sks CYCLONE User manual

1

CYCLONE/CYCLONE PLUS

MANUAL

2

CONTENTS

PARTS DIAGRAM

3

MACHINE INSTALLATION & PREPARATION

4

Checking For Damage

4

Installation

4

Environmental Conditions

4

OPERATION & MAINTENANCE

5-8

Cutting a Key - Cylinder

5

Cutting a Key - Mortice

5

Replacing The Cutters

6

Machine Adjustment

6-7

General Maintenance

7-8

HEALTH & SAFETY

8

3

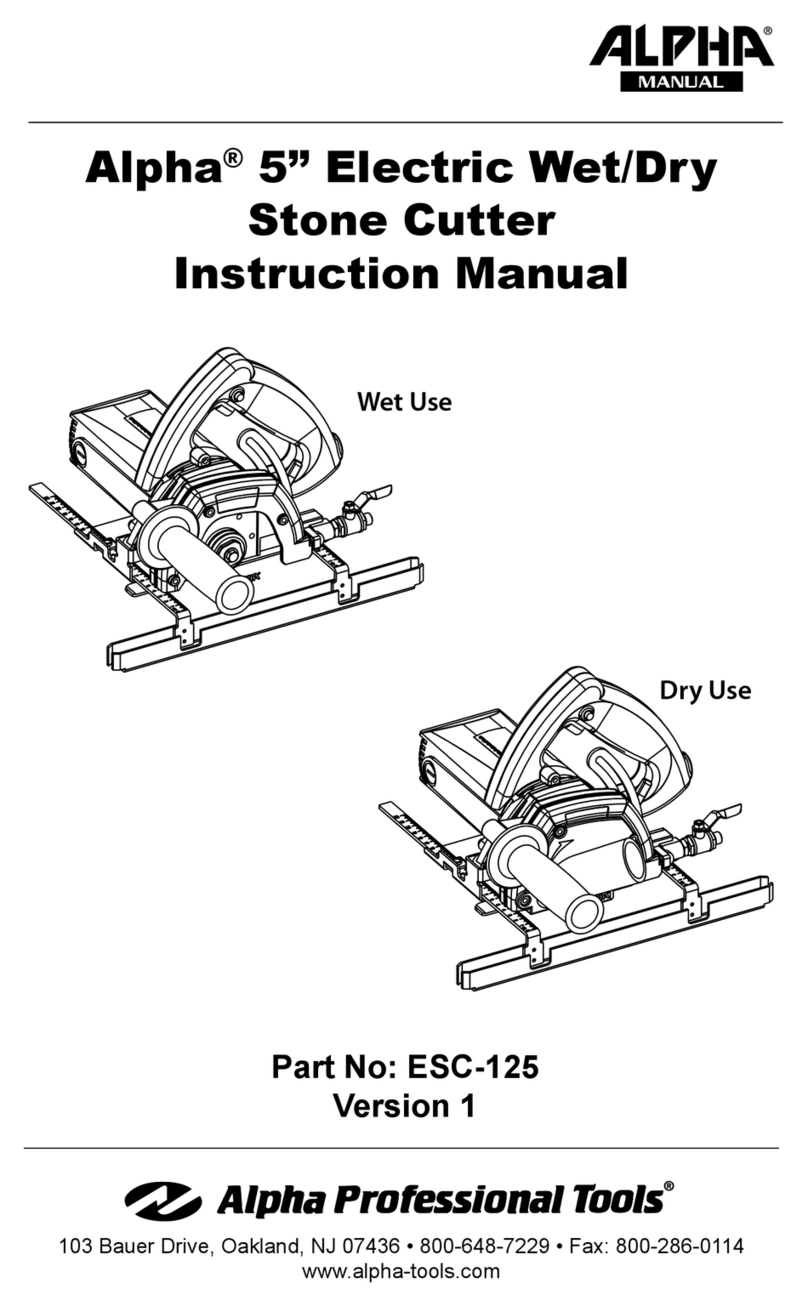

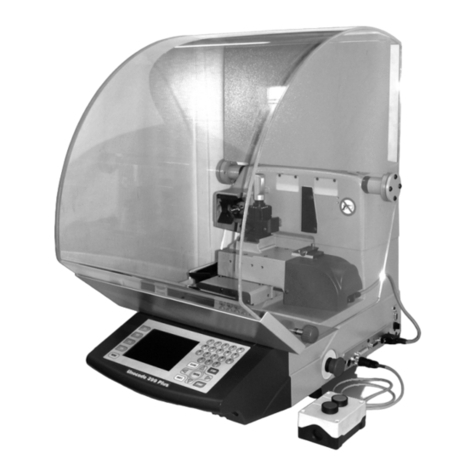

PARTS DIAGRAM

1. Light bulb and cover

2. Voltmeter

3. Cutter guard

4. Cylinder follower

5. Cylinder cutter

6. Cylinder jaws/carriage

7. Swarf tray

8. Protective shield

9. Brush

10. Switch

11. Main switch

12. Mortice cutter

13. Mortice follower

14. Wheel handle

15. Mortice jaws/carriage

4

MACHINE INSTALLATION & PREPARATION

The key cutting machine can be installed by the purchaser and does not require any special skills.

However, some checks and preparation for use need to be carried out by the operator.

CHECKING FOR DAMAGE

The key cutting machine is solid and compact and will not normally damage if transport, unpacking

and installation have all been carried out according to the instructions in this manual. However, it is

always advisable to check that the machine has not suffered any damage.

INSTALLATION

•Remove the machine from the box and place it in its working position on a flat bench or

counter

•Ensure that there is adequate lighting in the area and there is adequate space surrounding

the machine

•Fit the front handles to the key carriage and secure hand tight

•Fit the eye shield

•Fit the bulb cover and bulb

•Remove the red protective caps on the followers (4 & 13) before use

•Connect the machine to the mains power supply

•Switch the main power switch (11) on

•Check motor operation by switching the round switch (10) on

Please note, although the machine is calibrated at the factory, it is possible that the machine settings

are disturbed during transit. Please see ‘Machine Adjustment’ on pages 6-7 for instructions on how

to check and calibrate the machine.

ENVIRONMENTAL CONDITIONS

•Use in dry, well ventilated areas

•Ideal operating temperature 10°C - 40°C

5

OPERATION & MAINTENANCE

CUTTING A KEY –CYLINDER

Please ensure the 4-way jaw is at the correct position and that the right and left hand jaws are both

set to the same side.

SIDE A: Standard cylinder keys positioned on their backs and cruciform keys

SIDE B: Small cylinder keys (depth of less than 3.9mm) positioned on their backs

SIDE C & D: Double sided cylinder keys and keys to be clamped on their groove.

To change the jaw position, loosen the knob then lift the jaw from the bottom and turn to the

correct position.

•Clamp the original key in the left hand jaw then raise the key set guide to sit against the

shoulder

•Position the blank key in the right hand jaw so that the shoulder sits flush with the other side

of the key set guide and tighten the clamp

•Lower the key set guide and power on the machine

•Raise the carriage to the cutter, apply a reasonable amount of pressure and use the wheel

handle to trace the original key from the shoulder to the tip

•Lower the carriage, turn off the power

•Release the cut key and deburr, if necessary, using the brush

CUTTING A KEY –MORTICE

•Place the original key in the right hand jaw, pushing it in from the right until it stops at the

shoulder

•Repeat for the blank key on the left hand jaw

•Power on the machine

•Follow the cuts on the original key by moving the carriage side to side with the wheel handle

and using the black carriage handle to raise the key to the cutter

NOTE –Do not move the carriage sideways whilst cutting into the key

•Once completed turn off the power, remove the key and remove any excess material with a

file or the brush

The Cyclone Plus has tilting mortice jaws to allow you to round the cuts. To use this feature you just

need to remove the pin from the carriage. To lock the jaws back into the fixed horizontal position

just reinsert the pin.

6

REPLACING THE CUTTERS

WARNING! ENSURE MACHINE IS UNPLUGGED BEFORE UNDERTAKING ANY MAINTENANCE

•Remove the three screws holding the case on the machine (one each side and one at back)

then carefully lift the case off the machine

•Locate the cut-out on the shaft that runs between the two cutters and insert a 4mm allen

key (or similar) to lock the cutter shaft in position

•Undo the nut holding the cutter on (turning in anti-clockwise direction) and remove cutter

and washer

•Replace with new cutter, reusing the existing washer and tighten nut back on in clockwise

direction

MACHINE ADJUSTMENT

WARNING! ENSURE MACHINE IS UNPLUGGED BEFORE UNDERTAKING ANY MAINTENANCE

The machine calibration should be checked on a regular basis and especially after replacing the

cutter. There are two types of calibration, axis calibration which is regulation of the position of the

key left to right and depth calibration which obviously regulates the depth of the cuts

CYLINDER CALIBRATION

Axis Calibration:

Insert identical key blanks with shoulders on front and back into both jaws, lining them up with the

back shoulder against the jaw on Side A.

When correctly calibrated the key set guide should touch both shoulders and the tracer and cutter

should hit the shoulders simultaneously.

If the key set guide is out of alignment:

•Loosen the allen screws on the triangular guides

•Adjust until they are both touching the key shoulders

•Re-tighten the allen screws

If the cutter and tracer are out of alignment:

•Loosen the two large allen screws on the tracer housing

•Adjust the position of the tracer left or right until the tracer and cutter are both touching the

key shoulders

•Re-tighten the screws

Depth Calibration:

Insert identical key blanks with shoulders on front and back into both jaws, lining them up with the

back shoulder against the jaw on Side A.

When correctly calibrated, the cutter should skim the surface of the key on the right whilst the

tracer is making contact with the key on the left.

7

If this is out of alignment:

•Loosen the screw holding the tracer point

•Turn the tracer adjustment ring (clockwise to extend tracer and anti-clockwise to retract it)

until the cutter skims against the blank on the right whilst the key on the left is against the

tracer

•Re-tighten the allen screw.

MORTICE CALIBRATION

Axis Calibration:

Insert identical key blanks with shoulders on front and back into both jaws, lining them up with the

back shoulder against the jaw.

When correctly calibrated the side of the tracer and the side of the cutter should hit the shoulders

simultaneously.

If this is out of alignment:

•Loosen the allen screw on the tracer housing

•Adjust the position of the tracer left or right until the tracer and cutter are both touching the

key shoulders

•Re-tighten the screws

Depth Calibration:

Insert identical key blanks with shoulders on front and back into both jaws, lining them up with the

back shoulder against the jaw.

When correctly calibrated the cutter should skim the surface of the key on the left whilst the tracer

is making contact with the key on the right.

If this is out of alignment:

•Loosen the top allen screw on the tracer housing

•Turn the screw under the tracer (clockwise to extend tracer and anti-clockwise to retract it)

until the cutter skims against the blank on the left whilst the key on the right is against the

tracer

•Re-tighten the allen screw

GENERAL MAINTENANCE

WARNING! ENSURE MACHINE IS UNPLUGGED BEFORE UNDERTAKING ANY MAINTENANCE

It is advisable to periodically check the parts subject to wear on the machine, e.g. drive belt, cutters,

brush, tracer points, etc.

For long lasting, satisfactory operation of the key machine the following regular checks are also

recommended.

8

•Keep the machine clean of swarf, particularly the jaws and other moving parts using a dry

brush

NOTE –Do not use compressed air

•Ensure the sliding shaft is kept lubricated

•Check all screws and bolts for any slackness and tighten if necessary

HEALTH & SAFETY

For complete safety whilst operating the machine, please take the following precautions:

•Always wear safety goggles

•Always work with dry hands

•Check that the machine is properly earthed

•Keep loose clothing, ties, hair, etc. away from moving parts

•Only clamp keys when the motor is switched off

•Keep hands away from the cutters when the machine is in use

•Turn power off when not in use and ensure the machine is unplugged before undertaking

any maintenance

This manual suits for next models

1

Table of contents

Popular Cutter manuals by other brands

Logan Graphic Products

Logan Graphic Products 707 Instruction and operation manual

Caslon

Caslon ProCrease Operation and maintenance manual

Silca

Silca Unocode 399 Plus operating manual

Husqvarna

Husqvarna K 960 Workshop manual

Fry Factory

Fry Factory AFC-50 instruction manual

Vivid

Vivid Veloblade Volta user manual