9

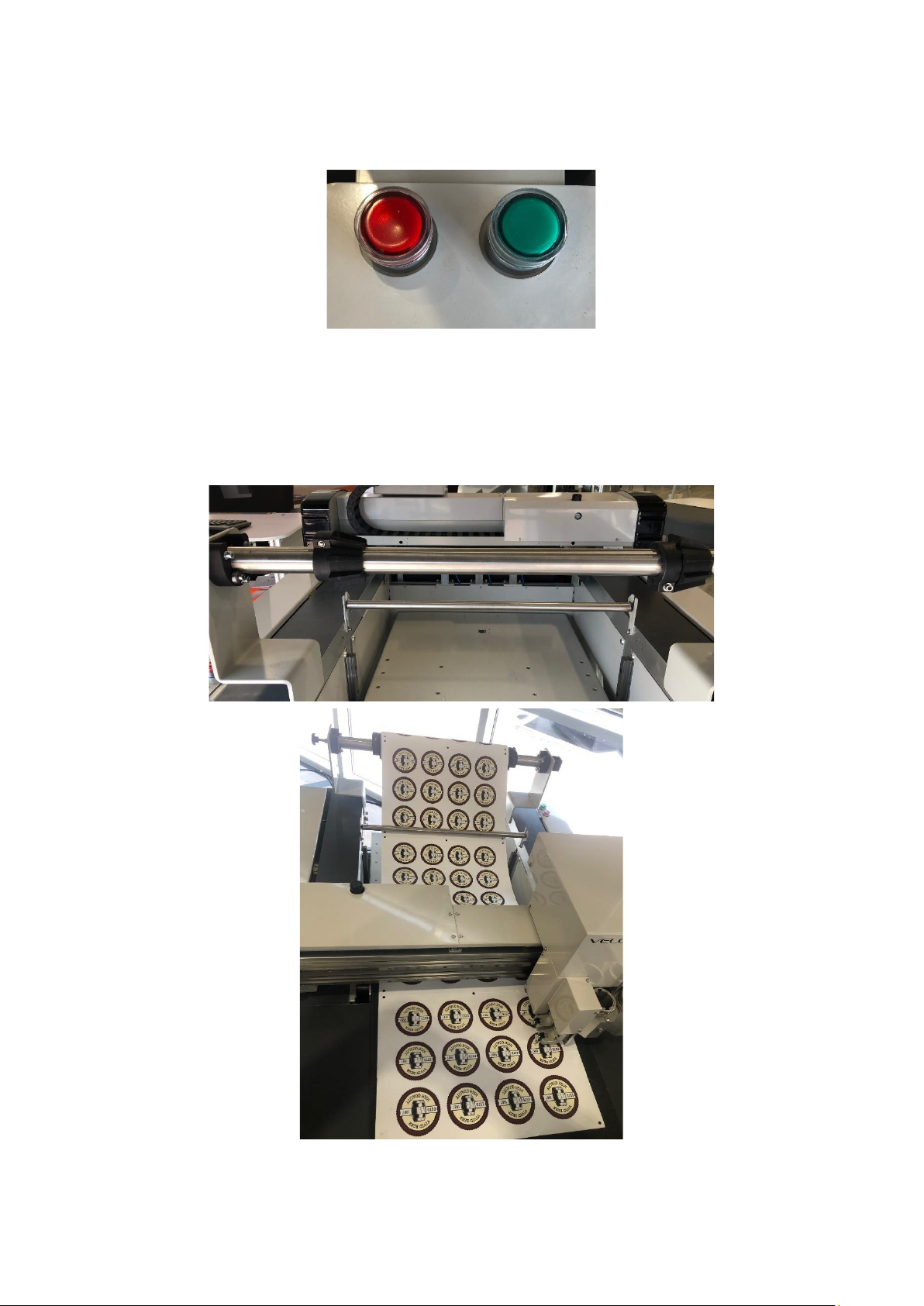

a circle on test material [this must be done on the belt of the machine] see

figure 3.13.

Once the blade is set and manually tested, return the tool to its position on the

machine and secure. The next step is to do a test cut, place a piece of scrap

material onto the belt, move the head into position over the media and press

T-depth in the Debug View window.

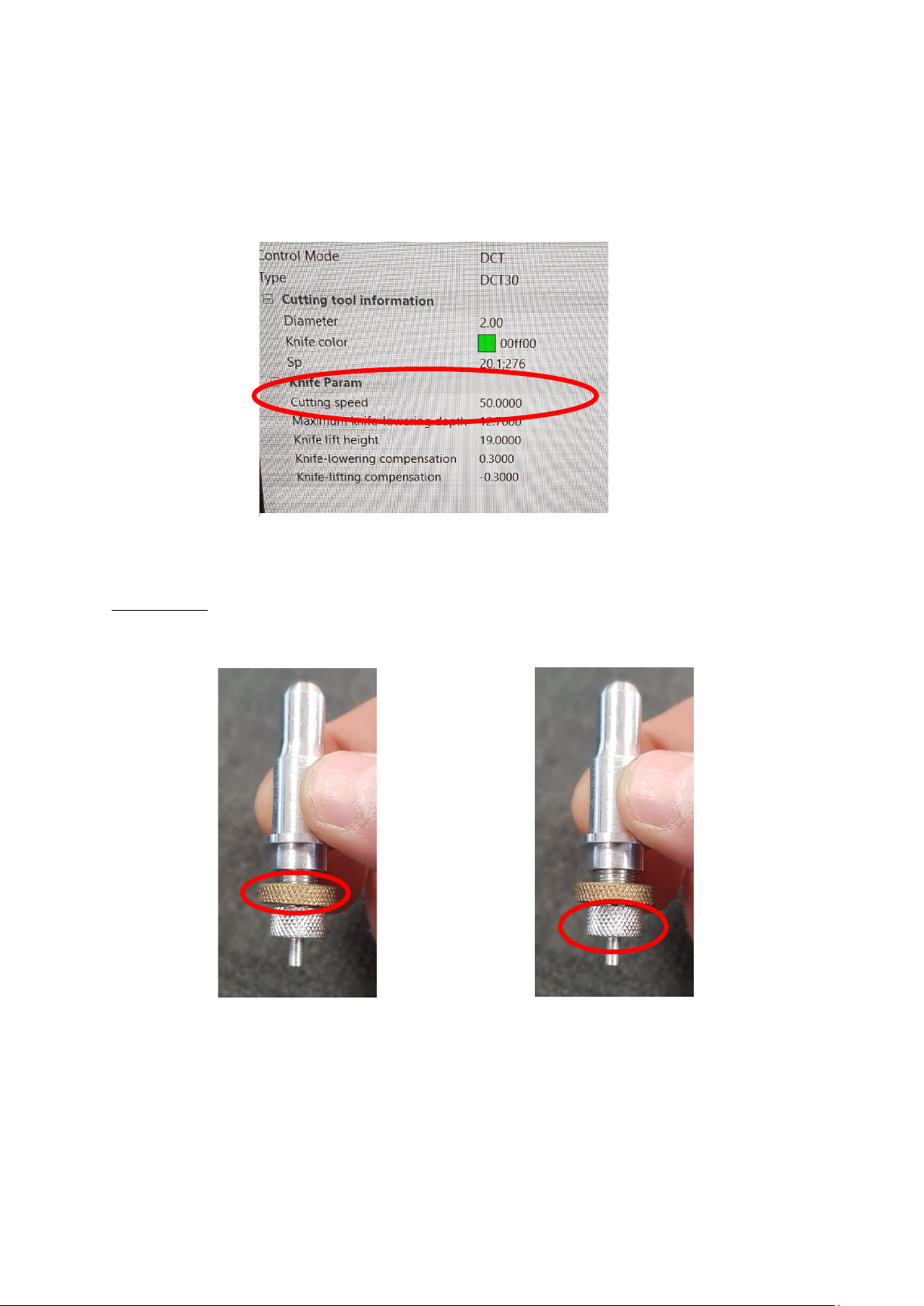

If you’re getting marking from the tool holder on the media [Figure 3.14] or the

tool is not making contact with the media, You will need to change the

pressure of the tool solenoid, Click on Cutting Tool Configuration, select the

number of the tool you are using [3 or 4], change the maximum knife lowering

depth.

Decreasing the number will apply less pressure.

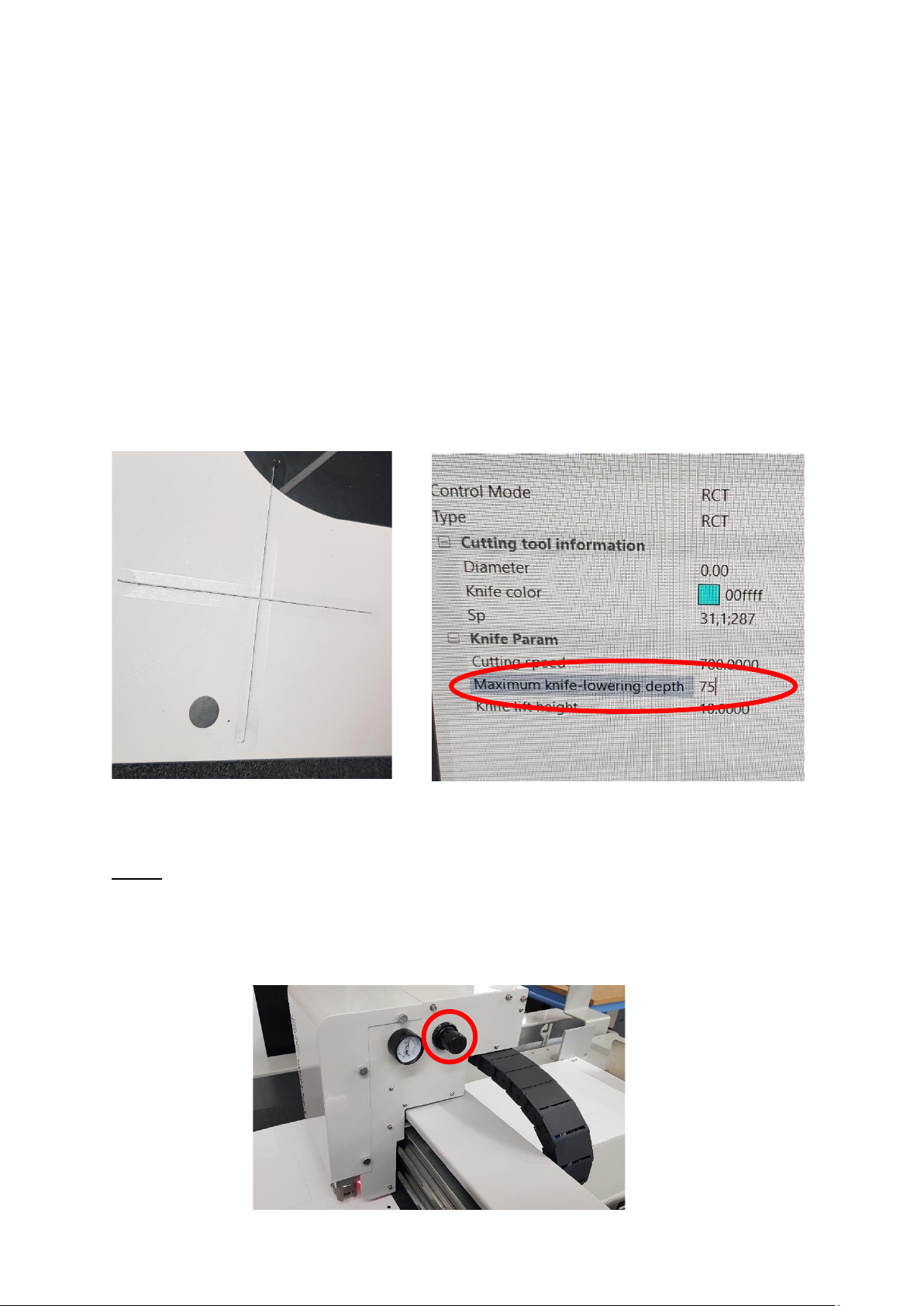

PCTT:

There are two ways to adjust the amount of pressure on the crease wheel, the

first is to adjust the valve and allow more or less air pressure [Figure 3.16].

Anticlockwise will reduce the amount of air pressure.