Sistemes Electrònics Progrés s.a. AGRONIC 2500 User manual

INSTRUCTION MANUAL

BASIC MODEL

VERSION 2

INDEX

1. DESCRIPTION OF BASIC FUNCTIONS ..................2

2. USER’S GUIDE........................................................8

- Sections for the installer -

3. TECHNICAL FEATURES..........................................9

4. DIMENSIONS ........................................................10

5. INSTALLATION......................................................10

5.1. EQUIPMENT PLACEMENT .............................10

5.2. CONNECTION LOCATIONS ...........................11

5.3. CONNECTIONS..............................................11

5.3.1. Connecting the power supply ..................12

5.3.2. Connecting the ground connection..........12

5.3.3. Connecting the digital sensors.................12

5.3.4. Connecting the outputs ............................12

5.4. INSTALLING THE OPTIONS ...........................14

5.4.1. Diesel option.............................................14

5.4.2. Double Voltage Option .............................15

5.4.3. Latch option..............................................16

5.4.4. Two Analog Sensor Option ......................17

5.4.5. Battery Charger Option ............................17

6. PARAMETERS.......................................................18

6.1. FERTILIZATION PARAMETERS ......................18

6.2. FILTER PARAMETERS....................................19

6.3. GENERAL PARAMETERS ...............................19

6.4. PROGRAM PARAMETERS..............................21

6.5. SECTOR PARAMETERS.................................21

6.6. COMMUNICATION PARAMETERS.................22

6.7. VARIOUS PARAMETERS................................22

6.8. INSTALLER PARAMETERS.............................22

6.9. DIESEL OPTION PARAMETERS.....................23

- Sections for the user -

7. PROGRAMS ..........................................................24

7.1. SEQUENTIAL PROGRAMS.............................25

7.1.1. Alternating sequential programs ..............26

7.2. FERTILIZATION ..............................................27

8. MANUAL................................................................28

9. READINGS ............................................................30

9.1. READINGS TOTALS .......................................30

9.2. READINGS ANOMALIES ................................30

10. CONSULTATION.................................................32

10.1. CONSULTATION - GENERAL.......................32

10.2. CONSULTATION - PROGRAMS ...................33

10.3. CONSULTATION - SECTORS.......................34

10.4. CONSULTATION - FERTILIZERS..................35

10.5. CONSULTATION - FILTERS .........................35

10.6. CONSULTATION - COMMUNICATIONS.......35

10.7. CONSULTATION - AGRÓNIC .......................35

11. DIESEL OPTION ANNEX.....................................36

PRESENTATION

We wish to take this opportunity to thank you for the confidence in us which you have demonstrated in expressing interest

or acquiring the AGRÓNIC 2500.

This confidence, for our part, stimulates our efforts to meet and surpass the expectations of our clients to justify the tradi-

tional quality of our products.

This manual will explain the specification of the equipment as well as its installation and use.

However, if after reading this you still have any doubts, contact us and we will happily answer them.

2

1. DESCRIPTION OF BASIC FUNCTIONS

Complete fertigation controller, entirely config-

urable with great potential to use and with many

extension and communication possibilities.

Equipped to control irrigation, fertilization,

pumping, filter cleaning and malfunctions detec-

tion, providing detailed chronological records of

events and totals.

Models have 9, 18 and 27 configurable outputs

and 6 digital inputs on the base, having also sever-

al versions and options.

Extensions are available to accommodate

readings from 2 analog sensors on the own base

or by using the AgroBee radio system to have

more inputs and outputs, reaching up to 30 irriga-

tion sectors, 2 pumps, 4 fertilizers and mixers, 1

fertilizer general, 9 filters, 1 filter general, 20 digital

sensors, 10 meter sensors, and 40 analog

sensors.

Programming according to time and

volume for both irrigation and fertilization, as

well as filter cleaning, with the option to have

independent working actions for each pro-

gram.

Starting conditions and irrigation or ferti-

lizer units can be influenced using climate or

crop-based sensors.

Remote management via mobile appli-

cation “Agrónic App”, SMS messages, as

well as PC connections to three users or to

an Irrigation Community software.

Basic model is completely scalable,

very easy to use, and has an additional list of options to become a high-performance model.

IRRIGATION

Up to 30 irrigation sectors can be controlled, which are governed by 50 separate programs with

their corresponding extensions, with the possibility of linking programs together to execute irrigation

sequences.

Each program can activate 1 to 4 irrigation sectors simultaneously. It can limit the simultaneous ac-

tivation of sectors of the base, from 1 to 8 among several programs.

Each program can start running at a specific time, selecting the days of the week, at the end of an-

other program, or triggered by an input when a contact is closed. Optionally, it can be activated when a

sensor reaches a certain value (°C, soil moisture, etc.), by mobile phone via SMS, by irrigation frequen-

cy (irrigating every day, every two days, every 3 days, etc.) or even irrigating everyday with several acti-

vations. In addition, the time of year when the unit must be operative can be indicated. When starting

using sensors, an active schedule or margin time between start-ups can be selected.

Irrigation units can be in time (hh:mm) and, optionally (mm:ss); in volume (m3); and, optionally, by

hectare volume (m3/ha); and by hectare time (hh:mm/ha), independently by program. There are time-

limited units when operating by volume.

Readings from each meter are proportionally distributed to totals and records, according to the

planned flow values for the simultaneous active sectors that are related to that meter.

Optionally, the modification of the irrigation and fertilization units by sensors may be influenced by

the values detected from the prior irrigation, such as rainfall, evapotranspiration, integrated solar radia-

3

tion, etc. or by using a virtual sensor (by manual or SMS command) to modify the irrigation units of all

the programs at the same time.

Optionally, one program currently irrigating can be temporarily suspended by sensor values, such

as wind, temperature, level, etc.

Optionally, complete monitoring for the instantaneous flow of irrigation meters is also available, with

programming of the planned flow in each sector and tolerances percentage based on excessive or de-

fault values. Detects lack of pulses or leakage.

FERTILIZATION

Number of fertilizers in separate tanks can be configurable from 0 to 4.

Pre and post irrigation values independent for each program.

Fertilization units measured by time (hh:mm) and, optionally (mm:ss); volume (L); or, optionally, by

hectare volume (L/ha).

Mixers use can be configured to be active or inactive, with pre-mixing and intermittent or continu-

ous mixing.

Fertilizers can be applied in three different ways:

In series: one type of fertilizer after another from a single injector.

Parallel: various fertilizers simultaneously with one injector per type.

Uniform (optional): applies and distributes each type of fertilizer uniformly between pre and post

irrigation. Applied in parallel.

Detection of the lack of pulses or water leakage is optional for volume sensors. Readings from each

meter are proportionally distributed to totals and records, according to the planned flow values for the

sectors that are related to that meter and that are being simultaneously fertilized.

PUMPING

There are 1 to 2 general irrigation outputs, or pumps, with activation sectors assignment and with

separate activation and deactivation temporizations. Temporizations are set to input and output for each

sector.

Optionally, a diesel engine or generator unit can also be controlled. Outputs for start-up, stop, con-

tact and preheating functions are available. Start-stop control of the electrical pump, as well as malfunc-

tions detection is also performed.

FILTER CLEANING

Configurable for 0 to 9 filters, with selectable cleaning time. Pause between filters is programmable.

Cleaning sequence may be started by the pressure differential and/or according to the time or vol-

ume of the water circulation.

Is it configurable to stop or not the irrigation sectors and fertilizers while the filters are being

cleaned.

Control over malfunctions due to continuous cleanings.

MANUAL

Manual commands can be used to start, stop, and remove irrigation programs from service, or

suspend them for certain times, sectors can be placed in manual or automatic mode, activate out of

service or general stop, start or stop filter cleaning, and finalize alarms and malfunctions. Optionally,

virtual sensors can be modified or outputs can be directly activated.

DETERMINING FACTORS

Optionally, the unit has a total of 30 completely configurable determining factors to trigger actions

that take into account certain conditions or values from digital or analog sensors and meters. There is a

wide variety of actions possible, such as the ability to make definitive, temporary or conditional stops

that are applied to specific programs or to all of them, start and/or stop irrigation, send a warning, adjust

irrigation or fertilizer units when starting an irrigation program according to an instantaneous value from

a sensor or the integrated value from a previous irrigation, etc. Moreover, each determining factor can

be configured to create a malfunction or send an SMS message to two private telephones and an SMS

message to another machine.

4

To give a few examples, it can be used to terminate irrigation due to a broken pipe, delay irrigation

due to the lack of water level or excessive wind, modify the volume of each irrigation according to the

value of the soil moisture or the solar radiation the plant received since its previous irrigation or the

evapotranspiration, terminate irrigation if a certain amount of rain has fallen since the previous irrigation,

or send a warning to the owner for an attempted theft, etc.

SOLAR IRRIGATION

Optionally, irrigation management on installations with solar panels connected directly to a variable

frequency drive to activate an irrigation pump. It also allows having hybrid installations with energy from

the power grid or from a power generating set. This operation has different priorities for irrigation at dif-

ferent pressures. The radiation sensor conditions the irrigation until there is enough energy to generate

the working pressure.

CONTROL PIVOTS

Optionally, management of up to 4 pivots with start and stop control, positioning, auto-reverse,

speed control, sectorisation and alarms.

DISPLAY

Full display using a LCD screen, 128x64 pixel graphics, LED automatic backlighting.

Watertight keypad features 15 keys with sound indicators when pressed.

Available in Spanish, English, French, Italian, Portuguese, and Catalan.

Entire program information is shown onscreen simultaneously.

READINGS

The unit stores all totals in non-erasable memory. Optionally, the events history and records of last

days anomalies can also be saved.

-General totals and totals by sector for irrigation and fertilization units in time and volume starting

from an initial date.

-Anomalies with time and date of the incident and related instructions.

Furthermore, also offers:

-Detailed records of every event occurring in the unit.

-Separate history per irrigation sector with the units in time and volume of the irrigation and ferti-

lizer applied everyday.

-History of every analog sensor with average value, with maximum and minimums in 10-minute

fractions.

-History of every meter sensor with the irrigation or fertilization values as well as leakages in 10-

minute fractions.

5

SMS MESSAGES

This option offers the possibility of receiving SMS messages from the Agrónic 2500 regarding

alarms, incidents, and selected workings, as well as the ability of users to send commands to start, stop

or modify a program, set to “Stop”, etc.

It can also send SMS messages to other controllers or devices related to an event or determining

factor.

PC MANAGEMENT

Optionally, the unit can be

managed using a personal com-

puter by the AGRÓNIC PC pro-

gram.

The connection options are via

cable (USB, RS485), by telephone

modem (GSM/GPRS) or radio (Ra-

dio-Link, Wi-Fi).

Cable: local or medium-

distance managing.

Modem: long distance or

even from another country.

Requires coverage, cost per

usage, and to include the

SMS. Socket connection:

TCP-Customer or Server.

Wi-Fi: LAN connection at a short distance and Internet for long distance.

Radio: distances from 1 to 20 km, depending on the orography. Shares the radio channel with

other units in order to be grouped into property dispersion or communities.

From the AGRÓNIC PC, punctual information can be obtained

from the controller (history, incidents, irrigation status, etc.), with the

capability to modify parameters, programs, ranges, etc., from any-

where using a PC. The connection can be permanent and grouped

together with other controllers (Agrónic 2000, Agrónic 4000, Agrónic

7000, Agrónic 5500, Agrónic BIT).

The Agrónic 2500 manages the communication between three

users; the information modified by one user automatically updates

the other two. The connection of the three users to the unit can be

simultaneous and permanent, according to the established link.

This is useful for the interaction between, for example, the owner,

ranch manager and installer.

6

EXTERNAL MODULES

Optionally, it allows the connection to AgroBee radio modules, increasing

the extension possibilities and the use of new features. This system is based

on the ZigBee protocol operating at 868/915 MHz band. Using different mod-

ules in the product line, digital sensors, analog sensors and the meters can

be easily allocated away from the irrigation valves.

SUMMARY OF PLUS OPTION FEATURES

The PLUS option for the AGRÓNIC 2500 offers a notable increase in features to the basic model,

which may come from the factory with the options pre-activated or carried out at any time during its op-

erable lifespan to meet any new demands that arise in the installation.

In the Programs function, in addition to the classic irrigation operation based on days of the week,

there is a day frequency option, allowing irrigations to be repeated every certain amount of days,

for example, every two days, one day on, one day off, etc.

Programs with several activations separated by an amount of time in hours and minutes, allowing

a pulsed irrigation.

Programs with active schedule to limit the irrigation application within a schedule; useful when

starting irrigation by sensor.

Programs with active periods to limit the operation of each program to specific dates.

Programs with safety times (hh:mm) between irrigation starts to prevent continuous commands

orders; useful when commands are sensor activated and an incident occurs.

Uniform fertilization. The uniform application in parallel and by volume is added in order to distrib-

ute fertilizer more homogenously within the irrigation units.

New format in the irrigation and fertilization programming, in cubic meters per hectare (m3/ha) and

liters per hectare (L/ha), respectively. The equipment carries out the calculations for the units ap-

plied at the start of every irrigation.

Determining factors: the number of determining factors has been increased from 5 to 30. Further-

more, they can affect all the equipment or be assigned to specific irrigation programs; digital, analog

or meter sensors can be used, or the integrated data from a previous irrigation; they can cause only

a record or anomaly to be created and send off warning SMS messages. Operatives:

oDefinitive stop.

oTemporary stop.

oConditional stop.

oStart and stop irrigation programs.

oWarning.

oModify irrigation.

oModify fertilizer.

oTerminate due to rain.

oFilter pressure gauge.

oDiesel pressure gauge.

oFertilizer Stop.

Text descriptions for programs, sectors, sensors and determining factors.

Possibility for 10 meters (up to 4 for fertilizers and the rest for irrigation) plus 40 analog sensors

and 20 digital sensors.

Manual commands, allowing programs to be placed out of service, to be suspended for a certain

number of hours or to be modified in order to change the days frequency meter or pending activa-

tions. In what regards the determining factors, a manual command can disable them or it can ter-

minate a definitive stop. Concerning the sectors, they can be left in automatic or manual start mode

7

or in manual stop mode. As for sensors, the manual commands permit values to be entered on a

virtual sensor.

As for Readings, there are new record and history sections. Chronological and detailed records

are made of each event occurring in the equipment. The history of the irrigation and fertilizer totals is

based on the time and volume applied per sector, grouped in days in the equipment and in 10-

minute fractions in the Agrónic PC program. The history of each analog sensor shows the average,

maximum and minimum values per day in the equipment and in 10-minute fractions on the PC. The

history of each meter sensor shows the irrigation or fertilizer values as well as the leakage value in

daily values or in 10-minute fractions on the PC.

MODELS AND OPTIONS:

Models for 9, 18 and 27 outputs. Models for 9 and 18 outputs can always be expanded to 27 if

desired, sending the unit back to the factory.

Version at 12 Vdc power and outputs at 12 Vdc or 24 Vac. However, it is also available with

220/24 Vac by means of a 220 Vac to 12 Vdc external power supply and a 50 VA transformer for

outputs from 220 Vac to 24 Vac. Power and outputs protection with resettable thermal fuses.

Version with unit housed in wall-hung box with see-through window.

Version with unit housed in box to build-in inset in a case or closet.

Diesel option for automatic start-up of pump motors or generators.

Double-voltage option for generators.

Options with outputs for 2 or 3 wire latch solenoids. Due to the very low power consumption of

the equipment and electrovalves they operate these versions are highly recommended for bat-

tery-operated facilities that do not have diesel motors or solar panels to recharge them.

Option PLUS, which adds features such as uniform fertilization, additional determining factors,

sensors, record, history, text description of each feature, more than one irrigation meter, totals

per meter and, concerning the irrigation programs, the option to operate by day frequency, acti-

vation, schedule and active periods.

Option to link to the AGRÓNIC PC program.

Option to link to the mobile application AGRÓNIC APP.

SMS messages option (includes GSM/GPRS modem).

USB link option.

Wi-Fi link option.

Radio-link option.

Option to link to AgroBee system.

Option to connect two analog sensors to the base equipment.

Battery recharging option.

GUARANTEE

Agrónic 2500 meets all the norms set by the CE.

The products created by PROGRÉS offer a two-year warranty against all manufacturing defects.

Compensation for direct or indirect damage caused by the use of the equipment is excluded from the

warranty.

8

2. USER’S GUIDE

The Agrónic 2500 is a complete irrigation controller whose features require the thorough awareness of the in-

staller and user in order for the make the most of the unit, so we highly recommended reading this manual in full.

The chapter on INSTALLATION [5] is intended for the installer who will be connecting the unit to the rest of

the equipment that completes the automated irrigation system.

The chapter on PARAMETERS [6] provides instructions on how to configure or initialize the unit according to

the needs particular to each facility. This is the task of the installer, but the user will find this section of interest if

having to make some modifications to the parameters after the unit has been installed.

The subsequent chapters, PROGRAMS [7], MANUAL [8], READINGS [9] and CONSULTATION [10] are pri-

marily intended for the user.

Keypad:

Number 0/ “NO” when confirming yes/no

questions.

Number 1/ Sunday,for questions related to the

days of the week.

Number 2/ Monday, for questions related to

the days of the week.

Number 3/ Tuesday, for questions related to

the days of the week.

Number 4/ Wednesday, for questions related

to the days of the week.

Number 5/ Thursday, for questions related to

the days of the week.

Number 6/ Friday, for questions related to the

days of the week.

“-“, for signs and choice-related questions.

Number 7/ Saturday, for questions related to

the days of the week.

Number 8/ Daily, for questions related to the

days of the week.

Number 9

“YES”, when confirming yes/no questions

“+”, for signs and choice-related questions.

Enter key, to accept a menu selection, the

last value entered or confirm the selection

in a question.

Function key, to access the functions menu and

also to go backward when inside the menus.

Consultation key, to access the consultation

menu and also to go backward when inside the

menus.

Down arrow key, to move the cursor in the

menus, jump to the next screen or the following

day in the records.

Up arrow key, to move the cursor in the menus,

jump to the previous screen or the previous day

in the records.

Operative:

or

or

FUNCTION

1.

PROGRAMS

2.

MANUAL

3.

READINGS

4.

PARAMETERS

CONSULTATION

1.

GENERAL

2.

PROGRAMS

3.

SECTORS

4.

FERTILIZERS

5.

FILTERS

↓

MANUAL

1.

Out of service

2.

STOP

3.

Programs

4.

Filters

5.

Clock

↓

MANUAL PROGRAMS

Program: 08

MANUAL PROGRAMS

Program: 08

Start: yes

Notes:

By pressing the “0” key on any

menu, the screen lights activate or

deactivate.

The “↓”character on the last line

of the menu indicates there are

more menu features on the next

screen.

9

3. TECHNICAL FEATURES

General power

supply

Voltage

12 Vdc +15 % -10 %

Frequency

= = =

Energy con-

sumption

Less than 12.5 W (0.24 W at rest)

Fuse

Input

Thermal (PTC) 1.1 Amp. at 25 °C, auto-resettable

Output power

source

Voltage

From 12 at 24 Vdc or Vac (maximum 30 V)

Fuses

Input

“R+”

Thermal (PTC) 3.0 Amp. at 25 °C, auto-resettable

Outputs

Digital

Number

9, extendable to 18 and 27.

Type

Per relay contact, with 24 Vac potential (external transformer)

Limits

30 Vac / 30 Vdc, 1 Ampere, 50-60 Hz, CAT ll (per output)

All outputs have double isolation in respect to the power supply.

Inputs

Digital

Sensors

Number

6

Type

Coupling options, operate at 12 or 24V

Analog

(option)

Number

2

Type

4-20 mA, 0-20 V. (upon request, with galvanized separation)

Atmosphere

Temperature

-5 °C to 45 °C

Weight

(Kg.)

Box model

Built-in model

Humidity

< 85 %

Height

2000 m

From 1.0 to 1.6

From 1.1 to 1.5

Pollution

Grade 2

Memory and Clock backup

Memory

No maintenance, 10 years for parameters and programs in

FRAM memory and FLASH memory records

Clock

48 hours without power

DECLARATION OF CONFORMITY

It follows the 89/336/CEE guidelines for the Electromagnetic Compatibility and the 73/23/CEE

guidelines of Low tension for the fulfillment of the product security. The fulfillment of the fol-

lowing specifications was demonstrated as indicated in the Official Diary of the European

Communities

Symbols which may appear

in the product

Protection Earth

terminal

Box

terminal

This symbol indicates that the electrical and electronic equipment should not be disposed of as general household

waste at its end-of-life. Instead, the product should be handed over to the applicable collection point for the recy-

cling of electrical and electronic equipment for proper treatment, recovery and recycling in accordance with your

national legislation.

10

4. DIMENSIONS

5. INSTALLATION

5.1. EQUIPMENT PLACEMENT

Place the unit at the right position and height. Avoid direct sun exposure, humidity, dust and vibrations.

Avoid proximity to any source of interference which could affect the correct working of the unit.

In the version with "box", the equipment is provided in a hermetically sealed box (IP65) with a transparent

front cover for the keyboard/display and an opaque cover for the connection housing. The 27-output model uses a

connector attached to the left side of the box.

To maintain the isolation of the unit, it is essential to keep the panels closed, as

well as to install cable glands at the cable outlets, which are provided with the equip-

ment.

For the wall-mounting of the unit, there are two holed pieces in the upper corners.

In the “built-in” model, a hole is to be done in the frontal part of the wall or desk,

according to the measures in the section [4.] DIMENSIONS. It will be held with the

screws at the corners, using the four pieces provided with the unit.

11

5.2. CONNECTION LOCATIONS

To connect the

“built-in” equipment

model, access the

backside located

inside the desk or

closet. Here we find

the connections for

the power supply,

inputs, and outputs

on the 9-, 18- or 27-

input models.

What’s more, when

more options have

been installed, there

may be connections

for the antennas

used in the AgroBee

option or a PC link

using GSM/GPRS or

radio-link; on the

sides there may be a USB port connection and the option for two analog sensors.

On the “wall-

mount box”, re-

move the bottom

cover to access the

connectors.

To insert ca-

bles, the necessary

holes will have to

be punched out (do

this with the con-

nection cover in

place and screwed

in to avoid breaking

it).

The 27-output

model has the last

nine outputs locat-

ed in a connector

on the left side.

The connect-

ors and antennas

from the rest of the

options are located on the right side.

It is recommended to connect the wires to the terminal using the terminal connectors that come with the

equipment. (The terminals accept cables of up to 2.5 mm2in diameter).

5.3. CONNECTIONS

The installation must be performed according to the current regulations applying to electrical installations.

The equipment will not be adequately protected if it is not used in the way that has been specified in this manual.

The unit shall be placed in such a way that the wiring connections of any elements susceptible to interfer-

ence, such as the sensor inputs, sensor power supply, PC links, and power supply intakes, are installed in the

best possible location so as not to receive interference from powered elements which may be nearby.

All the connection terminals on the Agrónic 2500 can be plugged in, which allows for quick maintenance.

12

5.3.1. Connecting the power supply

Power is supplied to all models using 12-volt continuous electrical current. For installations

connected to solar panels, generators, or diesel pump motors, the equipment will be connected

to a 12 V battery. In 110 or 230-volt systems, an accessory such as a 90-230 V / 12 V (50-60 Hz)

power supplier is used to connect the equipment. Power supply socket must be easily accessi-

ble.

The power supply intake has an auto-resetting thermal fuse and is also protected against reversed polarity

and overvoltage peaks. The installation must have a separate thermo-magnetic switch to protect the Agrónic 2500;

its output is connected to the general power supply and the transformer that powers the output.

When the diesel motor is running, avoid disconnecting the battery as the alternator will boost the electrical

tension considerably and damage the Agrónic.

5.3.2. Connecting the ground connection

The terminal used for the ground wires is located next to the power supply terminals; its function is to divert to

the ground any possible electrical sparks generated by storms that can enter via the input and output cables. An

arc spark over in the internal gas discharger is produced with 90 volts or more. It is extremely important to connect

up the ground in order to completely safeguard the equipment.

The build-in model has an additional ground connection on the side of the metal box when having to divert

this to the ground.

5.3.3. Connecting the digital sensors

Both the digital sensor inputs and the relay outputs are powered externally to 12 or 24 volts. This point to the

internal wiring has optical and mechanical safety isolation.

The device contacts connected to the digital sensor inputs normally have to be open and free of any voltage.

There are six inputs, listed from D1 to D6, plus a common marked CD.

Each sensor input can occupy a function or operative, and they configured in the section “Parameters - Gen-

erals”[6.3.].

Function list:

IM Irrigation meter

FM Fertilizer meter

SC Cleaning start

TM Temporary malfunction

DM Definitive malfunction

CS Conditional stop

PS Program start

AL Alarm (only with SMS option)

5.3.4. Connecting the outputs

All the outputs are operable at either 12 or 24 volts in alternating or continuous current (do not supply voltage

higher than 30 volts).

To be operative at 24 Vac, an external transformer with a double-insulated 24 Vac output must be installed

according to UNE EN61010 standards. There is an accessory for a 230/24 Vac 50 VA transformer to connect to

the equipment.

The power supply intake for the outputs is marked “R+” and “R-“.

The solenoids on the electrovalves, relays and contactors are connected between the “CR” output common

and the corresponding output between “R1” and “R27”.

The power supplied to the outputs and digital sensors is protected by an auto-resettable thermal fuse. In the

section “Consultation - Agrónic” [10.7.] it indicates whether there is voltage for the outputs or not. When there is a

short circuit in one of the outputs, the fuse will automatically be tripped, limiting the output until the short circuit

has terminated.

13

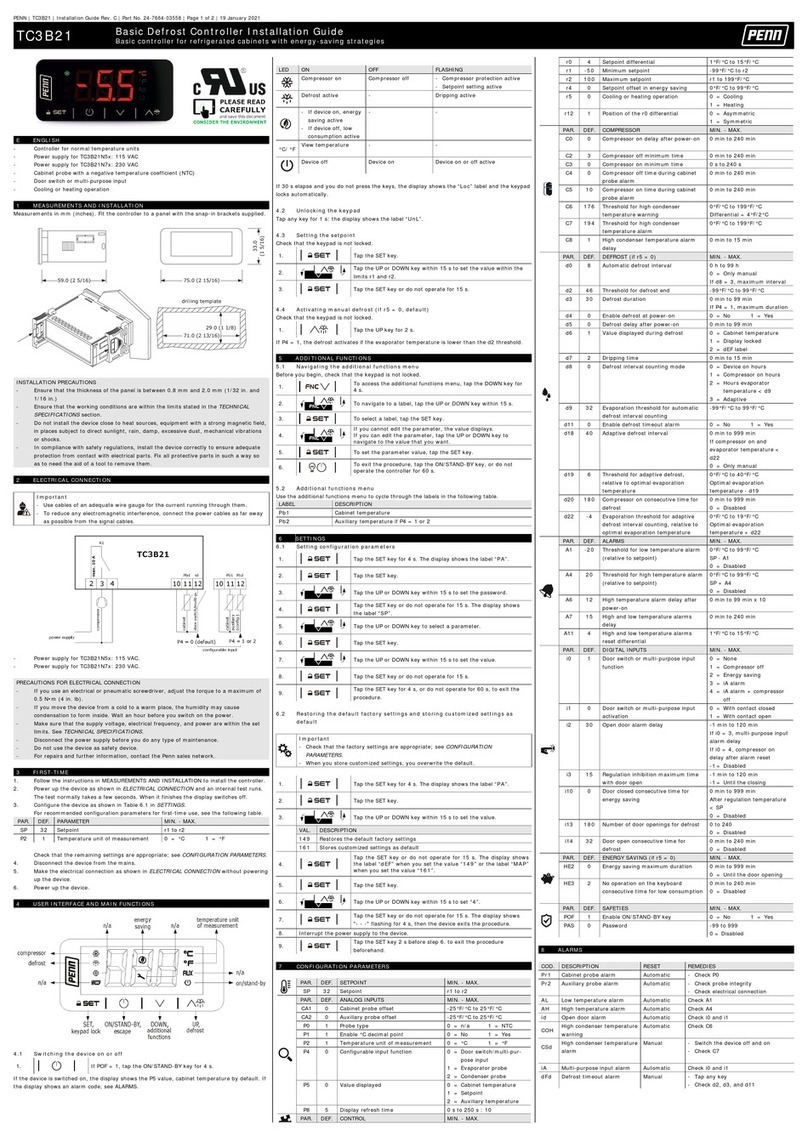

Example of the connections for a 230 V power supply:

Example of the connections for a 12 V power supply:

14

5.4. INSTALLING THE OPTIONS

5.4.1. Diesel option

When making the connections for the diesel motor start-up version, the following details must be taken into

account:

INPUTS:

Oil pressure gauge OP. In the diesel starter version, the function of input of pressure gauge is automatically

connected to input 6. There is a delay of 10 seconds in the detection. The pressure gauge can only be connected

to this input. The CD digital input common does not have to be connected to the pressure gauge as this is done

directly through the chassis of the motor.

OUTPUTS:

The outputs charge the positive battery pole. A supplementary relay is intercalated between each to prevent

damage to the internal relays.

The contact output is connected through the relay to the wire from the “15/54” terminal of the key. This is the

equipment in charge of connecting and disconnecting the contact, so the key has to be left in the inactive posi-

tion.

At the start-up output, a supplementary relay is intercalated with a capacity for 30 to 30 amperes, connecting

the output to the wire from the “50” terminal on the key.

If the motor is stopped by an electromagnet, this is connected to the supplementary relay from the stop out-

put.

If the motor is stopped when the fuel supply is cut off by an electrovalve, this is installed at the same injector

input for the stoppage to be as quick as possible. When the electrovalve is normally open, it is connected directly

to the stop output. If the electrovalve is normally closed, it is connected to the contact output.

When there is a preheating function, this is connected to the relay to be activated.

For greater safety, it is convenient to have a double-stopping system that uses an electromagnet for stopping

quickly and effectively, plus an electrovalve that is normally closed so as to cut off the fuel supply in the event an

incident or malfunction.

15

5.4.2. Double Voltage Option

Equipment installed with this option have a different output configuration that operates the last four outputs at

12 volts; these outputs are positive and is powered by the same electrical supply as the rest of the equipment.

Their function is to activate the start-up and stopping functions of a generator. The rest of the outputs operate at

24 volts and are available once the generator has been started up.

The digital inputs have a common CD, the negative battery pole; the four outputs than using 12 volts have a

common the negative battery pole; and the other outputs have a 24 V common on the connectors marked as CR.

12 Vdc outputs:

Agrónic 2500 –9 outputs: Start-up = 9 Stop = 8 Contact = 7 Preheating = 6

Agrónic 2500 –18 outputs: Start-up = 18 Stop = 17 Contact = 16 Preheating = 15

Agrónic 2500 –27 outputs: Start-up = 27 Stop = 26 Contact = 25 Preheating = 24

24 Vac outputs: Electro-pump (pump P1 output).

An example of the connections for equipment with 18 outputs:

16

5.4.3. Latch option

The low power consumption in this option allows facilities to operate where the power is supplied by a single

battery and a solar charger that uses a small battery attached to a 2- to 10-W solar panel, thus not having to

charge it manually.

Latch electrovalve, also called of impulse, function by hydraulically locking its open or close position, con-

suming energy only in the moment they change positions.

The installer can set up the equipment to use latch electrovalves in the two or three-wire format and a 12 or

22-volt trip voltage. See the “Parameters - Installer” section [6.8.].

If installing 3-wire models, it will be necessary to incorporate a diode box to the installation to connect the

start and stop commons. This is unnecessary in 2-wire models.

2-WIRE LATCH CONNECTIONS:

One of the two wires is con-

nected to the “CR” output com-

mon and the other to the corre-

sponding output between “R1”

and “R27”.

If the electrovalve activates

hydraulically in the opposite di-

rection than the order given by

the equipment, this order will be

inverted going to “Parameters

Installer - Various” [6.8.].

3-WIRE LATCH CONNECTIONS:

This electrovalve

model has two commons;

the one for starting (nor-

mally red) will be brought

to the diode box, to one

of the terminals marked

“Start”. The stop common

(normally black) is con-

nected to a terminal

marked “Stop”; the other

wire (normally white) is

connected to the corre-

sponding output between

“R1” and “R27”.

On the other hand, it

will be necessary to con-

nect the CM start and the

CP stop commons on the

equipment to the diode

box.

17

5.4.4. Two Analog Sensor Option

With the Plus option activated, this option allows up to two analog sen-

sors to be connected in order to measure different quantities (pressure, solar

radiation, soil moisture content, temperature, etc.). This is used by the

Agrónic PC program to record the sensors, or in the Plus Option to condition

irrigation programs.

It allows the sensors to make measurements, generating electrical cur-

rent from 0/4 to 20 mA or voltages between 0 and 20 Volts. The wiring in

this option has one switch per sensor to select the measurement using cur-

rents or voltages. The default is set to current; “I” position; to select voltage, it

must be set to the “V” position. The wiring is housed behind the keypad. The

location of the switch at each input it is necessary to set in “Parameters -

Installer” [6.8.].

The external connector located on the right side of the box-mount mod-

el, or on the bottom or the built-in model, has four terminals to connect up

the sensors.

Terminal 1: Output wire from sensor A1.

Terminal 2: Output wire from sensor A2.

Terminal 3: corresponds to the output wire for the sensor power supply, 12 V, 200 mA.

Terminal 4: common for the sensor inputs and common for the power supply output (0 V).

Example:

Sensor with independent power supply: Connect the common from the sensor to terminal 4 and the

sensor signal to terminal 1 or 2.

Sensor powered by the Agrónic: Connect the common from the sensor to terminal 4, the sensor signal

to terminal 1 or 2 and the power supply positive to terminal 3.

Sensor with only positive and return: Connect the positive to terminal 3 and the return to terminal 1 or 2.

5.4.5. Battery Charger Option

The Agrónic 2500 has a battery charger, optional in the “relay output” models and the “latch” model series.

12 V lead-acid batteries must be used that have a capacity between 3 and 7 Ah.

In the “latch” models the capacity of the solar panel can run between 2 and 10 W to 7 or 12 V. This is used

mainly at facilities without an electrical supply that use latch electrovalves, and can connect up to a solar panel

and charge the battery.

In the “relay output” models never it be connected a solar panel, in these models it will connect a 12 V ±5

% power supply (90-230 V / 12 V). This is used mainly at facilities with an electrical supply which need to send a

warning SMS when the power is out (implies the Plus and Communications options).

Technical features:

Maximum charging capacity: 160 mA (2 W)

Minimum solar input voltage: 7 V

Maximum solar input voltage: 18 V (“latch”) / 12V (“relay”)

Examples of the connections:

18

6. PARAMETERS

To install and set the equipment up for operation, it is necessary to enter the “PARAMETERS” section and

adapt them to the needs of each facility. Access the menu by pressing “Fun. \ 4 \ Enter”.

The menu is divided into eight sections. To enter one of them, just press the corresponding index number or

move to the selection with the arrow keys and then press “Enter”.

If a menu has more than 5 lines, the “↓“ symbol will be displayed to indicate that they do not fit on the screen,

so press the index number or move the “Down Arrow” key to access them.

6.1. FERTILIZATION PARAMETERS

The Agrónic 2500 can operate with a maximum of four fertilizers that are applied in series (one after another)

or in parallel (all at once), in units of time or volume and separate pre/post irrigation for each program.

In the “N. of fertilizers” question, we indicate to the equipment the

number of fertilizers installed in the irrigation system, with a maximum of 4.

Leave the value at 0 if there are none.

The fertilizer general is an output normally used to connect the injec-

tor in application by series, and is activated only when one of the fertilizers

activates.

Each fertilizer can be assigned a separate mixer.

Before a fertilizer is applied, it is possible to mix up the liquid in the

tank. To do this, enter the number of seconds necessary in the pre-mixing

question. Once the injection value of a fertilizer has been entered, perma-

nent, intermittent or stop mixing can be carried out. For the first condition,

only enter the “start mixing” time, for the second both the starting and

stopping times, and for the last, just the stop time. The time limit is 255

seconds.

When the fertilization ends, a cleaning of the fertilization head can be done. If the fertilization is in series, it

will be done when each of the fertilizers is finished. If it is not in series, it will be done when all the fertilizers are

finished. The general of fertilizer is activated together with the cleaning output. The maximum time is 999".

PARAMETERS

1.

Fertilization

2.

Filters

3.

Generals

4.

Programs

5.

Sectors

↓

6.

Communications

7.

Various

8.

Installer

FUNCTION

1.

PROGRAMS

2.

MANUAL

3.

READINGS

4.

PARAMETERS

FERTILIZATION PARAMETERS

N. of fertilizers: 4

Fertilizer general: yes

Mixer F1: no

Mixer F2: yes

Mixer F3: yes

Mixer F4: no

Pre-mixing: 015 “

Mixing start: 030 “

Mixing stop: 120 ”

Last cleaning: 030 “

19

6.2. FILTER PARAMETERS

When the automatic cleaning of the filters is to be made, the required

parameters are entered here. The first is for the number of filters in the

installation, with a maximum number of 9.

The initial wait is the time between the activation of the general of fil-

ters and when the cleaning of the first filter starts.

The activation time per filter corresponds to the seconds that water

circulates in order to wash each filter.

A pause can be applied between the washing of one filter and an-

other, whereupon the filter being cleaned will be closed and the unit will

wait the number of seconds indicated before activating the valves to wash

the next one. This is used to prevent a drop in pressure due to the hydrau-

lic delay that occurs when the valve is closed.

The units between cleanings correspond to the volume in m3 or the

irrigation time in minutes that must pass through the filters in order to

perform a new automatic cleaning; this can also be initiated by a differen-

tial pressure gauge or ordered manually. In any event, the internal meters

will be set to zero between cleanings.

It is possible to configure a filter general to activate an output during

the entire filter cleaning process.

In order to manage the automatic washing, it is necessary to know

the relation between pumps P1 and P2. Mark “yes” when the water be-

ing flushed through is circulating through the filters. By doing this we control the units of volume or time circulating

through the filters or monitor the differential pressure gauge.

When managing the cleaning using the differential pressure gauge and in the event it malfunctions, a maxi-

mum number of subsequent cleanings can be determined in order to stop them and create a malfunction. This

will only be considered an incident if a time less than five minutes has elapsed between the end of one cleaning

and the start of another. Once the incident in the pressure gauge has been resolved, we must access the “Manual-

Filters” section to remove the malfunction and thus activate the filter washing control system once again. Check

chapter [8.].

If necessary, sectors being irrigated can be stopped in order to best optimize pressure. In this case the pro-

grams being run that contain sectors related to the filters are temporarily stopped and continued at the same point

once the cleaning tasks have terminated. If a program is under way in a sector that does not activate the motor or

activates one non-related to the filters, it will continue without stopping during the cleaning cycle. Keep in mind

that when sectors are stopped, the motors related to the cleaning times will be activated; if the order to stop is not

given, the motors related to the sectors being irrigated will remain active.

6.3. GENERAL PARAMETERS

In this section, the general inputs and outputs on the Agrónic 2500

are configured so as to adapt them to each facility.

The equipment has two outputs for general motors or valves in order

for them to be activated or not.

Each pump output has temporization functions to adjust to hydraulic

delays and prevent waterhammers. The start temporization delays the

pumps input when irrigation starts and the stop temporization extends

the stopping period when irrigation is terminated.

If the irrigation must be terminated as the motor has to be stopped

immediately and the sector outputs are to remain active for a few more

seconds, we have to respond affirmatively to the question regarding

“Stopping the sectors”.

Example diagram:

FILTER PARAMETERS

N. of filters: 3

Initial wait: 000”

Time of activation

by filter: 045 “

Pause between filters: 04 “

Units between cleanings

Volume: 0000 m3

Time: 0000 ‘

General of filters: no

Relation with P1: yes

Relation with P2: no

Max. number of continuous

cleanings: 0

Stop of sectors: no

GENERAL PARAMETERS

Pump 1: yes

Temp. start: 018 “

Temp. stop: 012 “

Stopping the sectors: no

Pump 2: yes

Temp. start: 005 “

Temp. stop: 022 “

Stopping the sectors: yes

20

On the base of the Agrónic 2500 there are 6 inputs to connect up digital sensors (section [5.3.3.]). Different

functions can be assigned to them on the following screens.

IM Irrigation meter

FM Fertilizer meter 1 to 4. When fertilizing in series, there is

only one meter. In this case, the same input must be assigned to

each meter that has been enabled.

SC Start cleaning. Used to connect a differential pressure

gauge and make cleanings by increasing the pressure between

the inputs and outputs for a group of filters. There is a 30-second

delay after the pressure gauge gives the command. To accept the

input, a program must be running an irrigation cycle.

TM Temporary malfunction, causes current irrigation program to stop, but it lets the next sequence or

start continue as normal. Once the temporization is over, the sensor will be reactivated.

DM Definitive malfunction, is what causes a total and definitive stop of the system until it is manually

reactivated by the user in “Function - Manual”[8.].

CS Conditional stop, when activated, all the programs under way stop completely with their remain-

ing units intact. Once the stop is over, irrigation resumes at the same point. While in a conditional stop,

programs may begin and be placed on standby.

PS Start programs, a digital sensor will begin the irrigation of one or more programs. The input will no

longer be accepted if the programs or their sequences have not terminated.

AL Alarm, a digital sensor that is normally closed will send a SMS when the contact is opened.

When inputs have been assigned, the following associated values will be requested.

With the value per pulse in the irrigation or fertilizer meter, we indicate the volume to be counted per pulse

received. The units for both irrigation and fertilization run from 1 centiliter to 9999 liters.

The input allows a maximum of 5 pulses per seconds.

With the delay without pulse, minutes that it should be without receiv-

ing pulses from meter are shown in order to raise a definitive malfunction

(if it is an irrigation one) or a fertilization stop. Leaving it to 0, the malfunc-

tion is disabled.

For the rest of the stop, start or malfunction functions, a time in sec-

onds will be requested to delay the detection of the digital sensors con-

nected to the inputs. If the sensor disconnects the input, the temporization

will be reentered. This is used to filter out false events, such as a pressure

sensor triggered when the pipes are being filled.

Each general engaged in this section - either fertilizer or filter gener-

als - will request the allocation of an output. We must begin by providing

the last outputs the equipment has available to these generals, as the

sector outputs occupy to output 1 and so on.

Chart to note down allocations:

Output

Allocation

Output

Allocation

1

Sector 1

15

2

16

3

17

4

18

5

19

6

20

7

21

8

22

9

23

10

24

11

25

12

26

13

27

14

GENERAL PARAMETERS

Assign inputs :

IM FM1 FM2 FM3 FM4

1 2 0 0 0

Assign inputs :

SC TM DM CS PS AL

4 0 0 5 0 0

GENERAL PARAMETERS

Irrigation meter:

Value per pulse: 0100,00 L

Delay without pulse: 010’

Fertilizer meter:

Value per pulse: 0001,00 L

Delay without pulse: 010’

Detection delay

input SC: 030 “

Detection delay

input TM: 180 “

Assign outputs:

P1 P2

18 17

Assign outputs:

F1 F2 FG

15 14 16

Assign outputs:

M1 M2 LF

13 12 20

Assign outputs:

C1 C2 GC

10 9 11

Table of contents