2

TABLE OF CONTENTS

Introduction..................................................................................................................................3

About Symbols ....................................................................................................................3

Electrical Symbols...............................................................................................................3

Safety instructions .......................................................................................................................4

For Safe Operation..............................................................................................................4

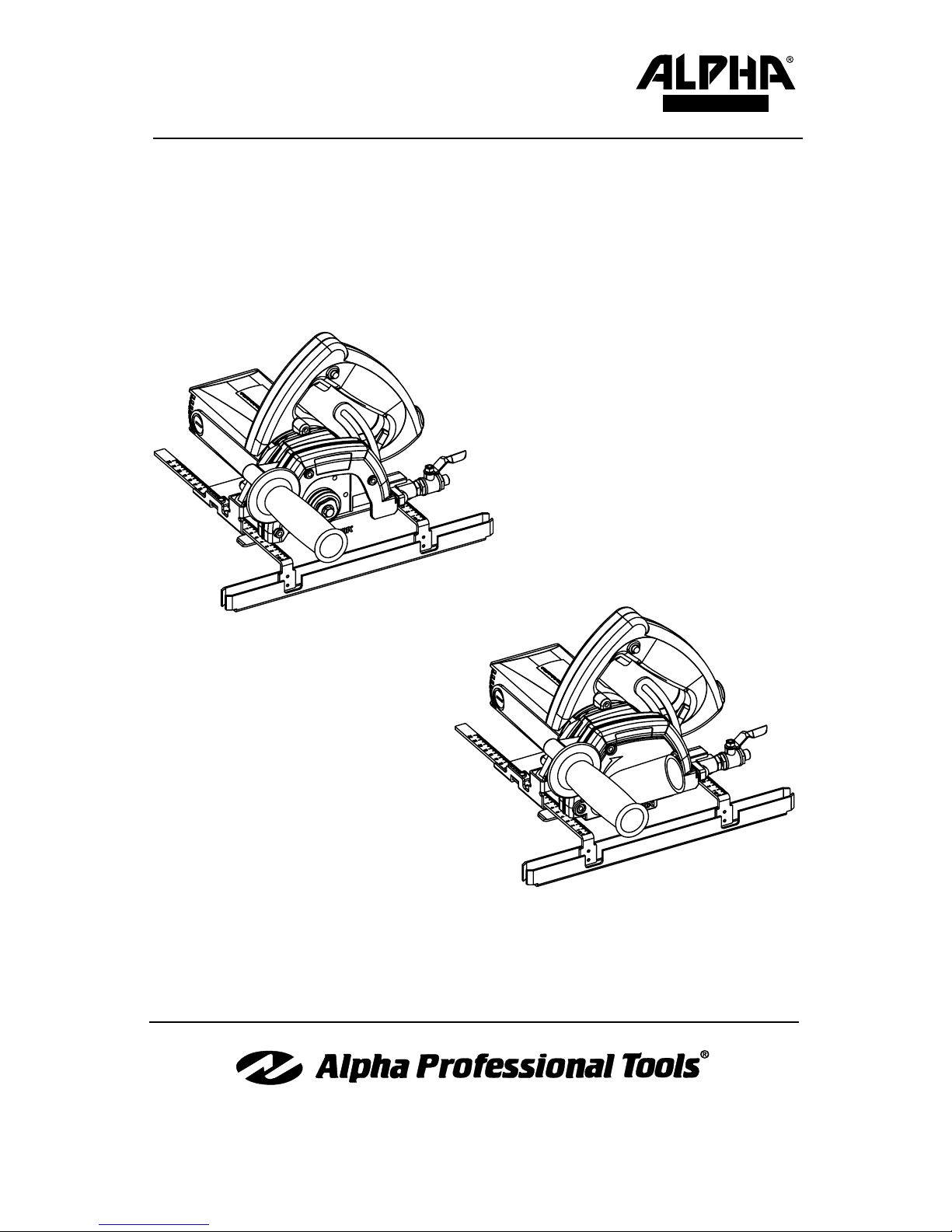

ESC-125 Overview......................................................................................................................6

Equipment Included ............................................................................................................7

Additional Precautions for Using the Wet/Dry Stone Cutter ........................................................8

ESC-125 Wet/Dry Stone Cutter Operation..................................................................................9

Main Connection .................................................................................................................9

Switching ON and OFF .......................................................................................................9

Ground Fault Circuit Interrupter ........................................................................................10

Before Use.................................................................................................................................11

About Double Insulation ....................................................................................................12

Laws and Regulations of Noise Levels .............................................................................12

Instructions for Installing the Felt Strips ............................................................................12

Installation of Water Hose Assembly (Wet Use)................................................................13

Supplying the Water Flow .................................................................................................13

Installation of Quick Connect Adapter ...............................................................................14

Installation of EasyOn-EasyOff Sleeve .............................................................................14

Adjusting the Cutting Depth ..............................................................................................15

Mounting and Dismounting Saw Blade .............................................................................15

Straight Cutting Blade Installation (Wet Use)....................................................................16

Curve Cutting Blade Installation (Wet Use).......................................................................16

Attaching the Dust Cover (Dry Use)..................................................................................17

Attaching the Vacuum Hose (Dry Use)..............................................................................17

Free-Hand Cutting.............................................................................................................18

Cutting Using TT Ruler Guide ...........................................................................................18

Cutting Using the Carriage Assembly and Guide Rail (Wet & Dry Use)............................19

Curve Cutting Application..................................................................................................19

Blade Inspection, Installation and Removal...............................................................................20

ESC-125 Maintenance ..............................................................................................................21

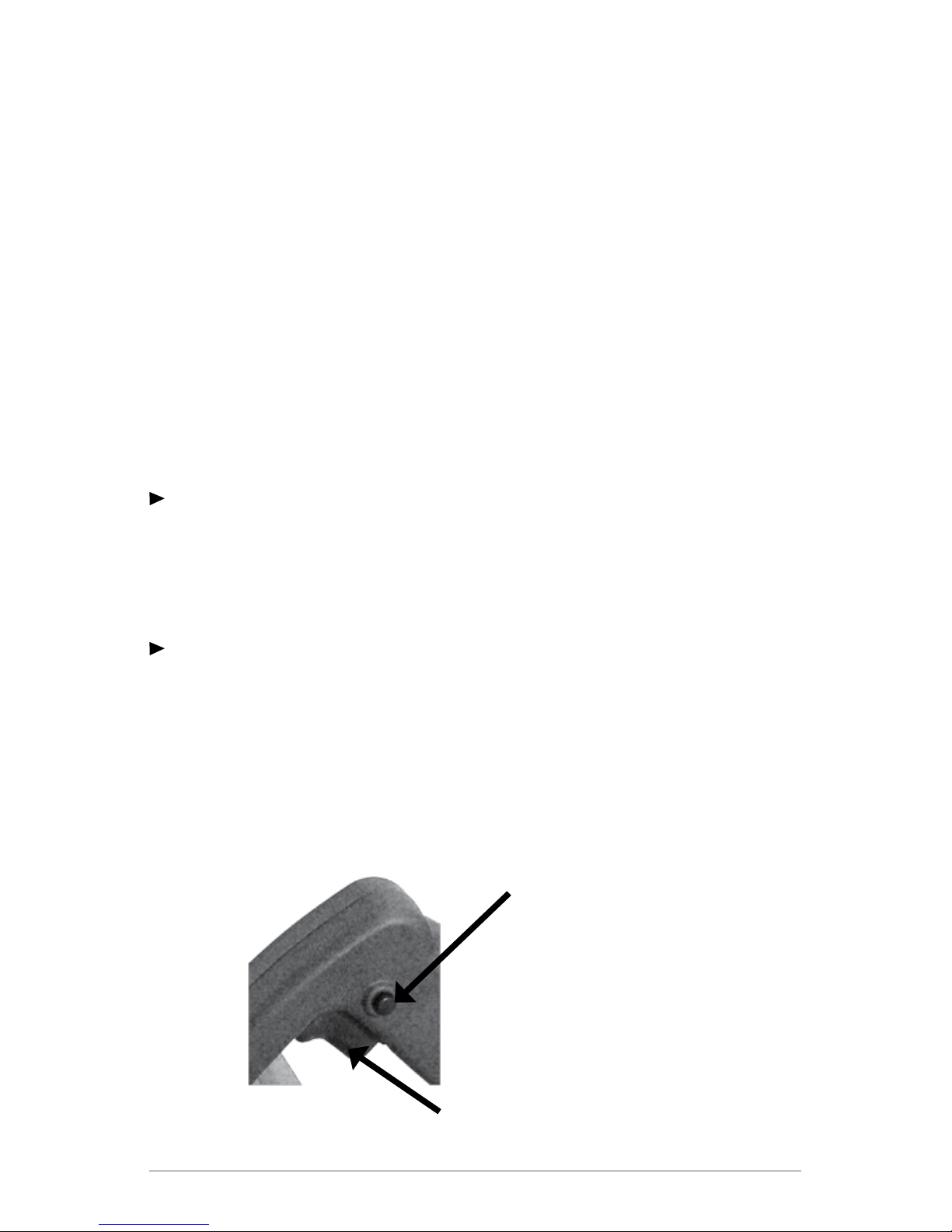

Replacing and Checking the Carbon Brushes...........................................................................22

ESC-125 Wet/Dry Stone Cutter Schematic...............................................................................23

ESC-125 Wet/Dry Stone Cutter Parts List.................................................................................24

EC Declaration of Conformity....................................................................................................26

Warranty ....................................................................................................................................26

Product Registration Card .........................................................................................................27