Sitron CF12 DC User manual

CF12 AC / CF12 DC

Thermal dispersion

Flow switch for Low Flow

USER’S GUIDE

Installation, Operation

03

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Models & Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CF12 Relay Status Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terms & Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

04

Introduction

The CF12 series of thermal flow switches is designed to monitor flow status of

liquids and gases and can also be used to detect level.

A chain of 8 LED's gives the user a visual indication of the flow status of the

switch.

There are two red LEDs that indicate whether or not the unit has detected flow,

a yellow LED to indicate the set point (for increasing or decreasing flows) and 5

green LEDs that indicate the amount of flow beyond the set point of the unit.

The CF12 also includes a di-chromatic (red/green) LED which shows the

switch point status of the unit.

The sensing element and connection of the CF12 are made with 316L S.S. and

can be coated when necessary .

The enclosure is offered in either glass filled nylon or aluminum. All models

can be ordered with a great variety of threaded, flange, or sanitary process

connections.

With the addition of a built in “T-Reducer” connection, the CF12 is now able to

detect flow rates between 3ml and 300ml per minute.

Characteristics

Simple to install.

Excellent low flow sensitivity.

No moving parts-maintenance free reliabity.

Maximum working pressure of 1450 PSI (100 bar).

Fast response time for flow or level (Adjustable from 1-10 seconds).

Thermal dispersion

Flow switch for Low Flow

05

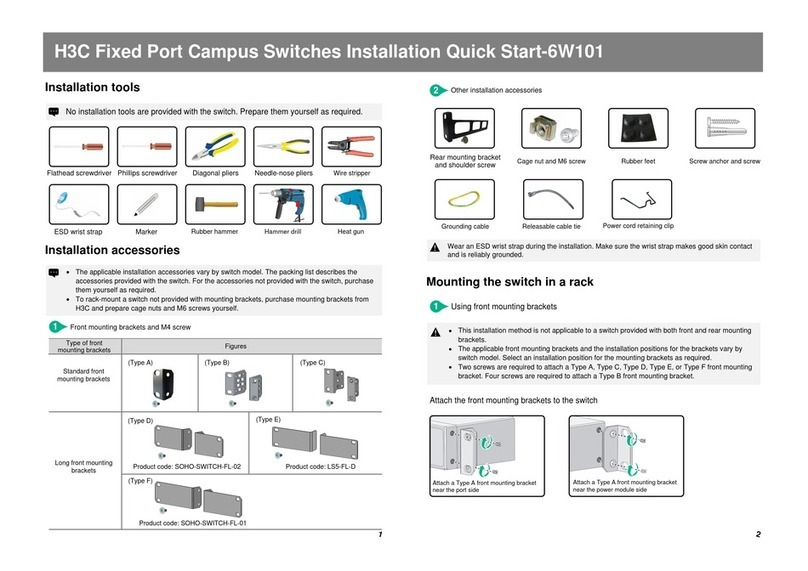

Models & Dimensions

Mounting Options

126mm

130mm

130mm

89mm

76mm

89mm

Nylon-N1 Aluminum-G1 Aluminum-G2

Body Dimension (standard)

6

Hex. 1 1/2"

BSP/ NPT female

49

110

More connections upon request

06

Electrical Connections

Standard Connection w/

2 meters of Cable

+

_

Bargraph (B1)

Bargraph (B1)

Adjust (P1)

Adjust (P1)

Central LED Status (L1)

(Red/Green)

Central LED Status (L1)

(Red/Green)

Adjust

CF 12 DC

Adjust

Red

White (NC)

Green and

Yellow

or solid Yellow

Blue (common)

Green (NO)

Black

Power

Supply

Contacts

Ground

CF 12 AC

2000mm

1

2

Connector

12mm

NO or NC

contact

2000mm

1

2

Connector

12mm

+

++

_

__

NO or NC

contact

Nylon Enclosure (N1)

M12 Connector Optional

M12 Connector Optional

1 - Power Supply (+)

2 - Power Supply (-)

3 - Ground

4 - NO Contact

5 - Common

6 - NC Contact

1 - Power Supply

2 - Power Supply

3 - NO Contact

4 - NC Contact

5 - Common

1 - Power Supply (+)

2 - Power Supply (-)

3 - NO Contact

4 - NC Contact

5 - Common

1

1

5

5

2

2

3

3

4

4

07

Electrical Connections

Aluminium Enclosure (G1/G2)

2SPDT

Bargraph (B1)

Flow 100 %0

+

-

1 2 345 6 7 9

8

CF12

+

_

1 2 3 4 5 6

Adjust

1SPDT

Bargraph (B1)

G2

G1

1 - Power Supply (+)

2 - Power Supply (-)

3 - Ground

4 - NO Contact

5 - Common

6 - NC Contact

(P1) - Set Point Potentiometer Adjust

(B1) - 8 LED´s Bargraph: Red LED

Yellow LED

Green LED

(L1) - Central LED - Green: With flow

Red: No flow

1 - Power Supply (+)

2 - Power Supply (-)

3 - Ground

4 - NO Contact

5 - Common

6 - NC Contact

7 - NO Contact

8 - Common

9 - NC Contact

Central LED Status (L1)

Red/Green

Adjust (P1)

Central LED Status (L1)

Red/Green

Adjust (P1)

( )

( )

( )

( )

08

Sentido Fluxo

Sentido Fluxo

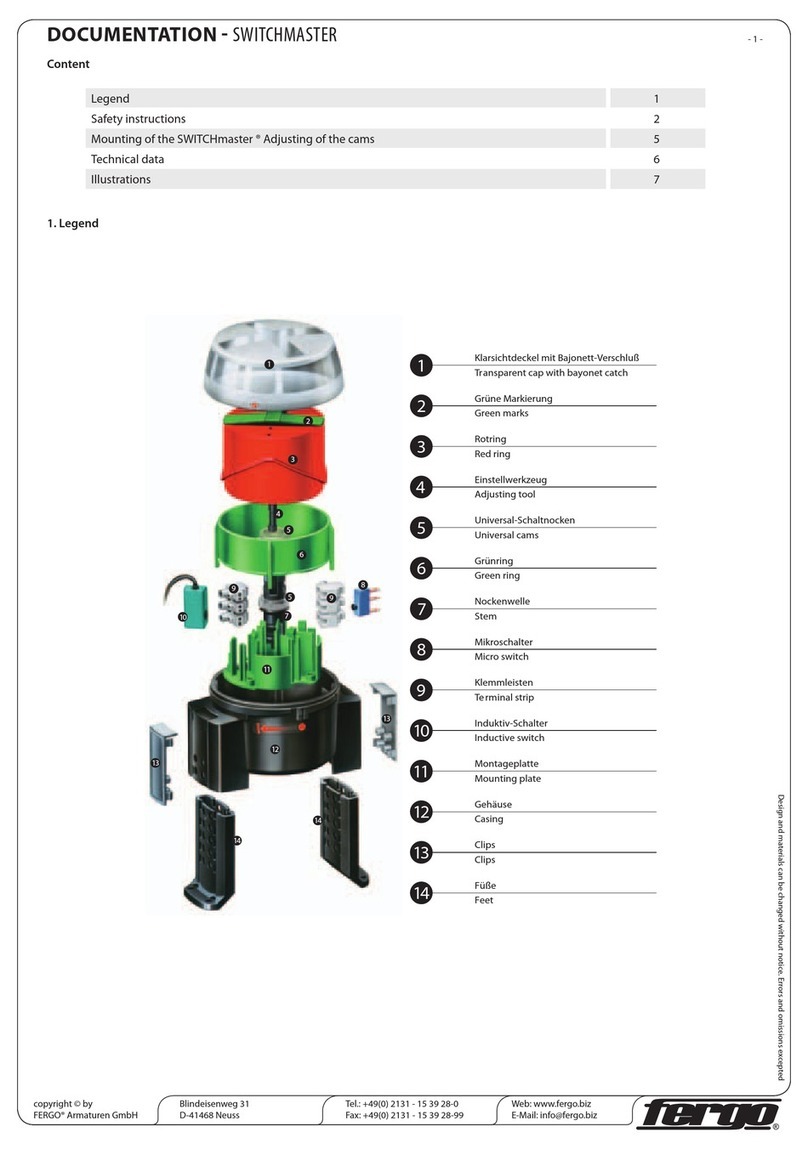

CF12 Relay Status Guide

Application Condition

No Flow

Flow

LED Status

RED

GREEN

Set Point

OFF

ON

CF12 SPDT

Status

NO (4) NC (6)

C (5)

C (5)

NO (4) NC (6)

09

Installation

Fig. 3

Pump

Fig. 2

Fig. 1

5xØ

Flow direction

1/2 meter

Sentido Fluxo

Fig. 4

Checks:

The flow switch must be installed so that the flow

direction follow the flow direction description tag.

1) Its recommended that the flow switch is

installed with a distance of ½ a meter of the pipe

bent where the flow enters and 5x times the

diameter of the pipe where the flow exits, enabling

it to have an accurate reading (Fig. 1).

Verify that the installation point isn’t near any

connections, valves, elbows or anything similar,

this can cause errors in the reading of the probe

due to turbulence in the pipe.

2) It is important that the flow switch is not installed

at the highest point in the pipe run or in a location

where there is the risk of air accumulating in the

pipe. Keep in mind that the ideal mounting

location is where the pipe is always full. This will

ensure that the switch is always immersed in the

flow. (Fig. 2 correct)

3) In pipes that have pressure pumps or retention

valves, we recommend that the probe be installed

before the pump due to the fact that it will have

less turbulence. (Fig. 3)

4) Confirm that the wire connections are correct

and that the available power supply is compatible

with the CF12 unit.

5) Verify that the operating pressure and

temperature of the process corresponds to the

operating parameters of the CF12 unit.

Do not expose the CF12 to excessive heat and

rain, avoid damaging the performance by making

adequate protection (Fig.4)

Flow direction

Flow direction

10

Calibration

Adjust

Adjust

0% 100%

BARGRAPH Lights ON

Set Point

0% 100%

BARGRAPH Lights Off

Set Point

Led Status

Red

Led Status

Blinking

To Start:

1 - Remove the enclosure lid (Note: the screws are self-retaining)

2 - Start the power supply and wait 5 minutes until the CF12 is active and has reached a

stable point within the medium.

3 - Let the regular or desired flow reach its point of normal operation.

Calibration for Flow / No Flow:

1 - Set the flow rate at the normal range of operation.

2 - Turn the potentiometer counter-clockwise until the central LED turns red.

3 - With the central LED red, turn the potentiometer clockwise until the central LED

changes to a blinking green state.

4 - Continue to turn the potentiometer clockwise until the first 3 green LEDs in the bar

graph turn on.

Set Point Adjustment:

The flow switch can be adjusted to indicate either increasing flow, or decreasing flow at

a specific set point within 3ml to 300ml/m.

It is important to determine the specific set point at which the flow switch should activate

or de-activate.

11

Technical Specifications

CF12DC / AC

Flow 100 %0

+

-

1 2 345 6 7 9

8

1 2 3 4 5 6

Repeatability

Application

Operating Voltage

Current Consumption

Electrical Connection

Operating Temperature

Gradient Temperature

Set Point Range

Output

Flow Rate Indication

Max Pressure

Accuracy

Response Time

Enclosure Material

Wetted Material

Class Protection

Process Connection

+/- 10%

1 to 10s

15ºC/min

Liquid: 3ml to 300ml/min

+/- 1% setpoint

Cable gland w/ 2000mm cable, M12 connector or ½” NPT

Red led - flow is below setpoint

Yellow led - flow is at setpoint

Green led - flow is above setpoint

1450 PSI (100 Bar)

IP 65 - Nylon (N1)

IP 66 - Aluminum (G1/G2)

Glass filled nylon / Aluminum painted

316L Stainless Steel

1/4" to 1/2” BSP or NPT (others upon request)

14 to 176º F (-10 to 80ºC)

Low Flow monitor for liquids

DC: 24 VDC (+/-10%)

AC: 85-264Vac (50/60hz) & 125Vdc

+/- 100mA

Relay (SPDT) 5A - 250Vac (N1/G1)

2 SPDT 5A-250VAC - G2

N1 Enclosure

G2 Enclosure

G1 Enclosure

12

Order Code

CF12AC

CF12DC

MODEL

F12

SIZE CONNECTION

T1

T1F

T2

T2F

1/4" (Female)

3/8" (Male)

3/8" (Female)

B

N

BSP

NPT

OTHER - SPECIFY

LT Standard

HOUSING

SC

N1

NB

NE

NT

G1

G2

NO ENCLOSURE

SMALL NYLON

N1 SHIELDED

N1 Encapsulated

NB + NE

SMALL ALUMINUM (1SPDT) 5A-250Vac

LARGE ALUMINUM (2SPDT) 5A-250Vac

0

1

2

3

4

5

6

7

8

9

C

J

M

P

ELECTRICAL CONNECTION

NONE

1/2" BSP (N1/G1/G2)

CABLE GLAND W/ 1/2" BSP (N1)

CABLE GLAND W/ 1/2" BSP - 2m CABLE (N1)

3/4" BSP (G1)

CABLE GLAND W/ 3/4" BSP (G1)

1/2" NPT (N1/G1/G2)

CABLE GLAND W/ 1/2" NPT

CABLE GLAND W/ 1/2" NPT- 2m CABLE (N1/G1/G2)

3/4" NPT (G1)

CABLE GLAND W/ 3/4" NPT (G1)

M15.8 Connector (9Pins) (G2/G1)

M12 Connector (4 or 5 pins for CF12AC) (N1)

M20 threaded (N1/G1/G2)

PROCESS CONNECTION TYPE

INSERTION LENGTH

SNONE

COATING

CF12DC T1 NSL50 N1 7

X

RANGE

3ml/min to 300ml/min

F1

F1

T3

T3F

1/4" (Male)

1/2" (Male)

1/2" (Female)

LT

13

Fault

Relay does not

change state.

LED off, no power

LED doesn’t change color

Check the installation

(insertion length)

Verify the calibration

Check power supply

Cause Solution

Radio frequency

interference

Sensor is potentialy

defective

Flow switch

turns on or

off suddenly

Relay remains

closed

Use armored cable

and shielded housing

Contact Sitron or your

local representative for

further instruction

Trouble Shooting

14

Terms & Conditions

Sitron's TERMS & CONDITIONS

Design: Sitron reserves the right to make any alterations or changes necessary to

improve the Products, correct defects or to make the Products safer, without prior notice

or consent by Buyer.

Pricing: All stipulated amounts shall be in US dollars and all prices quoted are valid for

thirty (30) days from date of offer, unless otherwise stated.

Safety and Instructions: The Buyer ensures that it and all its representatives and agents

will observe all safety and technical instructions in Sitron's operating manuals, catalogs

or other directions or instructions (either written or verbal).

Delivery and Freight: All goods are sold FOB point of shipment, Brasil. Transportation

to the destination is the Buyer's responsibility and Buyer alone shall bear the cost of

freight, optional or other shipping requirements, and or insurance. Sitron shall not be

liable for loss or damage to the Products after said Products are delivered to or received

by the shipper/carrier, and all risk of damage or loss shall immediately pass to Buyer.

Receiving, unloading and storing of Products will be the responsibility of the Buyer.

Buyer also accepts that courier may choose to return Products to Sitron if any local

taxes or duties are not paid by Buyer at point of delivery. Buyer must make any and all

claims for corrections or deductions within ten days of the delivery of the Products.

Shipment Delays: Sitron has no control over the length of time shipments may be held

at customs, etc. For this reason, Sitron commits only to a "shipment date", not a

"delivery date". Buyer shall not hold Sitron liable for claims resulting from delay in

shipment except in cases where these terms are accepted in writing by Sitron.

Acceptance of delivery of Products by Buyer shall constitute a waiver of all claims for

delay.

Partial Deliveries: While Sitron strives to deliver all orders on time and complete,

Sitron reserves the right to make partial deliveries when necessary.

Changes: Any changes initiated by the Buyer which affects the products specifications;

quantities ordered; delivery schedule; method of shipment or packing; or delivery

location, must be made in writing and signed by both parties.

In this case, Sitron reserves the right to adjust the pricing and or delivery of the order,

which will be agreed to by both parties before further work is performed on the order.

Any such requests will be priced according to the scope of changes and the status of the

current order. Customer must sign and return or acknowledge approval of drawings

along with any Purchase Order. If approval drawings are not returned with order, the

delivery date may be held or pushed back until Customer has acknowledged approval.

Cancellation: Any cancellation of the Contract by the Buyer shall be effective only if

made in writing and accepted, in writing by the Sitron. In such a case, Sitron is entitled

to reasonable cancellation charges including but not limited to labor, material and other

related expenses.

15

Termination Fee Schedule:

Order entered but not released for manufacturing 10%

Order in any stage of production 75%

Order complete and ready for shipment 100%

Warranty: Sitron warrants its product against manufacturing defects in material and

workmanship, when installed in applications approved by Sitron, for a period of one year

from the date of original shipment, unless otherwise stated in writing by Sitron.

Sitron is not responsible for damage to Sitron's Products or other equipment or products

because of improper installation or misapplication of the Products by Buyer. Installation

or startup of Sitron's equipment must be performed under the guidelines set forth in

Sitron's instruction manuals, wiring diagrams, etc., or performed under the direct

supervision of Sitron's field technicians or Sitron's authorized Sales Representatives, in

order to be covered by Sitron's warranty.

Sitron shall be under no liability in respect to any defect from fair wear and tear, willful

damage, negligence, abnormal working conditions, failure to follow Sitron's instructions

(whether written or verbal), misuse, modification or alteration or attempted repair of the

Goods without Sitron's approval.

Sitron shall not be liable under the above warranty (or any other warranty, condition or

guarantee) if the total price for the Products or the payment of Services rendered has not

been paid by the due date for payment.

The Buyer must make all tools, resources or personnel available to help Sitron to

diagnose the defect without any back charge. In absence of Buyer's cooperation in this

regard, there shall be no liability under the above Warranty.

Sitron's liability under this warranty shall be limited to repair or replacement at Sitron's

option of such defective Products, FOB factory, upon proof of defect satisfactory to

Sitron. Warranty does not include transport.

Return Goods: No goods may be returned without Sitron's permission and an RMA

number. Sitron assumes no responsibility for return shipments made without

permission. In issuing credit for such shipments, Sitron reserves the right to charge a

restocking fee dependent on Sitron's ability to recondition and resell the returned

equipment.

Insurance: The responsibility for insuring the Goods after the risk in them has passed to

the Buyer shall be that of the Buyer.

Confidential Information: All drawings, specifications, and technical information

provided by either Buyer or Sitron shall be treated as confidential and shall not be

disclosed to anyone other than those who require it as part of the fulfillment of the order.

Buyer agrees that the designs and/or any other related material provided are and

remain Sitron's exclusive property and that the Buyer acquires no right, title or interest to

this intellectual property, whether in whole or in part.

Errors: Sitron reserves the right to correct all typographical or clerical errors or

omissions, in its prices or specifications.

Terms & Conditions

Sitron - Brasil

R. Baronesa de Itu, 83

São Paulo - SP - 01231-001

T.: (5511) 3825-2111

F.: (5511) 3825-2171

www.sitron.com

BRASIL: [email protected]

Sitron - USA

1800 Prime Place

Hauppauge, NY 11788

PH: 516-935-8001

FX: 800-516-1656

08/18_rev 0

This manual suits for next models

1

Table of contents

Popular Switch manuals by other brands

3Com

3Com Switch 5500G-EI PWR 48-Port Quick reference guide

Compaq

Compaq Netelligent 1005 user guide

Moxa Technologies

Moxa Technologies EtherDevice EDS-205 installation guide

Alcatel-Lucent

Alcatel-Lucent OmniSwitch 6450-P10S Hardware user's guide

FM Systems

FM Systems VLS771-2 installation manual

Exsys

Exsys EX-1163HMS-WT manual