d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

toolsaredangerousinthehandsofuntrainedusers

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use.Manyaccidentsarecausedbypoorly

maintained power tools

f) Keep cutting tools sharp and clean.Properly

maintained cutting tools with sharp cutting edges are

lesslikelytobindandareeasiertocontrol

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions, taking into

account the working conditions and the work to be

performed.Useofthepowertoolforoperations

differentfromthoseintendedcouldresultina

hazardous situation

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensurethatthesafetyofthepowertoolismaintained

SAFETY INSTRUCTIONS FOR IMPACT DRILLS

GENERAL

• Thistoolshouldnotbeusedbypeopleundertheageof

16years

• Alwaysdisconnectplugfrompowersourcebefore

making any adjustment or changing any accessory

• Wear ear protectors(exposuretonoisecancause

hearing loss)

• Use auxiliary handle(s), if supplied with the tool (loss

ofcontrolcancausepersonalinjury)

• Usecompletelyunrolledandsafeextensioncordswith

acapacityof16Amps(U.K.13Amps)

• Do not work materials containing asbestos (asbestos

is considered carcinogenic)

• Dustfrommaterialsuchaspaintcontaininglead,some

woodspecies,mineralsandmetalmaybeharmful

(contactwithorinhalationofthedustmaycause

allergicreactionsand/orrespiratorydiseasestothe

operatororbystanders);wear a dust mask and work

with a dust extraction device when connectable

• Certainkindsofdustareclassiedascarcinogenic

(suchasoakandbeechdust)especiallyinconjunction

withadditivesforwoodconditioning;wear a dust

mask and work with a dust extraction device when

connectable

• Followthedust-relatednationalrequirementsforthe

materialsyouwanttoworkwith

BEFORE USE

• Alwayscheckthatthesupplyvoltageisthesameasthe

voltageindicatedonthenameplateofthetool(tools

witharatingof230Vor240Vcanalsobeconnectedto

a220Vsupply)

• Avoiddamagethatcanbecausedbyscrews,nailsand

otherelementsinyourworkpiece;removethembefore

youstartworking

• Use suitable detectors to find hidden utility lines or

call the local utility company for assistance (contact

withelectriclinescanleadtoreorelectricalshock;

damagingagaslinecanresultinanexplosion;

penetratingawaterpipewillcausepropertydamageor

an electrical shock)

• Secure the workpiece (a workpiece clamped with

clampingdevicesorinaviceisheldmoresecurelythan

byhand)

• Neverusethetoolwhencordisdamaged;haveit

replacedbyaqualiedperson

ACCESSORIES

• SKILcanassureawlessfunctioningofthetoolonly

when original accessories are used

• Useonlyaccessorieswithanallowablespeedmatching

atleastthehighestno-loadspeedofthetool

DURING USE

• Alwayskeepthecordawayfrommovingpartsofthetool

• Ifthedrillbitbecomesunexpectedlyjammed(causinga

sudden,dangerousreaction),immediatelyswitchoffthe

tool

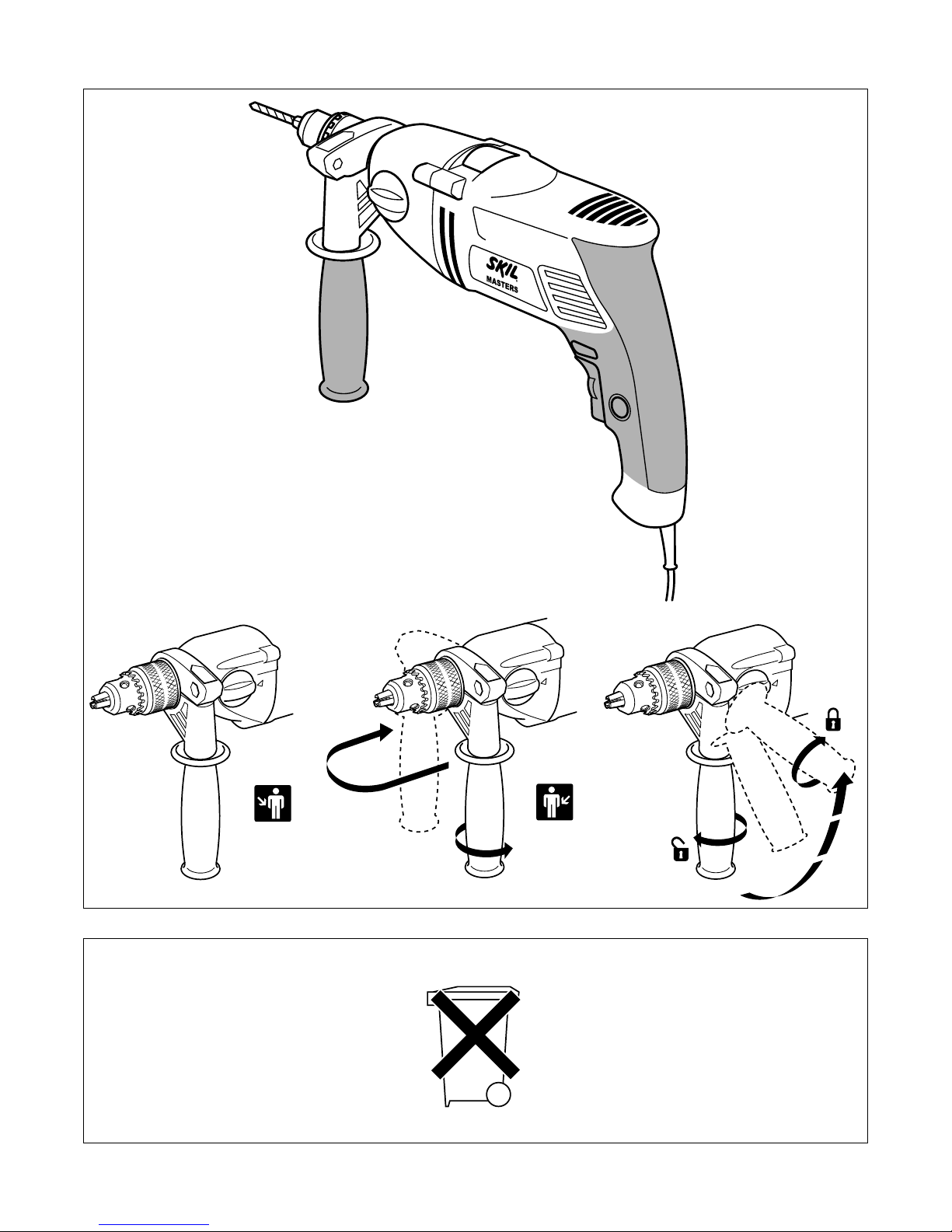

• Beawareoftheforcesthatoccurasaresultofjamming

(especiallywhendrillingmetals);always use auxiliary

handle G 2and take a secure stance

• Hold the power tool only by the insulated gripping

surfaces when performing an operation where the

accessory may contact hidden wiring or its own

power cord(contactwitha“live”wirewillalsomake

exposedmetalpartsofthepowertool“live”andshock

the operator)

• Incaseofelectricalormechanicalmalfunction,

immediatelyswitchoffthetoolanddisconnecttheplug

• Ifthecordisdamagedorcutthroughwhileworking,do

nottouchthecord,butimmediatelydisconnecttheplug

AFTER USE

• Whenyouputawaythetool,switchoffthemotorand

ensurethatallmovingpartshavecometoacomplete

standstill

WHEN CONNECTING NEW 3-PIN PLUG (U.K. ONLY):

• Donotconnecttheblue(=neutral)orbrown(=live)wire

inthecordofthistooltotheearthterminaloftheplug

• Ifforanyreasontheoldplugiscutoffthecordofthis

tool,itmustbedisposedofsafelyandnotleft

unattended

USE

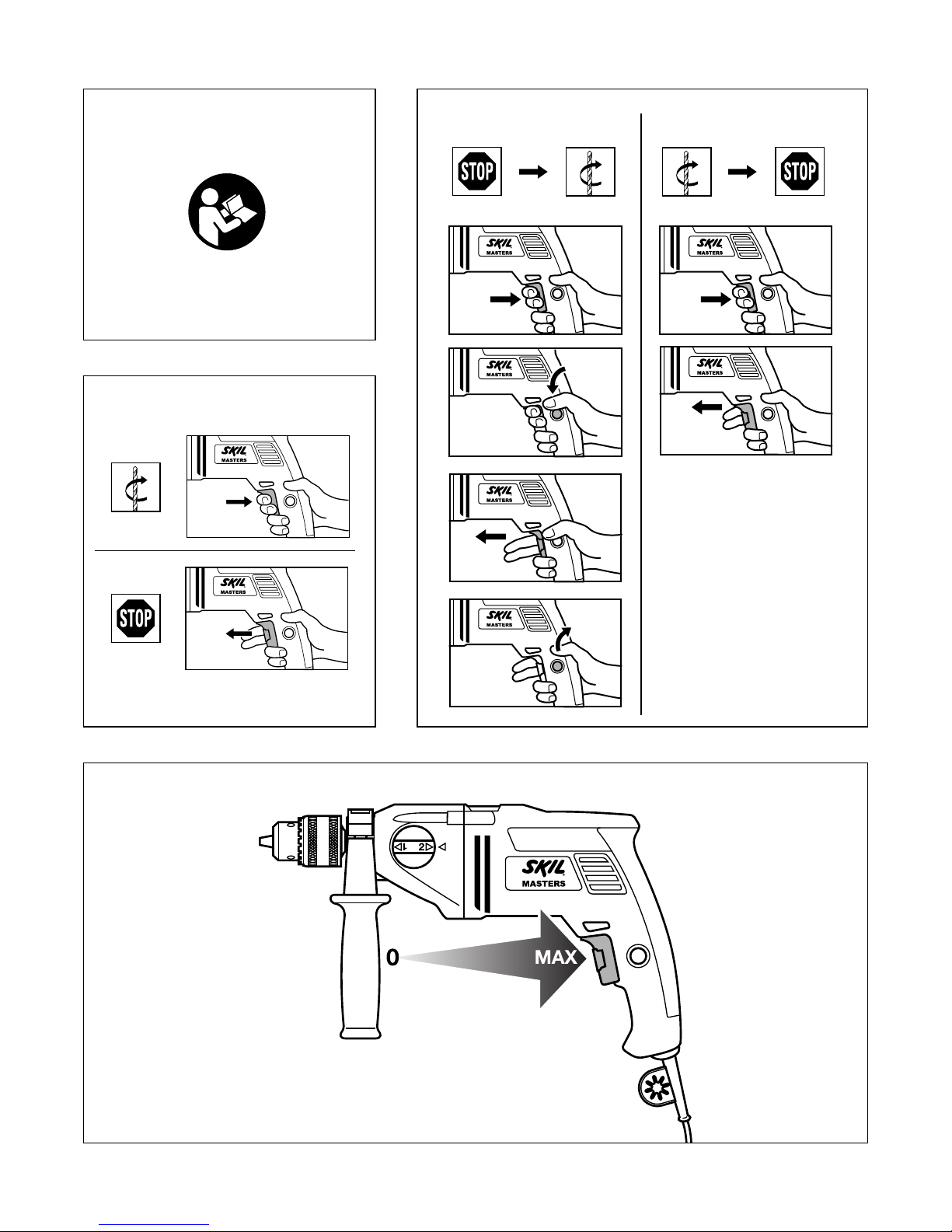

• On/off4

• Switchlockingforcontinuoususe5

• Speedcontrolforsmoothstarting6

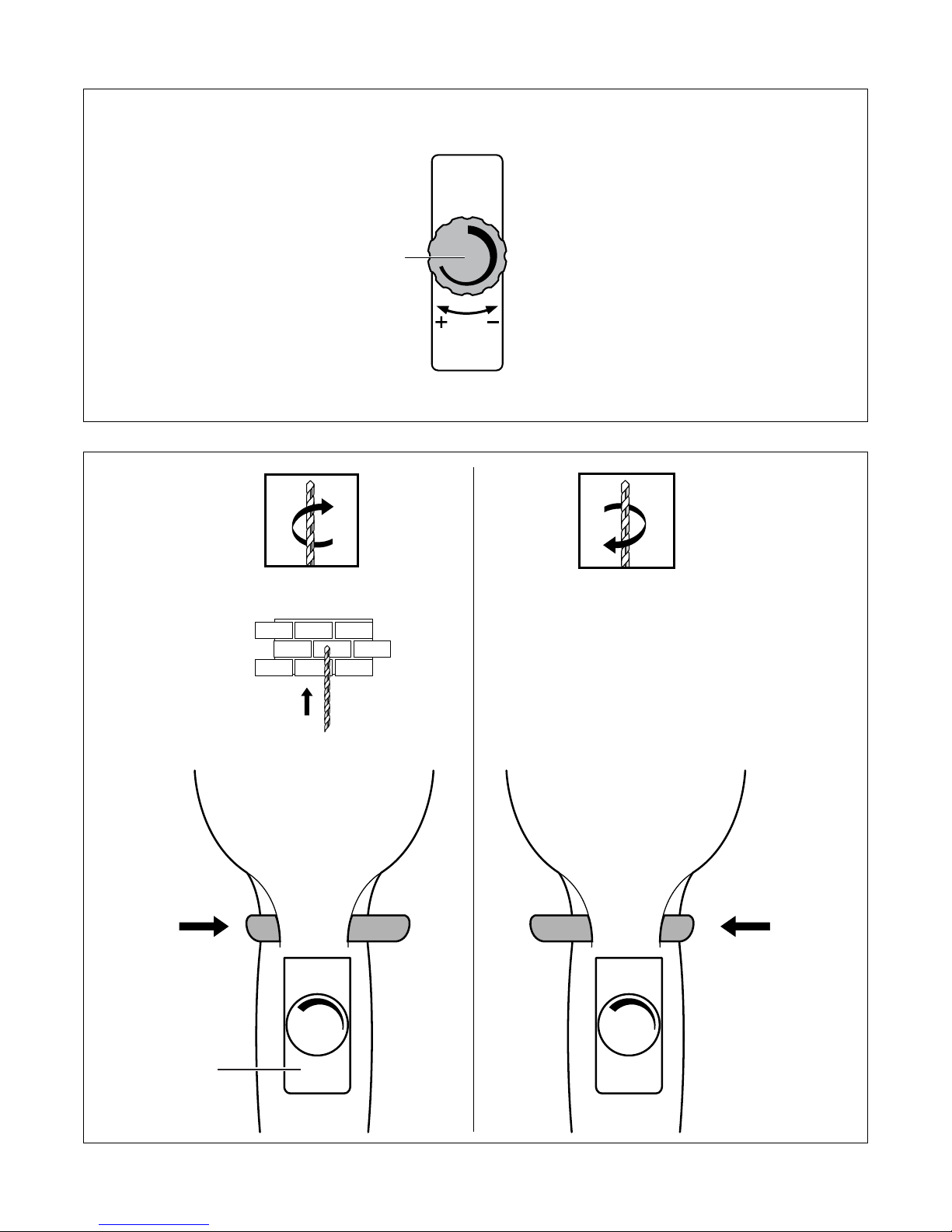

• Maximumspeedcontrol7

WithwheelCthemaximumspeedcanbeadjustedfrom

low to high

- switch on the tool

- lock the switch

- turnwheelCtoselectmaximumspeed

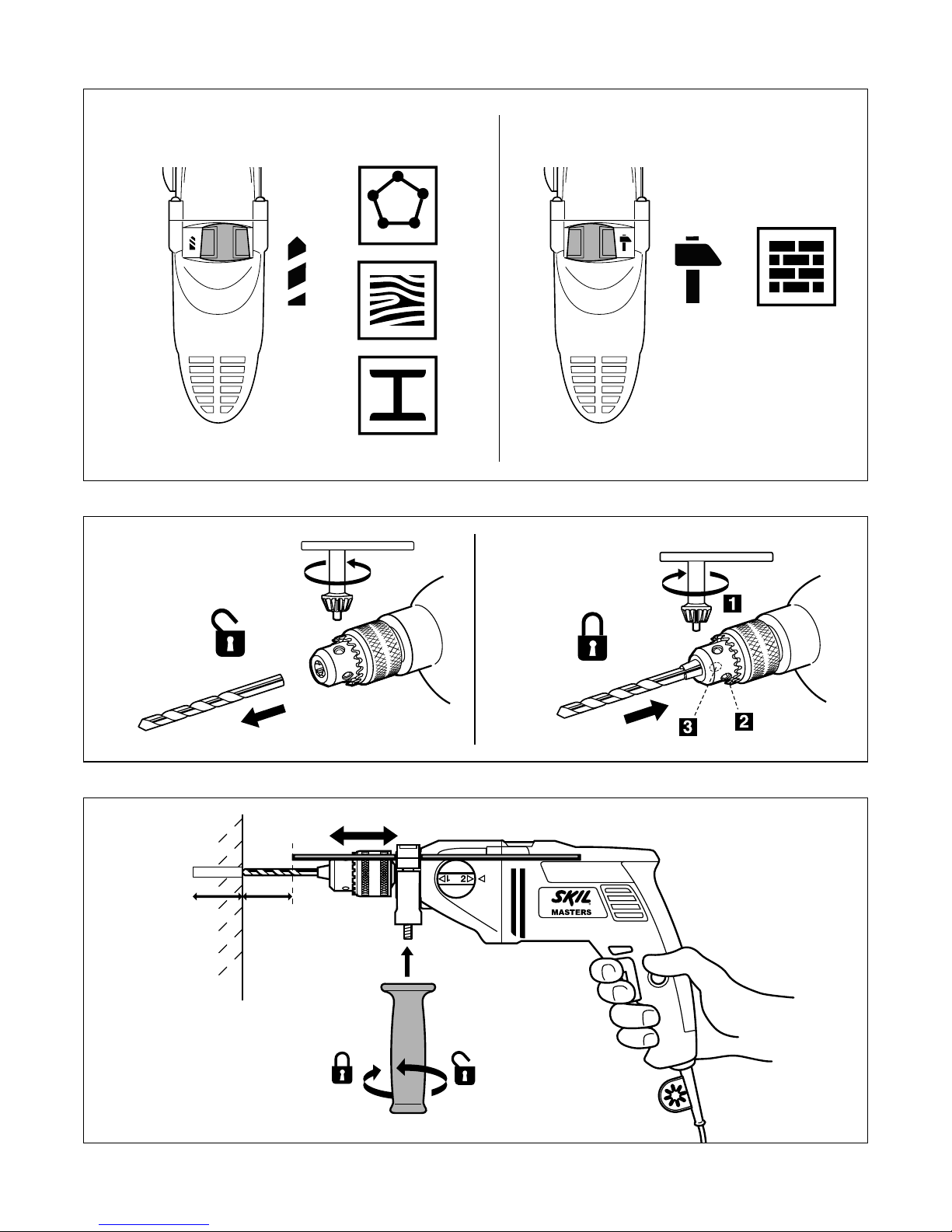

• Mechanicalgearselection

- set selector E 2to desired speed

! actuate the gear selector while tool is running

slowly