DOL 38-2 Frequency Converter

Technical User Guide

1 Product description ....................................................................................................................................... 5

2 Product survey ............................................................................................................................................... 6

3 Mounting guide............................................................................................................................................... 7

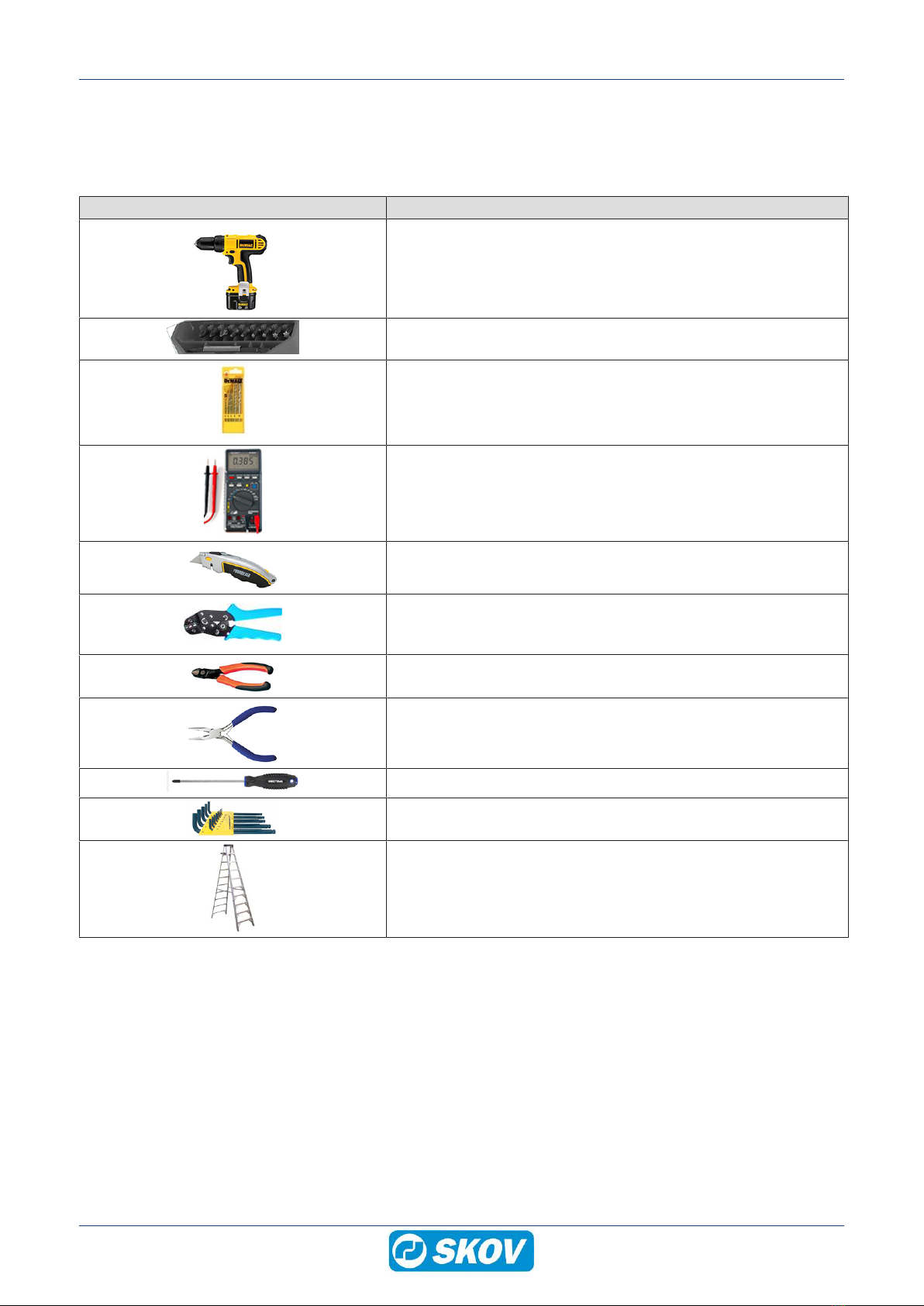

3.1 Recommended tools.................................................................................................................. 7

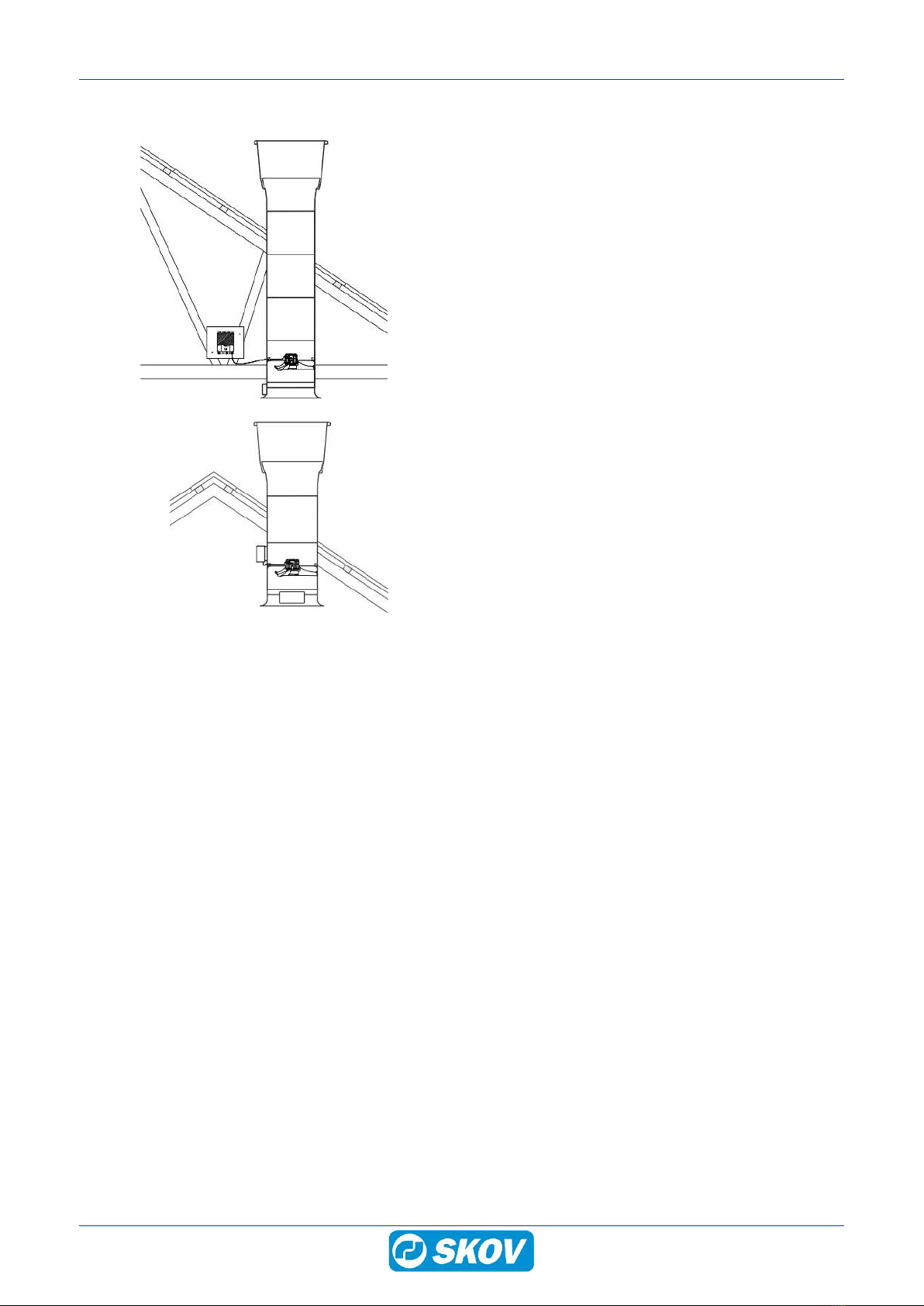

3.2 Position of motor controller/frequency converter .................................................................. 8

3.3 Mounting distances for the motor controller/frequency converter....................................... 8

3.4 Position of motor controller/frequency converter .................................................................. 9

4 Installation guide.......................................................................................................................................... 10

4.1 Electrical connection............................................................................................................... 10

4.1.1 Disclaimer at retrofitting fans ..................................................................................................... 10

4.1.2 Mains supply dimensioning regarding harmonic distortion ........................................................ 10

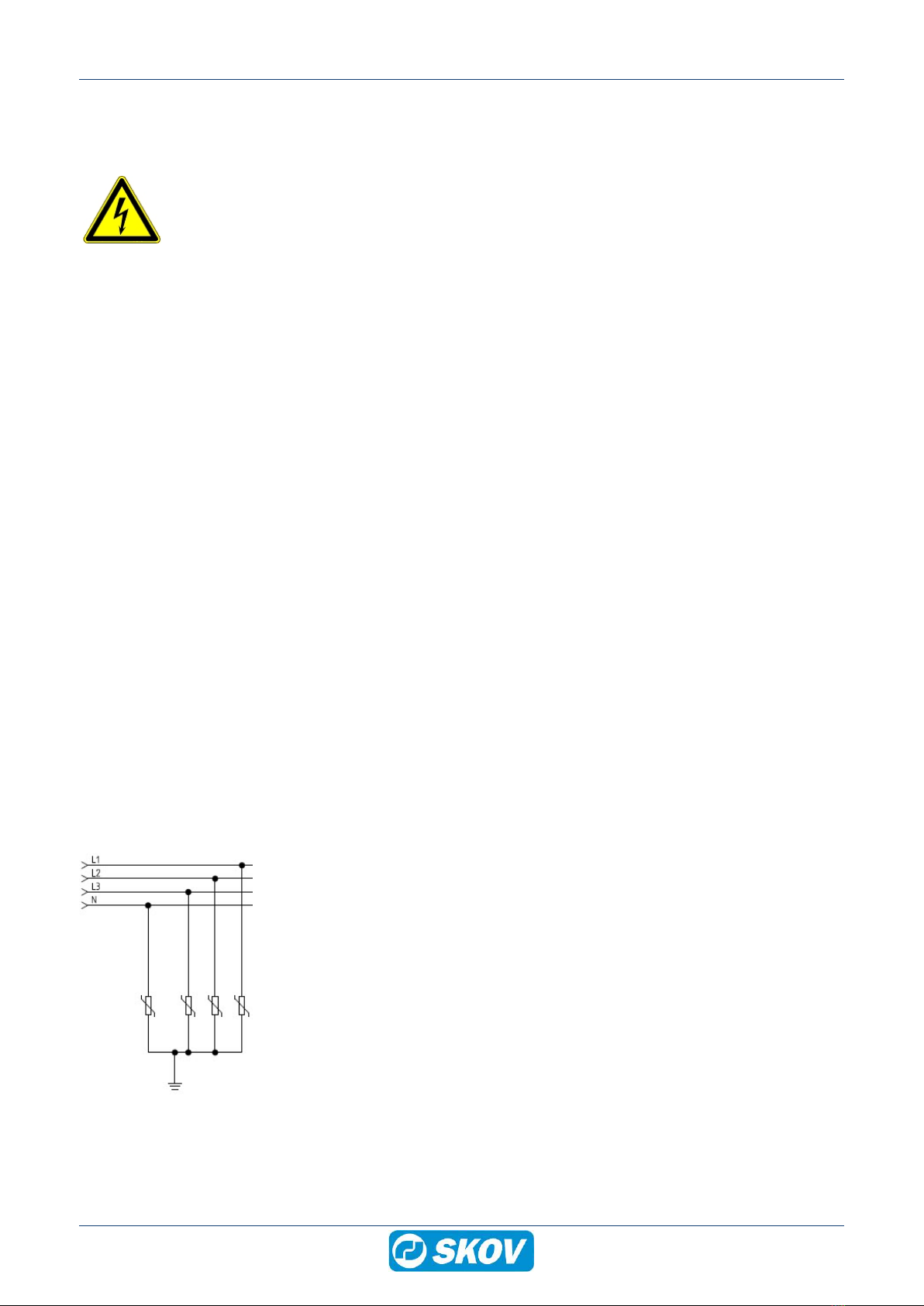

4.1.3 Overvoltage protection............................................................................................................... 10

4.1.4 Cabling in the exhaust unit......................................................................................................... 11

4.1.5 Cabling into the motor controller/frequency converter ............................................................... 11

4.2 Connection in the LPC motor controller/frequency converter ............................................ 12

4.2.1 Terminals for power supply........................................................................................................ 13

4.2.2 Terminals for supply of the fan motor ........................................................................................ 13

4.2.3 Signal terminals ......................................................................................................................... 14

4.2.4 Terminals on relay module......................................................................................................... 14

4.3 LED indication on the motor controller/frequency converter.............................................. 15

4.4 Alarms....................................................................................................................................... 15

4.5 Adjusting the jumper and connecting the shutter................................................................ 16

4.6 General information about circuit diagrams ......................................................................... 17

4.6.1 Color code.................................................................................................................................. 17

4.6.2 Power supply isolator................................................................................................................. 17

4.6.3 Letter code ................................................................................................................................. 17

4.7 Cable plans and circuit diagrams........................................................................................... 18

4.7.1 DOL 38-2 with fan ...................................................................................................................... 18

4.7.1.1 Cable plan.................................................................................................................................. 18

4.7.1.2 Circuit diagram........................................................................................................................... 19

4.7.2 DOL 38-2 with DA 74CV and DA 600 fan .................................................................................. 20

4.7.2.1 Cable plan.................................................................................................................................. 20

4.7.2.2 Terminals in DA 74CV ............................................................................................................... 20

4.7.2.3 Circuit diagram........................................................................................................................... 21

4.7.2.4 Circuit diagram - thermal cutout................................................................................................. 22

4.7.3 DOL 38-2 and DA 600 fan with reverse ..................................................................................... 23

4.7.3.1 Cable plan.................................................................................................................................. 23

4.7.3.2 Circuit diagram........................................................................................................................... 24

4.7.4 DOL 38-2 and DA 600 fan with alarm ........................................................................................ 25

4.7.4.1 Cable plan.................................................................................................................................. 25

4.7.4.2 Circuit diagram........................................................................................................................... 26

5 Maintenance instructions ............................................................................................................................ 27

5.1 Cleaning.................................................................................................................................... 27

5.1.1 Fan............................................................................................................................................. 27

5.1.2 Motor controller/frequency converter ......................................................................................... 27

5.2 Recycling/Disposal .................................................................................................................. 27

6 Troubleshooting guide ................................................................................................................................ 28

7 Technical data .............................................................................................................................................. 30

7.1 Dimensioned sketch ................................................................................................................ 31