Fels Mobilis ELITE User manual

Sommaire

Introduction

Sélection du produit 6

Calcul de ligne 10

Mobilis Elite

Présentation 17

Données techniques 20

Composants 31

Standard straight element 31

High temperature straight element 34

Straight element without earth marking 37

Straight element with protection lips 41

Covering flange 44

End-cap 47

Sliding hanger 49

Fixed hanger 52

Bracket 55

End-line feed 58

M25-M32 in-line feed 62

M40 in-line feed 67

Pre -mounted feed box on straight element 72

Introduction gate 76

Ventilation element 79

Expansion joint 82

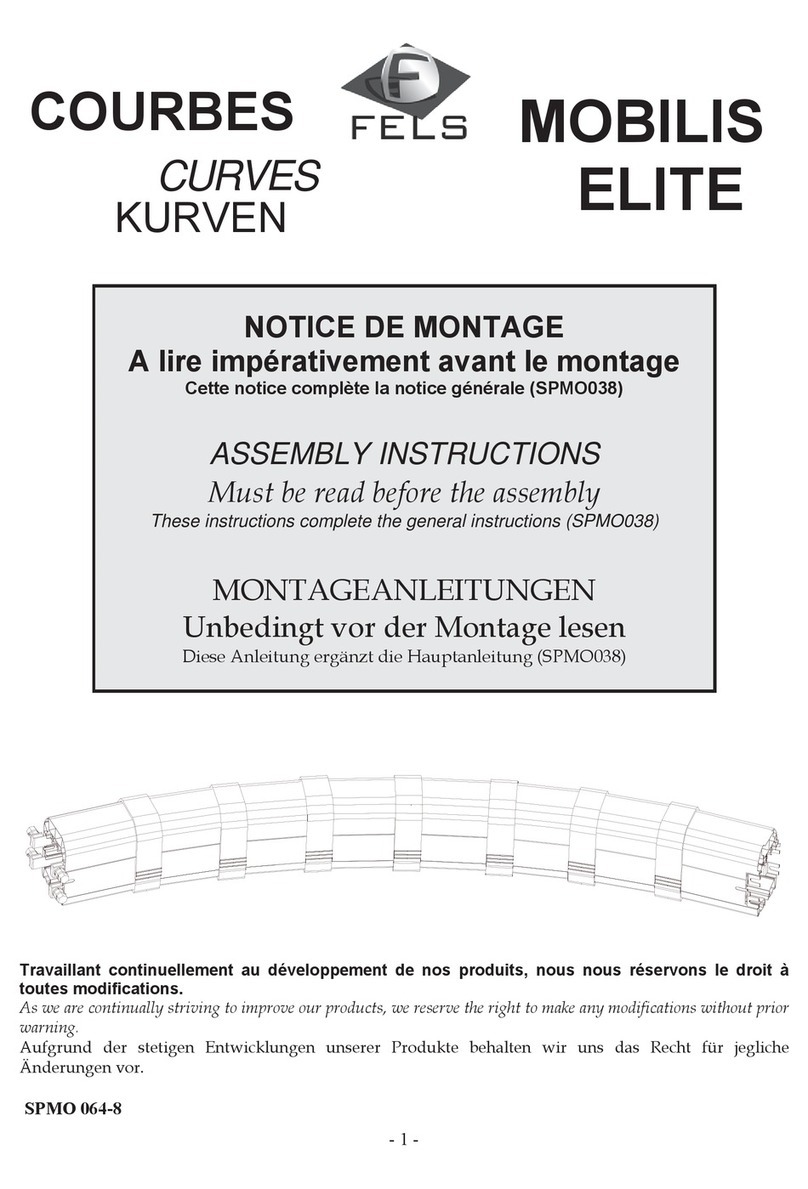

Horizontal curve 87

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 2/223

Transfer elements 90

Circuit interruption element 94

Rigid trolleys 97

Simplified trolleys 103

Articulated trolley 107

Special trolley for transfer element 112

High speed trolley 116

Cleaning trolley 121

Standard carrier 124

Carrier with box 127

Special carrier for long transfer element 131

Switching finger 134

Set of 5 screws + nuts 20A - 100A 136

Set of feed connection for 5th pole 137

Set of 10 screws + 5 nuts 130A 138

Set of connection screws 160A 139

Set of connections for 200A 5 poles 140

Set of connection screws 200A 141

Set of 4 collector brushes 142

Set of 5 collector brushes 143

Brush for simplified trolley 144

Set of 5 cleaning brushes 145

Set of 2 special screws for fixed hangers 146

Set of 2 carrier rings 147

Cone for short transfer element 148

Cone for long transfer element 149

Mobilis Movit

Présentation {††††‱㔱

}

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 3/223

Données techniques {††††‱㔴

}

Composants {††††‱㘱

}

Rail 161

Connection 165

Covering flange 168

Feeding box 171

End-cap 175

Sliding hanger 178

Fixing clamp 182

Collector 186

Collector bracket 191

Bracket 194

Expansion joint 197

Circuit interruption element 200

Cable eye stiffeners for feed 203

Brush for preparation of rail ends 204

Contact lubricant 205

Replacement brush for collector 206

Single cleaning collector 207

Cleaning and grindding brushes 209

Kit for unclipping sliding hangers 210

Ice shield 211

Gammes historiques

Composants {††††′ㄳ

}

Mobilis Elite 200A non -reduced Earth 213

Obsolete range MOBILIS CE 216

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 4/223

Trolley with cable Mobilis CE 217

Standard brushes for carriage mobilis CE 218

Brushes of trolleys mobilis CE for lines with transfer element 219

Remote control brush Mobilis CE 220

Obsolete range MOBILIS UNIT 221

Brush for pantograph 100A Mobilis UNIT 222

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 5/223

RELIABILITY, SAFETY, EASY USE, HIGH

PERFORMANCE

… right out of the box!

Pages of product selection .

OUTSTANDING ADVANTAGES:

Quick and easy installation of Movit and Elite

Tried and tested safety ensured

Reduced maintenance and exceptional operating life

Tried and tested reliability

No expansion issues

Product selection

Modular elements available in several lengths

Pre-assembled hangers

Clipped-on mounting of lines in self-aligning hangers

Safe and easy Elite connection by self-breaking screws guaranteeing tightening at optimum torque

Large number of accessories quickly mounted, with no special tool

All accessories are pre-assembled in the factory

Current collector brushes of Elite, removable without uninstalling collector wiring

Dust protection lips of Elite, pre-mounted in the factory for time saving on the site

Elite rails with safety pins for direction and intensity

Wear parts size specially designed for long maintenance-free operating life

Sturdy design , tried and tested over 40 years

Sturdy and tried and tested design of Elite and Movit

Light-weight and more rigid cellular structure of Elite

Qualification

and

endurance

testing

to

requirements

stricter

than

standards

before

placing

on

the

market

Issues of expansion differences in materials considered early at the design stage

Long lengths of line with no expansion joint needed

Expansion joints of innovative and compact design

Complies with international standards (EN60204-32, CEI61439-6)

Elite and Movit have IP23 protection index, which means that the equipment is protected so that

people cannot access the dangerous sections, even under the rain

Thousands of applications made safe by Mobilis worldwide over many years

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 6/223

Developed to meet the needs on the field

Ancillary costs reduced

Long lengths of line feasible

1. PRESENTATION

Multi-conductor Rail Single-conductor Rail

Mobilis ELITE:

Quick installation:

Multiple pole lines with 4 or 5 pre-mounted

conductors and many accessories to clip-on (no

tools required)

Quick and easy connection:

Connection system with built-in self-breaking

screws, guaranteeing tightening at optimum torque

Reduced voltage drop at connections:

The very large exchange surface, and tightening

maintained at optimum torque allow reducing and

controlling voltage drop

Excellent safety and operator protection:

The closed profile of the mounted line with the full

set of accessories has a protection level of IP23,

which means that the equipment is protected so

that people cannot access the dangerous

sections, even under the rain

Operating reliability: The current collectors, tested

against requirements stricter than the standards,

are designed to run for several thousand

kilometers, providing reduced maintenance of

facilities

Product selection

Mobilis MOVIT:

High speeds:

Up to 600m/min

High currents:

Up to 630A

High mechanical resistance:

H rigid profile and sturdy accessories, ideal

where reliability, safety, and high performance

are required

Optimized contact:

Collector contact under control due to

provision for angular offset

Cost-effective modular system: replacement of one element/quick and easy extension

Quick and easy mounting

Quick customer help and decision with the Online Quote and Design Tool

CAD 2D/3D File Package made available to reduce design & installation costs

Unlimited lengths of line due to expansion joints

Vitesse élevée

Mobilis ELITE ®

Mobilis MOVIT ®

Special accessories available to meet field requirements (ventilation elements, circuit

interruption, inlet gate, maintenance devices)

Vertical and horizontal curves

Elements for transfer

Easy assembly of ergonomic range: quick and intuitive to learn, visual assembly instructions on

rail for Elite

Materials suitable for the various industrial environments

Voir les composants

Movit

Quick installation

Quick and easy connection

Reduced voltage drop at

connections

Excellent safety and

operator protection

Optimized contacts

High mechanical resistance

High speeds

Operating reliability

High currents

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 7/223

Number of poles: 4 or 5 Number of poles: 1 to infinity

Intensities: 12A, 20A, 40A, 60A, Intensities: 315A,

100A, 160A, 200A 450A, 630A

Maximum operating voltage: 750V Maximum operating voltage: 750V

Protection Index IP23 according to EN60529 Protection Index IP23 according to EN60529

Complies with Standards EN60439-2, Complies with Standards EN60439-2,

EN60204-32, CEI61439-6 EN60204-32, CEI61439-6

INTRODUCTION :

As a specialist of electrical supply rail manufacturing for mobile equipment since the seventies, the

FELS Company has perfect knowledge and experience of the needs of the integrators, installers,

and end-users on this market worldwide, and of the special features of such devices. Its two

product ranges, MOBILIS Elite and Mobilis Movit have been designed to meet the requirements of

international standards. They offer a long operating life due to their robustness, with wear parts

strengthened to reduce maintenance of facilities. The high quality of materials and the great care

used for their workmanship also guarantee a long service life.

The high performance level achieved by all the ranges of rails results of the close contacts that

Fels has maintained over the years with the many manufacturers, installers, and end-users of such

equipment.

CLIENT SERVICE:

In order to meet the increasing demand for services on the part of its clients, Fels has developed a

capacity for listening and quick reaction within its organization. Each client is provided with

permanent and personalized assistance and follow-up. We insist on maintaining close contact, in

order to make the commercial and technical transactions, as much productive as possible, and

leading to improved quality in the interest of both parties. Service quality is indeed recognized by

clients as one of our main advantage.

A BROAD RANGE OF REFERENCES:

Since it was launched, the Mobilis Elite electric rail has proved its efficiency in all sectors where

top-quality mobile electrification is required. Fels has supplied its equipment to customers in

myriad plants throughout Europe and the world, proving that this leading-edge equipment can be

adapted to many applications: the car industry, aeronautics industry, chemicals, railways and

energy industries –everywhere where travelling cranes are essential.

With its network of partners, selected because they share the Fels philosophy in terms of quality

and service, Fels has broken into the market on all five continents, providing and efficient, reliable

service for companies in all sectors. When it comes to services, Fels also supplies the energy right

down the line !

2. DATA NEEDED TO SELECT EQUIPMENT

The following data must be known in order to define the intensity of a MOBILIS line:

Selection of product

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 8/223

Maximum intensity in continuous operation, or failing this power and types of receivers (cage

or slip-ring motors, electronic starters, resistors)

Receiver start-up intensity

Maximum ambient temperature

Maximum clearance between a receiver and the nearest feeding point

Permissible voltage and voltage drop in continuous operation and on start-up

Type of current (frequency, voltage)

Running cycle of the receiver (duty cycle, or operating time per 10-minute cycle).

In addition, review the following options to find out the most appropriate solution:

Installation with more than 5 conductors: select Mobilis Movit or arrange 2 Elite lines in parallel

Installations with curves and a radius shorter than 15m, or transfers between different circuits:

select Mobilis Elite

Installations with mobile speed greater than 180m/min: choose Mobilis Movit

For all other configurations, calculate intensity to select the best equipment.

All the above features along with the calculation of intensity (see below) will help you determine

which range is most appropriate to your needs, Elite 12A-200A Range or Movit 315A-630A Range,

The first selection criteria to be considered being the permissible current for Mobilis rails, which

must be higher than the installation intensity, and the second criteria being the voltage drop

involved.

You may also use the Online Calculation Tool on our website: www.fels.fr

The details above can also be used to fill out the online Consultation Sheet for assistance by our

Engineering Office.

3. TECHNICAL DETAILS:

See Technical data of Elite Range

See Technical data of Movit Range

4. LINE CALCULATION:

See the section Line calculation

5. OBSOLETE EQUIPMENT

See the section Historical ranges

6. GUARANTEE

Our equipment is guaranteed one year against any material or manufacturing defect recognized by

ourselves. As we are not responsible for its installation and operation, our guarantee covers only

replacement or repair (at our own choosing) of the part recognized to be defective.

We do not accept responsibility for any defects arising from faulty supervision or maintenance. We

also disclaim liability for any production stoppages that may result. Any arbitration shall be held in

Strasbourg, even when several defendants are involved.

Selection of product

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 9/223

LINE CALCULATION

To set the product and the intensity of the MOBILIS ELITE line, two parameters must be considered

simultaneously:

The voltage drop on line, which must be below the permissible value

The product current capacity, which depends on the ambient temperature and on the duty

cycle factor.

The following data must be known:

• Maximum intensity in continuous operation

• Type of receivers (cage or slip-ring motors, electronic starters, resistors)

• Receiver start-up intensity

• Maximum ambient temperature

• Maximum distance between a receiver and the nearest feeding point

• Permissible voltage and voltage drop in continuous operation and at start-up

• Type of current

• Running cycle of the receiver (duty cycle)

You can find out immediately the most suitable intensity by connecting to our website www.fels.fr

and using our on-line "Mobilis Price Calculator".

For help in calculation by our Customer Service Department, fill out the Consultation Sheet.

For manual calculation, follow the procedure below.

1. INTENSITY IN CONTINUOUS OPERATION

Take into account the number of receivers which run simultaneously and calculate the

corresponding intensity:

IN= I1+ I2+ … + In

The intensity may be worked out from the power of the receivers.

In a three-phase system, this gives:

Where:

In: absorbed current (in Amperes)

Pu: power output of the receiver (in Watts)

η: receiver efficiency (between 0.6 and 0.96 for

a cage motor)

U : operating voltage (in Volts)

cos ϕ: power factor

Mobilis line calculation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 10/223

In the absence of information about running simultaneity of consumers, please refer to the table

hereunder:

Number of

consumers

For the whole hoisting devices

1st motor

2nd motor

3rd motor

4th motor

Most powerful

motor¹

Motor, in power descending order¹

1

x

x

2

x

x

x

3

x

x

x

4

x

x

x

x

5

x

x

x

x

2 hoisting devices

working together

x

x

x

x

(1) For a drive through n motors of rated intensity ln’ in parallel, please consider ln= n x ln’

2. INTENSITY DURING THE START-UP PHASE

(2 seconds maximum)

Take into account the number of receivers starting up simultaneously and those already in

operation, then calculate the corresponding intensity. When the start-up intensity is not known, find

the approximate value as follows:

Id= K . Infor a single receiver

Where

(In general, K = 5 to 6 for cage motors, K = 2 for slipring motors, K = 2 with frequency converter)

In the absence of information about running simultaneity of consumers, please refer to the table

hereunder:

Number of

consumers

For the whole hoisting devices

1st moteur

2nd motor

3rd motor

4th motor

Id

In

Id

In

Id

In

Id

In

1

x

x

2

x

x

x

3

x

x

4

x

x

x

5

x

x

x

x

2 hoisting devices

working together

x

x

x

x

3. CALCULATION OF THE VOLTAGE DROP

Under normal running conditions, the voltage drop must be within 2% - 6% of the nominal voltage,

according to the operating phase and the upstream/downstream features of the installation. The

voltage drop between the origin of installation and any point of use shall not exceed the standard

or set values for the applications.

Mobilis line calculation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 11/223

Taking into account the mains voltage, the length of the section considered, the nominal intensity,

start-up intensity and the impedance of the conductor selected, voltage drops can be worked out

for the start-up phase and normal running phase using the following formulas:

Three-phase alternative current: ΔU = √3 . Z . Lt . I .

Continuous current: ΔU = 2 . R . Lt . I .

Voltage drop in %: ΔU% = (ΔU/U) x 100 .

I: current in continuous operation or at start-up, as appropriate (in Amperes)

Lt: length of the section considered (in m), taking Lt as per paragraph 4

Z: line impedance (in Ω/m) (see general technical data, paragraph 12 for Elite, 11 for Movit)

R: line resistance (in Ω/m) (see general technical data, paragraph 12 for Elite, 11 for Movit)

U: mains voltage (in Volts)

In the case of impulse running, the voltage drop can be quickly checked using the "continuous

operation" and "start-up" graphs (see on the following pages).

When operating at 60Hz, overheating is similar, but voltage drop is greater:

For any given intensity:

X60 being the reactance at 60Hz calculate X60 =X50 x 60 then re-calculate impedance at 60Hz

X50 being the reactance at 50Hz 50

4. FEEDING: LENGTH OF LINE SECTIONS

It is possible to have several feeding points along a line.

The judicious positioning of these points means voltage drop can be reduced.

If L is the line length, Lt is the maximum length of the section to be taken into account to work out

the voltage drop:

One end-line feeding point

One midway feeding point

Two feeding points

Mobilis line calculation

Three feeding points

Four feeding points

Five feeding points

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 12/223

5. QUICK SELECTION CHART

Continuous operation graph

Continuous operation under 400V at 50Hz, 35°C

Start-up phase graph

Starting : 2 seconds maximum under 400V at 50Hz, 35°C

Mobilis line calculation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 13/223

Quick Selection chart for Intensities 12A & 20A :

Continuous operation graph

Continuous operation under 400V at 50Hz, 35°C

Start-up phase graph

Starting : 2 seconds maximum under 400V at 50Hz, 35°C

Mobilis line calculation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 14/223

6. DUTY CYCLE FACTOR

The maximum permissible intensity in amperes depends on the maximum permissible ambient

temperature for the feeding rail considered, on the ambient temperature, on the duty cycle factor

(rate of equipment use over a short period), and on the Joule effect due to current carrying.

The duty cycle factor depends on the rate of equipment use, defined over ten-minute time periods

and expressed in %, corresponds to the ratio running time over total time. A duty cycle factor of

80% means that the machine will be used 8 minutes per each 10-minute period.

If the calculated nominal intensity is lower or equal to the permissible intensity for a selected duty

cycle factor at the maximum permissible ambient temperature, such intensity may be retained.

INIFM

An intensity lower than the nominal current may be retained if the requirements for voltage drop

upon start-up, nominal voltage drop, and duty cycle factor are met.

The higher the operating temperature, the lower the maximum permissible current.

ELITE Permissible current:

Ambient

temperature

Duty Cycle

Intensity

40A

60A

100A

130A

160A

200A

35°C

80%

72A

90A

117A

127A

162A

211A

40°C

80%

67A

86A

109A

117A

155A

195A

55°C

80%

48A

63A

86A

87A

131A

140A

35°C

100%

68A

85A

114A

120A

152A

184A

40°C

100%

64A

82A

106A

109A

145A

171A

55°C

100%

47A

61A

82A

83A

121A

126A

MOVIT Permissible current:

Ambient

temperature

Duty Cycle

Intensity

315A

450A

630A

35°C

80%

420A

540A

638A

40°C

80%

384A

496A

580A

55°C

80%

275A

345A

420A

35°C

100%

395A

500A

570A

40°C

100%

360A

460A

530A

55°C

100%

255A

320A

385A

Mobilis line calculation

The electrical supply rail Mobilis Elite meets the requirements of the most demanding

manufacturers, installers, and end-users of mobile equipment: higher safety, fast assembling,

operation reliability, and easy maintenance of this electrical supply rail for travelling cranes and

other mobile equipment requiring mobile power socket.

Quick installation: Multiple pole lines with 4 or 5 pre-mounted conductors

and many accessories to clip-on (no tools required)

Quick and easy connection: Connection system with built-in self-breaking screws,

guaranteeing tightening at optimum torque

Reduced voltage drop at connections: The very large exchange surface, and tightening

maintained at optimum torque allow reducing and

controlling voltage drop

Excellent operator safety and protection: The closed profile of the mounted line with the full set of

accessories has a protection level of IP23, which means that the

equipment is protected so that people cannot access the

dangerous sections, even under the rain

Operation reliability: The current collectors, tested against requirements

stricter than the standards, are designed to run for

several thousand kilometers, providing reduced

maintenance of facilities

1. DETAILS OF PROFILE

Number of poles: 4 or 5

Intensity: 12A, 20A, 40A, 60A,

100A, 160A, 200A

Maximum operating voltage:

750V

OUTSTANDING ADVANTAGES

Self-extinguishing closed PVC profile, of

modern design

Easy and quick mounting of the line in its

suspensions

Quick and reliable connection

No preparation required

Increased safety

Modular and interchangeable

Mobilis Elite presentation

Vitesse élevée

See Mobilis Elite

components

Mobilis Elite

Voir les composants

Movit

Quick installation

Quick and easy connection

Reduced voltage drop

at connections

Excellent operator safety

and protection

Operation reliability

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 17/223

2. STANDARDS

Protection level IP23 according to EN60529

Meets the requirements of Standards EN60439-2, CEI61439-6 and EN60204-32

3. SPECIAL ELEMENTS AVAILABLE

Transfer elements

Curves

Circuit interruption elements

Inlet gates

Ventilation elements

Switching fingers

Expansion joints

Special trolleys and carriers

Data transfer…

4. BENEFITS:

Safe, quick, and fast clipped assembly of the elements in the self-aligning hangers.

High range design and performance

Large series manufacturing

Modular and interchangeable: quick change of 4m elements. For extension of line or

moving of feed points.

Floating conductors fitted inside the profile to adjust to expansion differences of line

synthetic material.

Optimized cellular structures for excellent rigidity to the PVC, preventing access to

dangerous inner sections, and minimal weight. Fels was the first to introduce the cellular

structure of Mobilis Elite on the market.

Closed system for maximum safety, protecting against access to dangerous sections,

even under rain, according to international standards.

Quick and reliable connection system by built-in removable self-breaking screws:

guaranteeing tightening at optimum torque under all mounting conditions. Insulated

junctions by covering flanges clipped on quickly and reliably (no tools).

Reliable wiring thanks to earthing continuous marking, in-situ pole location, and safety

pins.

Tried and tested reliability of Mobilis Elite modular design with thousands of applications

world-wide.

Lines of long lengths made possible.

Dust protection: time savings with factory-mounted protection lips.

Voltage drops minimized due to the judicious choice of conductors' section, and of the

low electrical resistance of the connections, stable over time. Software tool to help in

calculation.

Easier maintenance thanks to quick connection dismounting, to quick change of trolley

brushes with no unwiring required (exclusive Mobilis Elite connector system), and the

accessory "inlet gate" for easier access to the trolleys in a multi-equipment line, or in

closed circuits.

Mobilis Elite presentation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 18/223

5. GENERAL TECHNICAL DATA

See the related section

(Uses, operating limits, ...)

6. COMPONENTS

See the related section

(Straight elements, feed boxes, hangers, accessories…)

7.DOWNLOADS

See website. http://catalogue.fels.fr/en/mobilis-elite/downloads

(Consultation Sheet, Assembly Instructions, CAD File Package)

8. GUARANTEE

Our equipment is guaranteed one year against any material or manufacturing defect recognized

by ourselves. As we are not responsible for its installation and operation, our guarantee covers

only replacement or repair (at our own choosing) of the part recognized to be defective.

We do not accept responsibility for any defects arising from faulty supervision or maintenance.

We also disclaim liability for any production stoppages that may result. Any arbitration shall be

held in Strasbourg, even when several defendants are involved.

Mobilis Elite presentation

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 19/223

See related sections

for special items

Curves & Transferts Ventilation, circuit

Interruption

1. APPLICATIONS

The electrical supply rails with mobile socket are generally used for the electrification of travelling

cranes, cranes and hoists, narrow-aisle stores, work station equipment (tasksaver systems),

elements of electric hoisting equipment, theater stages, sewage treatment and composting

equipment, and other diverse applications, inside and outside.

2. GENERAL TECHNICAL DATA:

Rated operational intensity:

The MOBILIS ELITE lines are available in several intensities 20 A, 40 A, 60 A, 100 A, 130 A, 160 A

and 200 A.

Number of poles:

The MOBILIS ELITE lines are available in 4-pole or 5-pole version.

The ground conductor (PE) is marked on the line by a green-yellow band.

The neutral conductor (N), when present, is located in the top section of the casing.

The phases (L1, L2 and L3) are located as shown on the diagram opposite.

Rated operational and insulation voltage:

750 V alternative, 50 Hz for standard version

440 V alternative, 50 Hz for high-temperature version

Temperature of use:

–30°C to +55°C in the standard version, –30°C to +75°C in the high temperature version.

Mobilis Elite Technical Data

Mobilis ELITE –Technical Data

www.fels.fr | T +33(0)3 88 67 10 60 | F +33 (0)3 88 55 01 79 | Edité le 04/01/2017 Page 20/223

Other manuals for Mobilis ELITE

1

This manual suits for next models

1

Table of contents

Other Fels Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

MK

MK GUF-P Technical documentation

Clark-Reliance

Clark-Reliance Levalarm EA100 Series Instructions for installing and operating

mainero

mainero 2240 manual

Siemens

Siemens BD01-AK IP55 Series installation instructions

Crafco

Crafco SUPER SHOT 60 parts manual

InterTest

InterTest iShot Imaging MZ4 HD-UV GTIS Operation and service manual