Contents

1About this document .......................................................................................... 7

1.1 Target groups ............................................................................................... 7

1.2 Storage.........................................................................................................8

1.3 Name plate ...................................................................................................9

1.4 Abbreviations................................................................................................9

2Safety instructions............................................................................................ 10

2.1 Presentation of warnings ............................................................................ 10

2.2 Intended use............................................................................................... 10

2.3 Product-specific risks.................................................................................. 11

2.3.1 Risks imposed by mechanical equipment........................................ 11

2.3.2 Risks imposed by electricity............................................................. 12

2.3.3 Risk imposed by pneumatic system ................................................ 12

2.3.4 Risks imposed by noise................................................................... 12

2.3.5 Risks in case of fire.......................................................................... 13

2.4 Safety.......................................................................................................... 13

2.4.1 Working area................................................................................... 13

2.4.2 Emergency-stop .............................................................................. 14

2.4.3 Warning signs on the machine ........................................................ 15

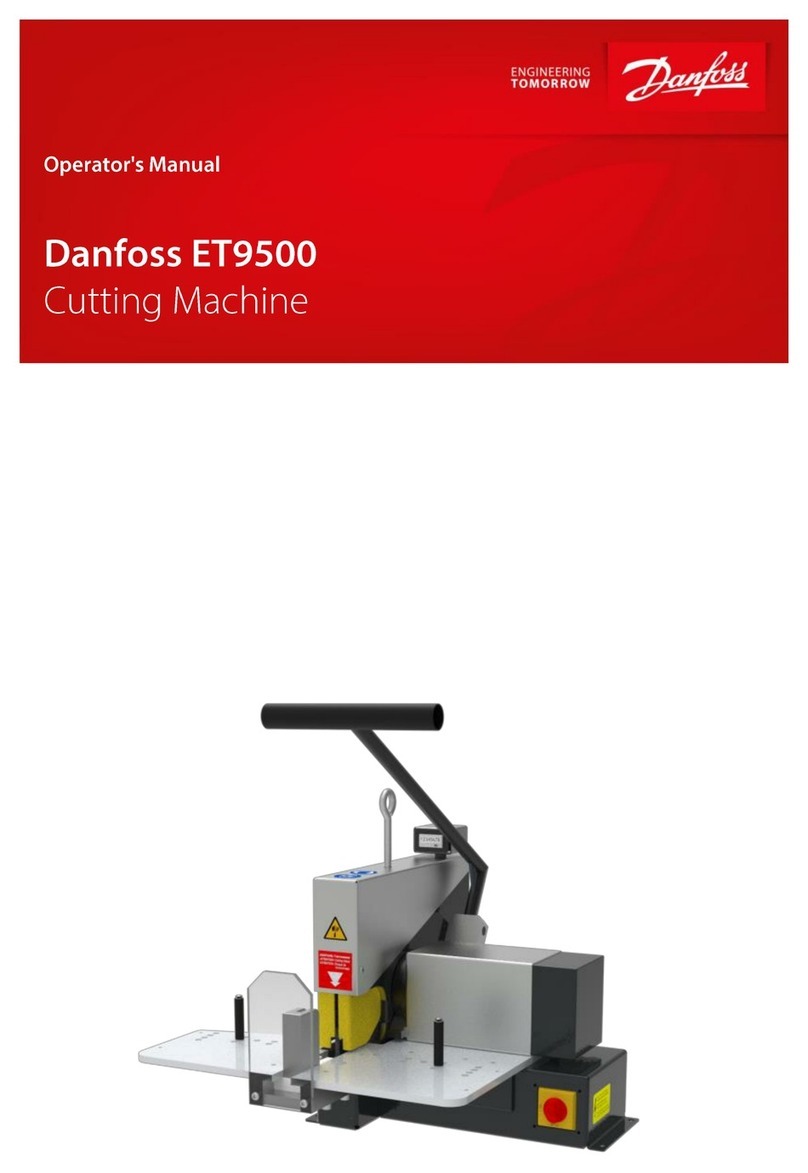

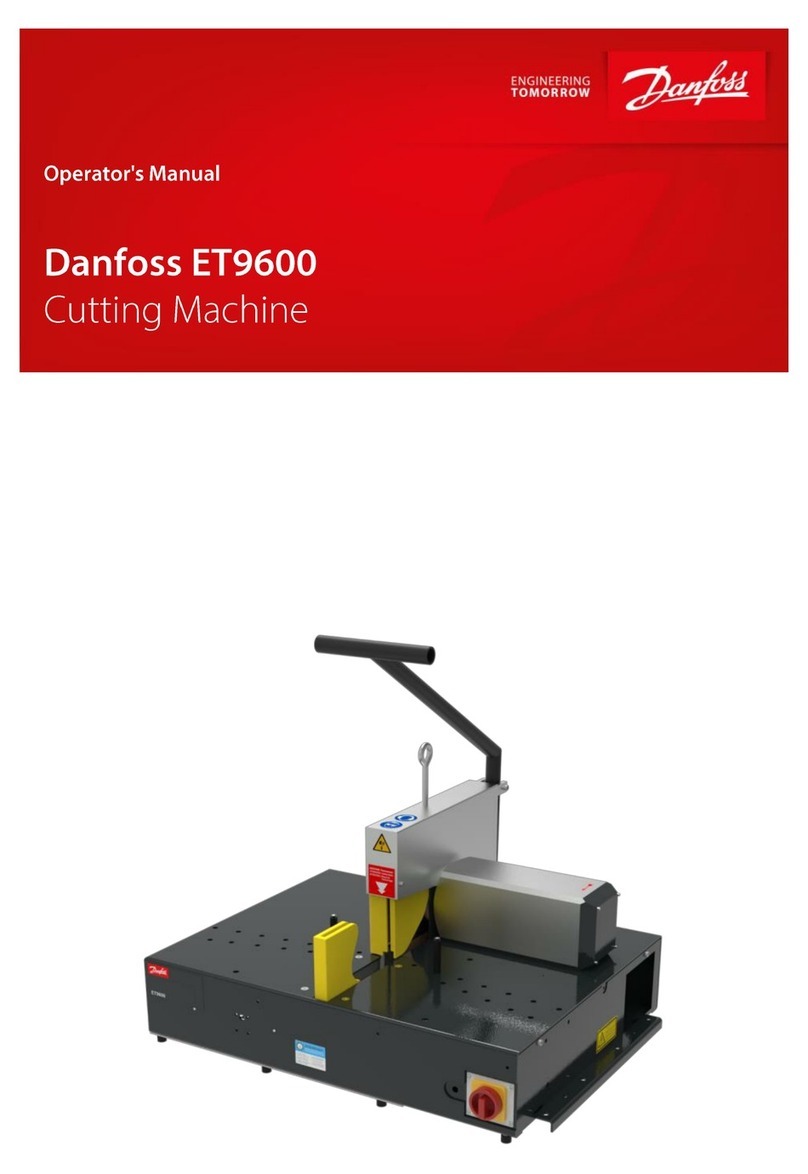

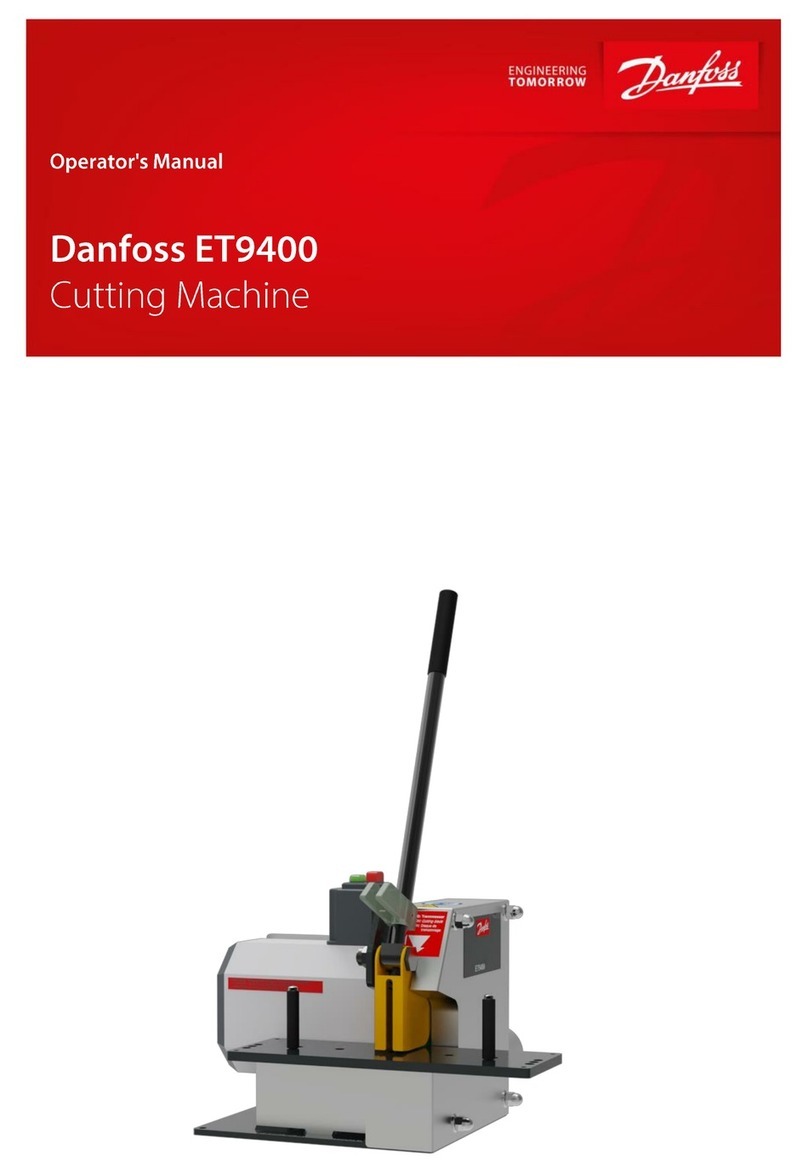

3Machine description.......................................................................................... 17

3.1 Design and function.................................................................................... 17

3.2 Accessories ................................................................................................ 18

3.3 Operation and display elements ................................................................. 19

3.4 Technical data ............................................................................................ 20

4Transport and commissioning......................................................................... 23

4.1 Transport .................................................................................................... 23

4.2 Intermediate storage of machine/unit.......................................................... 24

4.3 Commissioning ........................................................................................... 24

4.3.1 Extraction process for TM/TMG cutting knife................................... 25

4.3.2 Extraction process for TMC cutting knife......................................... 26

4.3.3 Connection of compressed air......................................................... 27

4.3.4 Electrical connection........................................................................ 28

4.3.5 Initial operation ................................................................................ 29

5Operation ........................................................................................................... 31