Skil-aire Mini-Spot 1-3T Systems Manual

Mini-Spot 1-3T Systems

Operating and Maintenance Instructions

Cooling Operation

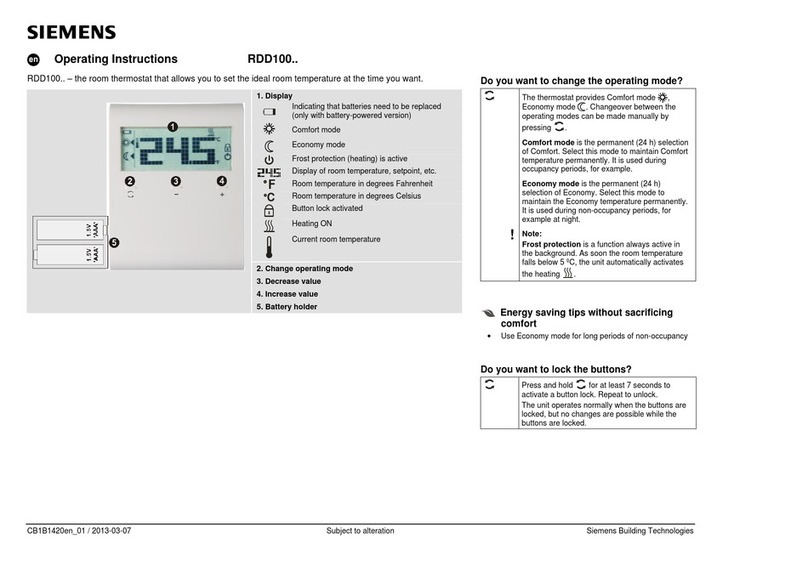

Wall Mounted Thermostat

A wall-mounted thermostat controls the cooling set point. Upon a call for cooling, compressor

contact and evaporator fan relay contacts close. This will energize compressor and

evaporator fan and condenser fan when applicable. As temperature falls below the room set

point, the compressor contacts and evaporator fan contacts will open de-energizing the

system.

Unit Mounted Thermostat

A unit-mounted thermostat controls the set point. Upon a call cooling, compressor contact

relay closes. This will energize compressor and condenser fan when applicable. As the

temperature falls below the room set point the compressor contacts will open.

Fan Operation

Wall Mounted Thermostat

The evaporator fan will operate in either auto or continuous mode, which is controlled by the

thermostat sub-base. In the auto on position, the evaporator fan will run continuously.

Unit Mounted Thermostat

On units with unit mounted thermostats, the evaporator fan relay is kept energized by factory

installed jumper between terminals R & G.

Humidification

When the humidity drops below the set point on the wall mounted humidistat; the auxiliary fan

relay is on if it was off. At the same time, the water solenoid is energized, supplying water to

the evaporator pad When the humidity set point is reached the auxiliary relay and solenoid

valve are de-energized.

INSTALLATION INSTRUCTIONS TO THE INSTALLER

A.) Hanging the unit.

B.) 1) Remove ceiling tile where unit is to be located and remove any adjacent tiles that

would be helpful in handling the unit while positioning it in the ceiling.

2) Secure suitable type material (such as slotted angle) in place. The material should

be capable of supporting the weight of the unit. Now attach all thread rods (3/8”

field supplied) to angle. The rods should have double nuts. See diagram #1 for

spacing of rods to ensure they will line up with hanger when unit is raised into the

ceiling.

3) Next drill holes for hanger positioning screws. Hangers’ positions are marked on

the sides of the units. Do not mount hangers to the unit at this time. Note: if it is

possible to remover one of the 4’ T bar section from the ceiling, then the hangers

can be mounted prior to lifting unit into ceiling.

4) Now raise unit into the ceiling. The use of a high jack is recommended, once unit

is above the ceiling attach mounting brackets to unit and then attach all thread rods

to hangers. Once all thread rods are attached to hangers raise unit several inches

above the ceiling to allow placement of the grille into the ceiling grid. After grille is

in place lower unit just far enough for the frame to form an airtight seal with the

foam backing on the grille. The unit is now ready for electrical wiring or water

piping.

B) Installing Remote Condenser Fan

1) The remote condenser fan can be mounted using a hanger strap or with hangers

provided with the fan and short pieces of angle(field supplied)

2) Prior to hanging the condenser fan section mount the 2x4 junction box to the top of

the unit. Attach wiring harness and connect fan motor wires to the wiring harness

supplied.

3) It is STRONGLY recommended that a field supplied flexible duct connector be

used when attaching condenser section to the evaporator sections.

C) Electrical

All field wiring should be done by a qualified electrician and should meet all local codes.

Knockouts for the unit power, control wiring, and condenser fan are located in the top of the

unit directly above the control section. A wiring harness for the remote condenser fan is

supplied with the unit. The end of the harness with the stacons is attached to the control

section of the unit. Connect the stacons to spade terminal on the main contact on the load

side.

D) Condensate

A ¾” mpt fitting is supplied on each side of the unit. Cap the fitting that will not be used.

E) Water Regulation valve (Water Cooled units only)

Water regulation valves are factory adjusted to maintain an approximate head pressure of

260 lbs psig. If adjustment becomes necessary remove the access panel on the condenser

side and adjust accordingly.

F) Humidifier

The evaporative type humidifier pad is factory installed. Connection of water line and

humidifier water valve is made on control panel side of unit. Humidifier should be connected

to 140 degrees F water supply to insure effective operation.

G) Zone Valve (Chilled Water Units)

A 2 or 3 way water valve is provided with the chilled water unit. This valve is factory installed

and is serviceable through access door adjacent to the control panel. The valve control head

is easily removable for replacement. There is also a manual operation capability built into the

valve to provide temporary operation should control head pressure fail.

H) Low Ambient Control (MAA/D Model Optional)

Low ambient controls that can be provided by means of a pressure activated switch mounted

in the compressor section of the unit. This control is factory adjusted but may be field

adjusted if necessary.

I) Motor Speed

All 2 and 3 ton units are shipped with three speed motors. Changing the motor leads in the

evaporator section of the unit may change the motor speed. Access to leads is through the

access door on the control panel side of the unit. Leads will either be color coded of number

coded.

On units with color-coded leads the colors represent the following speeds: On units with

number coded leads the Number represents the following speeds

YELLOW = COMMON = 1

RED = LOW SPEED = 4

BLUE = MEDIUM SPEED = 3

BLACK = HIGH SPEED = 2

To change the speed of the unit first disconnect power to the unit. Disconnect speed now in

used and cap this lead with suitable device. Reconnect lead from fan relay to speed desired.

Note 1: On units that have both humidifier and reheat the auxiliary relay is omitted and a

jumper is installed between terminals (R) and (G).

Note 2: 140 degrees domestic hot water should be supplied to humidifier in order to satisfy

rated capacity.

Note 3: a small plastic orifice installed between the solenoid valve and the evaporator pad

regulates the water flow.

Note 4: the humidistat and dehumidistat can either be wall mounted or unit mounted.

DEFROST CONTROL FOR HEATPUMP UNIT

The Skil–Aire heat pump utilizes a defrost system controlled by a temperature sensing

device. The defrost cycle initiates when the bulb attached to the outdoor coil senses a

temperature of 30 F or less. This means that the unit (when in the heating cycle) will go into

a defrost cycle only id the outdoor coil is cold enough to accumulate frost. The defrost cycle

ends when the outdoor coil temperature rises to 80 F.?

DE-HUMIDIFICATION AND REHEAT

(Wall Mounted thermostat)

Upon an increase in humidity beyond the set point on the wall mounted de-humidistat the

cooling cycle is energized. The unit will remain in cooling until the humidity level in the room

reaches the set point on the de-humidistat. If the room temperature falls below the set point

on the room thermostat the reheat coil will energize to offset the cooling effect of the de-

humidification cycle. There must be at least a low load in the room to maintain room

temperature.

(Unit Mounted thermostat)

On units with a unit mounted thermostat the reheat is controlled by the same thermostat that

controls the cooling cycle. Reheat can not be energized except when there is a call for de-

humidification which functions the same as the units with wall mounted controls.

SYSTEM SAFETIES

The unit has several inherent safety devices. High and Low pressure switches are an

integral part of the refrigeration system. Should an unsafe high and or low-pressure condition

exist the appropriate safety device will trip. Condensate overflow switches are installed on

the drain pan of each unit. There are two switches and should the condensate level rise to

an unsafe level the switches will cause the unit to shut down operation. This is accomplished

by interrupting the low voltage power supply from the 24-volt transformer. Both compressor

and fan motor have an internal automatic reset safety, which is the thermal type.

MAINTENANCE

Filter Changes: The unit is supplied with a 20 x 20 x 1 disposable filter. Access to

the filter is through the hinged return air grille. This filter should be

changed a minimum of four times per year. A higher frequency of

filter changes may be necessary depending on the area where the

unit is installed.

Fan motor Lubrication: The evaporator fan motor should be oiled once per year using a

SAE#10 or SAE#20 non-detergent oil. There are oil ports at each

end of the motor.

Evap. and Cond. Coil: Clean both coils with a stiff brush. Be careful of the coil fins due

to the fact that they are razor sharp. After brushing use a vacuum

or compressed air to clean away brushed off dirt.

Remote Condenser Coil: Clean coil as stated above or use low pressurized water or steam.

Condensate pan & Drain: Check and clean on a bi-monthly basis.

Humidifier: Check canister on a bi-monthly basis for material builds up,

replaces as required.

Reheat: Reheat units have a tendency to collect minute dust/dirt particles.

When energized, these particles will burn off. Energize reheat

during normal maintenance procedures. NOTE: disable halon

system to prevent possible discharge during reheat test.

CHARGING PROCEDURE

Before charging make sure that no air was allowed to enter the system. If pre charged tubing

was not used evacuate the system completely and check for leaks. When charging the unit

do not use liquid refrigerant in the suction side. Charge with vapor refrigerant only. A manual

shut-off valve is provided between the receiver and expansion valve. By shutting off this valve

charging the system can be accomplished faster. Be sure to open the valve when charging is

completed.

Note: The low-ambient refrigerant control valve will bypass whenever the head pressure is

lower than 220 psig. This is normal.

AIR COOLED UNITS- REFRIGERANT LINE SIZING

Unit tonnage CircuitLiquid Drain Line Hot Gas Line

1 1 ½”½”

2 1 5/8”7/8”

3 1 5/8”7/8”

1) Each circuit will have a liquid drain line and a hot gas line.

2) The liquid line is an n oversized liquid line that runs between the condenser and receiver

(unit). Its size allows vapor in the receiver to return to the condenser against the flow of

liquid refrigerant.

3) On horizontal runs the hot gas line should be pitched downward in the direction of flow ½”

for every ten feet (10 ft)

4) On vertical rises the hot gas line should be trapped every twenty feet (20 ft)

5) Refrigerant lines should be properly supported to avoid pulsation vibrations.

6) Avoid running refrigerant lines in areas where low noise levels are required.

AIR COOLED UNITS –REFRIGERANT CHARGE

The tables below indicate the amount of refrigerant required per circuit to adequately operate

the unit. Please note; if you are charging the unit in a warm ambient condition not all of the

recommended charge is needed to operate the unit at that condition. However, all the

recommended charge must be used in order for the equipment to operate properly the year

round.

1) Basic Unit charges

Unit tonnage Circuits Charge per circuit (lbs)

1 1 5

2 1 8

3 1 11

2) Interconnection pipe charge

For split-systems you need to consider the refrigerant charge being held in the

interconnection piping (liquid drain line, hot gas line). The amount of charge

held in the hot gas line is minimal. Therefore, we will consider only the liquid

line for calculation purposes.

Liquid line size copper tubing Charge per circuit

½” O.D. .7 lbs/10 ft

5/8” O.D. 1.2 lbs/10 ft

7/8” O.D. 2.4 lbs/10 ft

3) Total Charge

To calculate the total charge, add one (1) the basic unit charge and two-(2)

piping charge. Remember the amounts given above are per circuit

IMPORTANT

If your unit is equipped with a

CANISTER HUMIDIFIER:

The canister must be changed approximately one to two times per year.

Please call

1-800-625-SKIL

For parts and information.

Please have your model number ready:

For 208/230 volts, use model #102

For 460 volts, use model #104

FU INFORMATION

Warning the manufacturer’s warranty does not cover any damage or defect to the air

conditioner caused by the attachment of use of any components, accessories or

devices (other than those authorized by the manufacturer) into, onto or in conjunction

with the air conditioner. You should be aware that the use of unauthorized

components, accessories or devices may adversely affected the operation of the air

conditioner and may also endanger life and property. The manufacturer disclaims any

responsibility for such loss or injury resulting from the use of such unauthorized

components, accessories or devices

GENERAL

The information contained in this manual has been prepared to assist in the proper

installation, operation and maintenance of the air conditioning system. Improper

installation, or installation not made in accordance with these instructions, can result in

unsatisfactory operation and/or dangerous conditions, and can cause the related

warranty not to apply.

Read this manual and any instructions packaged with separate equipment required to

make up the system prior to installation. Retain this manual for future reference. To

achieve unit design operation efficiency and capacity, the indoor cooling coils listed in

the condensing unit specification sheet should be used.

CHECKING PRODUCT RECEIVED

Upon receiving unit, inspect if for any shipping damage. Claims for damage, either

apparent or concealed, should be filed immediately with the shipping company. Check

condensing unit electrical characteristics and accessories to determine if they are

correct. Check system components (evaporator coil, condensing unit, evaporator

blower, etc. to make sure they are properly matched.

Remove shipping bracket under compressor if supplied. With the thermostat in the

“Off” position, turn the power on to the furnace and the condensing unit. Before

starting condensing unit allow 12 hours time to elapse, giving the crankcase heater (if

provided) time to drive refrigerant from the compressor, thus preventing damage

during start-up. Start the condensing unit and the furnace with the thermostat. Make

sure the indoor air handler is operating.

Table of contents