SKI AccuFlo Zero User manual

AccuFlo®Zero

Automatic Zero-Point Calibration

For Differential Pressure Transmitters

Installation and Operating Instructions

AccuFlo®Zero –Installation and Operating Instructions

2

Installation and operating instructions AccuFlo®Zero

Attention:

Please refer to the warning information on page 3 and 4 before commissioning!

Content

1General information ......................................................................................................3

1.1 Safety information...............................................................................................................................3

1.2 Qualified personnel.............................................................................................................................3

1.3 Further information .............................................................................................................................3

1.4 Special warnings.................................................................................................................................4

2Correct usage ................................................................................................................5

3Description of functions ...............................................................................................5

4Inspection of incoming goods......................................................................................6

5Electrical connections and assembling ......................................................................7

5.1 Installation of the AccuFlo®Zero .........................................................................................................7

5.2 Electrical connections.........................................................................................................................8

5.3 Status relay.........................................................................................................................................9

5.4 Manual zero-point calibration..............................................................................................................9

5.5 Terminal assignment ..........................................................................................................................9

6Commissioning............................................................................................................13

6.1 General procedure............................................................................................................................13

6.2 Successful set up..............................................................................................................................13

6.3 Optional correction of positioning with steam measurements and condensate in the system.........13

6.4 Delete a correction of positioning .....................................................................................................14

6.5 Signaling to the control station..........................................................................................................14

7Operation .....................................................................................................................14

8Errors............................................................................................................................14

8.1 Signaling of errors.............................................................................................................................14

8.2 LED lights up permanently................................................................................................................15

8.3LED does not light up .......................................................................................................................15

8.4 LED is flashing permanently.............................................................................................................15

9Technical data..............................................................................................................16

9.1 General information ..........................................................................................................................16

9.2 Electrical data ...................................................................................................................................17

10 Declaration of Confirmity............................................................................................18

S.K.I. Schlegel & Kremer Industrieautomation GmbH

Hanns-Martin-Schleyer-Str. 22 –41199 Mönchengladbach

Tel: +49 (0) 2166/62317-0

AccuFlo®Zero –Installation and Operating Instructions

3

Installation and operating instructions AccuFlo®Zero

1 General information

1.1 Safety information

This device left the factory free from safety problems. In order to maintain this status and to ensure safe

operation of the device, please observe the safety information and warnings contained in this instruction.

The device/system may only be set up and used in conjunction with this documentation.

Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance by qualified personnel.

This device may only be used for the applications described in the technical description and only in

connection with devices or components from other manufacturers which have been approved or

recommended by S.K.I. GmbH.

You are obliged to respect the test certificates, provisions and laws applicable in your country during

connection, assembly and operation of the device/system.

The device can be operated both at high pressure and with aggressive and hazardous media.

Therefore, improper use of this device may lead to serious injury and/or considerable damage to

property. Especially, it must be noted when the device was in use and is to be exchanged.

Commissioning and operation of a device/system may only be performed by qualified personnel. This

personnel has to see to it that appropriate voltage is used (see type stamp), that ensures that in normal

operation or in case of default of the device or of components no hazardous voltages may damage the

device. Insofar, improper use of this device may lead to serious injury and / or considerable damage to

property.

1.2 Qualified personnel

The installation and operating must be realized by qualified personnel. Qualified personnel includes persons

familiar with the installation, assembly, commissioning and operation of the product and who have the

appropriate qualifications for their activities such as

They are authorized, trained or instructed in operating and maintaining devices and systems according

to the safety regulations for electrical circuits, for media under high pressure or aggressive or hazardous

media.

For explosion-proof devices: They are authorized, trained, or instructed in carrying out work on electrical

circuits for hazardous systems.

They are authorized, trained or instructed in safety standards for maintenance and use of appropriate

safety equipment.

Training in first aid.

1.3 Further information

For clarity reasons, this notice does not contain all detailed information of all types of products and may not

consider every possible application or maintenance.

Attention: If you need more information or have particular problems which are not covered sufficiently by the

operating instructions, get in touch with S.K.I. GmbH directly (see last page). You may find contact information

in the internet.

The contents of these instructions shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. All obligations on behalf of S.K.I. GmbH are contained in the respective sales

contract which also contains the complete and solely applicable warranty conditions. Any statements contained

herein do not create new warranties or modify the existing warranty.

The content reflects the technical status at the time of printing. We reserve the right to make technical changes

in the course of further development.

AccuFlo®Zero –Installation and Operating Instructions

4

Installation and operating instructions AccuFlo®Zero

1.4 Special warnings

Exceeding pressure: Appropriate measures are to be taken to secure that the allowed operation pressure

according to the stamp on the type plate is not exceeded.

Normal usage: On acceptance and within the required control intervals, a compression test under overpressure

and a leakage test have to be conducted for the whole system.

Exceeding or underrunning of the allowed operation temperature limits: Appropriate measures are to be

taken to secure that the allowed operation temperature limits are not exceeded.

Damage: Please observe that the product is not dropped and that it is not affected by excess forces.

Too many load cycles: Appropriate measures are to be taken to secure that the allowed number of load cycles

is not exceeded. The maximum load cycles are defined in EN 13480-3; 10.2 c).

Opening under pressure: Appropriate measures are to be taken to secure that the valves of the product are

not opened under pressure.

Fire near the product: Appropriate measures are to be taken to secure that the product is taken out of

operation in case of damage.

Improper mounting of the flow computer: Please observe that the several components of the product are

mounted properly.

Improper mounting of the device: Please observe that the device is mounted properly.

Assembling of pieces of equipment, valves etc.: In case of assembling of pieces of equipment and when

starting the working load, the pressure devices shall not be exposed to any loads which may endanger the

operating safety. Especially, additional static and dynamic loads are not allowed.

Welding of pieces of equipment: Please observe that no welding, heat treatment or other interventions

concerning the safety are carried out. Necessary reparations have to be approved by the manufacturer.

Corrosion: Please observe that the product is used and installed as intended.

Electricity: Caution of voltage! Switch off the device before interfering in the wiring.

Other risks: Please observe that the operation instructions of the manufacturer are respected at all times.

Especially, pressure devices have to be used for the specified media.

AccuFlo®Zero –Installation and Operating Instructions

5

Installation and operating instructions AccuFlo®Zero

2 Correct usage

The AccuFlo®Zero is used for automatic zero-point calibrations. The device may only be used for the purposes

specified in these instructions. All changes to the device are the sole responsibility of the user if they are not

explicitly stated in these instructions,.

3 Description of functions

The AccuFlo®Zero continuously monitors the temperature of the measuring cell of the differential pressure

transmitter. The device performs a zero-point calibration in case the temperature change exceeds a pre-defined

threshold value. If no inacceptable temperature change occurs during an individually determined interval the

AccuFloZero® will perform a zero-point calibration to avoid long term drift of the differential pressure

transmitter’s zero point.

During any zero-point calibration the latest output signal will be upheld as a fixed value. Therefore, the

AccuFlo®Zero ensures that a continuous output signal is maintained even during zero-point calibration in order

not to disrupt subsequent control systems.

Communication between AccuFlo®Zero and differential pressure transmitter takes place via HART®-interface.

Thus the function of the AccuFlo®Zero is usually independent of the transmitter brand and model if the

transmitter supports the necessary functions via HART®. The automatic zero point calibration is executed

directly in the transmitter analog to a manual calibration with a possible present local computer or the use of a

HART®-terminal. Please contact us for a list of supported differential pressure transmitter models.

Properties

Integration in the system: Easy installation directly at the differential pressure transmitter.

Conservations of results: During the zero-point calibration the latest output signal generated by the

transmitter will be upheld as a constant output signal.

Duration of calibration: Approximately 30 sec.

Calibration by time interval: The zero-point calibration will be executed after an individually adjustable interval.

This standard interval is 24h.

Calibration by drift: The temperature of the cell in the transmitter is monitored and compared with a

value of the latest balance. Should this difference exceed an adjustable value, the

zero point balance will be executed. The standard value is 10 K.

Correction of the position: In case of deviations due to an improper assembling of the transmitter for steam

measurements a static offset may be fixed in the AccuFlo®Zero.

Communication

Analog output: The analog output of the transmitter is passed-through.

SPS or control terminal: Two relays transmit the status of the AccuFlo®Zero. These relays may be

combined to a sum alarm (see chapter 5.5, table 3 and following)

At any time, the zero-point calibration may be executed manually by a signal (see

chapter 5.4).

AccuFlo®Zero –Installation and Operating Instructions

6

Installation and operating instructions AccuFlo®Zero

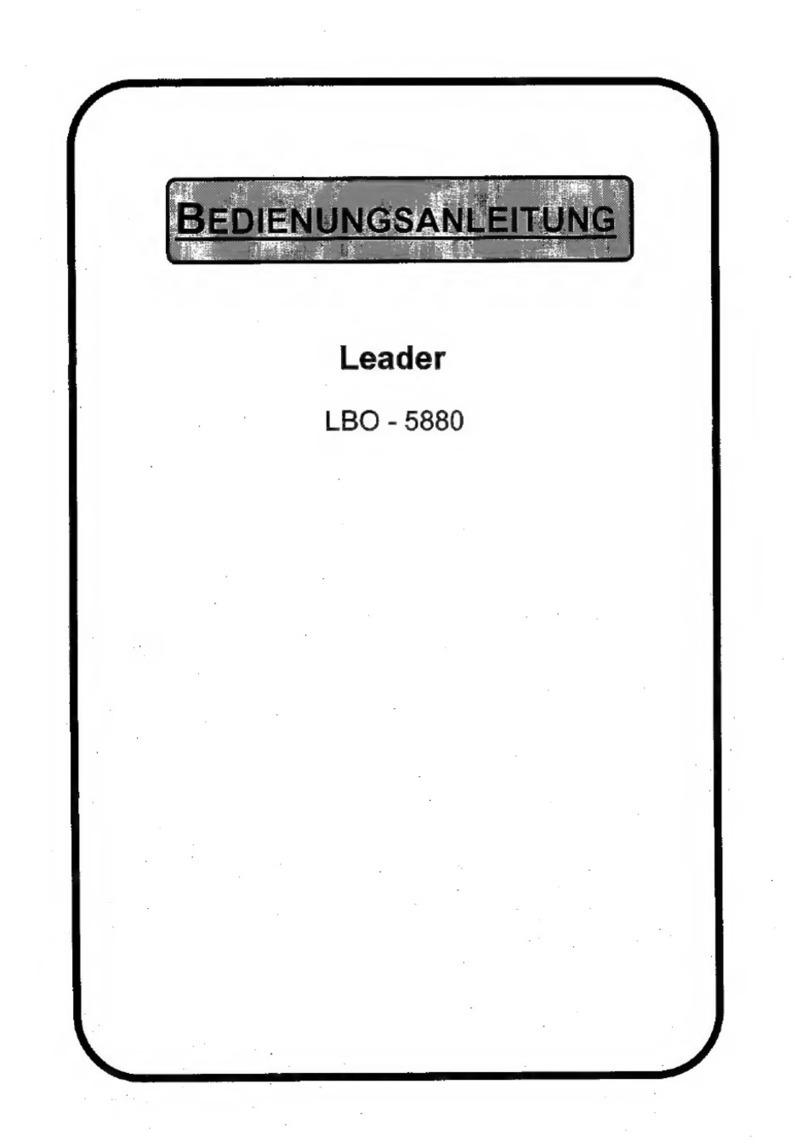

4 Inspection of incoming goods

Please check the scope of supply for the following items:

AccuFlo®Zero

AccuFlo®Zero

1. AccuFlo®Zero

2. Threaded rods and screw nuts:

7/16-UNF or M10 (according to the

transmitter) for assembling of the

system.

3. PTFE-seals for the connection between

the AccuFlo®Zero and the transmitter.

4. (Optional) Two locking screws with

bleeder valve function for steam or

liquid applications.

5. Documentation

AccuFlo®Zero –Installation and Operating Instructions

7

Installation and operating instructions AccuFlo®Zero

5 Electrical connections and assembling

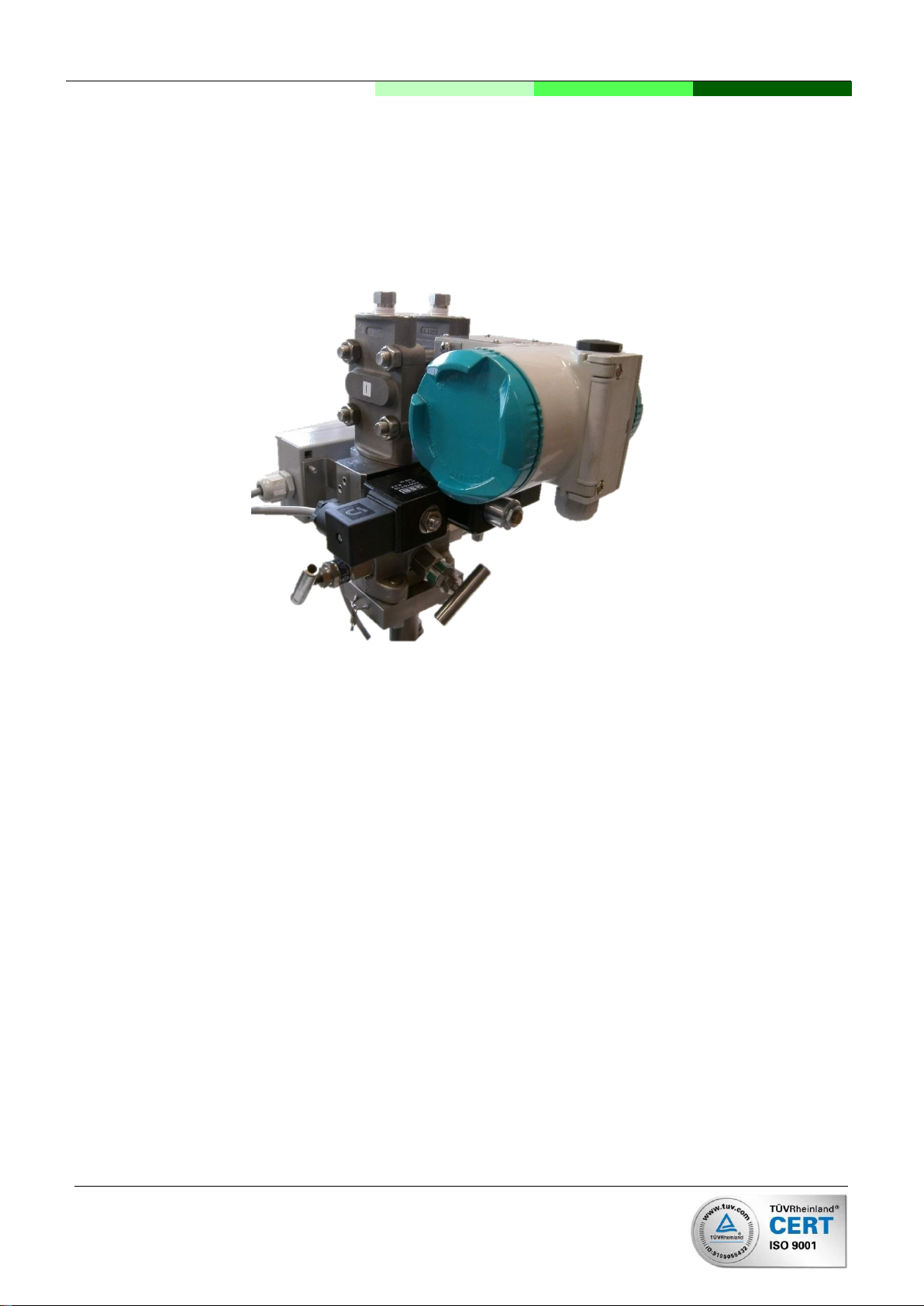

5.1 Installation of the AccuFlo®Zero

The AccuFlo®Zero has to be installed between the valve manifold and the differential pressure transmitter (see

Figure 1).

Figure 1: Assembled AccuFlo®Zero

The following has to be considered when installing the AccuFlo®Zero:

The use of the enclosed PTFE-seals prevent leakage when assembling the transmitter on the

AccuFlo®Zero and to the valve manifold.

The use of the right threaded rods (M10 or 7/16-UNF) guarantees the proper position of the devices.

This depends on the chosen transmitter.

The screws fix the AccuFlo®Zero and the transmitter to the manifold.

In case of measurement of liquids or steam the two locking screws without valve (see above in Figure 1:

Assembled AccuFlo®Zero) are to be replaced by the delivered locking screws with valve (bleeder valve).

After assembling and after maintenance these valves ensure that the impulse pressure pipes to the

transmitter are completely vented. After venting the impulse pipes the valves have to be tightened

thoroughly.

Instruction of procedure

Dismount the existing connection between the transmitter and the valve manifold. The existing screws

or threaded rods have to be removed from the transmitter. (This is only necessary if the transmitter and

the valve manifold are already connected).

Afterwards, the proper threaded rods have to be screwed into the transmitter.

The seals have to be laid in the grooves of the AccuFlo®Zero (see figure Figure 2). The side with the

seals points to the transmitter. The junction box can be placed at the front or the back.

AccuFlo®Zero –Installation and Operating Instructions

8

Installation and operating instructions AccuFlo®Zero

Figure 2: Metal block of the AccuFlo®Zero

Then the AccuFlo®Zero is pushed upon the threaded rods.

Now the seals are laid in the grooves of the valve manifold (or existing ones are replaced). The valve

manifold is pushed upon the thread rods as well.

Last, the nuts are screwed loosely on the thread rods. After checking the right positions of all

components tighten the screws.

Attention: The assembling has to be checked thoroughly before commissioning!

5.2 Electrical connections

In the following chapter all electrical connections are described:

Power supply:

oThe AccuFlo®Zero needs a voltage supply of 24 V DC with a power rating of at least 2.1 ampere.

oWe recommend a switch-mode power supply.

oWe recommend positioning the power supply nearby the AccuFlo®Zero.

Wires from the AccuFlo®Zero to the transmitter:

oOne cable with 2 wires (two-wire interface 4–20 mA).

Wires from the AccuFlo®Zero to the control station:

oOne cable with 2 wires (two-wire interface 4–20 mA).

oOptional: one cable with 2 ore 3 wires for the status relay (or accordingly more wires for the

interface mentioned above).

oOptional: One cable with 2 wires for the manual triggering of the zero-point calibration (or

accordingly more leads for the interface mentioned above).

Attention: The AccuFlo®Zero does not dispose of a galvanic separation between the GND of the power supply

and the GND of the control station.

AccuFlo®Zero –Installation and Operating Instructions

9

Installation and operating instructions AccuFlo®Zero

5.3 Status relay

The AccuFlo®Zero includes two status relays which may offer following signals:

The relay “in operation” issues signal “1” if the AccuFlo®Zero is switched on and the transmitter is identified. In

case of error it issues a signal “0”. Possible errors: powerless AccuFlo®Zero, no transmitter identified, default on

the AccuFlo®Zero.

The relay “balanced” provides a 1-signal if the zero-point calibration is effected and real time results are

provided in the current loop. In any other case it provides a 0-signal: before the first zero-point calibration,

during the calibration if the calibration did not succeed. (Last results of the current loop is fixed and shown

statically during this period).

Both relays may be connected in series in the AccuFlo®Zero and provide a group signal. A 1-signal is only sent

if the AccuFlo®Zero is switched on, the transmitter is identified and the last zero-point calibration succeeded

(that means no zero-point calibration is needed). In all other cases (as well during the 30-seconds calibration) a

0-signal is provided.

There are two choices: either the AccuFlo®Zero sends a +24-V-signal to the control station or the relays switch

a signal sent by the control station.

5.4 Manual zero-point calibration

A zero-point calibration may be triggered by the control station or an external operator station. Then, the

terminal connection “G3” has to be connected with GND.

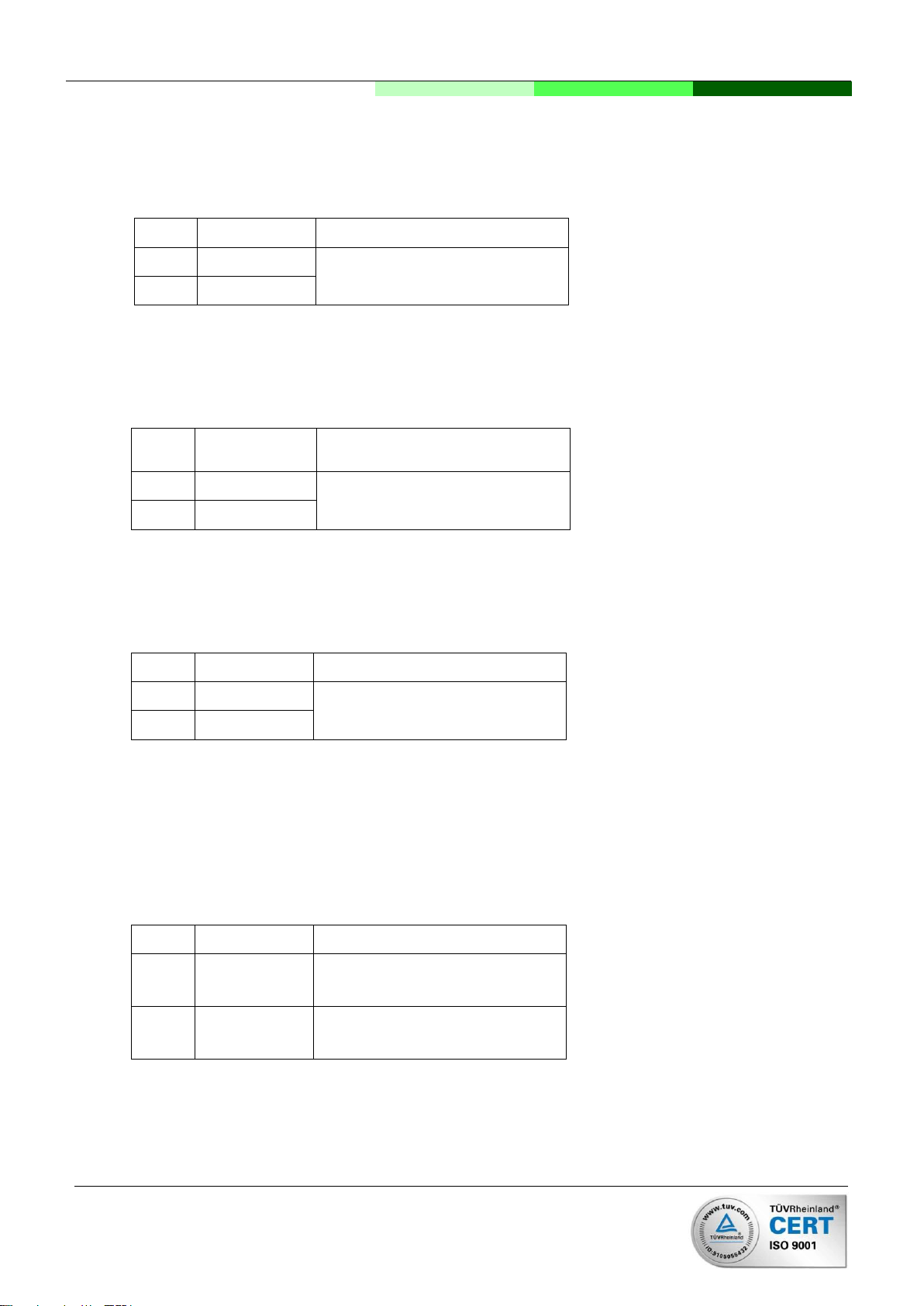

5.5 Terminal assignment

Overview of all terminal blocks on the AccuFlo®Zero:

Figure 3: Open AccuFlo®Zero

E1

E2

E3

E4

F1

F2

F3

F4

G1

G2

G3

G4

A1

A2

A3

A4

B1

B2

B3

B4

C1

C2

C3

C4

D1

D2

D3

D4

J1

J2

AccuFlo®Zero –Installation and Operating Instructions

10

Installation and operating instructions AccuFlo®Zero

Power supply of the AccuFlo®Zero:

Table 1: Jumper "J1" set/closed

Terminal

Description

Use

G4

+24 V

Power supply

E1

GND

24 V DC / 2 A

Connection between the AccuFlo®Zero and the differential pressure transmitter:

Table 2: Connection to the transmitter

Terminal

Terminal

in transmitter

Use

A4

+

Differential pressure transmitter 4–20 mA

D2

−

Connection between the AccuFlo®Zero and the control station:

Table 3: Analog signal to the control station

Terminal

Description

Use

A1

+

Analog output signal

A2

−

4–20 mA

If necessary:

Option 1: +24-V-signal from AccuFlo®Zero to the control

station mode „error“ and „OK“

Jumper „J1“ set/closed!

Table 4: Relay outputs –option 1:

Terminal

Description

Use

E3

+ (Calibrated)

Signal „Calibration Successful“

+24 V after successful zero-point calibration

E4

+ (Ready)

Signal „Ready“

+24 V if AccuFlo®Zero is ready

AccuFlo®Zero –Installation and Operating Instructions

11

Installation and operating instructions AccuFlo®Zero

Option 2: +24-V-signal from AccuFlo®Zero to the control

station mode as group message

Remove/open jumper „J2“. Connect terminal “E4” with “F4”!

Table 5: Relay output - option 2:

Terminal

Description

Use

E3

+

Signal „Ready and Calibration Successful”

+24 V if AccuFlo®Zero is ready and zero-

point calibration is successful

Option 3: Externally supplied signal from AccuFlo®Zero to

control station for status „Error“and „Ready“

Remove/open jumper „J2“.

Table 6: Relay outputs –option 3:

Terminal

Description

Use

E2

external + *

Externally supplied signal

E3

+ (Calibration)

Signal „Calibration“

+ of the manually supplied signal after

successful zero-point calibration

E4

+ (Calibration)

Signal „Ready“

+ of the manually supplied signal if the

AccuFlo®Zero is ready

Option 4: Externally supplied signal from AccuFlo®Zero to

control station as “group message“

Remove/open jumper „J2“.

Table 7: Relay outputs –option 4:

Terminal

Description

Use

E4

external + *

Externally supplied signal

E3

+ (Ready and

calibration

successful)

Signal „ Ready and calibration successful “

+ of the manually supplied signal, if the

AccuFlo®Zero is ready and the zero-point

calibration is successful

*Since mechanical relays may be used, also for example

alternating voltage may be chosen.

AccuFlo®Zero –Installation and Operating Instructions

12

Installation and operating instructions AccuFlo®Zero

If necessary: external triggering of the zero-point

calibration

Table 8: Signal „start zero-point calibration“ from the control

station to the AccuFlo®Zero

Terminal

Description

Use

D4

GND

GND of the AccuFlo®Zero

G3

GND = Start

calibration

If GND is connected to „G3“, the zero-point

calibration is initiated.

AccuFlo®Zero –Installation and Operating Instructions

13

Installation and operating instructions AccuFlo®Zero

6 Commissioning

6.1 General procedure

If all components are connected, please switch on the power. The control of the display of the differential

pressure transmitter shows the operational state of the transmitter. A LED in the AccuFlo®Zero (see Figure 3,

page 9) will light up after short time and indicate that the device is powered. After a few seconds the flashing of

the LED indicates that a HART®-communication to the transmitter is established. A few seconds later, an initial

zero-point calibration is triggered which is indicated by a continuous light of the LEWD. After a short time, a

sound of the magnetic valves is audible.

Attention: The electrical terminals are not to be dismounted during operation!

6.2 Successful set up

The successful set up is indicated by a permanent lightening of the LED (see Figure 3, page 9).

6.3 Optional correction of positioning with steam measurements and

condensate in the system

To avoid incorrect measurement of steam flows due to wrong positioning of the device, we recommend an offset

measurement of the zero-point. Please procedure as follows:

1. Ensure the process in the pipe system is stopped and there is no flow.

2. Ensure that the system (differential pressure transmitter, AccuFlo®Zero, manifold, impulse pressure

lines) and the condensate vessels are filled with water, are stable and completely vented..

3. Switch on the power of the AccuFlo®Zero and wait until the zero-point calibration is triggered once. (The

LED (see Figure 3, page 9) is blinking permanently for more than 20 seconds.)

4. Now, the transmitter is reconnected with the process. Since the system is switched off, the transmitter

should measure a differential pressure close to “0” (The display of the transmitter may have to be

adapted to show the differential pressure. If you prefer to control the exit power of the transmitter, the

result should be around 4.00 mA.

In this case, no correction of the position has to be effected.

In the transmitter does not read 0 there is a wet-leg error due to the unequal heights of the water

columns of the “+” and the “-“-side of the transmitter. Please continue with step 5.

5. By establishing a short connection of the contacts „D1“ and „D2“ (see Figure 3, page 9) the actual

measurement result will be stored as offset for the correction of positioning.

6. Effect a zero-point calibration by establishing a short connection of the terminals “G3” and “D4”.

7. After the zero-point calibration the transmitter is reconnected with the process. Now, the display of the

transmitter indicates a result around “0”.

AccuFlo®Zero –Installation and Operating Instructions

14

Installation and operating instructions AccuFlo®Zero

6.4 Delete a correction of positioning

If no correction of positioning is needed, it may be deleted from the system. This is reasonable for example for

the use of the transmitter on a different measure point after demounting. Procedure:

1. Switch on the power of the AccuFlo®Zero and wait until the zero-point calibration is effected once. (The

LED (see Figure 3, page 9) is blinking permanently for more than 20 seconds.)

2. A short bridging of the contacts “D3” and “D4 (see Figure 3, page 9) results in the deletion of the offset

of the positioning correction.

3. Effect a zero-point calibration throughout the short connection of the terminals “G3” and “D4”.

4. Now, the display of the transmitter indicates a result without positioning correction.

6.5 Signaling to the control station

Status information may be transmitted from the AccuFlo®Zero to the control station. Two relays are available.

For more information on the available signals please refer to chapter 5.3.

7 Operation

During operation, no user interference with the AccuFlo®Zero is necessary.

Normally, every 24 hours a new zero-point calibration is released automatically. The zero-point calibration is

also triggered if the measured cell temperature of the transmitter deviates more than 10 K (or from any other

defined threshold value) from the result of the last calibration.

The accurate operation is signalized by a permanent blinking of the LED (see Figure 3, page 9). Furthermore,

the signals of the AccuFlo®Zero may be evaluated (see chapter 5.3)

8 Errors

8.1 Signaling of errors

Errors are indicated by the status signals of the AccuFlo®Zero (see chapter 5.3). Furthermore, the LED in the

AccuFlo®Zero (see Figure 3, page 9) indicates the status of the device.

AccuFlo®Zero –Installation and Operating Instructions

15

Installation and operating instructions AccuFlo®Zero

8.2 LED lights up permanently

After switching on the LED lights up permanently for more than one minute or errors occur during the zero-point

calibration:

Is the connection to the transmitter is faultless?

Is the external load <300 Ω?

Error in communication:

oA switching power supply provokes less ripple in the used frequency range than a conventional

power supply with classical transformer. A substitution is recommended.

oShielded wires may decrease the influence of external interference. Connect the shield only

one-sided with the ground potential.

8.3 LED does not light up

The LED does not light up and the transmitter does not operate:

Is the power-supply faultless?

Are the electrical connections faultless?

8.4 LED is flashing permanently

The LED is flashing permanently and no calibration is performed:

The device is in waiting mode. This is an intended operational mode.

No sufficient cell temperature deviation is identified.

The interval of the automatic calibration has not yet expired.

AccuFlo®Zero –Installation and Operating Instructions

16

Installation and operating instructions AccuFlo®Zero

9 Technical data

9.1 General information

Automatic zero-point calibration

Cycle length between calibrations

Configurable at order (factory setting: 24 h)

Temperature trigger

Configurable at order (factory setting: 10 K

temperature difference between last calibration)

Length

30 s

Maintaining of analog output signal

Last available measurement output value is held

constant by transmitter during zero-point calibration

Commissioning mode

Correction of permanent zero-point errors due to

installation errors

Supported flow meters

All differential pressure based flow meters (ISO 5167

and AGA-3-primary elements, pitot tubes, v-cones,

etc.)

Process and signal connection

Material of wetted parts

Stainless steel (1.4571)

Process connection manifold

IEC 61518 / DIN EN 61518 Groove Ø18.5 mm

Process connection transmitter

IEC 61518 / DIN EN 61518 Type A with spigot

Pressure rating

PN 100

Ambient conditions

Ambient temperature of wetted parts

–20 … 50 °C

Climate conditions

Humidity 0–100 %, external moisture condensation of

installed device permitted.

Protection class

IP 65 ( IEC 60529)

Electromagnetic protection

According to EN55011:2009+A1:2010, Group 1,

Class B und EN61326-1:2013

Design

Weight

2.8 kg

Dimensions

120x40x140 mm³

Life expectancy

At least 10.000 calibrations

Retrofittability

For all differential pressure based flow meters

Certificates and standards

Pressure Equipment Directive

DGRL 2014/68/EU

For gases fluid group 1, liquids fluid group 1;

fulfills requirements according to Art. 4 (3) (good

engineering practice)

AccuFlo®Zero –Installation and Operating Instructions

17

Installation and operating instructions AccuFlo®Zero

9.2 Electrical data

Attention: before assembling and operation you have to operating voltage and the copolarity. Furthermore,

choose the correct terminals (see chapter 5.5).

Electrical connections

Supply voltage

24 V DC; at least 2.1 A

Signal to the status relay

Option 1: +24-V-signal from AccuFlo®Zero to control

station

Option 2: connected AC/DC-signal (max. 48 V) with

supply from the control station

Inputs

Transmitter

Two-wire-interface 4–20 mA

Supply of the transmitter

Provided

Digital communication

HART®

Maximum wire length between AccuFlo®Zero

and transmitter

5 m

Outputs

Output signal

Two-wire-interface 4–20 mA

Maximum wire length between AccuFlo®Zero

and control station

1 km with standard wire and 2 km at use of wires with

low capacity (< 95 pF/m)

Maximum load

300 Ω

Status relays

Two status relays for signaling of „zero-point

calibration successful“ and „ready“ (may be grouped

up to one signal)

Interfaces

External RS485-Bus

AccuMind®(flow computer unit of SKI GmbH)

Configuration

Permanent bridges

Basic functions are to be chosen by using jumpers.

Short-time bridges

A manual zero-point calibration or a correction of

positioning may be influenced by a quick connection

of terminals

AccuFlo®Zero –Installation and Operating Instructions

18

Installation and operating instructions AccuFlo®Zero

10 Declaration of Confirmity

AccuFlo®Zero –Installation and Operating Instructions

19

Installation and operating instructions AccuFlo®Zero

AccuFlo®Zero –Installation and Operating Instructions

20

Installation and operating instructions AccuFlo®Zero

S.K.I. Schlegel & Kremer

Industrieautomation GmbH

Postfach 41 01 31

D-41241 Mönchengladbach

Hanns-Martin-Schleyer-Str. 22

D-41199 Mönchengladbach

Tel: +49 (0) 2166/62317-0

Web: www.ski-gmbh.com

Registered trademarks and logos are the property of their owners. Subject to technical changes.

The illustrations may contain optional installations.

BA-AccuFloZero-en-L-1643.docx

Table of contents

Other SKI Test Equipment manuals

Popular Test Equipment manuals by other brands

Apera Instruments

Apera Instruments PH60F-Z instruction manual

Rhopoint

Rhopoint UFT operating instructions

RenewAire

RenewAire PA ERV Series Installation, operation and maintenance manual

SENTRONIC

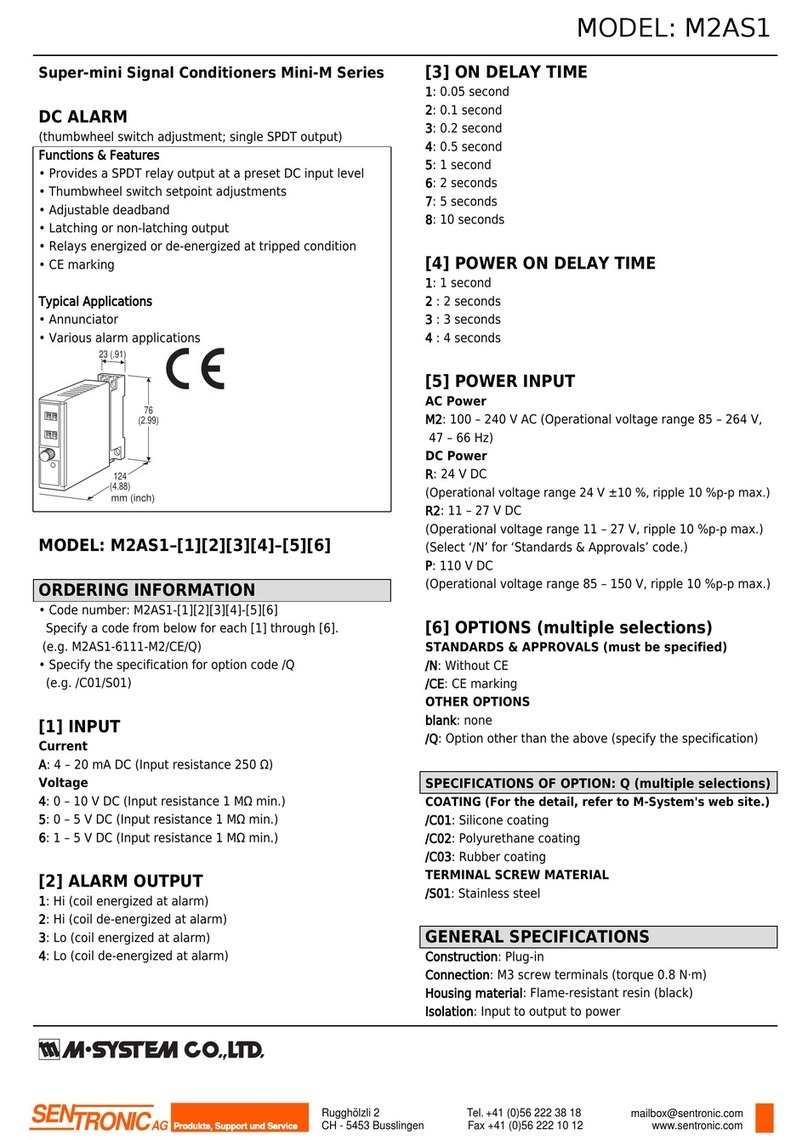

SENTRONIC M-SYSTEM Mini-M Series quick start guide

Keithley

Keithley Interactive SourceMeter 2450 Declassification and security instructions

ABB

ABB SACE PR010/T instructions

Kikkoman

Kikkoman Lumitester PD-30 instruction manual

Hartridge

Hartridge CRi-PC Operating and servicing manual

Tektronix

Tektronix TBS1022 Security instructions

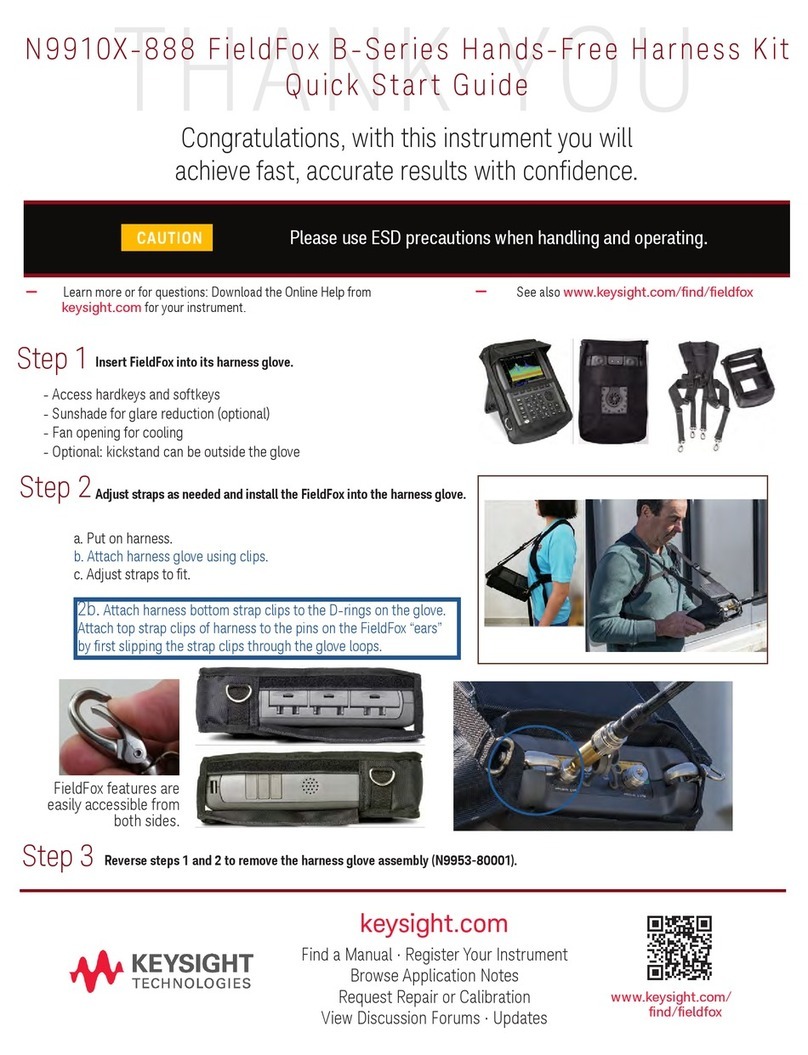

Keysight Technologies

Keysight Technologies N9910X-888 quick start guide

Keysight

Keysight 16034G Operation manual

KINGSINE

KINGSINE K68i instruction manual