SKETCHNBUILD SNB-K2A User manual

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

1

6/2016

SNB-K2A AUTOMATIC

EDGE BANDER

MANUAL

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

2

6/2016

CONTENTS

1. SAFETY………………………………………………………………………………………………….……………….….3

2. SPECIFICATIONS & FEATURES……………………………………..………………………………………….…4

3. MACHINE PARTS……………………………………………………………..…………………………………….….6

4. TRANSPORTATION & INSTALLATION (WIRING)….………………..……………………………….…...8

5. OPERATION…………………………………………………………………………………………………….………..8

6. MAINTENANCE………………………………………………………………….…………………………………...17

7. PARTS LIST………………………………………………………………………………………………………………18

CAUTION: Read these instructions carefully before turning on the machine.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

3

6/2016

1. SAFETY

1. KEEP GUARDS IN PLACE and in working order

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of checking to see that

keys and adjusting wrenches are removed from the machine before turning on.

3. KEEP WORK AREA CLEAN. Cluttered work areas invite accidents.

4. DO NOT USE IN HAZARDOUS OR DANGEROUS ENVIRONMENTS. Do no operate

machine in damp, wet locations or where any flammable or noxious fumes may

exist. Keep work area well lit.

5. KEEP CHILDREN, VISITORS and PETS AWAY. All children, visitors and pets should be

kept away and at a safe distance from work area. Make workshop child or pet proof

with padlocks, master switches and by removing starter keys.

6. DO NOT FORCE MACHINE. Machine will work safer at the rate in which it is designed

when not forced to operate.

7. USE THE RIGHT EQUIPMENT. Do not force machine or attachment to do a job for

which it is not designed.

8. WEAR PROPER SAFETY APPAREL. Do not wear loose clothing, gloves, neckties, rings,

bracelets or other jewelry which may get caught in moving parts. Non-slip footwear

is recommended. Wear protective hair covering.

9. ALWAYS USE SAFETY GLASSES. Also use a face or dust mask if work area is dusty.

Everyday eyeglasses only have impact resist lenses and they are NOT safety glasses.

10. SECURE WORK. Use clamps or a vise to hold work when working. It is safer than

using your hands and frees both hands to operate the machine.

11. DO NOT OVERREACH. Keep proper footing and balance at all times.

12. MAINTAIN MACHINE WITH CARE. Keep parts sharp and clean for safer performance.

Follow instructions for lubricating and changing accessories.

13. USE RECOMMENDED ACCESSORIES/PARTS. Use of improper accessories may cause

risk of injury.

14. RISK OF UNINTENTIONAL START. Always disconnect from power source before

adjusting or performing any maintenance. Make sure the switch is in the OFF

position before reconnecting.

15. KICKBACK. Many woodworking machines can “kickback” the work piece towards the

operator. Know what conditions can create “kickback” and learn how to avoid them.

16. DMAGED PARTS. Before further use of a part, guard or other part that is damaged,

check carefully to determine if it is able to operate properly and perform its

intended function. Check for alignment of moving parts, binding of moving parts,

broken parts, mounting or any other conditions that may affect its operation. A part

that is damaged should be replaced.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

4

6/2016

17. NEVER LEAVE THE MACHINE RUNNING OR UNATTENDED. TURN POWER OFF. Do not

leave the machine until it comes to a complete stop.

18. NEVER OPERATE THE MACHINE WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS

OR ALCOHOL. Full mental alertness is required at all times when running a machine.

19. NEVER ALLOW UNSUPERVISED OR UNTRAINED PERSONNEL TO OPERATE THE

MACHINE. Make sure any instructions given in regards to the operation of the

machine is safe and clearly understood.

2. SPECIFICATIONS & FEATURES

The SNB-K2A Automatic Edge bander is able to handle an array of material from PVC, ABS,

laminates, wood tape, and wood strips with thickness ranges from 0.5mm–3.0mm thick on

panels ranging anywhere from 14 - 40mm thick. For tapes up to 3 mm and plastic laminate

strips.

Features:

(a) Easy to adjust, high quality finishing

(b) Simultaneous adjustment for tape thickness, guide and gluing roller by a

single meter.

(c) Automatic feeder for tape rolls and end cutting system.

(d) Trimming unit at 9000 R/min.

(e) Automatic temperature control by the machine during all the working

process.

(f) Panel feeder with wide multi-layered belt.

(g) Front telescopic table extension with rollers.

Specifications:

(a) Motor Power: 3HP

(b) Power Source: 3Phase / 220v / 60Hz

(c) Minimum panel length –11 in

(d) Minimum panel width –3 ½ in

(e) Minimum edge thickness –0.4mm

(f) Maximum edge thickness –3mm

(g) Minimum panel thickness –3/8 in

(h) Maximum panel thickness –1 ¾ in

(i) Minimum Edge width –7/16 in

(j) Maximum edge width –1 7/8 in

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

5

6/2016

(k) Dust Extraction Port –4”

(l) Air pressure - 0.6Mpa

(m)Feeding Speed –6.4m/min

(n) Buffing Motor –0.2 HP

(o) End Cutting Motor –0.16 HP

(p) Glue Tank Motor –0.2 HP

(q) Edge Seal Motor –0.2 HP

(r) Trimmer Speed –11000r/min

(s) Conveyor Belt Speed –6m/min

(t) Roller holder capacity –24 in diameter

(u) Tank capacity - 2.2 Pounds

(v) Work temperature - 347° F- 410° F

(w) Feeder motor power: - 0 .53 HP

(x) Trimmer motor power - 0.2 HP

(y) Gluing motor power -0.05 HP

(z) Total power –3.5HP

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

6

6/2016

1

2

9

13

14

11

12

Fig. 2

5

6

7

8

10

4

3

Fig. 1

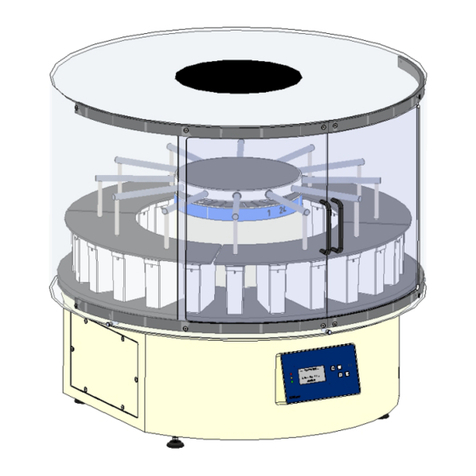

3. MACHINE PARTS

INSIDE & FRONT

1) Conveyor Belt 8) Edge Strip Conveyor

2) Conveyor Belt Height Setting 9) Edge Strip Support Table

3) Buffing Components 10) Edge Strip Conveyor and Cutter Switch

4) Trimming Components 11) Control Panel

5) End Tracking Components 12) Horizontal Expansion Table

6) Glue Tank 13) Back and Forth Expansion Table

7) Edge Trimmer 14) Terminal Cover

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

7

6/2016

A

B

C

D

E

Fig. 3

BACK

A. Trimming & Cutting Adjustment D) Glue Tank Adjustment

B. Buffing Adjustment E) Rear End Plate

C. Glue Tank Bearing Greasing Hole

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

8

6/2016

Fig. 4

4. TRANSPORTATION & INSTALLATION (WIRING)

1. Machine is delivered completely assembled. Choose a suitable location and check

that it is accessible from all sides.

2. The machine should be installed in a closed space. Working conditions of a

workshop are considered enough.

3. Floor surface should be even and stable, and if necessary, machine can be bolted to

the floor.

4. Install the extension worktable, and the support table for the edge strip to their

corresponding positions (see Figs 1/2/3 above).

5. Electrical: Take off the external terminal cover; connect 3 live lines separately to L1

、L2、L3,neutral line to N, earth line to PE (fig 4). Make sure to tighten the screws

to secure the wires.

5. OPERATION

1. Make sure the trimming motor is moving in the same cutting direction.

2. Ensure the pressure regulating valve for air pressure reads 0.6-0.8Mpa.

3. Adhesive must be a high-temperature hot melt glue which is to be applied at 350°F -

400°F and have a minimum speed of 7m/min.

4. Workpiece panels should be of the same thickness with a smooth surface. Make

sure the surface after being sealed is straight and level with no dust or oil and is

perpendicular to front side of the panel.

Edge banding strips should be from the same batch and have the same size.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

9

6/2016

1

2

3

4

5

6

7

8

Fig. 5

5. Make sure edge strip is clean with no oil contamination, tool marks or cracks.

Caution: Don’t run the machine until the temperature reaches 400°F, default factory

glue temperature setting is 400°F.

CONTROL PANEL

The functions of the control panel shown in Fig.5 are as follows:

1. Main switch: Off is 0and On 1; controls the machines power supply; digital thermometer

lights up. Turn the Key to the ON position and the machine is ready to operate. The

machine will not start up without opening the control system with the key.

2. Trimming and cutting components: designed to trim the upper and lower edge

overhang. Off is 0and On 1.

3. Automatic side-by-side end cut components are designed to cut before and after the

edge overhang, there are two buttons which control the rotation of the milling cutters,

Off is 0and On 1.

4. Automatic belt conveying device: Off is 0and On 1.

5. The top button is a time relay that controls the length of the edge strip being fed, and

the bottom button controls rotation of the glue roller and moves the edge strip. Off is 0

and On 1.

6. The meter on top indicates and controls the glue temperature. The bottom right button

is the heater switch. Off is 0and On 1. The lower left is a signal lamp, which indicates

that the switch is On and ready to operate.

7. Emergency switch: once the switch is impelled all functions will stop immediately, and

the switch is in a locked state. You have to turn the knob to the right to restore electric

transmission.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

10

6/2016

START UP

1. Make sure the work piece conveyor safety switch is off. The emergency stop switch

⑧should be in the “ON” position.

2. Access to power: Turn the power key to “On”, next, turn the main switch to make

the arrowhead point to “1”, at this point, all power is on and the power

indicator(green) and digital display temperature-controlled meter should light up.

3. Press the button ⑤to start the conveyor, and then check the direction of

movement to make sure it corresponds to the power connection instructions above.

If not, change the position of any two of the three live lines until it runs in the

correct direction.

4. After the conveyor runs in the right direction, turn the heating switch to “ON”, the

glue tank will start to heat up. (Caution: Do not run the machine until the

temperature reaches 400°F (default factory glue temperature setting is 400°F).

5. The machine is now ready to work

ADJUSTMENTS

Fig. 6

Fig. 7

B

E

C

N

D

Fig. 8

A

B

C

D

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

11

6/2016

Installing the edge belt reel and the edge sealing belt regulator.

1. Put the edge sealing reel in the carrier as shown in Fig.6.

2. Push the edge sealing belt through the leading fields (2sets) as shown in Fig.7.

Adjust the upper cover plate B (loosen the locking knob C) according to the width of

the edge sealing belt, and push it through the roller to avoid tightening the edge

sealing belt.

3. Loosen bolt N and knob C so that base plate D and cover plate B rotate along

column E. Note: Base plate D needs to be in its normal position, it should be 18mm

between the topside of D and the table board, and the width of the edge sealing belt may

not be more than 2 mm on each side of the work piece. Ex: The maximum width of the

edge sealing belt should be 22mm if the thickness of a work piece is 18mm.

4. The edge sealing belt regulator as shown in Fig.8 consists of the base frame A, the

elastic sheet B, carrier C and adjusting screw D. Adjust the twisting screw D in

bracket C so that the edge strip produces adequate resistance between the elastic

sheet B and base frame A. Make sure it can move forward with adequate force and

can’t run freely in order for the edge strip to stay in position.

Mechanical Conveying of Edge Banding Belt

1. Once the temperature of glue reaches 400°F, and the glue roller and edge sealing

belt roller begin to rotate, press the “1” button in column ④as shown in Fig.5. The

edge banding process is now ready to begin.

Fig. 9

C

A

B

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

12

6/2016

2. The operating distance of the knurl roll may be adjusted with 4 screw bolts

represented by B (as shown in Fig.9).

Caution! Don’t touch work piece or edge tape when a work piece entering into or leaving

the guillotine to avoid possible inquiry. Make sure to cut off the machine’s power before

servicing.

Trimming the edge bander from the edge sealing belt disc.

1. The cutting clamp begins to operate when a work piece reaches the micro switch A

in Fig.10.

Glue Tank Components

Fig. 10

A

Fig. 11

A

B

Fig. 12

A

B

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

13

6/2016

The glue tank components apply melted glue onto the work piece to be sealed.

1. Put glue pellets inside the glue tank, and its liquid is about 1 cm from the edge.

2. Adjust the temperature controller to the suggested temperature F (default factory

glue temperature setting is 400°F) Adjust the temperature as required.

3. Start the glue roller once the glue temperature is achieved. The amount of glue

applied may be controlled by adjusting level B (Fig.11).

4. Pay attention to amount of the glue while sealing and add glue to the tank to

maintain the liquid level at 1cm from the edge.

5. Turn off the machine to add grease oil. Use special oil gun to inject high

temperature grease into oil hole A as shown in Fig.12.

Caution! Hot surface inside! Do not touch! To avoid possible skin in burns, disconnect and

lockout power and allow surfaces to cool down before servicing.

Automatic side-by-side end trimming components

The components are designed to automatically cut any unwanted edging before and after

(side-by-side for short).In order to ensure that the sealing belt’s section is similar with that

of the material.

Fig. 13

3

2

1

9

7

8

5

6

4

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

14

6/2016

The functions of the major parts are as follows:

①Front side-by-side and follow-up control switch

②Follow-up control switch

③Longitudinal guide rail along with motor and side-by side saw blade slide

longitudinally

④Back stroke control switch

⑤Side-by-side control switch

⑥Side-by-side saw drive motor

⑦Vertical guide rail

⑧Front side-by-side saw blade

⑨Rear side-by-side saw blade

Caution! Moving saw blades for end cutting are in high-speed rotation when the machine is

running. Don’t touch to avoid injury! Make sure to turn off the machine’s power and allow the

saws to stop spinning before making any adjustments or replacement.

Leveling & Trimming Functions

1. Milling Cutter: Adjustments are as shown in Fig. 14 & Fig. 15

2. The components level and trim extra edge banding on both sides (upper & lower).

You may obtain different sealing effects such as common angle, inclined angle or

rounded angle according to cutter selected and thickness of edge banding used. The

components are equipped with two cutters 2⅞” in diameter, which rotate in the

reverse milling. There are 6 cutter heads with a standard cutting angle of 1.5mm

each and spin at 11000r/min.

3. The height of upper trimming cutter may be automatically adjusted by connecting

rod A in Fig.15 to change height of the work piece conveyor to fit the thickness of

the work piece.

4. There is a 4” diameter dust exhauster located in the upper and lower cutters to

clean trimmed waste residues. The air force of dust absorption is 0.75miles/minute.

Caution! Moving cutters are in high-speed rotation when machine is running. Do not

touch to avoid injury! Don’t touch to avoid injury! Make sure to turn off the machine’s

power and allow the cutters to stop spinning before servicing.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

15

6/2016

Adjustment of leveling Components

1. The components are equipped with two adjusting systems in which one is the axial

cutter and the other is a vertical detector. The axial adjustment may move the cutter

by adjusting two knobs: C and D (Fig.15). This adjustment is frequent and needs to

be made while the cutter is operating.

2. There is a direction board at the back of the machine as shown in Fig.16 (”+”)

forward and (“-”) backward. The vertical adjustment in radial direction may be made

by adjusting bolts F and G (in Fig.14) to change the clearance of detector E to be

accommodate the changes in the cutter diameter. This adjustment should be made

while changing the cutter (when the cutter becomes blunt).

Note: bolts F and G need to be adjusted to the same number of turns so that the

detector and the worktable are parallel. The maximum width of the edge banding

beyond both sides of the work piece is 2mm each side (as shown in Fig. 17).

Fig. 14

G

G

F

F

E

Fig. 15

D

C

A

Fig. 16

Fig. 17

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

16

6/2016

Workpiece Conveyor

1. The conveying system for work pieces to be sealed consists of a high-density friction

belt. It not only guarantees that the work piece moves forward but it also it makes

the work piece remain on the glue roller with the assistance of the table rubber

rollers to ensure no damage is done to the work piece.

Note: the belt should be used at full width to avoid skidding or being damaged.

2. The conveyor is operated by three-phase motor reducer. Wheel handle B in Fig.18

controls the conveyor D to ascend and descend.

3. The height of the conveyor adjustment in proportion to the work piece thickness

may be read on counter A as shown in Fig.18. Loosen handle C in Fig. 18 before

adjusting the height of the conveyor.

Caution! Moving parts can crush and cut .Keep guards in place. Make sure to turn off the

machine’s power before servicing.

Fig. 18

D

A

B

E

C

Fig. 19

A

1

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

17

6/2016

TRIAL RUN

1. Push work piece frame and edge strip frame to the pre-calculated position.

2. Adjust the height of conveyor by the hand wheel in Fig.18 to ensure it corresponds

to thickness of a work piece.

3. Add glue to the tank A in Fig.11 to the required level of ¼” from top.

4. Start the machine when the glue temperature reaches 400°F

5. Press the gluing button in column⑥(Fig.5) and the edge strip conveyor button in

column ⑥as shown in Fig.5. The amount of glue applied can be controlled by

adjusting lever B (Fig.11).

6. Start all the other switches in succession.

7. Place the panel against the work piece conveyor, and move the work piece with the

conveyor belt to complete the sealing process.

6. MAINTENANCE

1. Make sure to First Turn-off power before any repair and maintenance is started.

Follow the application requirements.

2. It is essential to keep the machine clean to ensure the quality to avoid accident and

so as to extend the machine’s service life.

3. Don’t run the machine unless the work environment is good and all safety

protection covers, dust exhausters are working normally to avoid emission of chips

and dust.

4. Do Not Open the electrical cabinet unless servicing the machine.

5. Make sure to use trained service technicians to service the machine.

6. Clean up the dust outer and inside of the machine completely during storage. Keep

the machine and the environment clean and tidy inside plastic sheeting and with

engine oil on it to avoid rust.

7. Moving parts must be lubricated often. Good lubrication ensures a longer life of the

machine.

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

18

6/2016

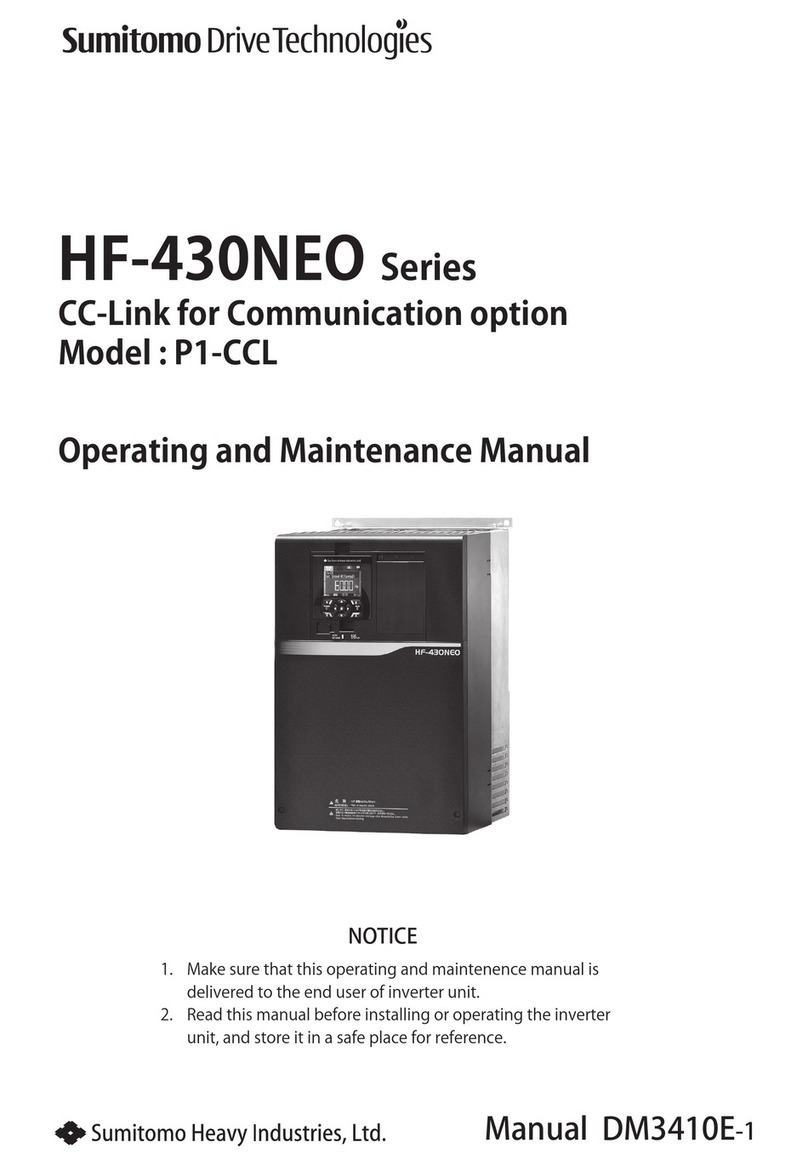

7. PARTS LIST

①Pressure regulating valve

②Air units

③Follow-up time relay

④Manual button of rim charge magnet valve

⑤Tool magnet valve cut off

⑥Manual tool magnet valve cut off

⑦Side-by-side and follow-up magnet valve

⑧Manual button of side-by-side and follow-up magnet valve

⑨Side-by-side saw descending throttle valve

Fig. 20

3

4

5

6

8

7

10

9

11

12

13

14

1

2

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

19

6/2016

⑩Manual button of side-by-side saw lifting magnet valve

⑪Side-by-side descending throttle valve

⑫Side-by-side saw lifting throttle valve

⑬Side-by-side advancing throttle valve

⑭Side-by-side backset throttle valve

BEARINGS LIST

Location

Model

Dimensions(mm)

Qty

Remarks

Glue Process upright shaft

SNB6005

25x47x12

2

Normal speed

and not sealed

Glue pot supporting rack

SNB6005

25x47x12

2

Normal speed

and not sealed

Rim charger rubber roller

SNB6002

15x32x9

2

Normal speed

and not sealed

Cross sliding block clutch-lower

SNB6203

17x40x12

2

Normal speed

and not sealed

Transition steel roller

SNB6202

15x32x11

4

Normal speed

and not sealed

Pressing rubber roller

SNB6002

15x32x11

2

Normal speed

and not sealed

Milling cutter shafts-upper & lower

SNB6002

15x32x9

4

Normal speed

and not sealed

Conveyor belt axle head

SNB6002

15x32x9

1

Normal speed

and not sealed

Conveyor belt roller

SNB6004

20x42x12

2

Normal speed

and not sealed

Carrying roller

SNB6004

20x42x12

28

Normal speed

and not sealed

Side-by-side saw

SNB6002

15x32x9

2

High Speed

and fully

sealed

Buffing shafts-upper & lower

SNB6002

15x32x9

4

High Speed

and fully

sealed

Follow up roller

SNB6002

15x32x9

4

Second High

Speed and fully

sealed

SNB-K2A AUTOMATIC EDGE BANDER MANUAL

20

6/2016

Plate thickness adjustor

SNB51201

12x28x11

2

Planer Bearing

Milling cutter carrier

SNBLM12UU

12x21x30

10

Linear Bearing

Buffing carrier

SNBLM12UU

12x21x30

10

Linear Bearing

Side-by-side vertical guide rail

SNBLM12UU

12x21x30

4

Linear Bearing

Side-by-side horizantal guide rail

SNBLM12UU

12x21x36

4

Linear Bearing

Table of contents

Other SKETCHNBUILD Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Adkins

Adkins Alpha Calender Roll-Master 1.2 Operator's handbook

Tanco

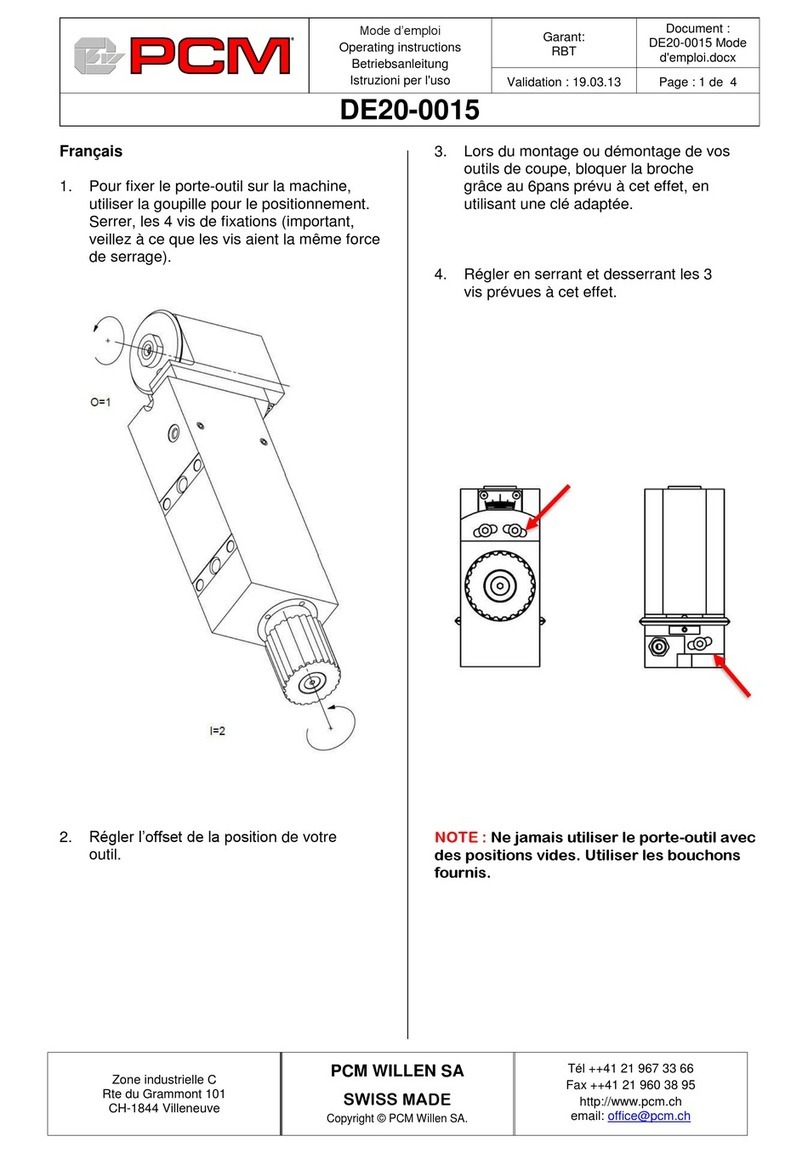

Tanco E100 SA Quick reference guide

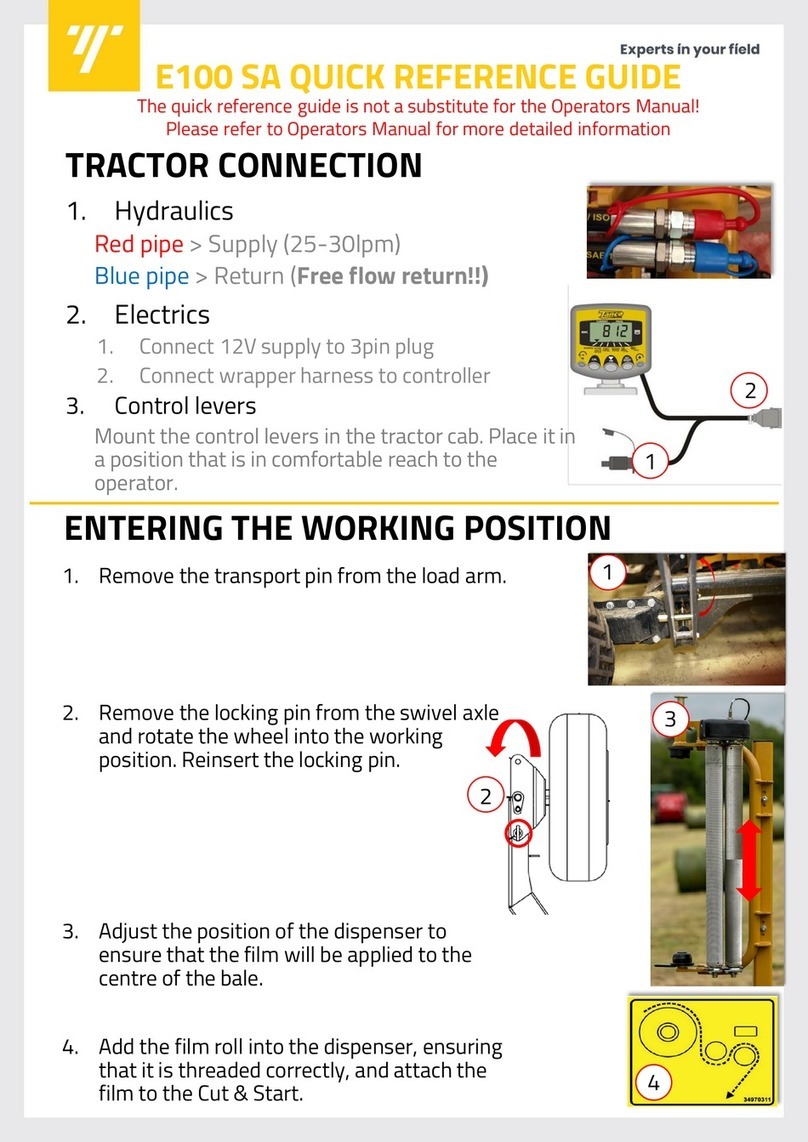

Sumitomo Drive Technologies

Sumitomo Drive Technologies HF-430NEO Series Operating and maintenance manual

PCB Piezotronics

PCB Piezotronics ICP 320C15 Installation and operating manual

PACLITE Equipment

PACLITE Equipment IMPACT430DE Operator's manual

Toro

Toro 110-5076 installation instructions