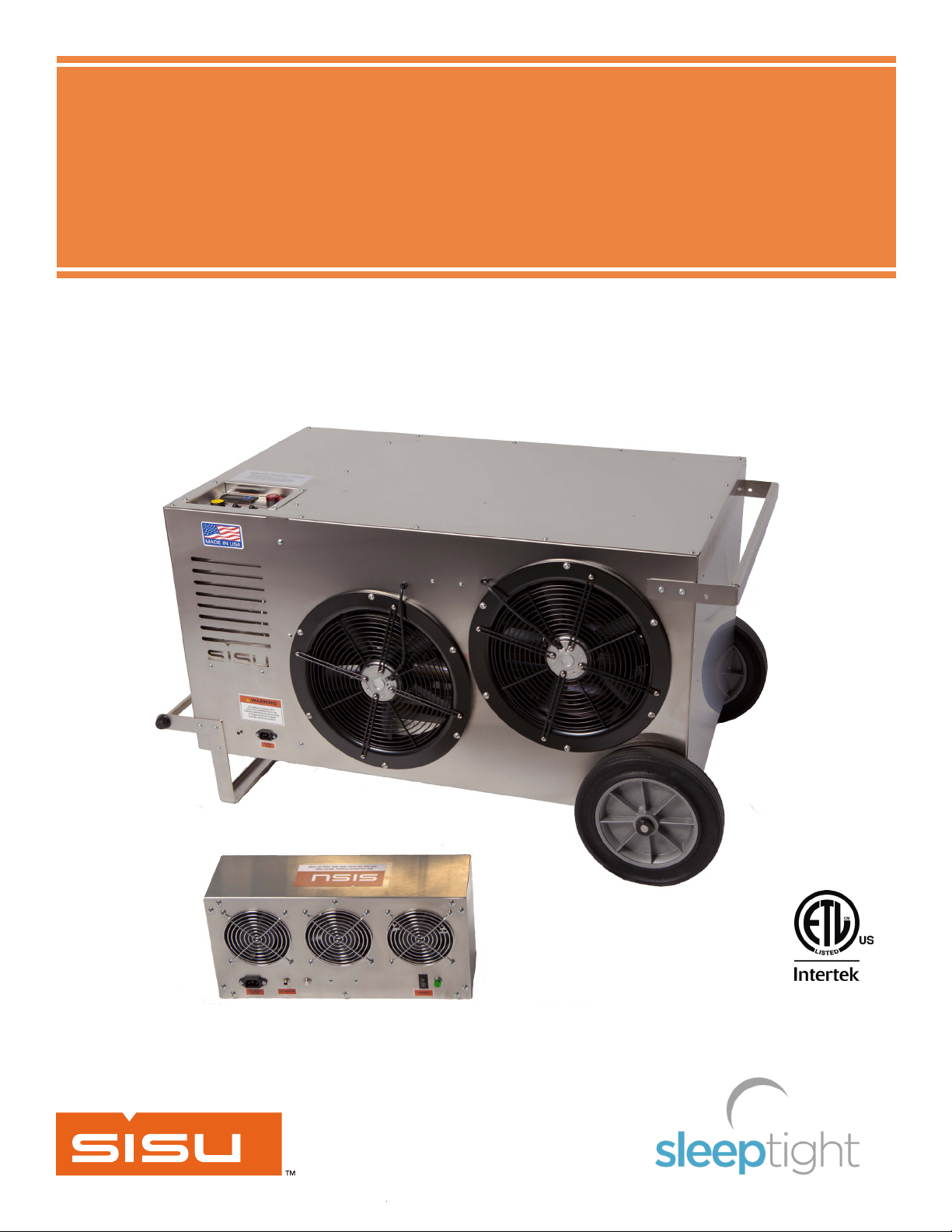

Sisu Commercial Products Sleeptight 1500SD Manual

Sleeptight 1500SD

Rev B – Sept. 2019

OWNER’S MANUAL AND INSTRUCTIONS

COMMERCIAL PRODUCTS

5009709

Sisu Commercial Products, LLC (“Manufacturer”) warrants its products (“the Products”) to be

free from defects in material and workmanship. Manufacturer’s Sleeptight Products shall be

warranted for a period of 12 months from the date of shipment.

Buyer’s sole and exclusive remedy for any nonconformity with this warranty shall be, at

Manufacturer’s option, repair or replacement of nonconforming parts, provided that Buyer

shall return to Manufacturer, shipping prepaid, said non-conforming part(s) bearing a

durable tag indicating the Serial Number of the Product from which the part was taken.

In addition, Manufacturer may opt not to repair or replace nonconforming Product or

part(s), but instead may refund to Buyer the price thereof, in lieu of repair or replacement.

In no event shall Manufacturer be liable for more than a refund of the purchase price or

replacement value of the Product or part(s), whichever is less. This Warranty does not apply

to eld labor charges.

This Warranty does not apply and shall be void as to any Products that are misused or

misapplied, that are installed, operated or maintained not in conformity with Manufacturer’s

design, specications, instructions, or Owner’s Manual, or are installed, operated or

maintained in violation of any applicable national or local codes or industry standards.

Manufacturer does not warrant Products, if they are abused, improperly operated or

maintained, subjected to abnormal wear and tear, damaged due to improper gas or electric

service, damaged in transit, or that have been repaired or modied by others without

Manufacturer’s written authorization.

Buyer shall have no right to enforce this Warranty unless it has complied with all of its

obligations under the contract for purchase/lease of the Products, including without

limitation, being current on all payment terms.

THIS LIMITED WARRANTY IS MANUFACTURER’S ONLY WARRANTY WITH RESPECT TO THE

PRODUCTS, AND IT IS IN LIEU OF AND SUPERSEDES ANY AND ALL OTHER WARRANTIES OF

ANY KIND WHATSOEVER, WHETHER WRITTEN, ORAL OR IMPLIED, INCLUDING WITHOUT

LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. THE REMEDIES AFFORDED BUYER BY THIS WARRANTY ARE THE

ONLY REMEDIES AFFORDED BUYER FOR ANY NONCONFORMITY WITH THIS WARRANTY

OR FOR ANY DEFECT IN PRODUCTS, SERVICES, OR REPRESENTATIONS PROVIDED

BY MANUFACTURER IN CONNECTION WITH SUCH PRODUCTS. IN NO EVENT SHALL

MANUFACTURER BEAR ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF

ANY KIND WHATSOEVER, INCLUDING WITHOUT LIMITATION PERSONAL INJURY (INCLUDING

DEATH), PROPERTY DAMAGE, LOST PROFITS OR OTHER ECONOMIC LOSS.

Buyer acknowledges that the foregoing warranty, limitations, and exclusions are a

reasonable allocation of commercial risks by and among sophisticated business entities

and are not subject to dispute as to their commercial reasonableness, fairness or ability to

satisfy the essential purposes of the parties’ transaction.

Sisu Commercial Products, LLC has a continuous product improvement program; it reserves

the right to change design and specications without notice.

LIMITED WARRANTY

1

2

General Hazards........................................................... 3

Hazard Summary ......................................................... 4

System Description ...................................................... 5

Minimum Clearance to Combustible Materials....... 5

Specications ............................................................... 5

Air Quality Warning ..................................................... 6

System Components.................................................... 7

Electrical Interface Locations...................................... 8

Operator Interface Location ....................................... 8

Usage Instructions ..................................................9-14

Gas Train and Electrical Components .................... 15

Control Components ........................................... 16-17

Fresh Air Module Wiring Diagram ........................... 18

Heater Wiring Diagrams............................................ 19

Replacements Parts & Service.................................. 19

Maintenance Instructions ......................................... 20

Ignition Board Troubleshooting............................... 21

TABLE OF CONTENTS

GENERAL HAZARD WARNING:

Failure to comply with the precautions

and instructions provided with this

heater can result in death, serious

bodily injury and property loss

or damage from hazards of re,

explosion, burn, asphyxiation, carbon

monoxide poisoning, and/or electrical

shock.

Only persons who can understand and

follow the instructions should use or

service this heater.

If you need assistance or heater

information such as an instruction

manual, label, etc. contact the

manufacturer.

WARNING:

Fire, burn, inhalation, and explosion

hazard. Keep solid combustibles,

such as building materials, paper,

or cardboard, a safe distance away

from the heater as recommended

by the instructions. Never use

the heater in spaces which do or

may contain volatile or airborne

combustibles, or products such as

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

FOR YOUR SAFETY:

The use and storage of gasoline or other ammable vapors and liquids in

the vicinity of this appliance is hazardous.

WARNING:

Not for home or recreational vehicle

use.

3

GENERAL HAZARDS

Hazard Identication – Warnings, Cautions and Notices appear in appropriate

sections throughout this Owner’s Manual. Read these carefully!

WARNING - Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION - Indicates a potentially hazardous situation which may result

in minor or moderate injury. It may also be used to alert against unsafe

practices.

NOTICE - Indicates a potentially hazardous situation which, if not avoided,

could result in property damage.

WARNING:

Operation, service, and repair of this equipment could result in exposure

to electrical, mechanical or other potential safety hazards and should only

be performed by qualied personnel. Use extreme caution and observe

safety regulations at all times.

WARNING:

Any unauthorized modication of this equipment shall void warranty.

Additional Hazards – The following safety precautions apply to the operation and

maintenance of the equipment described by this Owner’s Manual.

HAZARD SUMMARY

4

AIR QUALITY WARNING

•Do not use this heater for heating human living quarters.

•Use of direct-red heaters in the construction environment can result in exposure to levels of CO,

CO2, and NO2 considered to be hazardous to health and potentially life threatening.

• Do not use in unventilated areas

•Know the signs of CO and CO2 poisoning

• Headaches, stinging eyes

• Dizziness, disorientation

•Diculty breathing, feels of being suocated

•Proper ventilation air exchange (OSHA 29 CFR 1926.57) to support combustion and maintain

•acceptable air quality shall be provided in accordance with OSHA 29 CFR Part 1926.154, ANSI

•A10.10 Safety Requirements for Temporary and Portable Space Heating Devices and

•Equipment used in the Construction Industry or the Natural Gas and Propane Installation

• Codes CSA B149.1

•Periodically monitor levels of CO, CO2 and NO2 existing at the construction site – at

the minimum at the start of the shift and after 4 hours.

•Provide ventilation air exchange, either natural or mechanical, as required to maintain accept-

able indoor air quality.

WARNING

Air Quality Hazard

•Ensure that the ow of combustion and ventilation air exchange cannot become obstructed.

• As the building ‘tightens up’ during the construction phases ventilation may need to be

• increased.

HIGH ALTITUDE USE

Installation or use of this appliance at altitudes above 2000 ft (610 m) shall be in accordance with

local codes, or in the absence of local codes, the National Fuel Gas Code, ANSI Z223.1/NFPA

54, or National Standard of Canada, Natural Gas and Propane Installation Code, CSA B149.1.

USA 8-Hr Time weighted average Canada 8-hr time weighted average

(OSHA 29 CFR 1926.55 App A) WorkSafe BC OHS Guidelines Part 5.1

and Ontario Workplaces Reg 833

CO 50 ppm CO 25 ppm

CO2 5000 ppm CO25000 ppm

NO2NO23 ppm (Reg 833)

USA-Ceiling Limit

(Short Term Exposure Limit=15 minutes)

Canada STEL (15 minutes Reg 833/1 hour WSBC) WorkSafe BC

OSH Guidelines Part 5.1 and Ontario Worksplaces Reg 883

CO CO 100 ppm

CO2CO215000 ppm (WSBC)

30000 ppm (Reg 833)

NO25 ppm NO21.0 ppm (WorkSafeBC)

5.0 ppm (Reg 833)

5

The Sleeptight 1500SD, patent pending, is designed for indoor use only. It is intended

for use in providing portable, temporary heat to buildings under construction,

alteration or repair. Adequate ventilation must be provided while heater is operating.

Combustible solids, such as building materials, paper or cardboard must be kept

at the minimum distance from the heater as shown in the table below. Never use

this heater in spaces which do or may contain volatile or airborne combustibles,

or products such as gasoline, solvents, paint thinner, dust particles or unknown

chemicals. Adequate building relief must be provided so as to not over pressurize the

building when this heater is operating at its rated capacity.

Gases: Propane

Capacity: 140,000 Btu/Hr maximum

Blower: 3000 CFM at 0.5”wc total static pressure

Electrical: 115V, 60Hz, 1Ph, 6.3Amps

Min Amb Temp: 32 Degrees F

Max Amb Temp: 140 Degrees F

Min Gas Supply Press: 14” wc

Max Gas Supply Press: 2 psi

Weight: 198 lbs

SYSTEM DESCRIPTION

SPECIFICATIONS

ETL certified to ANSI Z83.7-2017 Gas-Fired Construction Heater

6

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS

Top 24 inches

Bottom 0 inches

Outlet side 36 inches

Inlet Side 24 inches

Front/Back 12 inches

5009709

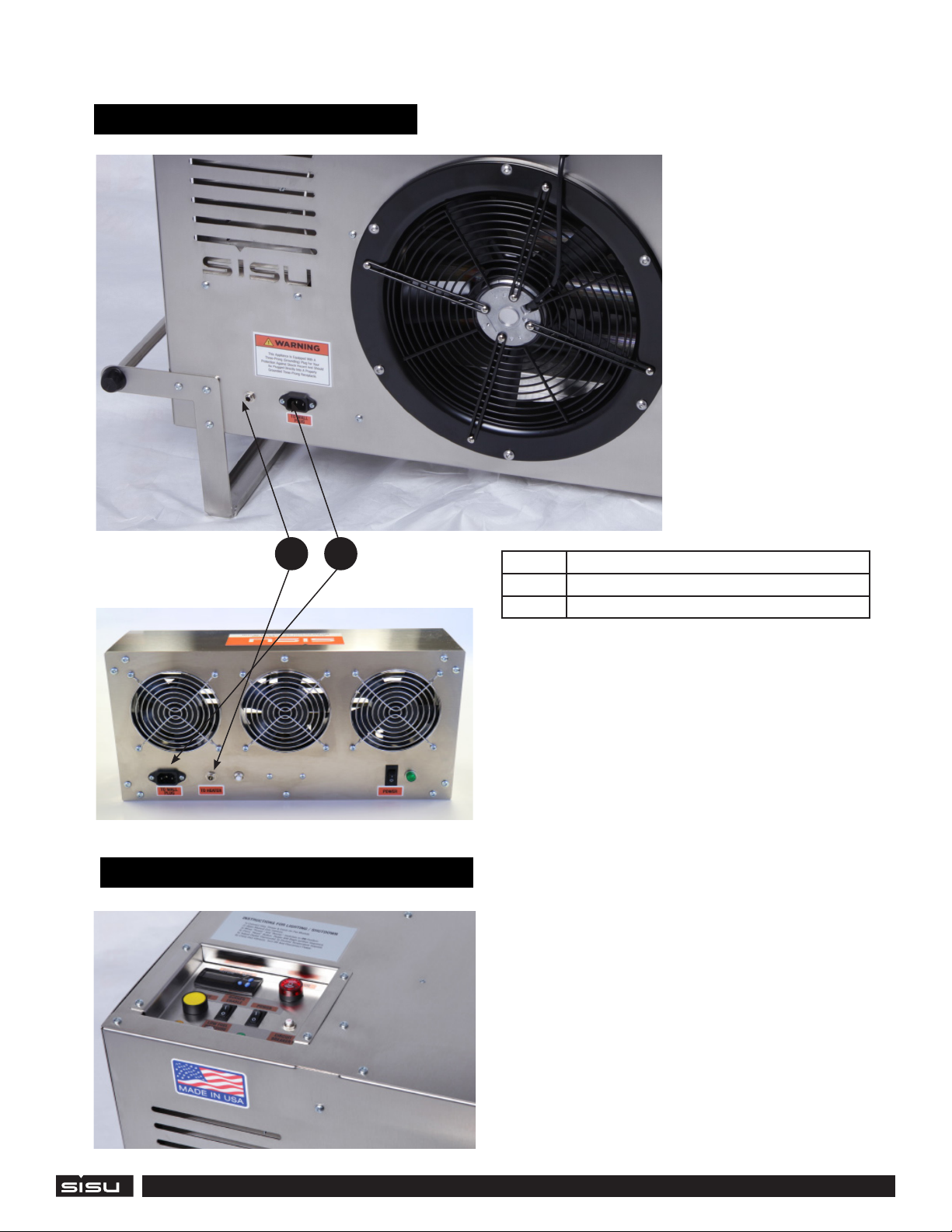

SYSTEM COMPONENTS

Heater Unit

LP Gas Hose Assembly

Fresh Air Fan Module

3-way LP Tank Manifold

7

Interconnect Cable

Unit shown in upright transport and storage position

Electrical Interface Locations

21

Operator Interface Location

ITEM DESCRIPTION

1 INTERCONNECT CABLE SOCKET

2 POWER ENTRY RECEPTACLE

8

USAGE INSTRUCTIONS

Visual Inspection and Placement

a. Check for any physical damage from shipping, storage, or installation that could

render heater unsafe or inoperable.

b. Locate heater on level ground near the target area and observe and obey all

minimum safe distances of the heater to the nearest combustible materials. (Heater

must be kept away from combustible solids, such as building materials, bedding,

walls, paper or cardboard a minimum distance as shown on Page 5, reproduced

below.

c. Fresh air fan module installation

i. The Fresh Air Module can be installed in an exterior door frame, or external

window opening.

ii. If securing the Fresh Air Fan Module to an exterior window, the module must

securely be attached in a manner that prevents the module from falling outside.

WARNING: Fresh Air Fan Module may fall out of the window if not securely

fastened to the window frame.

9

Unit shown in operating position

Top 24 inches

Bottom 0 inches

Outlet side 36 inches

Inlet Side 24 inches

Front/Back 12 inches

WARNING: Fresh air fan module must be installed to supply a continuous

stream of fresh ventilation air into the area being heated at all times during

heater operation. Failure to comply can result in death or serious bodily injury

from hazards of asphyxiation or carbon monoxide poisoning.

WARNING: For indoor use only. Adequate ventilation shall be provided in

accordance with OSHA 29 CFR 1926.154, Safety Requirements for Temporary and

Portable Space Heating Devices and Equipment, ANSI A10.10, National Fuel Gas Code,

ANSI Z223.1/NFPA 54, Liqueed Petroleum Gas Code, NFPA 58 or the Natural Gas and

Propane Installation Code, CAN B149.1, as applicable.as Co

a. Ensure all manual shut-o valves on the gas hose and LP tank manifold are in the

closed position. Verify the connections of all the gas ttings are tight.

b. A minimum of two (2) 20 lb LP cylinders manifolded together, or one (1) 100 lb LP

tank is required to operate heater. Storage, handling and use of propane must be

in accordance with all local codes and ordinances, as well as NFPA 58 and OSHA

regulations.

WARNING: Supply cylinders must be designed, fabricated, tested and marked

in accordance with regulations of the U.S. Department of Transportation, Canadian

Transport Commission or the Interstate Commerce Commission, and must be

arranged to provide for vapor withdrawal from the operating cylinder(s).

WARNING: Connection to Liquid Propane gas (LP) cylinder(s) must conform

with local codes or, in their absence, with the Standard for the Storage and

Handling of Liqueed Petroleum Gases, ANSI/NFPA 58 or the Natural Gas and

Propane Installation Code, CSA B149.1, as applicable.

c. Connect the LP cylinder(s) to the provided tank manifold/regulator assembly and

connect the provided gas hose assembly between the regulator and the heater gas

train by utilizing the supplied ½” quick connect ttings.

Gas Connection

USAGE INSTRUCTIONS

10

USAGE INSTRUCTIONS

WARNING: The tank manifold/regulator assembly and gas hose assembly

must be visually inspected prior to each use of the heater. If there is evidence of

excessive abrasion or wear, or any hose is cut, it must be replaced prior to the

heater being put into operation.

WARNING: The heater must be located at least 10 feet from any propane gas

container. The heater’s discharge air shall not be directed toward any propane gas

container within 20 feet. Do not store propane in the space where the heater is to

be operated.

WARNING: The gas supply hose assembly must be protected from trac,

building materials and contact with hot surfaces both during use and while in

storage.

d. Slowly open all the gas supply manual valve(s) and allow pressure to equalize.

e. Check all pipe connections, hose connections, manual valves, ttings, and adapters

upstream of the heater’s electronic gas control valve for gas leaks using approved

gas leak detectors. In the event a gas leak is detected, check the components

involved for cleanliness and further tighten as necessary to stop the leak. Do not

proceed until all leaks are eliminated.

WARNING: All gas leaks detected must be repaired before heater is placed

into service.

Electrical Connection

a. Plug the Interconnect Cable into the fresh air fan module and the heater.

b. Plug the electrical power cord into the Fresh Air Fan Module and Heater. Plug both

into a properly grounded 115V 60Hz outlet (15A or greater).

WARNING: This appliance is equipped with a three-prong (grounding) plug

for your protection against shock hazard and should be plugged directly into a

properly grounded three-prong receptacle.

11

USAGE INSTRUCTIONS

Heater Start-Up

a. Turn the fresh air fan module’s POWER switch to the “ON” position. The fresh air

fans will begin to run.

b. Turn the heater POWER switch to the “ON” position and the circulating fans will

begin to run. The CO monitor will begin its initialization cycle and the alarm will

sound for several minutes until the system is operational.

c. Press the RESET button to enable the burner ignition system. The yellow Reset

Light and Low Gas Pressure Light will go o.

d. Turn the BURNER ENABLE switch to the “ON” positon to allow the burner to re.

e. Heater will attempt ignition after a 30 second pre-purge cycle.

NOTE: It is normal for air to be trapped in the gas hose upon each initial startup.

The heater may require more than one trial for ignition before air is nally purged

from line and ignition takes place.

f. Adjust the digital operating thermostat to the desired room temperature using the

“up” and “down” arrows. See detailed thermostat operating instructions below.

12

i. Press and release SET. The current value of the temperature set point SP1 is

displayed. SP1 and led OUT1 blink.

ii. Press UP or DOWN to increase or decrease the value.

iii. Press SET to conrm the new value. The current value of temperature set point

SP2 is displayed. SP2 and led OUT2 blink.

iv. Press UP or DOWN to increase or decrease the value. Press SET to conrm the

new value and exit.

NOTE: Only SP1 is utilized at this time. SP1 may only be set between 120 and 140

degrees F. OUT1 led energizes when thermostat SP1 is satised. The on/o set

point dierential is 2 degrees F.

USAGE INSTRUCTIONS

Heater Shut-Down

a. Close the LP cylinder valve(s) and allow the heater to burn o any fuel gas

remaining in the gas supply hose.

b. Turn the BURNER ENABLE switch to the “OFF” position.

c. Allow the heater circulating fan to continue to run for several minutes to cool the

heater.

d. Turn the heater POWER switch to the “OFF” position.

e. Close the remaining manual shut-o valve(s) and disconnect the gas supply piping

from the heater’s external connection. Plug all gas supply inlets to prevent the

entry of debris.

f. Turn the fresh air fan module’s POWER switch to the “OFF” position.

g. Unplug the power cord from the wall outlet and both the Fresh Air fan Module and

Heater.

h. Unplug the Interconnect Cable Fresh Air fan Module and Heater. Remove fresh air

fan module return door or window to its normal position.

i. When the heater is stored indoors, the connection between the propane supply

cylinder(s) and the heater must be disconnected and the cylinder(s) removed

from the heater and stored in accordance with the Standard for the Storage and

Handling of Liqueed Petroleum Gases, ANSI/NFPA 58 or the Natural Gas and

Propane Installation Code, CSA B149.1, as applicable.

WARNING: The gas supply hose assembly must be protected from trac,

building materials and contact with hot surfaces both during use and while in

storage.

13

Heater Shut-Down

1. Power on the Fresh Air Fan Module. Fresh air fans run.

2. Power on the heater unit. Circulating fan runs.

3. Press the RESET button and turn on BURNER ENABLE switch on the heater unit.

4. Thermostat closes on call for heat providing 24 VAC to Ignition Control.

5. Draft Inducer is energized (@ line voltage).

6. Air Switch closes initiating pre-purge period.

7. At end of pre-purge period, Spark and Gas Valve are energized for an ignition trial

period.

8. Burners ignite and carryover.

9. Flame is detected by ame sensor and control operates in steady state heating

condition.

10.Burners continue to re until the thermostat is satised.

11.Thermostat opens interrupting power to control and closes fuel valve to stop ring.

12.The unit enters its post-purge period.

13.If ignition is not achieved within the trial period, the gas valve is shut o; the inducer

continues to run for a 30 second inter-purge period. Additional ignition trials follow

the specied sequence. If all trials (3) for ignition have occurred without proper

ignition and ame detection, the control locks out. See ash codes on Page 20.

14.Control may be brought out of lockout by cycling the BURNER ENABLE switch or

shutting o power for a minimum of 5 seconds.

15.If ame is lost once it has been established, the control will shut o the gas

supply within 2.0 seconds and enter the inter-purge period. Control will allow a

predetermined number of ame losses before lockout. (To restart, refer to step 13)

16.If ame sensor indicates presence of ame during purge period, when no ame

should be present, the inducer will remain energized, but the gas valve will remain

o until the cause of the “false ame” is removed.

14

Sequence of Operation Overview

USAGE INSTRUCTIONS

15

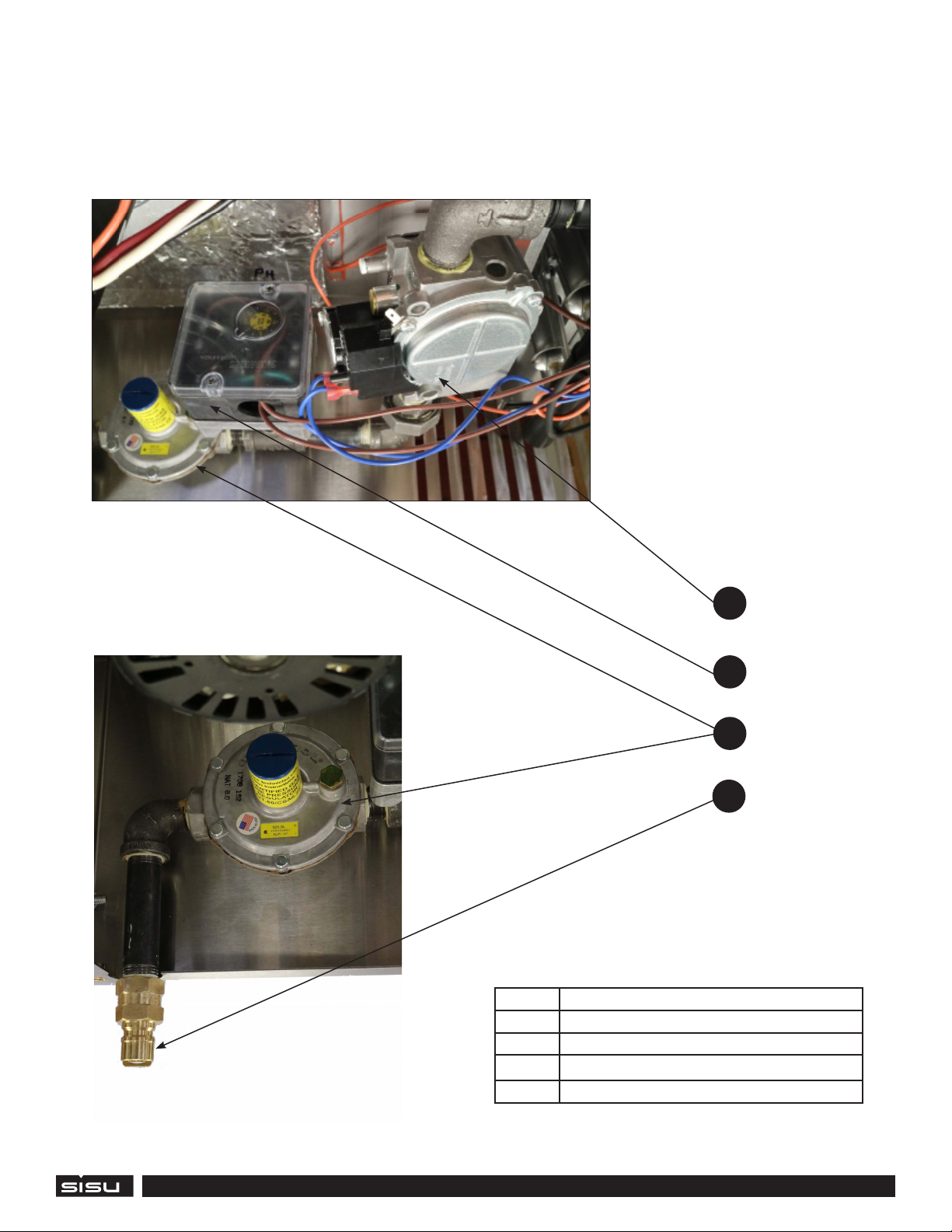

3

5

6

GAS TRAIN COMPONENTS

4

ITEM DESCRIPTION

3 GAS SHUT OFF VALVE

4 GAS PRESSURE SWITCH

5 APPLIANCE GAS REGULATOR

6 MALE QUICK CONNECT- 1/2” NPT

CO MONITOR

R1

TSH1

TILT

T2 T1

R2

12VDC SUPPLY

120VAC BUS

L N G L N G

L

N

GND

V-

V+

F-1

2A FUSE

297 SERIES

CONTROLS COMPONENTS

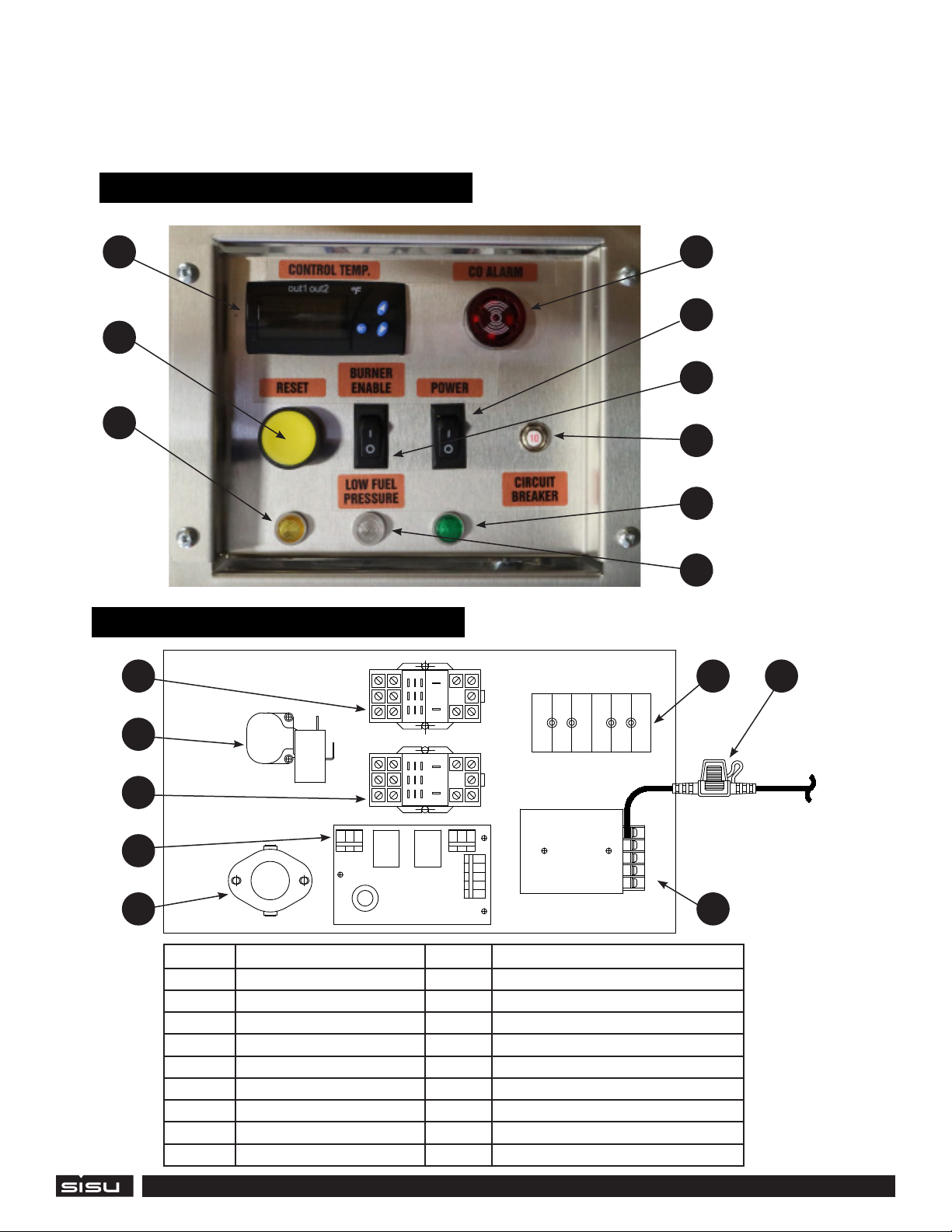

16

8

13

11

10

9

7

23

Operator Interface (Top of Heater)

Control Panel

15 12

14

22

21

20

16

17

ITEM DESCRIPTION ITEM DESCRIPTION

7 Digital Thermostat 16 Inlet Temperature Switch

8 CO Alarm Indicator 17 Tilt Switch

9 Power Switch 18 Manual Reset Relay

10 Burner Enable Switch 19 Low Fuel Pressure Relay

11 Heater Reset Button 20 CO Monitor

12 Circuit Breaker 21 Power Terminal Block

13 Power Indicator 22 Power Supply

14 Low Fuel Pressure Indicator 23 Fuse Holder

15 Reset Required Indicator

18

19

24 29

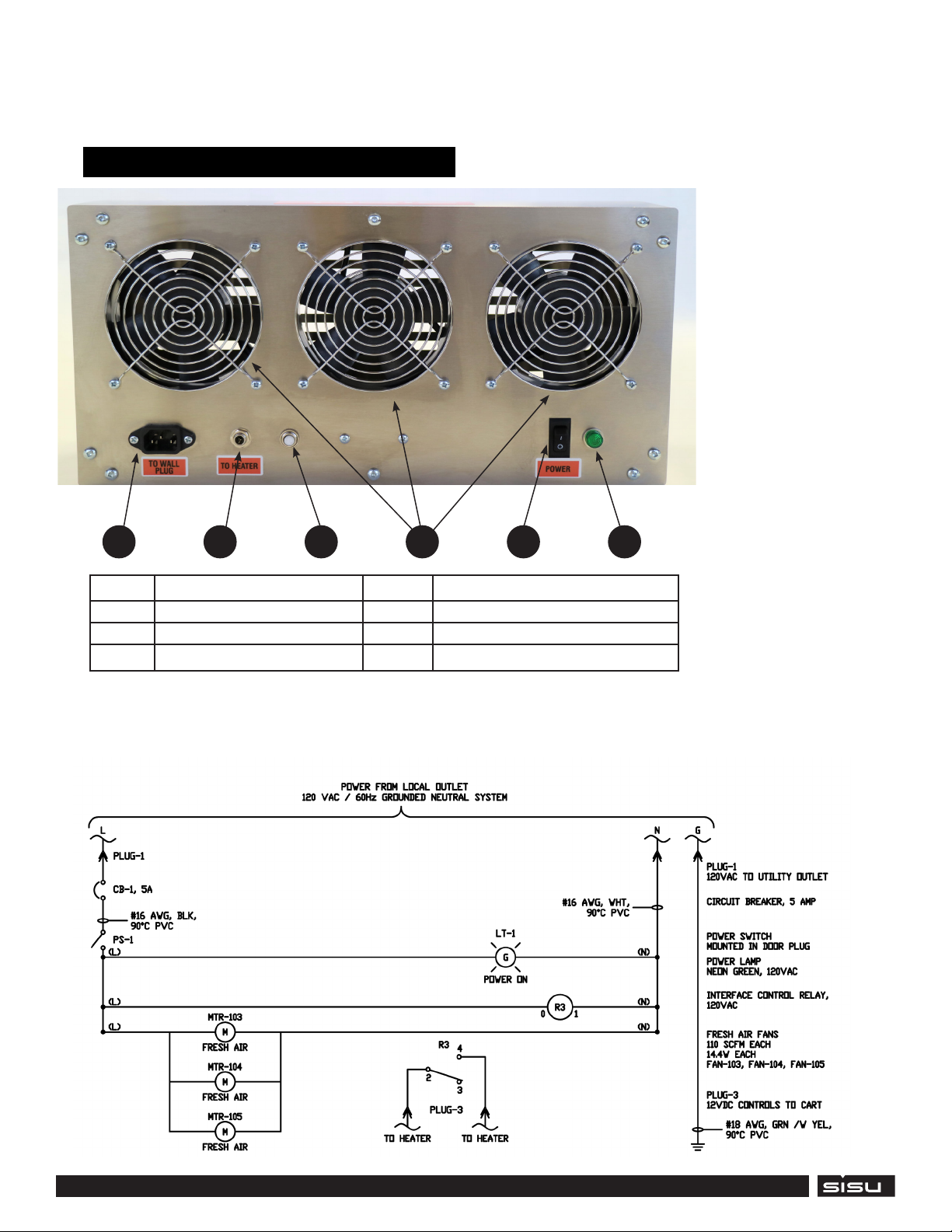

FRESH AIR MODULE WIRING DIAGRAM

17

ITEM DESCRIPTION ITEM DESCRIPTION

24 POWER ENTRY RECEPTACLE 27 FRESH AIR FANS

25 INTERCONNECT CABLE SOCKET 28 POWER SWITCH

26 CIRCUIT BREAKER 29 POWER INDICATOR

282725 26

Fresh Air Module Interface

CONTROLS COMPONENTS

18

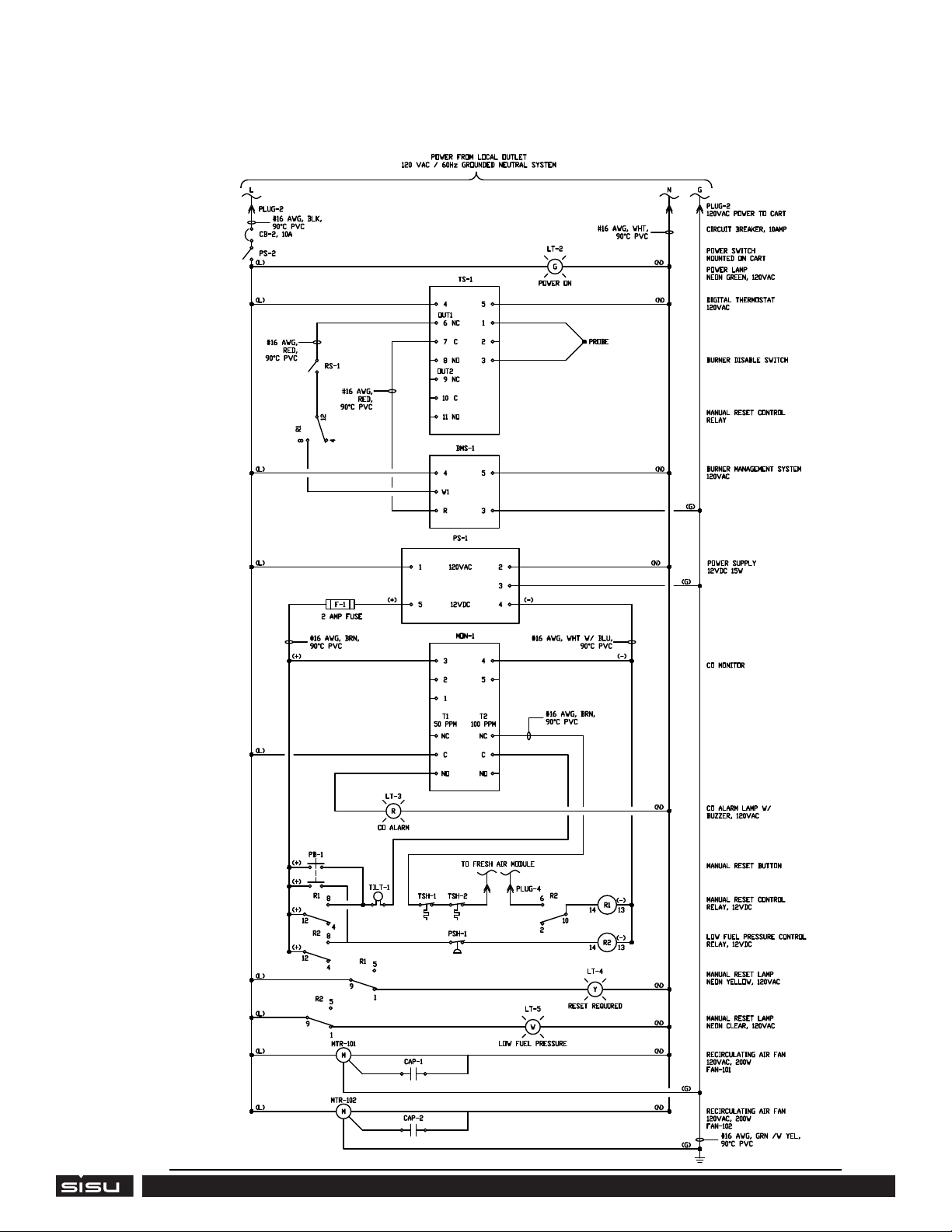

HEATER WIRING DIAGRAM

COMMERCIAL PRODUCTS

WIRING DIAGRAM

REPLACEMENT PARTS

19

P/N Location Description

21-003 Fresh Air Module Power Switch - Rocker Switch, Non Illuminated, SPST, On-O, Black, Panel, 20 A

21-014 Fresh Air Module Fresh Air Fan - Axial Fan, Terminal, Ball, 4715FS Series, 115 VAC, 119 mm, 38 mm, 110 cu.ft/min

21-027 Fresh Air Module Thermal Circuit Breaker, W57 Series, 250 VAC, 50 VDC, 5 A, 1 Pole, Panel

21-100 Fresh Air Module Indicator, Pnl-Mnt; Neon; Green; 0.500 In.; 105-125VAC; High Hat; 0.187 Terminals

04-200 Heater Axial Fan 398 dia. x 98.3 mm

19-002 Heater 2nd Stage LP Gas Regulator

19-010 Heater 1st Stage LP Gas Regulator

19-018 Heater Low gas pressure switch

21-001 Heater Alarm indicator

21-002 Heater Digital Operating Thermostat

21-003 Heater Power Switch - Rocker Switch, Non Illuminated, SPST, On-O, Black, Panel, 20 A

21-005 Heater 12VDC Power Supply

21-006 Heater CO Monitor

21-011 Heater 12VDC Fuse - Automotive Fuse, MINI 297 Series, 2 A, Fast Acting, 32 V, 10.9mm x 3.8mm x 8.8mm

21-013 Heater PTC Sensor for Operating Thermostat

21-016 Heater 15ft 16AWG Power Cord Cable w/ 3 Conductor PC Power Connector Socket (C13/5-15P) - Black

21-027 Heater Thermal Circuit Breaker, W57 Series, 5 A, 1 Pole, 50 VDC, 250 VAC, Panel

21-100 Heater Indicator, Pnl-Mnt; Neon; Green; 0.500 In.; 105-125VAC; High Hat; 0.187 Terminals

21-101 Heater Indicator, Pnl-Mnt; Neon; Amber; 0.500 In.; 105-125VAC; High Hat; 0.187 Terminals

21-104 Heater Indicator, Pnl-Mnt; Neon; Clear; 0.500 In; 105-125 VAC; Lens, High Hat; 0.187 Terminals

21-105 Heater Idec Relay, RH3B-U-DC12V

21-108 Heater Tilt Switch

21-109 Heater Recirculating Air Inlet Temperature Switch - 3L01-165

21-110 Heater Recirculating Air Outlet Temperature Switch - 3L01-300

21-111 Heater Fan Capacitor

Table of contents

Other Sisu Commercial Products Heater manuals

Popular Heater manuals by other brands

EUROM

EUROM E-Convect LCD in-control 351538 instruction manual

Dimplex

Dimplex DuoHeat Duo300i operating instructions

nedis

nedis HTOI30WT7 quick start guide

Russell Hobbs

Russell Hobbs RH09C Instructions and warranty

L.B. White

L.B. White GUARDIAN Smart Sense AD250 Owner's manual and instructions

wallas

wallas 270 Installation, operation and service instructions