SITE DRAINER SD 1500T User manual

INSTRUCTION MANUAL

SITE DRAINER PUMPS

MARCH 2020

WHAT IS THE SD 1500T?

Site Drainer’sTM SD 1500T is a Corrosion-resistant,

Stainless Steel, electric, submersible dewatering pump

system using patented technology to remove water

without clogging.

ü

It continues to perform when other pumps clog

and fail

ü

It has virtually limitless applications

ü

It is patented in USA, EU, Japan, China, Australia,

Canada, and Republic of South Africa; patents

pending in additional countries

ü

It is made in the USA

THE NON-CLOGGING SOLUTIONTM 2

HOW IT WORKS

§

Stainless Steel construction allows for use in

difficult environments

§

Canister surrounding the pump diffuses

water suction pressure over a large area

§

Fine mesh openings only allows particles

<6.35mm (.25 inch) to pass

§

Patented, free-flow design technology allows

water in, and leaves debris behind

THE NON-CLOGGING SOLUTIONTM 3

§

Has an external Tethered float for auto

On/Off and continuous worry-free

operation.

§

Optional burlap sack accessory

eliminates erosion concerns

§

Uses electric current –220 Volt @ 60Hz

§

Portable handle - 63 lbs.

SPECIFICATIONS

THE NON-CLOGGING SOLUTIONTM 4

Model

SD

1500T

Type

Submersible Pump

Impeller

Polyurethane

Discharge Size

2”

Maximum Pumping

Capacity

7200

gallons/hr

120

gallons/min

66

feet Head

Discharge

Height

Above Pumping

Level (Pump Head)

5’, 7200 gal/hr

10’,

7044 gal/hr

15’,

6786 gal/hr

20’,

6018 gal/hr

25’,

5280 gal/hr

30’,

5046 gal/hr

35’,

4800 gal/hr

40’,

4224 gal/hr

45’,

3852 gal/hr

50’, 342

6gal/hr

55’, 2652 gal/

hr

60’, 1680 gal/

hr

65’, 768 gal/

hr

66’, 0 gal/

hr

SPECIFICATIONS

Model

SD

1500T

Power

2

HP (1500 Watts)

Voltage

220

v

Power

cable length

33’ one

-piece molded rubber

Running Amps

20

amps (capacitor start)

Thermal

Overload Protection

Yes

Dimensions

16.5

”H, 10” D

Dry Net Weight

63.25

lbs. (including cord)

Temperature

34

- 104 F

Intermittent usage to 140 F (max. 5

min)

Safety

Pump

motor is UL and CE listed

THE NON-CLOGGING SOLUTIONTM 5

THINGS TO KNOW

§

Stainless Steel pump housing allows the pump to work in salt water,

corrosive and PH imbalanced environments

§

External variable float switches the pump On/Off automatically for worry-free

operation in changeable environments

§

304 Stainless Steel cage - 20 gauge thickness

§

2” male discharge port – at top of pump, accepts 2” NPT female hose

§

For greater versatility, can come with quick connect coupling

§

Powerful yet portable – 63 lbs

§

Durable carrying handle for easy transportation

§

Maneuverable into tight spaces, easily adjusted

§

Debris larger than .25” remains outside of canister, not affecting water flow

§

If grit, sand, or silt is present: Can’t discharge into storm sewers? – use

available fitted Burlap Sack to filter and comply with local de-watering

regulations

THE NON-CLOGGING SOLUTIONTM 6

THINGS TO KNOW

§

Pump and motor section form a pressure-tight encapsulated unit

§

Shaft is made of stainless steel

§

Impeller made of Polyurethane (a very tough and corrosion resistant plastic)

§

Watertight cable inlet connection chamber with wick-free cover and and built-in

strain relief

§

Water being pumped flows around the motor housing for optimum heat

dissipation

§

Motor is dynamically balanced with temperature monitor in the stator, which

switches off the pump in the case of overheating and switches on again

automatically after cooling down

§

Environmentally safe oil-free motor with food-grade lubricant

§

Air filled capacitor start motor

THE NON-CLOGGING SOLUTIONTM 7

SAFETY INFORMATION

§

Pump water only

§

Never use worn or damaged cables. Inspect for cuts in the insulation.

§

Never attempt to use the power cord as a lifting or lowering device for

the pump

§

Always lift the pump by it’s carrying handle or attached rope to carrying

handle

§

Always make sure electrical connections are properly grounded, GFCI is

always recommended

§

Do not allow a partially submerged pump to freeze. The expansion of

water freezing in the volute may crack the pump. If there is danger of the

pump being subjected to freezing temperatures, lift the pump from the

water and allow it to drain thoroughly

THE NON-CLOGGING SOLUTIONTM 8

WARNING

§

Do not operate near potentially explosive environment

§

Do not use in presence of flammable liquids or gases

§

Make sure product is properly grounded and provided with leakage breaker

to prevent users from serious electric shock

§

Always turn off the power before inspection, maintenance, and adjustment

§

Never attempt to change the settings of all protective devices without

consulting with licensed electrician

§

The product is designed for moving water. The following shall not be handled

for the pump and your safety:

•

Flammable, toxic, abrasive, crystallizing, and polymerizing liquid

•

Liquid chemical and food, alkaline and corrosive liquid

•

High temperature, high viscosity, and high solid matter content liquid

THE NON-CLOGGING SOLUTIONTM 9

WARNING

§

Always protect the electric plug or end of power cable from invasive

moisture

§

Never touch the piping or electrical connections while the pump is

running

§

Never touch the water while the pump is connected to electricity

§

Never force the pump into operation if it has been partially

disassembled

§

Do not run the pump without water, do not operate the pump out of

water or insufficient water

§

Do not use the pump if the power cable is damaged

THE NON-CLOGGING SOLUTIONTM 10

PRODUCT WARRANTY

Site Drainer’s sole obligation under this warranty shall be limited to the repair or

replacement of any parts that the Seller determines, at its discretion, to be defective.

The warranty is void if the damage is caused by the following factors:

§Improper installation

§Deficient maintenance

§Damage caused by improper use, or abuse

§Third party modifications made or attempted to alter the pump

§Normal wear and tear

§The pump has been used for purposes other than those for which it is intended

Site Drainer assumes no liability for the following:

§Bodily injuries

§Material damages

§Economic losses

THE NON-CLOGGING SOLUTIONTM 11

PUMP INSTALLATION

Before installation, check you local electrical and plumbing regulations. These

regulations are for your safety

Use the pump dimensional drawing to ensure proper installation

Make sure the cables are not kinked or nipped

Ensure that hoses and valves are suitable for the pressure of the pump. Place the

pump on a flat base and make sure it cannot fall over or sink

Make sure that the pump cannot rotate at the startup or during operation

Should there be any problems that occur during installation, please contact a Site

Drainer representative

DO NOT dismantle the product before/during installation without any authorized

instructions from Site Drainer

THE NON-CLOGGING SOLUTIONTM 12

MAINTENANCE AND INSPECTION

Regular checkups and preventive maintenance will ensure a more reliable and safe

operation. An initial inspection of the pump within 3 to 4 months after installation is

recommended. Subsequent inspections/maintenance can be carried out every 6

months

Always disconnect the pump from the power supply before inspecting the pump

Make sure that the pump cannot roll or fall over to injure people and damage

property

Rinse the pump thoroughly with clean water before working on the pump

The pump should not be activated if it is partially dismantled

Worn impellers often have very sharp edges. Be very careful when replacing them.

THE NON-CLOGGING SOLUTIONTM 13

EU REGULATORY NOTICE AND UL LISTING

The product complies with the following EU directives:

§2006/42/EC Machinery Directive

§2014/35/EU Low Voltage Directive

§2014/30/EU Electromagnetic Compatibility Directive

UL 778 listing by May 1, 2020

THE NON-CLOGGING SOLUTIONTM 14

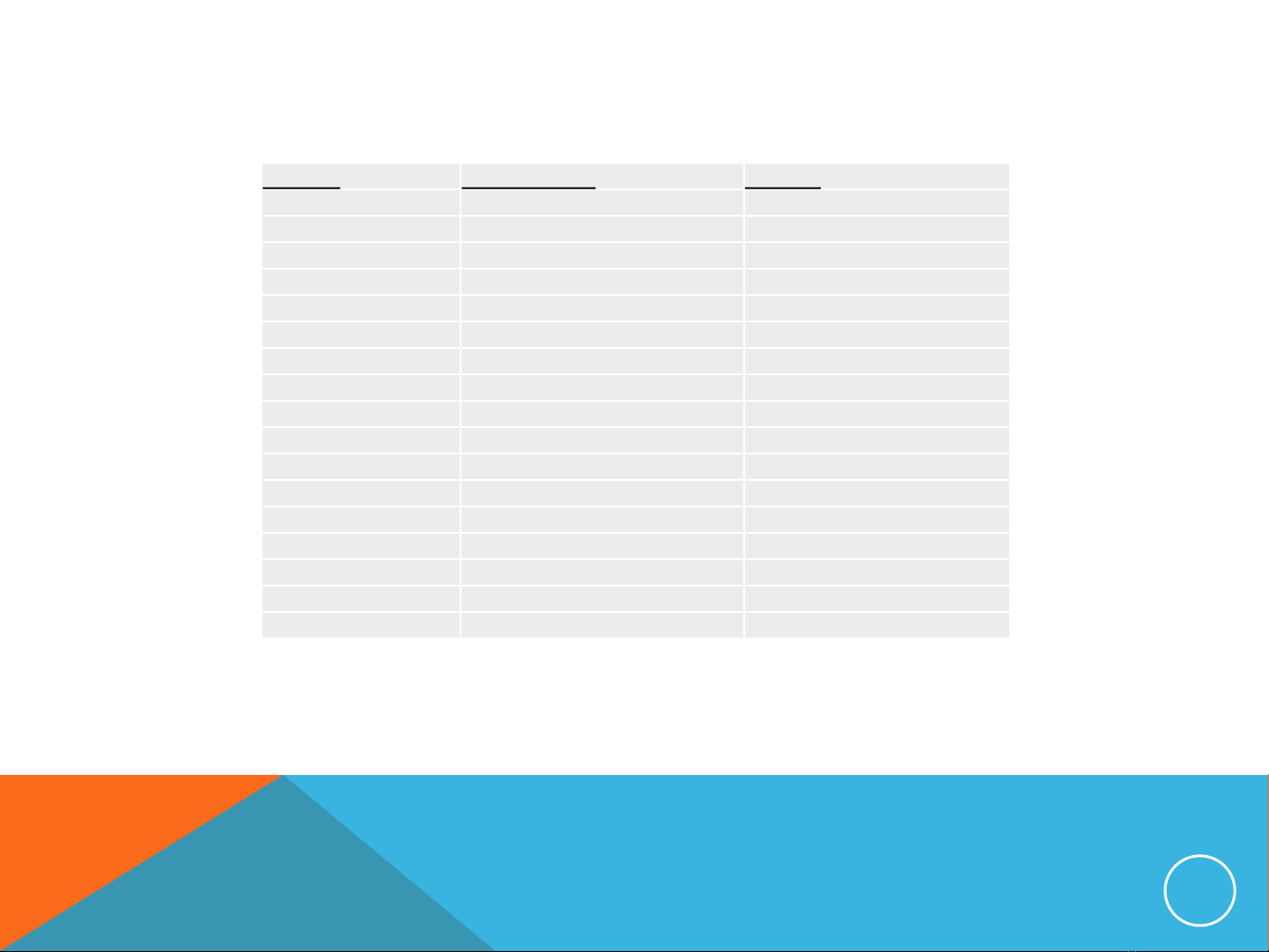

TROUBLESHOOTING

Problems

Possible Causes

Solutions

Pump fails to start

No electricity >

Check power source

Open circuit or poor connection >

Check if there is an open circuit

Impeller is clogged >

Inspect the impeller

Pump starts but stops

Impeller is clogged >

Inspect the impeller

immediately

Motor abnormal >

Repair the motor or replace

causing the motor

The pump is picking up too much

Place the pump on a concrete

protector to activate

sediment >

surface to prevent sediment

pickup

The pump's head and

Impeller is worn >

Replace impeller

pumping volume

Hose may be clogged >

Unclog hose, reduce # of bends

is low

Pump makes a noise

Motor bearings may be worn >

Replace bearings

or vibrates

THE NON-CLOGGING SOLUTIONTM 15

Check Valve with Quick Connect Burlap Sack Commercial Grade Discharge Hoses

1-1/2” Double Male Threaded

Aluminum Fittings

1-1/2” to 2” Threaded

Plastic Fittings 1-1/2” PVC Fittings 1-1/2” Quick Disconnect Fittings

OPTIONAL ACCESSORIES

THE NON-CLOGGING SOLUTIONTM 16

Table of contents

Other SITE DRAINER Water Pump manuals

Popular Water Pump manuals by other brands

Affetti Pumps

Affetti Pumps CGV-L user manual

Clarke

Clarke CSP1530 Operation & maintenance instructions

Grundfos

Grundfos LC 231 instructions

CPR

CPR CS100 user manual

Grundfos

Grundfos CR Series Installation and operating instructions

KIRLOSKAR

KIRLOSKAR IN 40/160 IL Instructions on Installation, Operation and Maintenance Manual