SKI uFLOW 100LSE-QAL User manual

BA-µflowQAL-en-L-1740.docx

µFLOW 100LSE-QAL

compact calculator for

gas applications

Instruction manual

Valid from software version LSE-QAL-211

2

content

Explanations of symbols _____________________________________________________ 3

General Hints______________________________________________________________ 3

Qualified Personnel_________________________________________________________ 3

Technical data _____________________________________________________________ 4

Dimensions___________________________________________________________________________4

Mechanical mounting___________________________________________________________________4

Cleaning _____________________________________________________________________________ 4

General hints for Electrical connection _____________________________________________________5

Connection examples for inputs___________________________________________________________5

Connection examples for the output________________________________________________________ 5

The terminals in detail __________________________________________________________________6

Choice of function (QAL or LSE) _________________________________________________________7

Exchange of the fuses___________________________________________________________________ 7

The displays _______________________________________________________________ 7

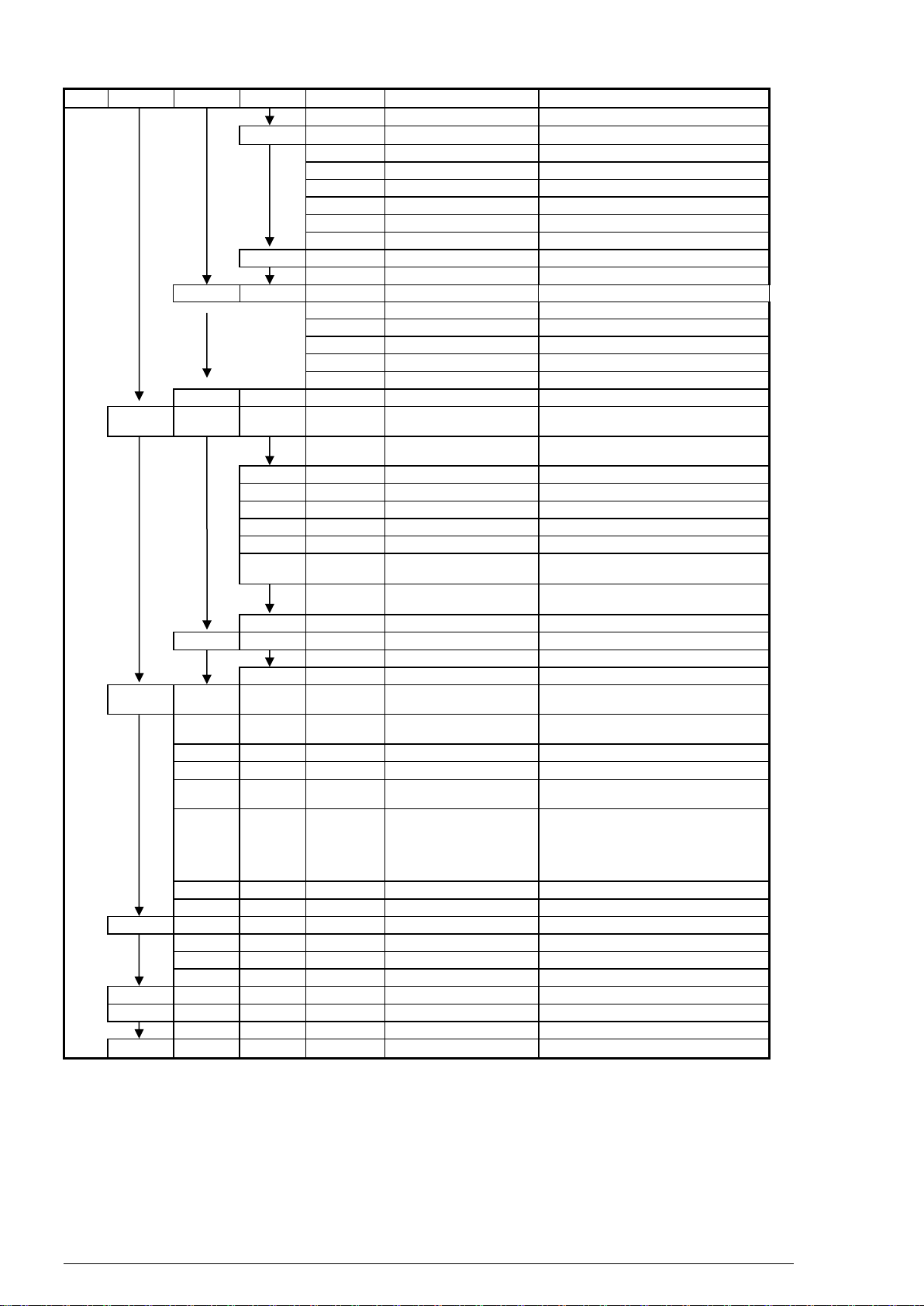

Menu tree _________________________________________________________________ 9

Short example for changing parameter value________________________________________________ 11

Access _____________________________________________________________________________ 11

Sensorbyte –menu point SENSORS (Level C/65) ___________________________________________ 11

k-Factor –Menu point k-factor (level D/7) _________________________________________________ 12

The transfer characteristic ______________________________________________________________ 12

Application of the RS232 Interface _______________________________________________________ 12

Link and control of the µFLOW with a PC _________________________________________________ 12

Adjusting the Baudrate - menu option BAUD (level D/46)_____________________________________ 12

Adjusting the duration of the transmission cycle _____________________________________________ 12

Parameters __________________________________________________________________________ 13

Protocol ____________________________________________________________________________ 13

Data format__________________________________________________________________________ 13

Trouble shooting __________________________________________________________ 14

Description of the failure _______________________________________________________________ 14

Possible reason_______________________________________________________________________14

EC-Declaration of Conformity _______________________________________________ 15

3

Explanations of symbols

Warning of a danger place (caution: consider documentation)

ISO 3864, No. B.3.1

Warning of dangerous electrical voltage

ISO 3864, No. B.3.6

General Hints

For reasons of clarity this manual does not contain detailed information about all types of products and

cannot take into account every conceivable case of installation, operation or maintenance.

If you require further information or should problems occur which are not sufficiently explained in the

manual, you can consult us directly to obtain the necessary information.

May we also draw your attention to the fact that the contents of the manual are not part of a previous or

existing agreement, approval or legal relationship or an amendment thereof. All obligations of the S.K.I.

GmbH result from the contract of purchase which also contains the full and solely valid warranty

agreement. These contractual warranty conditions are neither extended nor restricted by the contents of

the manual.

Qualified Personnel

are persons familiar with the installation, assembly, commissioning and operation of the product and who

have the appropriate qualifications for their activities such as:

Training or instruction or authorization to operate and maintain devices/systems

according to the standard of safety technology for electrical installations.

Training or instruction in the proper care and use of protective equipment in accordance

with appropriate safety practices.

Rendering first aid.

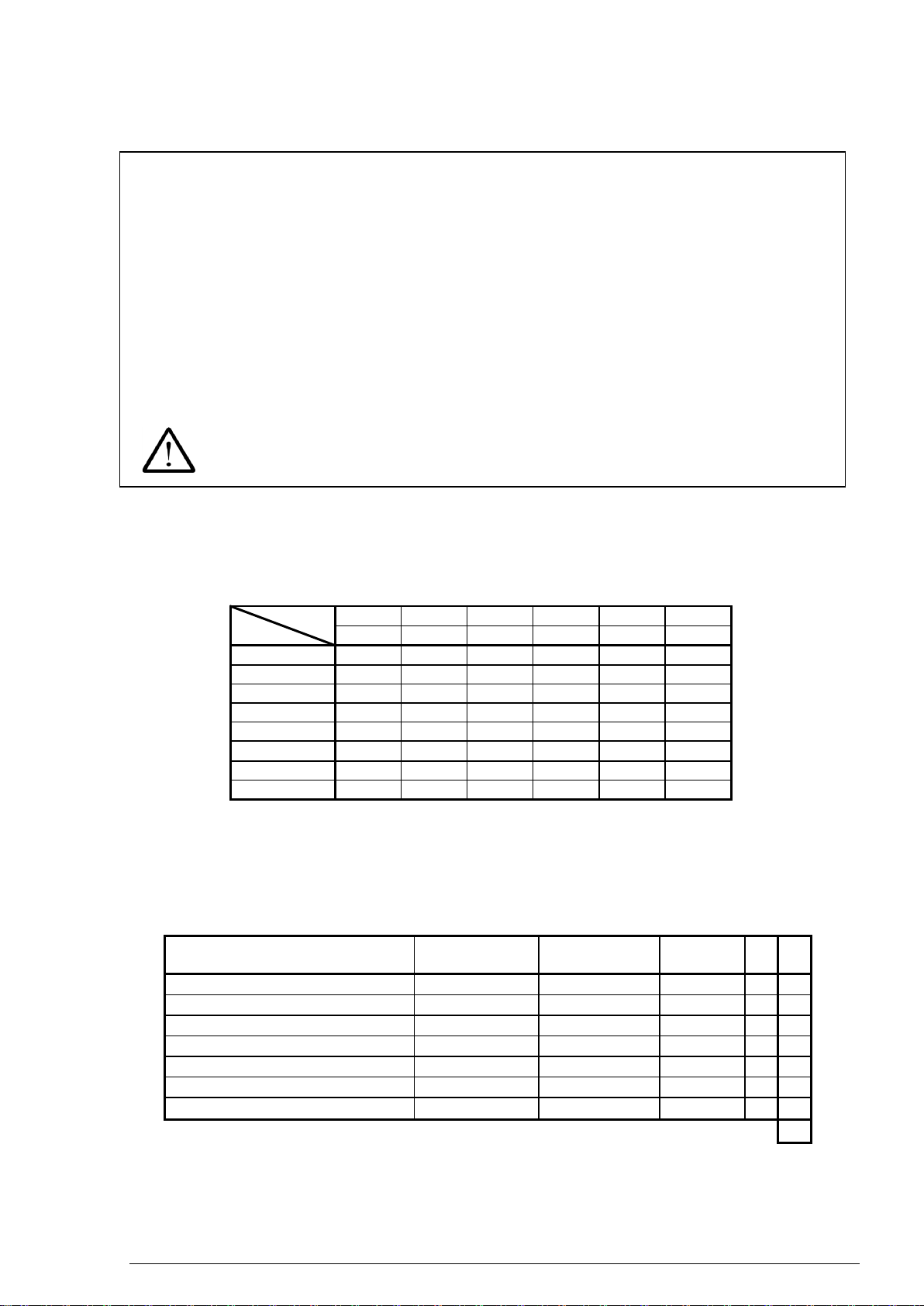

attention

During start up no buttom on the front panel must be pressed

CAUTION

This equipment is a Limit Class A once. It can cause radio disturbance in

residential. On this case costumer has to take care appropriate measure.

This equipment should only be installed and operated after qualified personnel

have ensured that suitable power supply (see name plate) will be used and that

during normal operation or in case of a defect in the system or in components no

hazardous situation can occur. Therefore serious injuries and/or considerable

material damage cannot be ruled out in the event of improper handling of the

device.

The perfect and safe operation of this equipment is conditional upon proper

transport, proper storage, installation and assembly as well as on careful operation

and commissioning.

4

Technical data

indication: LC-Display, 2 lines with 16 signs

nominal voltage: 230 VAC (10%)

115 VAC (optional)

24 VDC (optional)

frequency range: 50 Hz 10%

nominal current: 65 mA @230/115V 50Hz

500 mA @24 VDC

nominal power 15 VA @230/115V 50Hz

12 VA @24 VDC

maximum main interference: 150 V/20 ms, followed by automatic RESET by integrated monitoring

module with backup of the count

EMV tests: according to EN 55011/ 55011-A1; EN 61326-1/ 61326-A1 and

EN 50082-1/2

Functional test: Watchdog, FAIL function with drop-out contact in the event of fault

Available auxiliary power: 24 VDC/160 mA for transmitter supply (with auxiliary power 115/230

VAC only) No transmitter supply is possible with auxiliary power 24 V

DC

analog inputs: 5x 0/4-20 mA switchable via software

1x switchable to Pt100 direct input

measuring range for Pt100: –200°C....+500°C

Internal resistance 24 Ohm per current input, >10 Mfor Pt100

Analog/Digital converter 16 bit resolution with integrated 50Hz-suppression; complete

electrical isolation from the computer and all outputs(except in the

case of transmitter supply)

Frequency input: 0,1 up to 10kHz

Analog outputs: 1x 0/4-20 mA, optional 2x 0/4-20 mA

max. load: 500 Ohm

Contact (open collector): max. 1W, max 30 V

resolution of the outputs: 14 bits, completely electrically isolated from the computer and all

inputs

relay outputs: 1x free configurable, 1x Fail-relay, 1x service relay

max. load of the contacts: 250VAC/8A

*Caution: Before installation and operation costumer has to check the nominal voltage.

Only the declaration on the type plate is guilty!

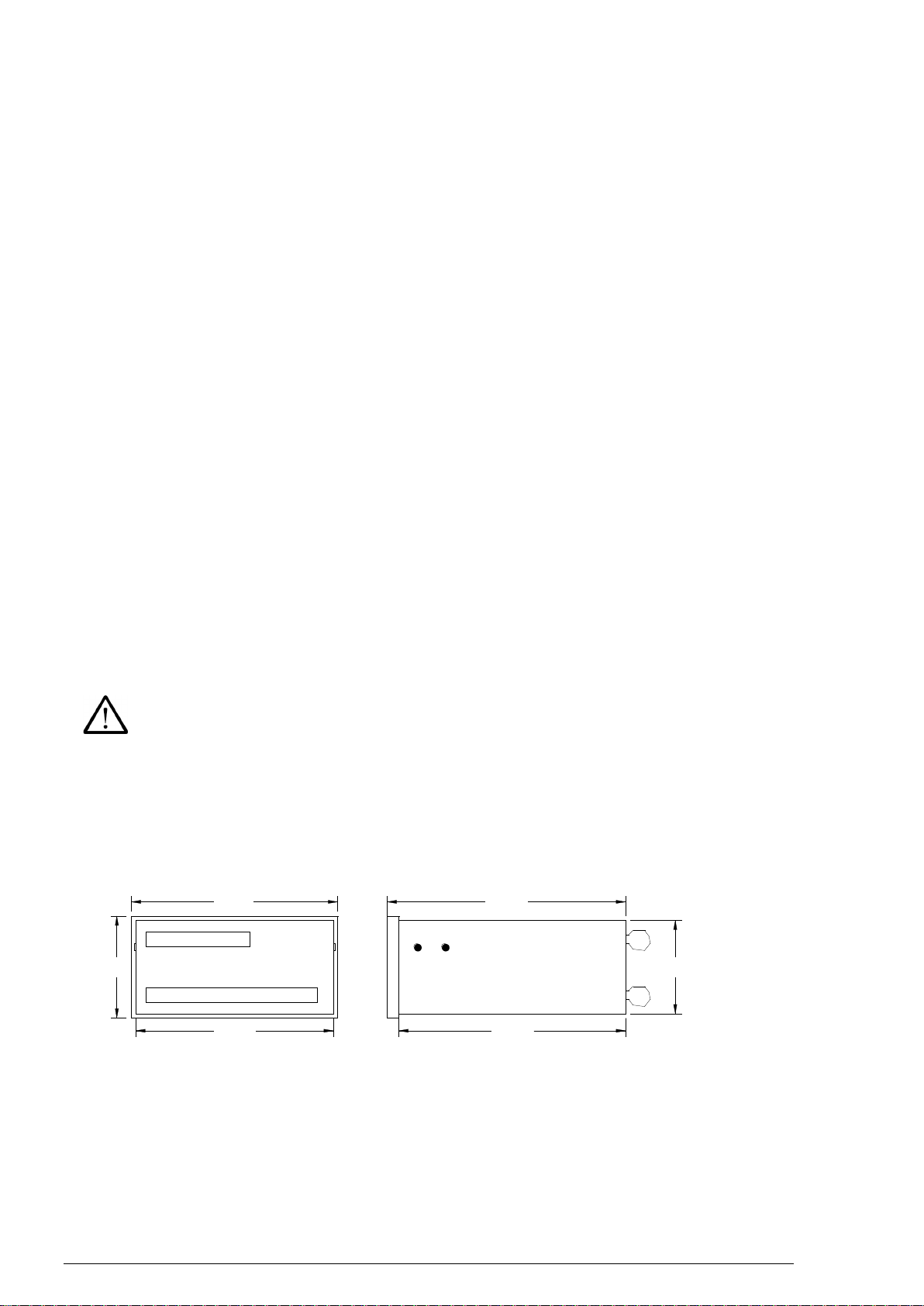

Dimensions

enclosure: glass-fibre-reinforced Noryl, front panel 144x72 mm²(DIN)

material: Noryl SE1 GFN2

protection class: IP 20 (enclosure); IP64 (display unit)

depth: ca. 170 mm

panel cut-out: 5.45“ x 2.7“ (138 x 68 mm²)

5.67“ 6.41“

Mechanical mounting

The standard µflow is a panel mounting unit. After preparing the panel cut-out, costumer has to mount the

µFlow while using the delivered mounting brackets. Please pay attention to use the delivered seal

between panel and µFlow-housing.

Cleaning

The µFlow has to be cleaned only with a dry duster.

65mm

135mm

144mm

72mm

163mm

155mm

5

picture 3: without temperature measurement

picture 4: without pressure

measurement

General hints for Electrical connection

Signal leads must be shielded, one end of the shield has to be connected to mass. Signal

and main leads have to be layed separately.

For electrical installation following determinations are to be observed:

power supply wiring has to be designed for nominal current

power supply has to be installed, so that the power supply of µFlow can be switched off

switch off power supply before opening the µFlow

Connection examples for inputs

Connection examples for the output

picture 6: frequency input for the flow

signal

Picture 5: active signals, the transmitters

are powered by an external

supply.

HE = auxiliary power

picture1: passive current inputs, the

µFlow powers the transmitters

picture 2: passive current inputs, with

Pt100 direct connection instead of

using a temperature transmitter

25

31

µFlow

33

36 o. 37

P

I =

I =

temperatur

e

pressure

k

T

-

+

-

I =

Q

flow

+

+

-

µFlow

press

ure

I =

-

Pt100

P

Q

flow

+

+

I =

-

24

25

26

31

33

36 o.

37

+

P

pressure

-

I =

31

flow

+

Q

-

I =

µFlow

33

36 o.

37

+

tempera-

ture

I =

T

-

flow

+

I =

Q

-

25

36 o.

37

33

µFlow

I =

I =

I =

temperatu

r

T

HE

press

urek

flow

Q

P

HE

HE

-

25

+

-

31

33

+

-

+

µFlow

34o.35

flow

+

Q

-

18

19

µFlow

37

37

37

37

6

Connection examples for outputs

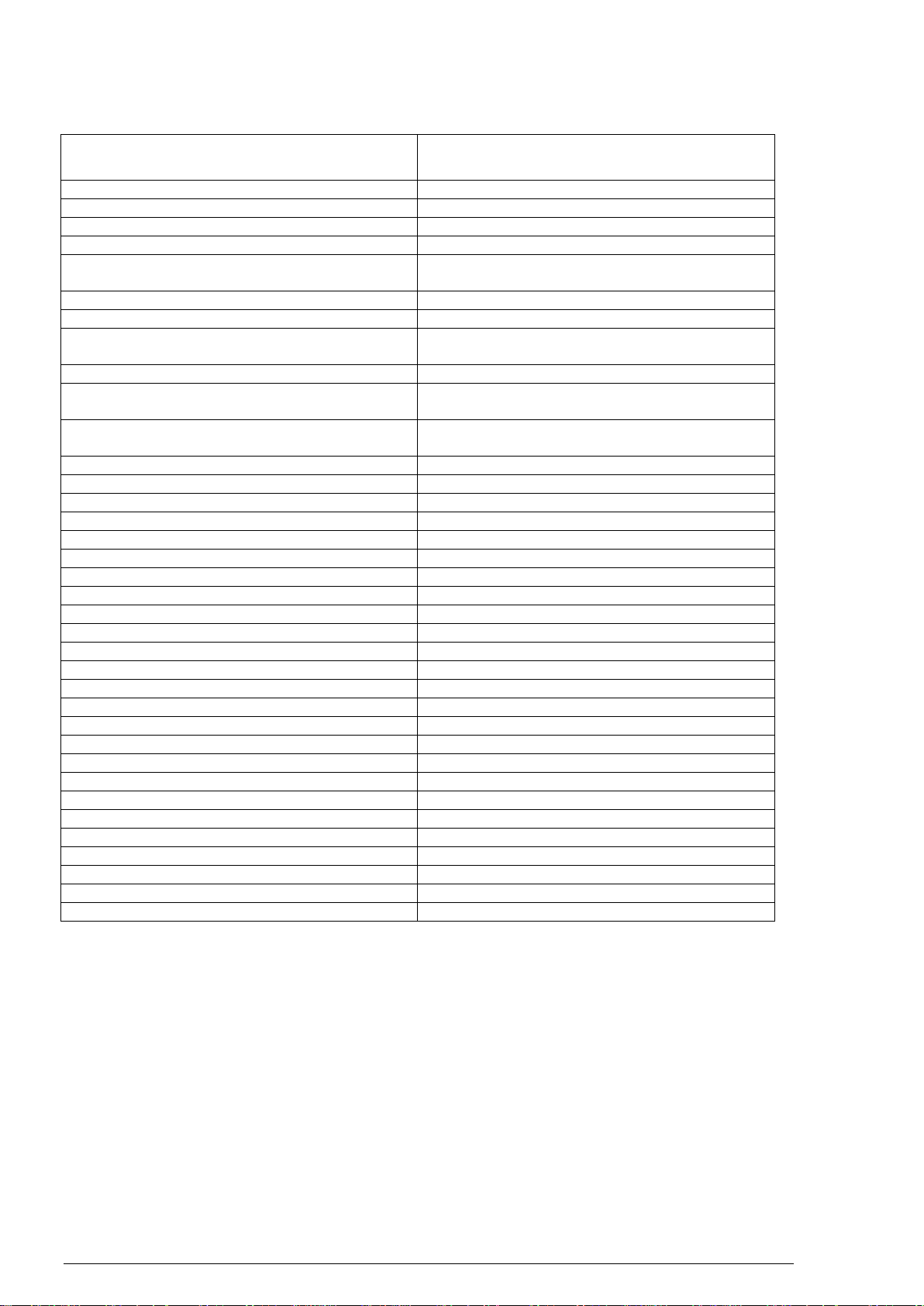

The terminals in detail

Long terminal row short terminal row

terminal

name

use

terminal

name

use

1

L/DC+

Power supply, (24 V DC + optional)

24

B

2

N/DC-

Power supply, (24 V DC - optional)

25

A/IN5

Current input T1 or

3

PE

mass

26

b

4

RXD

Transmit Data

27

B

Limit switches 2 –4 (purging)

TXD

Receive Data

28

A/IN6

Limit switch 1 (operating)

6

DGND

Data Ground

29

b

Power supply for limit switches

7

CNT

contact NPN Open collector

30

IN4

Not used

8

DGND

GND for pulse output

31

IN3

Current input pressure

9

CO

32

IN2

Current input Flow 2

10

NO

Relay 1 (purging relay)

33

IN1

Current input Flow 1

11

NC

34

GND

GND for transmitters

12

CO

35

GND

GND for transmitters

13

NO

Relay 2 (maintenance relay)

36

24V

Auxiliary power for transmitters

14

NC

37

24V

Auxiliary power for transmitters

15

CO

16

NO

Fail-Relay

17

NC

18

Freq+

Frequency input

19

Freq-

20

OUT2-

Analog output 2 (Option)

21

OUT2+

22

OUT1-

Analog output 1

23

OUT1+

picture 7: contact (open collector) for

indicating that the flow velocity

is smaller than the chosen

value of the –Alarm (menu tree,

level 8a).

In this case the voltage drop at

the resistance rises to appr. 24

volts.

picture 8: analog output

outputs are active, there is no need

for an external power supply. The

max. load is 500

Picture 11:main circuit board with

Jumpers for the

frequency input

Picture 12:CPU circuit board with the DIP-

switches for the temperature input

and QAL/LSE

+

-

22(20-OUT2)

23(21-OUT2)

µFlow

Fuse for

24V DC supply

Sof

tw

are

RTD1

or

Temp1

LSE

or

QAL

ON

ON

1

2

1

2

Pt100

Main fuse

Trafo

1

2

3

4

5

6

7

8

7

Choosing the signal for the temperature input (Pt100 or current)

Choosing the software function

Picture 12 shows the location of the DIP switches for the adjustment of the temperature input and the

software function. The switches are reachable after dismounting the back panel. Additional setting for

QAL-Software: Level 54 in the menu tree has to be changed to “extern”.

switch

1

2

Pt100

off

on

Current

on

off

Exchange of the fuses

The main fuse is located on the main circuit board (see picture 11). The fuse for the 24 V auxiliary power

is located on the CPU circuit bord (see picture 11. The fuses are reachable after dismounting of the back

panel. The type of fuse to be used is depending on the power supply

Power supply

Main fuse

Fuse for 24V

230V AC

250V/80 mAT

250V/160 mAT

115V AC

250V/80 mAT

250V/160 mAT

24V DC

250V/0,5 AT

-

Status displays and status signals

Operating

On the next page the displays that can be chosen during a trouble-free operation are shown. The fail-

relay is energized and the maintenance relay is de-energized.

Disabled state

The function of the device is monitored permanently by a „Watch dog”. In case of a malfunction the fail-

relay de-energizes. E.g.: If the supply voltage falls below a permissible value the fail-relay de-energizes

and the display will be darker.

Maintenance

Before carrying out a maintenance both “Prog"-keys have to be pressed simultaneously. The

Maintenance Relay energizes and the following display will be shown:

switch

1

2

LSE

off

off

QAL

on

on

M

a

i

n

t

e

n

a

n

c

e

!

I

D

=

0

0

0

0

8

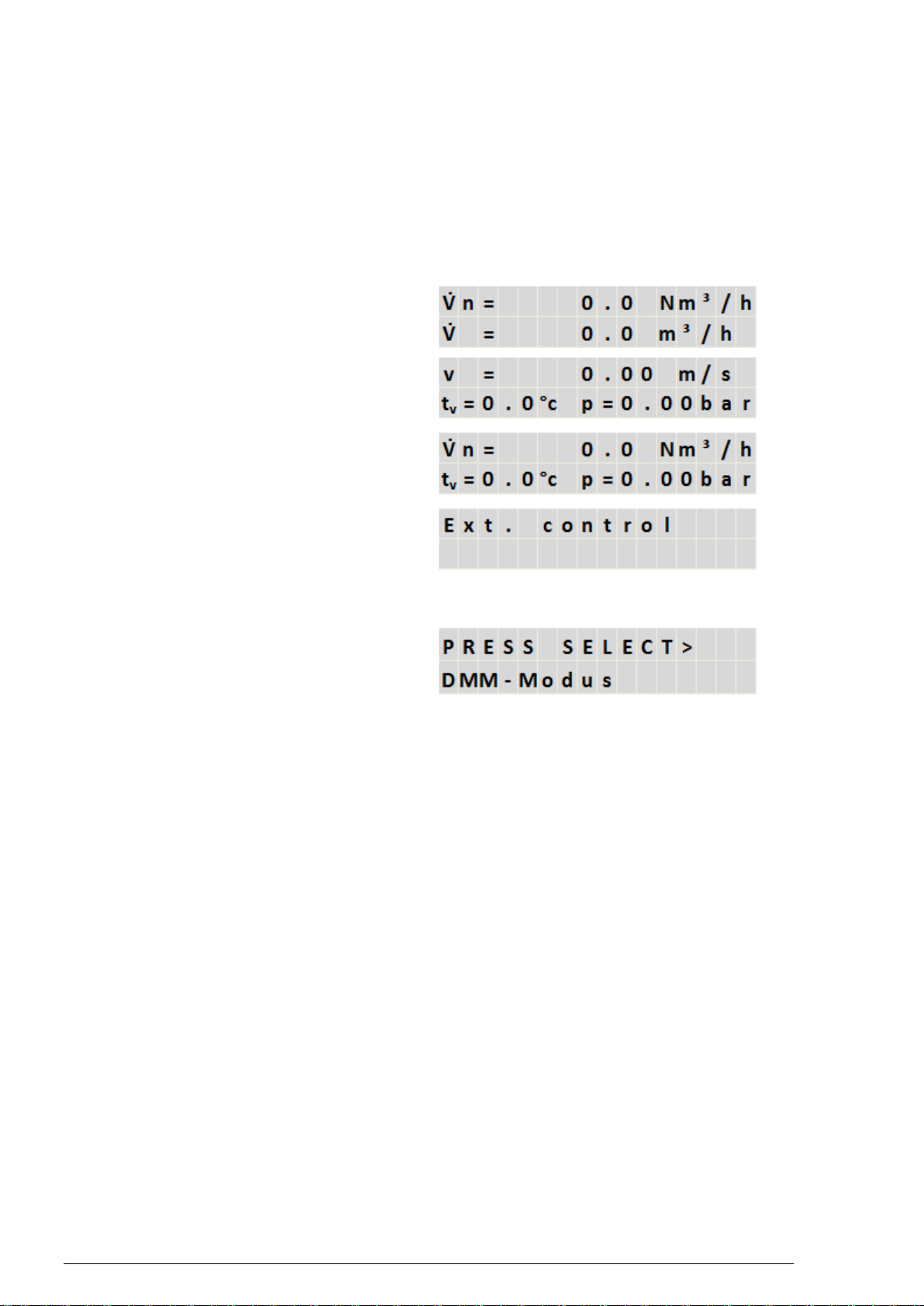

The displays

The following table show the different displays. By pressing the "" key, it is possible to switch between

the displays in descending order of the table. By pressing the "" key, it is possible to switch in the

opposite direction. After pressing the SELECT key, the TAG-no., which can be programmed by the user,

will be indicated. After pressing the SELECT key again, you get back to the normal display mode.

standard volumetric flow

and Actual volumetric flow

flow velocity,

temperature and pressure

standard volumetric flow,

temperature and pressure

air purging device

(ext. switch or time control)

branching of subdisplays for value reading

only available with access for Laboratory, OEM

or Factory

9

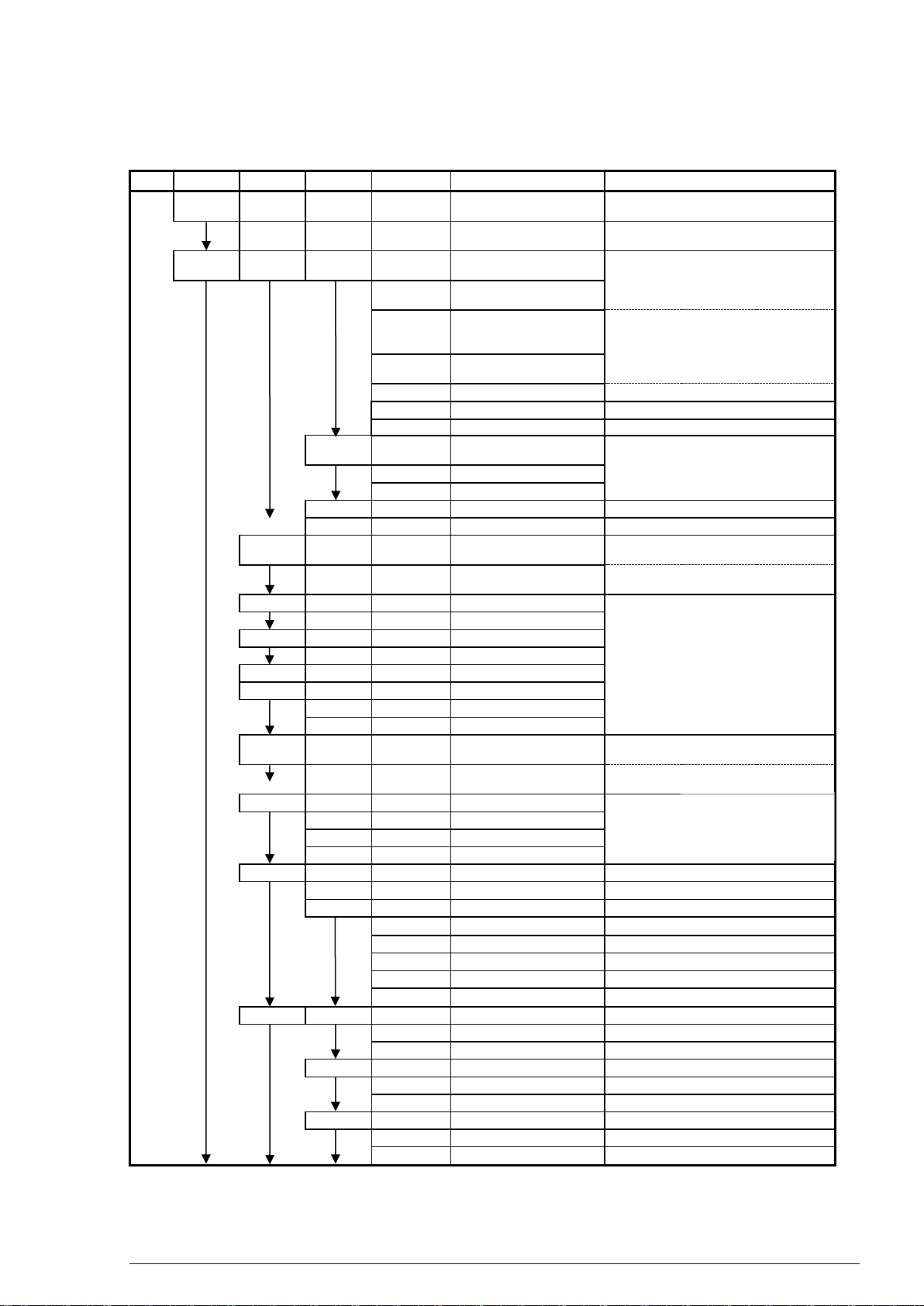

Menu tree

attention: For some parts of the menu the access is denied.

Level

A

B

C

D

Input / indication

comments

1

Info

Version

Ver. GAS-1.9917ff

Indication of the software version, no

input possible

2

Ser.No..

SN: ....

Indication of the serial number, no input

possible

3

Params

Flow1

dp

dP1.min

Input of dP-value for

0/4mA

Does not appear, if a velocity sensor is

chosen

4

dP1.max

Input of dP-value for

20mA

5

dp2.min

Input of dP-value for

0/4mA

Attention: if no second dp- transmitter is

connected, the values for dp2.min +

dp2.max must be set to zero

6

dP2.max

Input of dP-value for

20 mA

7

k-factor

Input of value

Specification of the k-factor

8

density

Input of value

in kg/Nm³

8a

-Alarm

Input of value

0-60 m/s

9

velocity

Puls/V

Input of value

Does not appear, if a dp-sensor is

chosen

10

Vmin

Input of value

Zero point in m³/h

11

Vmax

Input of value

span in m³/h

12

Pipe-ID

Input of value

Internal pipe diameter

13

cutoff

Input of value

cutoff in %

14

Temp

T1.min

temperature according to

0/4mA

15

T1.max

temperature according to

20mA

16

COMP 1

G1min

Input of value

in Vol. %

17

G1max

Input of value

in Vol. %

18

COMP 2

G2min

Input of value

in Vol. %

19

G2max

Input of value

in Vol. %

20

LIMIT

Input of value

in Vol. %

21

density

Rho1

Input of value

in kg/Nm³

22

Rho2

Input of value

in kg/Nm³

23

Rho3

Input of value

in kg/Nm³

24

press

p.min

Pressure according to

0/4 mA

25

p.max

Pressure according to

20 mA

26

RG_DAT

CO2-CON

Input of value

in %

27

N2-CON

Input of value

in %

28

Ho,n

Input of value

in MJ/m³

29

density

Input of value

in kg/Nm³

30

Signal

Damping

Input of value

31

Timebas

Hours, minutes, seconds,

choosing the timebase

32

UNIT

VN

Nm³, Nl

Unit for standard volumetric flow

33

*

VN

Nm³, Nl

Unit for summation of VN

34

m

kg, t, lbs

Unit for mass flow

35

*

m

Kg, t, kt

Unit for summation of m

36

t

°C, K, F

Unit for temperature

37

p

bar, kPa, hPa, psi

Unit for pressure

38

Outputs

Relay1

fnction

VN, V.akt, m, t., p

Function of Relay

39

Charact

min, max

Characteristic of Relay

40

value

Input of value

41

Relay2

fnction

VN, V.akt, m, t., p

Function of Relay

42

Charact

min, max,

Characteristic of Relay

43

value

Input of value

44

Analog1

fnction

VN, V.akt, m, t., p

Function of analog output

45

Charact

4-20, 0-20

Current characteristic

46

Lo-Val

Input of value

Value for 0/4 mA

Only available, if the

process GASKOMP is

chosen in level 75

Only available, if the

process AGA is chosen

in level 75

10

Level

A

B

C

D

Input / indication

comments

47

Hi-VAL

Input of value

Value for 20 mA

48

Analog2

fnction

VN, V.akt, m, t., p

Function of analog output

49

Charact

4-20, 0-20

Current characteristic

50

Lo-Val

Wert eingeben

Value for 0/4 mA

51

Hi-VAL

Input of value

Value for 20 mA

52

53

54

55

RS232

Cycle

Input of value

56

Baud

4800, 9600

Baud rate

Purging

Wait

1… 120 sec

Waiting for signal of position indicator

Cycle

0… 6000 min

Duration between purging cycles

Duration

5… 60 sec

Duration of purging

Extern

Extern/timer

External or time triggered control

Level

High/Low

Level for external signal

Pulse Length

1… 20 *10 ms

Pulse length for external signal

57

Tag.No.

Input of signs

Specification of TAG-No

58

calibrt

inputs

IN1

Lo-VAL

Connect 4mA to input,

press ENTER o. Reset

Calibration of current input 1 low value

59

Hi-VAL

Connect 20mA to input,

press ENTER o. Reset

Calibration of current input 1high value

60

IN2

see IN1

see IN1

see IN1

61

IN3

see IN1

see IN1

see IN1

62

IN4

see IN1

see IN1

see IN1

63

IN5

see IN1

see IN1

see IN1

64

IN6

see IN1

see IN1

see IN1

65

RTD1

LO-VAL

Connect 0 to input,

press ENTER o. Reset

Calibration or Pt100 input low value

66

HI-VAL

Connect 330 to input,

press ENTER o. Reset

Calibration or Pt100 input high value

67

RTD2

see RTD 1

see RTD 1

68

outputs

OUT1

DAU-LO

adjustment: 4,0 mA

Output calibration for 4 mA

69

DAU-HI

adjustment: 20,0 mA

Output calibration for 20 mA

70

OUT2

see OUT1

see OUT1

71

Config

Remote

Remote Control

To leave remote control press the

RESET keys

72

Usernam

Input of value

Input of a username by using the arrow

keys

73

Languag

Deutsch, English

Choose language

74

Struct

Sensors

Input of value

Choosing the sensor structure

75

Process

Ideal, AGA, Ethyl,

Gaskomp

Calculation basis for the density

76

Reset

SW-Res, HW-Res, both,

none

Reset of parametrisation and/or

Structure ATTENTION!

new calibration and parametrisation

required

77

Acc_Cnt

N.o.acc.: 21

Account counter

78

In-Byte

Input of value

Choosing inputs as 0..20 or 4..20 mA

79

Factory

SERIAL.

Input of value

Serial number

80

Access

Reset of account counter

81

HW-Byte

Input of value

Selecting the outputs

82

Name

Input of signs

Startup message

83

-Reset

Reset of summations

84

Access

ID-No.

Input of value

Choosing the access

85

Level

list

Choosing the access

86

Measure

Back to normal operation

*internal adders do not have a run over, that means that depending on configuration the value of the

counter can be so high, that it is not possible to indicate the unit and the formula sign. For this reason

it is necessary to reset the adders in time.

11

Short example for changing parameter value

It is necessary for you to change the value of temperature for 20 mA. Follow the short instruction below:

Access

The following table shows the most important ID-codes with the available parts of the menu.

Code

0000

1508

2552

xxxx

xxxx

xxxx

Menu

blocked

worker

Eng.

Labor.

OEM

Factory

INFO

x

x

x

x

x

PARAMS

x

x

x

x

CALIBRG

x

x

x

CONFIG

x

x

FACTORY

x

-RESET

x

x

x

x

x

ACCESS

x

x

x

x

x

MEASURE

x

x

x

x

x

Sensorbyte –menu point SENSORS (Level C/65)

The sensorbyte indicates, which inputs are available and how they can be used.. The following table

should enable you to choose the correct sensorbyte.

inputs

criteria:

0

criteria

1

choose

0 or 1

Bit

temperature 1

Transmitter

PT 100

0

1

0

Temperature 2

Transmitter

PT 100

0

2

0

pressure

Gauge pressure

abs pressure

1

4

4

Flow input 1 kind of sensor

velocity

dp

1

8

8

Flow input 1 signal

rad/current

lin/frequency

0

16

0

Flow input 2 kind of sensor

velocity

dp

0

32

0

Flow input 2 signal

rad/current

lin/frequency

0

64

0

Sensorbyte

=

12

Press simultaneously both PROG-keys. If flow computer has a password, you have to set ID-no..

Programm „2552“. Now you allowed to change most of all menu points (see table below „Access“).

Now press -key. „PARAMS“ is indicated on the left side of display. Press SELECT-key. Press -

key as long as „TEMP1“ is shown on left side of display. Press SELECT-key. Press -key as long as

you can read „TEMP1,max“ on left side of display. Press SELECT-key. Now you can change value of

temperature while using -, -, - and -key. Finish parameter setting while pressing SELECT-

key. Press -key as long as „ENDE“ is shown on left side of display. Press SELECT-key. Press -

key as long as „MEASURE“ is shown on the side of display. Press SELECT-key. Now the flow

computer save parameter changing and starts measuring mode. If you want to protect parameter

mode press both PROG-keys. Then press -key as long as „ACCESS“ is shown on the left side of

display. Press SELECT-key. Press one time -key. Now „LEVEL“ is indicated. Press SELECT-key.

Now „locked“ is shown on the left side of display. Now press SELECT-key. Go to menu-point END

and then MEASURE to leave parameter mode. Now the flow computer is protected to not authorized

programming.

warning: RESET-keys are only in use for factory setting

12

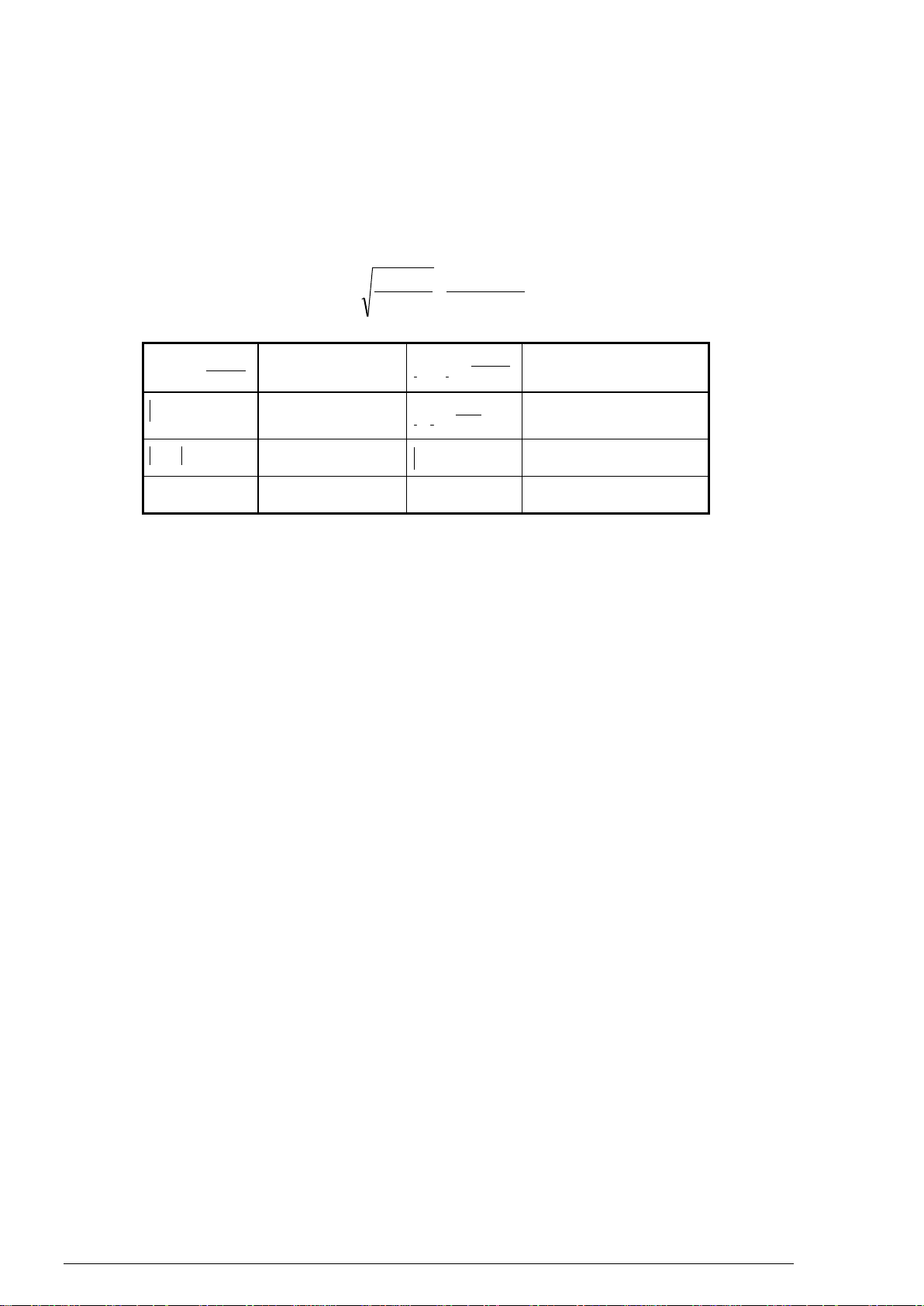

k-Factor –Menu point k-factor (level D/7)

By using an averaging pitot tube, the k-factor of the dp-sensor can be taken from the differential pressure

calculation sheet. For unknown k-factors the value can be calculated by using the following equation.

kT

p p V

D

N A

A

N

i

15 232

,

used units:

VNm

h

N3

Standard

volumetric flow

Nkg

Nm

3

Density at T=273,13K

and p=101,325 kPa

Dmm

i

Internal diameter of

the pipe

kg

m3

Density under operation

conditions

p mbar

Full scale

differential pressure

p kPa

A

Design medium pressure

T K

A

Design medium

temperature

The transfer characteristic

A square rooted or a linear characteristic can be chosen. The µFLOW offers the possibility to link a

second differential pressure transmitter for the extension of the measuring range by measuring point

switching. Under the menu options dp.min. and dp.max. the measuring range boundaries for this second

transmitter can be indicated in the same way as it is already described above for the first transmitter.

Application of the RS232 Interface

The RS232 interface supports data logging.

Link and control of the µFLOW with a PC

The connection between µFLOW and PC is made by a three-core cable with max. 10 m length. The TxD

clamp at the µFLOW is to be connected with the RxD line at the PC interface and the RxD clamp at the

µFLOW with the TxD line of the PC.

The terminal software of the selected COM interface should be adjusted to operation without protocol or

with XON / XOFF protocol. Only if a hardware protocol is intended, the appropriate handshake lines at

the serial interface are to be short circuited.

Adjusting the Baud rate - menu option BAUD (level D/46)

Possible are 4800 and 9600 Baud.

Adjusting the duration of the transmission cycle - menu option CYCLE (level D/45)

The transmission cycle influences directly the developing data flood. Since it concerns with currents in all

rule slow processes, the quantity of data which can be stored should be reduced to a meaningful

measure. The µFLOW therefore supports a minimum interval of 5 seconds.

13

Parameters

According to the transfer parameters selected in the very most applications the µFLOW transmits with

8 data bits

1 stop bit

without parity

with XON / XOFF log

The Baud rate as well as the time between two transfers are adjustable, other parameters are not

adjustable.

Protocol

Due to the low absolute transfer rates it should not come to any conflict in the communication between

µFLOW and PC. Therefore a protocol is actually unnecessary. Nevertheless the transmission activity of

the µFLOW can be controlled by transmitting XOFF by the PC and be continued with XON afterwards

again for all cases. If the interruption should last longer than a transmission cycle, then the data resulting

in the meantime are ignored.

Data format

The µFLOW transmits text character sequences (ASCii) with information about the momentary flow, the

status of the totalizer as well as the primary status data pressure and temperature. The individual values

are separated by blank (ASCii code 32).

A typical line read from left to right could look as follows:

1 2 3 4

1. actual value of the flow in adjusted unit

2. totalizer in adjusted unit

3. temperature in adjusted unit

4. pressure in adjusted unit

The entry and the processing of the measuring data is made according to the standard of the used hard-

and software on the PC.

2436 192873 23.4 101

14

Trouble shooting

Description of the failure

Possible reason

No indication on thr display

Auxiliary power is missing

Main fuse is defective (see page 8)

Instrument does not react on the current inputs

Sensorbyte chosen wrong ( see page 12)

Instrument does not react on the frequency input

Sensorbyte chosen wrong ( see page 12)

Setting of the jumper does not fit to the signal

( see page 6)

Instrument does not react on the Pt100 input

Sensorbyte chosen wrong ( see page 12)

DIP-switches in wrong position ( see page 8)

Auxiliary power for the sensors is missing

Fuse for 24VDC defective (see page 8)

There is no fuse from SN1001

External short circuit

Indicated measured and calculated values are not

realistic

Wrong parametrisation

Output current wrong

Wrong structure 0..20 mA instead of 4..20 mA or

the other way round

Zero or span value wrong

Of course this listing can not be complete. If any mistake occurs, which is not described here, please do

not hesitate to contact us.

15

EC-Declaration of Conformity

according to Article 10.1 of the Directive 2007/108/EEC

(EMC-Directive)

We,

S.K.I. Schlegel & Kremer Industrieautomation GmbH,

Hanns-Martin-Schleyer-Str. 22, 41199 Mönchengladbach

declare in the whole responsibility that the product:

Sensor Unit

__________________________________________________________________

Product

µFLOW

___________________________________________________________________

Type designation and (if necessary) serial number

the requirements under the Council Directive 2004/108/EC to compliance with the laws of Member States

relating to electromagnetic compatibility fulfilled.

The product complies with the requirements of the following guidelines:

EMISSION

EN 55011: 2009 –Limit Class A

(Limits and methods for the determination of electromagnetic radiations of industrial, scientific and

medical (ISM) equipment)

IMMUNITY

EN 61326-1: 2006

(Electrical equipment for measurement, control and laboratory use - Part 1 General Requirements)

- use of the product in residential and industrial areas -

This declaration is based on:

The above mentioned standards have been harmonized and published into the official journal of the EC

Nbr. C59/2011

29.03.2011 Friedhelm Kremer

General Manager

16

S.K.I. Schlegel & Kremer Industrieautomation GmbH

Postfach 41 01 31

D 41241 Mönchengladbach

Hanns-Martin-Schleyer-Str. 22

D 41199 Mönchengladbach

Telefon: +49 (0)2166-62317-0

Web: www.ski-gmbh.com

e-mail: info@ski-gmbh.com

Trademarks and logos are the property of their owners

Subject to technical changes. Illustrations may contain options

Table of contents

Other SKI Test Equipment manuals

Popular Test Equipment manuals by other brands

Risco

Risco VITRON quick start guide

Chauvin Arnoux

Chauvin Arnoux C.A 8220 user manual

Softing IT Networks

Softing IT Networks LinkXpert manual

Gastrolyzer

Gastrolyzer Gastro CH4ECK user manual

Tektronix

Tektronix ths3000 series Installation and safety manual

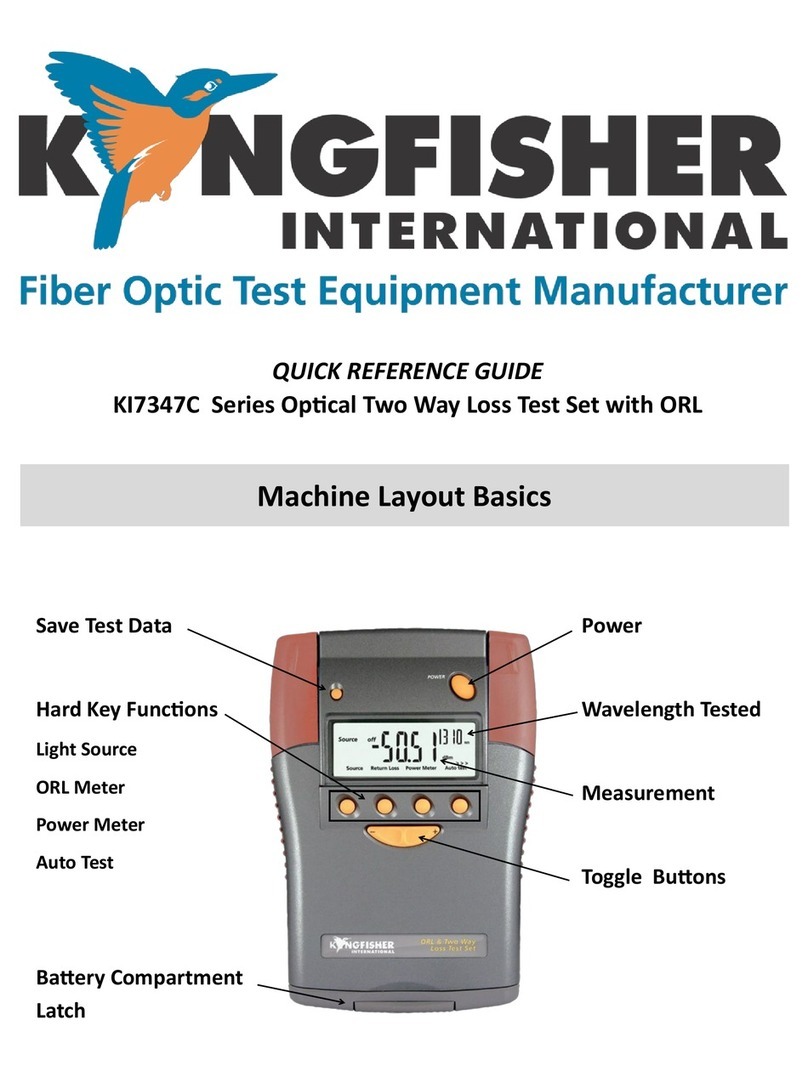

Kingfisher

Kingfisher KI7347C Series Quick reference guide