrier. You must notify SIS anufacturing Ltd immediately of any received

damaged or tampered items or of any lost shipments.

WARNING FOR BIOLOGICAL APPLICATIONS

THE SIS ACHINE 200 IS ELECTRONICALLY CALIBRATED WITH

EXTRE E PRECISION IN THE ' ICRO' ( ICRO-CURRENT— ICROBIAL

SETTINGS) OPERATIONAL ODE FOR THERAPEUTIC BIOLOGICAL

ELECTRO-STI ULATION ONLY IN CO BINATION WITH THE SIS

SILVER-NYLON CLOTH ELECTRODES. ONLY USE SIS ELECTRODES IN

THESE APPLICATIONS: USE OF OTHER ELECTRODES CAN CAUSE

ADVERSE AND UNPREDICTABLE BIOLOGICAL EFFECTS. IF ' ICRO'

OPERATIONAL ODE IS USED FOR ANY OTHER THERAPEUTIC

BIOLOGICAL ELECTRO-STI ULATION, ONLY USE SIS ELECTRODES

OR OTHER ELECTRODES APPROVED FOR BIOLOGICAL CONTACT AND

EDICAL/THERAPEUTIC APPLICATIONS. READ THE

CONTRAINDICATIONS AND SAFETY INSTRUCTIONS IN THIS ANUAL.

DEVICE DESCRIPTION

The SIS machine 200 model is designed for electromedical direct current

(DC) silver iontophoresis, and nano- to micro-current electro-stimulation. The

device is also designed for stand-alone, nano- to micro-ampere DC

generation for any non-medical non-therapeutic non-diagnostic application

including research/laboratory and experimental purposes, Life Sciences,

microiontophoresis and water treatment.

Page 3. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

OPERATIONAL MODE

' ICRO' ( ICRO-CURRENT) operational mode with a nanoampere

adjustment and resolution constant Output Current capability, is used for any

in vivo or in vitro constant nano- to micro-current application. The Output

Currents generated in the 'BACT' and 'VIRUS' operational modes of the 100

model can also be user-programmed.

1. POWER SOURCE

The 200 is powered by replaceable AAA type batteries (not included with

delivery of device for air shipping regulations reasons). Rechargeable

batteries can be used and do not compromise its correct function.

Do not use zinc-carbon batteries, which can leak and damage the device.

1.1. INSERTING AAA BATTERIES

a. POWER OFF the device if it is operating.

b. Remove the shockproof silicon cover from the casing.

c. Remove the battery compartment cover.

d. Insert 3×AAA batteries. Ensure correct polarity of the batteries—follow

the battery diagram and polarity symbols inside the battery

compartment.

e. Replace the battery compartment cover.

f. Replace the shockproof silicon cover over the casing.

2. ELECTRODE HARNESS (CABLE) CONNECTION

2.1. CONNECTION OF ELECTRODE HARNESS TO SIS MACHINE

For a 3 pin type connector, bring the harness connector in contact with the connection

socket, but do not attempt to insert. With minimum force, rotate the harness connector

slowly to align its 3 pin receivers with the 3 pins inside the connection socket; the harness

connector will engage and insert easily into the connection socket when correctly aligned.

Screw tighten the harness connector to lock to the SIS machine connection socket.

AUGUST 2016 ONWARDS: For a 3.5mm type connector, insert the harness

connector plug directly into the SIS machine connection socket.

2.2. ELECTRODE HARNESS POLARITY

It is usually easier to position and secure the SIS electrodes to the body or to

Page 4. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

the in vivo circuit interface first, and then connect the SIS electrode harness

to the two SIS electrode wires. Two SIS electrodes are always needed for

biological targets. SIS electrodes are physically interchangeable:

•The SIS electrode that is connected to the red wire of the electrode

harness is the SIS Positive Electrode.

•The SIS electrode that is connected to the black wire of the electrode

harness is the SIS Return Electrode.

! NOTE: The silver-nylon side of an SIS electrode is the active surface that

contacts the body.

2.3. CONNECTION OF ELECTRODE HARNESS TO SIS ELECTRODES

Insert the two gold metal 'banana plugs' at the ends of the SIS electrode

harness into the two white plastic connectors at the ends of the SIS electrode

wires; insert the 'banana plugs' all the way in until they are no longer visible.

NOTE: Do not tape the connections of the harness to the electrode wires.

3. KEYPAD CONTROLS

Hold down the POWER ON OFF button continuously for 2 seconds and then

release the button to power on the device. Hold down the POWER ON OFF

button continuously for 5 seconds and then release the button to power off.

The SOUND|DISPLAY button turns on and off the audio alerts and the

organic light emitting diode (OLED) screen display. The default setting of the

device when powered on is OLED display and sound turned on. If no keypad

input is detected during normal operation, the OLED display turns off after 2

minutes for power saving. Press and release the SOUND|DISPLAY button to

turn the OLED display on or off. Hold down the SOUND|DISPLAY button

continuously for 3 seconds to turn the audio alerts on or off.

The BATTERY CHARGE LED and 'BATTERY CHARGE' audio-visual alerts

are not under user control. The BATTERY CHARGE LED remains flashing at

all times when the device is operating.

3.1. OPERATIONAL MODE PROGRAMMING

MICRO operational mode is the default setting of the 200 model after

powering on.

Page 5. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

3.2. OUTPUT SETTINGS

The and PROGRAM buttons adjust and program the Output Current.

Press and release the buttons repeatedly to increase or decrease the

constant Output Current. Hold down the buttons continuously to fast

scroll through the constant Output Current parameter. Press and release the

PROGRAM button to program the selected constant Output Current.

4. APPLICATION INSTRUCTIONS

4.1. Internal Organ and Tissue Infections

Diagrams of SIS electrode applications for some common infections are

available from http://www.siselectromed.com/ applications/

! NOTE: The SIS machine 200 can be targeted at almost any infected

tissue. However, the device cannot determine the type of microbe(s) present;

standard diagnostics and differentiating information based on anatomical

location, clinical signs, presentation and laboratory testing must be applied.

4.2. OPERATIONAL MODE SETTING

Follow 5.1. OPERATIONAL ODE SETTING instructions to program a

bacterial or viral infection treatment.

4.3. SELECTING SIS ELECTRODE SIZE

The SIS Positive Electrode must completely 'cover' the target internal organ

or tissue. The electrode must be at least the same size or slightly larger than

the target internal organ or tissue as it would be seen 2-dimensionally in an

X-ray taken from the position and anatomical plane of the electrode on the

body surface. Do not use an over-sized SIS Positive Electrode, as the SIS

machine can more accurately monitor the electrode's contact with the body

the smaller its size.

The SIS Return Electrode must be approximately the same size or larger

than the SIS Positive Electrode.

DO cut the SIS electrodes to size and shape as necessary.

DO NOT cut the SIS electrode wire inside the SIS electrodes.

Page 6. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

4.4. SECURING SIS ELECTRODES TO BODY

Use adhesive surgical or wound dressing tape (e.g. Fixomull®) and/or Velcro®

or other stretch strap, bandages or other emergency means to affix or hold

the SIS electrodes to the body. When positioning an SIS electrode onto

normal intact skin, extend the dressing tape beyond all edges of the

electrode.

4.4.1. Follow 2.2. ELECTRODE HARNESS POLARITY instructions.

4.5. POSITIONING SIS ELECTRODES ON THE BODY

a. Position the SIS Positive Electrode onto the skin directly over the

target infected organ or tissue. Secure electrode to body.

b. Position the SIS Return Electrode onto the opposite anatomical

surface of the body to the SIS Positive Electrode so that the target

infected organ or tissue is aligned as much as possible bet ween the two

SIS electrodes.* Secure electrode to body.

*This electrode positioning configuration focuses silver ion flow into the target organ or tissue

between the two SIS electrodes. 'Wasted' current flow through the skin between the

electrodes is thereby prevented or minimized.

Page 7. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

4.6. ELECTRODE SKIN CONTACT

The contact of the entire surface of an SIS electrode positioned onto normal

intact (i.e. non-damaged) skin should be as uniform as possible to surface

anatomy geometry.

The lower end of dry, intact skin electrical resistance (R), measured in units of

'Ohms' (Ω), is approximately 50kiloohms (kΩ). Relatively large variation from

this lower limit depending on many factors, up to approximately 1megaohm

( Ω), is normal, and the SIS machine continuously self-adapts to the R value

encountered. Wet skin has a lower R value range. Real-time updating R = is

shown on the OLED display. The closer to the lower end value R = 50kΩ, the

better the electrode-skin contact and the SIS machine can operate with lower

voltage more efficiently:

•Shave the skin if necessary to establish or improve electrode contact.

•Wet the silver-nylon surfaces of the SIS electrodes with distilled, tap or

other clean water if available to reduce the electrical resistance R = of

the electrode-skin contact area (interface).

•Che ck 4.4. SECURING SIS ELECTRODES TO BODY instructions .

Repl ace or apply additional dressing tape if necessary.

•Check electrode is not discolored (12-72 hours lifetime); replace if

necessary.

onitor 10. AUDIO AND VISUAL ALERTS.

•

Page 8. SIS ANUFACTURING LTD, NZ. AY 2017.

! INFORMATION: RECOMMENDED ELECTRODE LIFETIME FOR SEVERE INFECTION:

SIS POSITIVE (RED WIRED) ELECTRODE: 24-48 HOURS

SIS RETURN (BLACK WIRED) ELECTRODE: 48-72 HOURS

SIS MACHINE M200 MODEL OPERATING MANUAL

5. Constant Ultra-Low Output Current

5.1. OPERATIONAL MODE SETTING

For an in vitro anti-bacterial effect or in vivo bacterial infection treatment, use

the default Output Current setting I = 2.5uA (2.5microamperes). For an in

vitro anti-viral effect or in vivo viral infection treatment follow 3.2. OUTPUT

SETTINGS instructions to program I = 7.5uA (7.5microamperes).

5.2. ELECTRODE MONITORING SELECTION

onitoring ( NT) of the contact of the SIS or other electrode(s) with the body

for in vivo applications, or with the stimulation target or circuit interface for in

vitro applications can be user enabled or disabled.

To access ELECTRODE ONITORING press and release the PROGRAM

button twice. The display ain Window of the display will show:

ELCTRODE MNT

SELECT: ON

Press and release the buttons to select electrode contact NT ON or

OFF. Press and release the PROGRAM button to program the NT

selection; the device will then return to the programmed operational mode.

NOTE: If NT is disabled, measurement of Total Circuit Resistance is

inactivated; the display will not show an R = value.

5.3. Follow 2.2. ELECTRODE HARNESS POLARITY instructions. For in vivo

applications, follow 4.3. SELECTING SIS ELECTRODE SIZE and 4.4.

SECURING SIS ELECTRODES TO BODY instructions.

5.4. Use the alligator clip adapters supplied with the SIS machine to convert

the SIS electrode harness for connection to many other electrodes and

applications. Insert the gold 'banana plugs' at the ends of the black and red

wires of the electrode harness into the plastic connector ends of the adapters.

5.5. Follow 3.2. OUTPUT SETTINGS instructions to program the constant

Output Current. Positive conventional current polarity is always applied.

onitor 10. AUDIO AND VISUAL ALERTS if NT is enabled.

Page 9. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

6. Water Treatment

6.1. OPERATIONAL MODE SETTING

Follow 3.2. OUTPUT SETTINGS instructions to program I = 20uA

(20microamperes); then follow 5.2. ELECTRODE ONITORING

SELECTION to disable ELECTRODE ONITORING.

6.2. ELECTRODES

Connect two SIS electrodes, other pure silver or other pure metal electrodes

to the SIS electrode harness.

Follow 5.4. instructions to convert the SIS electrode harness for connection to

many other electrodes and applications, as required.

Immerse the electrodes into the water container near its opposite edges. The

two electrodes must not contact each other.

The interior surface of the water container should preferably not be metallic. If

a container with a metallic interior surface is used, then the electrodes must

be immersed without making contact with the interior surface.

The maximum recommended volume of water that can be treated using this

method is approximately 1-2litres.

The ionic/silver particle concentration in the water can be indirectly assessed

using a water electrical conductivity or total dissolved solids meter (not

supplied with the SIS machine).

If SIS electrodes are used, the rate of silver ion introduction into the water will

depend on the SIS electrode size; larger electrode size will give a faster rate

of silver ion production, and vice versa.

NOTE: To produce pure ionic silver solution (“colloidal silver”), distilled or

highly purified water must be used, preferably with a starting electric

conductance measurement of ≤1microsiemens.

Page 10. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

7. AUDIO AND VISUAL ALERTS

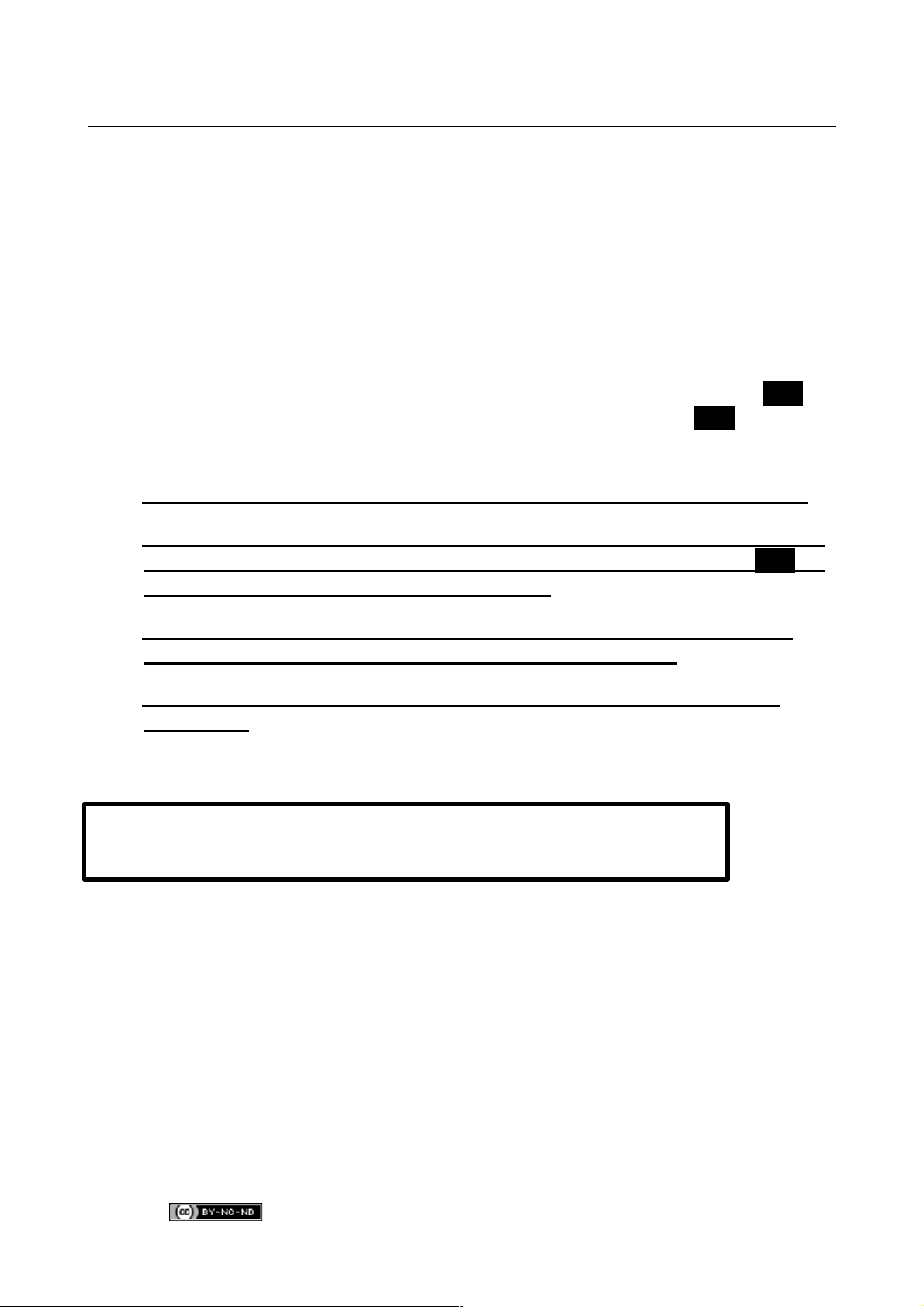

The user-programmed operational mode is displayed in the lower right ode

Window of the OLED display. Alerts [Table 2] are displayed in the lower left

Alert Window. The following real-time values are shown in the ain Window

of the display [Figure 2]:

1. Output Current I =

2. Output Voltage V =

3. Total Circuit Resistance R = averaged over the last 1-2seconds; circuit

Open Load (break) detection is shown as R = OL.

Audio activation or deactivation is indicated by the symbols in the upper

right of the ain Window.

Main Window

I = ___nA/μA

V = ___nV/mV/V

R = ___kΩ/MΩ

Alert Window Mode Window

Figure 2: LED display layout.

STDBY CALI

CONTACT OK

CONTCT LOW

CNTCT FLUC

CIRC BREAK

NO CALI

BATT LOW

MNT OFF

VOLT ALERT

STANDBY CALIBRATING to skin.

Electrode CONTACT OK.

Electrode CONTACT LOW statistically.

Electrode CONTACT FLUCTUATING.

Effective or physical CIRCUIT BREAK.

NO CALIBRATION possible.

BATTERY LOW charge.

CIRCUIT MONITORING OFF.

High Output VOLTAGE ALERT.

Table 2: Displayed M200 audio-visual alert abbreviations.

Page 11. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

M200 M100-IP model

CORRECTIVE ACTION

ALERT TYPE AUDIO VISUAL

OLED DISPLAY AUDIO VISUAL

LED

OPERATIONAL

MODE

INITIALIZATION

─ Operational mode

is programmed. 1 BEEP [MODE NAME]

Unhighlighted 1 BEEP ─ ─

─ Calibrating to body. 1 BEEP

5 SEC INT

STDBY CALI

FLASHING

5 SEC INT

1 BEEP

5 SEC INT

MODE LED

FLASHING

5 SEC INT

• Standby, wait for alert to stop.

─ Operation normal.

─[MODE NAME] ─

MODE LED

FLASHING

5 SEC INT

─

CIRCUIT

MONITORING

─ Electrode contact

OK: Wit in all

user-programmed

and factory limits.

─CONTACT OK ─

MODE LED

FLASHING

5 SEC INT

─

─ Fluctuating SIS

electrode contact

in s ort time-frame

(1-2seconds)

exceeds operating

limits.

2 BEEPS

5 SEC INT

CNTCT FLUC

FLASHING

5 SEC INT

2 BEEPS

5 SEC INT

MODE LED

2 FLASHES

5 SEC INT

All applications

• For SIS electrode(s) positioned onto

intact skin, check:

◦ 4.6. ELECTRODE SKIN

CONTACT.

• If alert continues, follow instructions:

◦ 7.2. ELECTRODE CONTACT

ONITORING SETTING

◦ 7.3. ELECTRODE HARNESS

CHECK

─ SIS electrode

contact

statistically lower

t an electrode

contact monitoring

(MNT) limits for

user-programmed

Output Current.

3 BEEPS

5 SEC INT

CONTCT LOW

FLASHING

5 SEC INT 3 BEEPS

5 SEC INT

MODE LED

3 FLASHES

5 SEC INT

─ Output Voltage

statistically ig er

t an 1.5volts

during previous 10

minute logged

monitoring period.

LONG BEEP

5 SEC INT

30 SEC

DURATI N

VOLT ALERT

FLASHING

5 SEC INT

30 SEC

DURATI N

LONG BEEP

5 SEC INT

30 SEC

DU ATION

─

All in vivo applications

• Check for skin irritation under contact

area of SIS Positive Electrode.

• To prevent or if skin irritation is

present, follow instructions:

◦ 4.6. ELECTRODE SKIN

CONTACT.

CIRCUIT

MONITORING

Page 12. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

M200 M100-IP model

CORRECTIVE ACTION

ALERT TYPE AUDIO VISUAL

OLED DISPLAY AUDIO VISUAL

LED

─ Circuit break

(consecutive Open

Loads). Effective

or p ysical circuit

break.

Programmed Open

Load trigger is

R>3.8megao ms.

10 BEEPS

5 SEC INT

CIRC BREAK

FLASHING

5 SEC INT

OL

Main Window

10 BEEPS

5 SEC INT

MODE LED

10 FLASHES

5 SEC INT

All applications

• Check for loose connections or breaks

(including alligator clip connectors if

non-SIS electrodes are used).

• Check:

◦ 2.1. CONNECTION OF

ELECTRODE HARNESS TO SIS

ACHINE.

◦ 2.3. CONNECTION OF

ELECTRODE HARNESS TO SIS

ELECTRODES.

◦ 4.4. SECURING SIS ELECTRODES

TO BODY.

• For SIS electrode(s) positioned onto

intact skin, check:

◦ 4.6. ELECTRODE SKIN CONTACT.

• If alert continues, follow instructions:

◦ 7.3. ELECTRODE HARNESS

CHECK.

─ Device powering

off. Continuously

insufficient

electrode contact

over last 4-8

minutes.

5 BEEPS

5 SEC INT

NO CALI

FLASHING

5 SEC INT

5 BEEPS

5 SEC INT

ALL MODE

LEDS

5 FLASHES

5 SEC INT

─

─ Circuit MoNiToring

(MNT) turned OFF

by user .

─MNT OFF

───

─ Maximum circuit

resistance (load)

exceeded for target

user-programmed

Output Current.

Device cannot

deliver target

Output Current.

─I = [value]uA

FLASHING

C NTINU US ─ ─

All in vivo applications

• Check for CONTCT LOW or

CIRC BREAK alerts.

Check 14. DEVICE SPECIFICATIONS:

Output Voltage in Current Stimulation

(modes).

─ Stabilizing to target

Output Current. ─

I = [value]uA

FLASHING

INTERMITTENT

─ ─

• No action required. Information only.

SOUND

CONTROL

─ Sound turned OFF. ─ 1 BEEP ──

─ Sound turned ON. 2 BEEPS 2 BEEPS ──

BATTERY

CHARGE

─ C arge OK.

─

BATTERY

CHARGE LED

FLASHING

5 SEC INT

─

BATTERY

CHARGE LED

FLASHING

5 SECS INT

─

Page 13. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

M200 M100-IP model

CORRECTIVE ACTION

ALERT TYPE AUDIO VISUAL

OLED DISPLAY AUDIO VISUAL

LED

─ C arge low for

correct operation.

1 BEEP

5 SEC INT

BATT LOW

FLASHING

5 SEC INT.

BATTERY

CHARGE LED

ON

C NTINU US

1 BEEP

5 SEC INT

BATTERY

CHARGE LED

ON

CONTINUOUS

• Replace batteries, follow instructions:

◦ 1.1. Inserting AAA Batteries.

Abbreviations: SEC (seconds), INT (interval between sets of beeps).

7.1. HOW TO MONITOR AND RESPOND TO AUDIO-VISUAL ALERTS

Page 14. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

7.2. Electrode Contact Monitoring Setting

The CIRCUIT ONITORING audio-visual alerts are based on real-time

updating statistical and algorithmic analysis of Total Circuit Resistance

measurements due to any changes of the contact of the SIS electrodes with

the body or with their in vitro interfaces. This complex monitoring system

ensures reliable delivery of the pre- and user-programmed target Output

Currents and Output Voltages with extended, continuous use.

If the contact of the SIS or other electrode(s) continues to trigger CIRCUIT

ONITORING alerts even after following the CORRECTIVE ACTION points

in the AUDIO AND VISUAL ALERTS table above, the user can vary a master

parameter of the electrode contact monitoring ( NT) algorithms.

Press and release the PROGRAM button to interrupt the current operational

mode. Then press and release the button repeatedly until MNT is shown in

the ode Window of the display. Press and release the PROGRAM button

again to select the NT adjustment mode. The ain Window of the display

will then show:

ADJ ELCTRODE MNT

4=MAX(FAC),1=MIN

SELECT: 4

The default factory (FAC) NT setting is the maximum sensitivity, 4; the

minimum sensitivity is 1. Each time the device is powered off and on, the

device defaults to the factory NT setting.

Press and release the buttons repeatedly to increase or decrease the

sensitivity of the monitoring (1-4). Press and release the PROGRAM button

again to program the selected NT setting; the last programmed operational

mode then automatically resumes at its point of interruption.

If no keypad input is detected during any 30 second period during this

selection procedure then the device powers off.

Page 15. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

7.3. Electrode Harness C eck

This procedure tests the integrity of the SIS electrode harness for non-visible

internal core breaks:

1. Power off the device.

2. Follow 2.1. CONNECTION OF ELECTRODE HARNESS TO SIS

ACHINE instructions. Do not connect electrodes to the harness.

3. Power on the device.

4. Hold the two gold 'banana plugs' at the ends of the black and red wires

of the electrode harness in contact with one another for a maximum of

55 seconds; make sure the contact between the 'banana plugs' is

continuous and do not touch the banana plugs with your fingers or any

other object.

If R = SC is shown in the ain Window of the display then the harness is OK.

If R = OL is shown in the ain Window of the display then the harness is

BROKEN. Replace the electrode harness.

Page 16. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

8. CONTRAINDICATIONS AND SAFETY

DO NOT POSITION ELECTRODES OVER THE BRAIN. CONSULT WITH A

SPECIALIST HEALTHCARE PROFESSIONAL BEFORE APPLICATION.

DO NOT POSITION ELECTRODES OVER THE HEART (CENTRAL AND LEFT SIDE

OF CHEST). CONSULT WITH A SPECIALIST HEALTHCARE PROFESSIONAL

BEFORE APPLICATION.

DO NOT POSITION ELECTRODES ON THE ABDO EN IF THE SUBJECT IS

PREGNANT OR IGHT BE PREGNANT.

DO NOT POSITION ELECTRODES NEAR A PACE AKER OR OTHER I PLANTED

ELECTRO-STI ULATOR. CONSULT WITH A SPECIALIST HEALTHCARE

PROFESSIONAL BEFORE APPLICATION.

DO NOT POSITION ELECTRODES ACROSS THE EYES. CONSULT WITH A

SPECIALIST HEALTHCARE PROFESSIONAL BEFORE APPLICATION.

DO NOT POSITION ELECTRODES ACROSS THE ANTERIOR NECK (CAROTID

SINUS). CONSULT WITH A SPECIALIST HEALTHCARE PROFESSIONAL BEFORE

APPLICATION.

DO NOT USE IF THERE IS A HISTORY OF SEIZURES. CONSULT WITH A

SPECIALIST HEALTHCARE PROFESSIONAL BEFORE APPLICATION.

DO NOT USE IF THERE IS A SUSPECTED OF KNOWN SERIOUS INFECTIOUS

DISEASE THAT REQUIRES HEAT OR FEVER TO BE SUPPRESSED. CONSULT

WITH A SPECIALIST HEALTHCARE PROFESSIONAL BEFORE APPLICATION.

DO NOT EXPOSE THE W cA P STI ULATOR TO WATER. DISCONNECT

ELECTRODES FRO HARNESS (CABLE) OR RE OVE FRO BODY WHEN

ENTERING WATER.

DISCONTINUE USE IF SKIN IRRITATION OCCURS.

FOR EXTERNAL USE ONLY.

KEEP AWAY FROM CHILDREN.

Page 17. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

9. MEDICAL DISCLAIMER

Information provided for education and research only. This manual contains

general information about medical conditions and treatments. The information

is not advice, and should not be treated as such. The information in this

manual is made available on the basis that no professional advice on a

particular matter is being provided, and should not be treated as such. No

liability is accepted for any injury, loss or damage incurred by use of or

reliance on the information provided in this manual. SIS anufacturing Ltd

New Zealand (NZ) makes no representations or warranties express or implied

in relation to the medical information in this manual. Without prejudice to the

generality of the foregoing statements, SIS anufacturing Ltd NZ does not

warrant that: The medical information contained within this manual will be

constantly available, or available at all; nor that the medical information in this

manual is complete, true, accurate, up-to-date, nor non-misleading. You must

not rely on the information in this manual as an alternative to medical advice

from your doctor or other professional healthcare provider. If you have any

specific questions about any medical matter you should consult your doctor or

other professional healthcare provider. If you think you may be suffering from

any medical condition you should seek medical attention. You should never

delay seeking medical advice, disregard medical advice, or discontinue

medical treatment because of information in this manual. Nothing in this

medical disclaimer will limit any of the liabilities of SIS anufacturing Ltd NZ

in any way that is not permitted under applicable law, or exclude any of its

liabilities that may not be excluded under applicable law.

Page 18. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

10. MAINTENANCE

10.1. DEVICE

The device is maintenance free. Only clean the external surfaces with a damp

cloth. Do not use any kind of detergent or solvent. Avoid strong impacts on

the device. aintain the protective shockproof silicon cover on at all times

during operation and storage. Avoid leaving the device exposed to direct

strong sunlight without ventilation or air-conditioning. Do not leave on or next

to heaters or other heat-emitting devices.

10.2. SIS ELECTRODES

To prolong the lifetime of an SIS electrode, when removing from the body

between non-wound applications, if adhesive surgical or wound dressing tape

(e.g. Fixomull®) has been used, do not tear off the tape from the electrode.

Cut the tape back to the SIS electrode size and shape, leaving the tape as a

layer permanently stuck to the non-stimulation white foam surface of the

electrode. On the next application of the same SIS electrode to the body,

apply new dressing tape on top of the previous layer. The layers of tape

remaining on the SIS electrode do not interfere with its electrical

characteristics for correct operation.

The silver-nylon stimulation surface of an SIS electrode that has been applied

only to normal intact skin can be cleaned by gently wiping with a clean damp

cloth or cotton wool (use tap/other clean water) to remove dead skin cells and

sweat.

10.3. STORAGE

Remove the batteries from the device during long-term storage to prevent

damage from battery leaks and to avoid very gradual draining of charge of the

batteries.

Store the device in a dry place away from heat-generating sources.

Page 19. SIS ANUFACTURING LTD, NZ. AY 2017.

SIS MACHINE M200 MODEL OPERATING MANUAL

11. WARRANTY

Each new SIS machine (“the Device”) carries a 3 year limited Warranty for defects

in materials, components, assembly and operation of its electronic hardware. This

Warranty is subject to all of the following exclusions and conditions. The Device

enclosure is not opened except the battery compartment nor tampered with in any

manner. No modifications or repairs are made to the Device other than by one of

our engineers. No voltage or current source is applied to the harness connection

socket or to anywhere else on the Device. No power supply other than specified in

the operating manual is applied to the Device. For biological applications, the

Device has not been used with non-SIS electrodes that are not approved for skin

contact, therapeutic and medical applications. The Device is not used beyond its

intended applications. You can experiment with the Device if you wish, but subject

to all other Warranty conditions and exclusions and not in such a way that could

reasonably be expected to damage the Device in any way as determined by our

engineers. The casing (‘enclosure’) of the 200IP casing model was IP67 rated

before minor manufacturing modification to receive the membrane keypad. The

membrane keypad design and its seal to the casing has an anticipated IP65

performance (completely dustproof and waterproof to a 30kpa water jet). The

200IP model is therefore warranted for use up to the IP65 performance standard.

The non-IP casing models ( 100/ 200/W200) must not be used in any manner

that requires an IP rating above IP40 to protect them from ingress of dust or other

sub-1mm particulate matter, or that requires protection from water or other liquids

that can damage or interfere with the internal electronics of the Device. The SIS

electrode harness (connecting cable) is included in this Warranty only for a period

of three months, and only if it is not used in any way that contradicts the

recommendations for use given in this operating manual. If a non-SIS electrode

harness is used with the Device this warranty shall be void. This Warranty is

expressly limited solely to the original purchaser of the SIS equipment and does not

extend to any transferee or temporary user of the Device. This Warranty does not

cover damage caused by improper connection of the components of the SIS

equipment (harness, connectors, sockets, electrodes), damage caused by accident,

abuse, misuse, neglect or improper maintenance, damage caused by unusual

physical or electrical stress, routine cleaning or normal cosmetic and mechanical

wear. Non-compliance to any degree with any one of these Warranty conditions

shall automatically void this warranty completely. SIS anufacturing Ltd New

Zealand expressly disclaims all warranties not stated in this limited Warranty.

Page 20. SIS ANUFACTURING LTD, NZ. AY 2017.

Table of contents

Other SIS Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual