DOL 100 Water 8l/16l Box

Technical User Guide

1 Product description........................................................................................................................................5

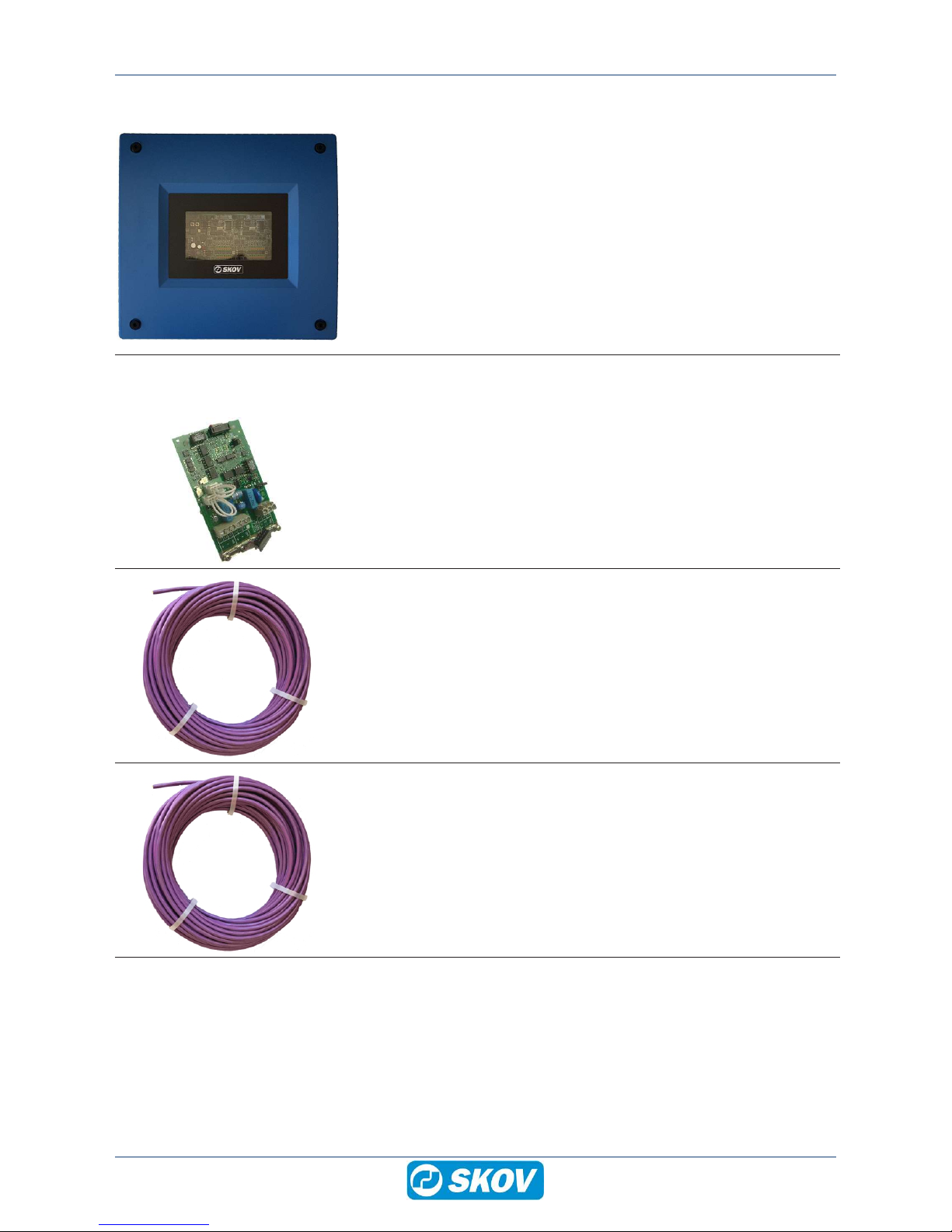

2 Product survey ...............................................................................................................................................6

2.1 Accessories.................................................................................................................................. 6

3 Mounting guide...............................................................................................................................................7

3.1 Recommended tools .................................................................................................................... 7

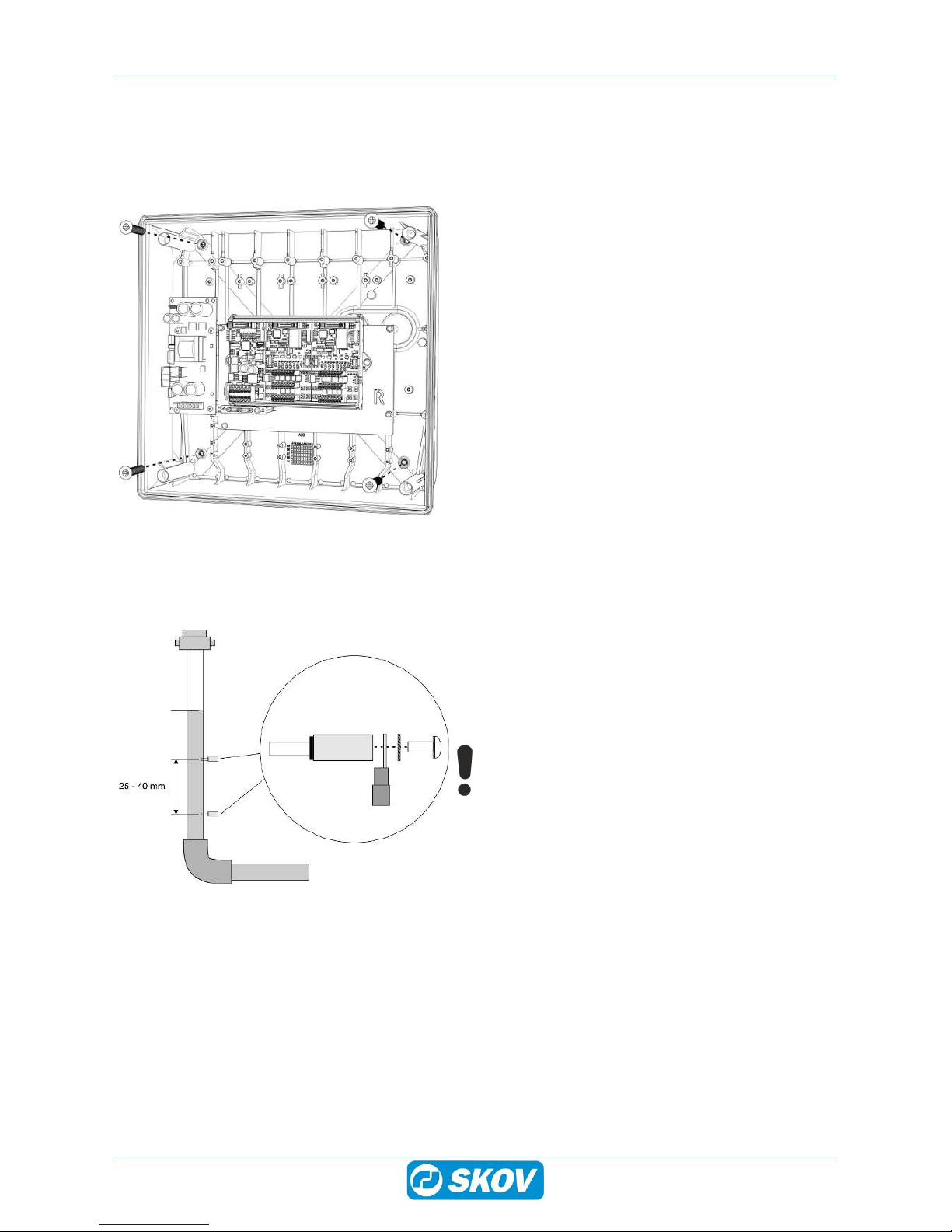

3.2 Assembly ..................................................................................................................................... 8

3.2.1 DOL 100 Water box ..................................................................................................................... 8

3.2.2 Water level sensor ....................................................................................................................... 8

4 Installation guide ............................................................................................................................................9

4.1 Electrical connection .................................................................................................................... 9

4.2 Cable routing................................................................................................................................ 9

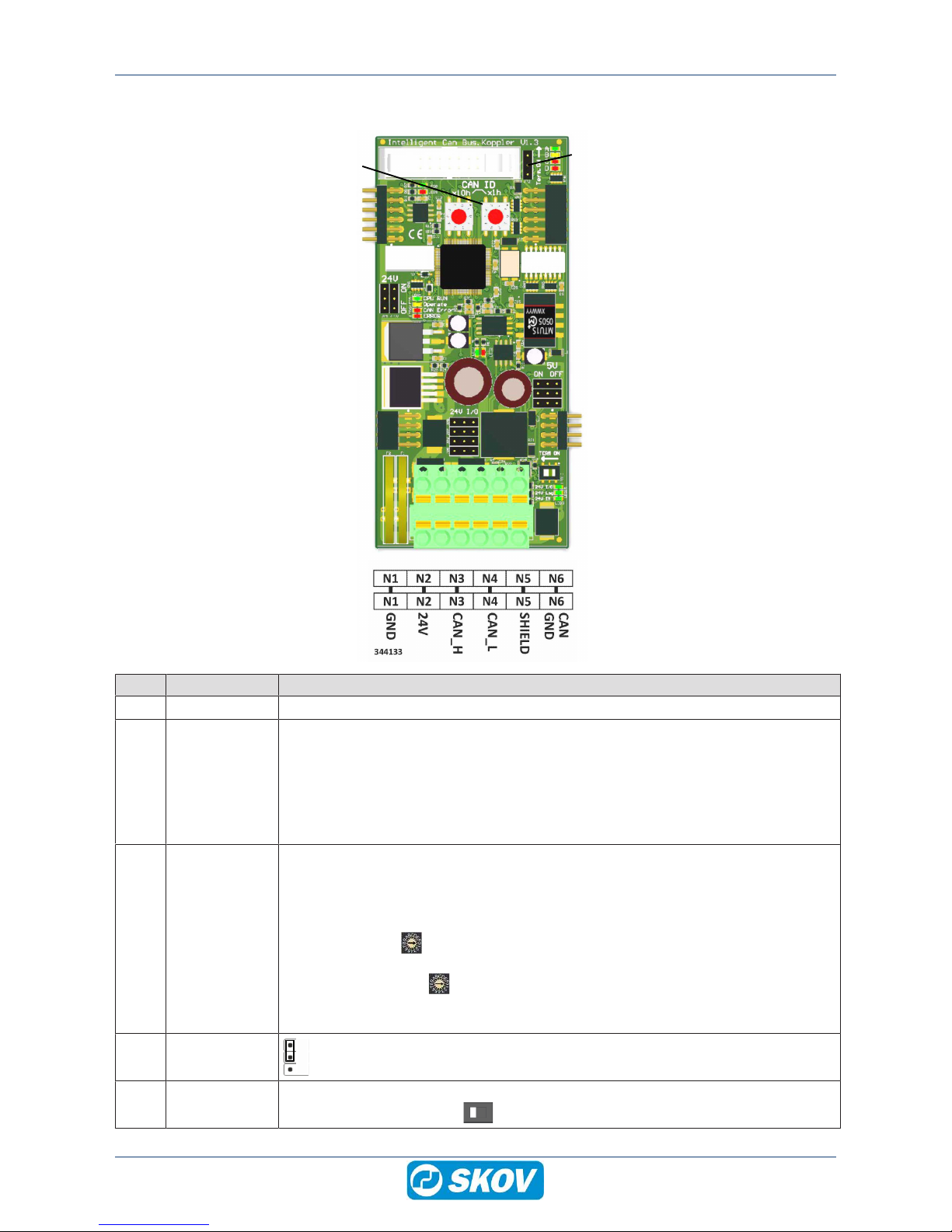

4.3 Nano CAN bus coupler .............................................................................................................. 10

4.3.1 LED indication on the CAN bus coupler..................................................................................... 11

4.4 Nano I/O module water 8l .......................................................................................................... 12

4.5 Connection in DOL 100.............................................................................................................. 13

4.6 Setting up the DOL 100 in the controller.................................................................................... 14

4.7 Cable plan.................................................................................................................................. 15

4.7.1 Water level sensor connected in series ..................................................................................... 15

4.8 Circuit diagram........................................................................................................................... 16

4.8.1 Water level sensor connected in series ..................................................................................... 16

5 Cleaning ........................................................................................................................................................17

6 Troubleshooting Guide ................................................................................................................................18

7 Technical data...............................................................................................................................................19