1.2 SPECIFICATIONS

Range of action, m, range "10-100" 10...100

range "1-15" 1...15

Settable thresholds, dB 1, 2, 3

(approximately 15, 30 and 45% absorption by smoke)

Response time in the mode "ALARM (FIRE)", s, no more than 30

Readiness time, s, no more than 10

Power disruption time to reset, s, not less than 1

Operating voltage of transmitter and receiver, VDC 18...30

The transmitter and receiver are insensitive to the polarity of the supply voltage

Operating current of transmitter or receiver, mA, up to 8

Receiver current in mode "ALARM", mA, not less than 18

The maximum switched voltage by contacts

“ALARM”, "FAULT", V 100

The maximum switched current by contacts

“ALARM”, "FAULT", A 0.15

Maximum resistance of closed contacts of relay “FAULT", Ohm 30

Operating distance of remote control, m from 1 to 20

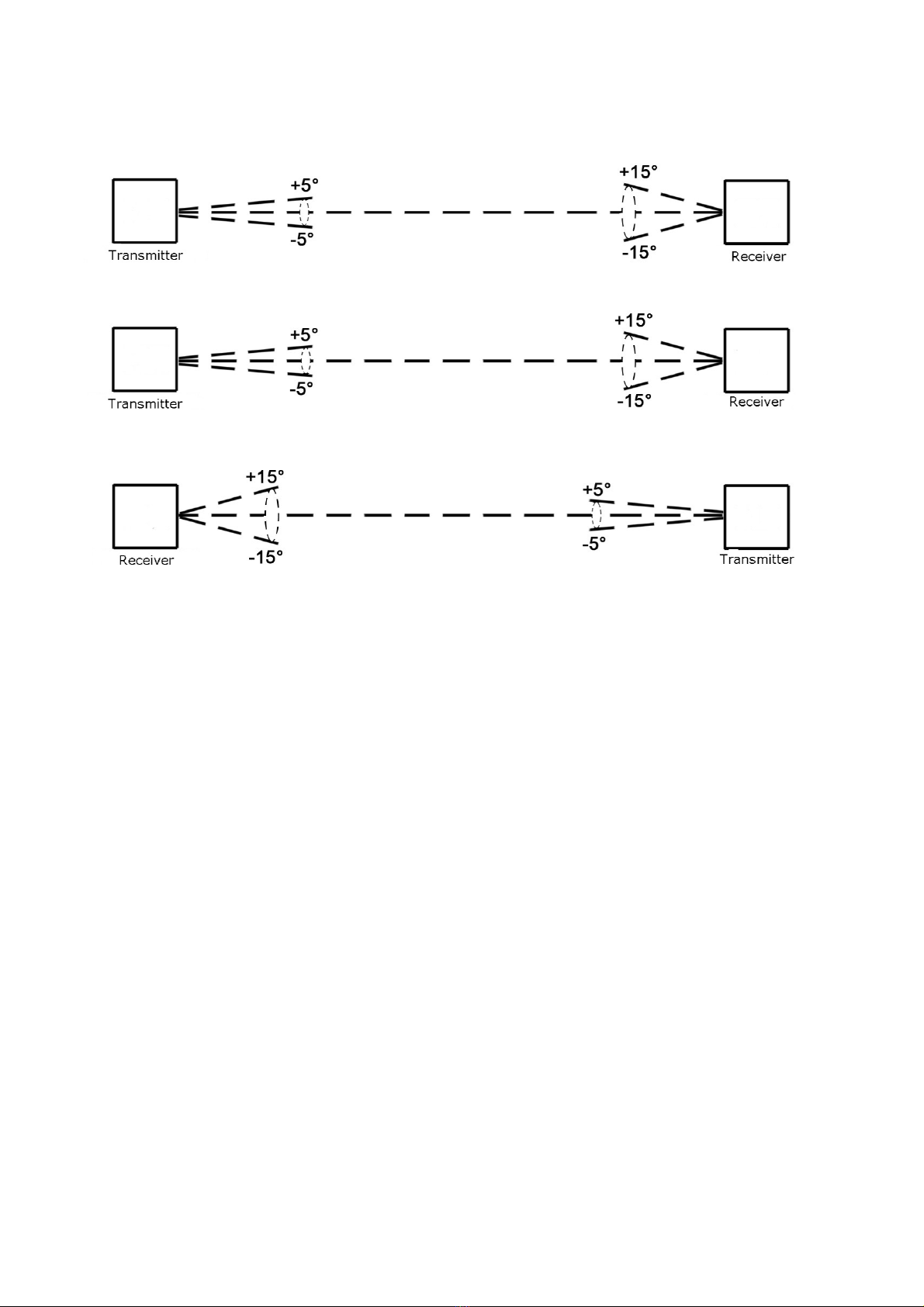

The deviation of the optical axis of the transmitter

relative to optical axis of the transmitter-receiver, degrees, not more than

during installation ±5

during operation ±2

The deviation of the optical axis of the receiver

relative to optical axis of the transmitter-receiver, degrees, not more than

during installation ±15

during operation ±2

Operating conditions of the transmitter, receiver:

Ambient air temperature, degrees Celsius from minus 5 to 40

Relative air humidity at 25°C, %, up to 98

Atmospheric pressure of air, kPa 84...107

Degree of protection of the detector and receiver shell IP40

Working position any

Working hours round-the-clock continuous

Service life, years 10