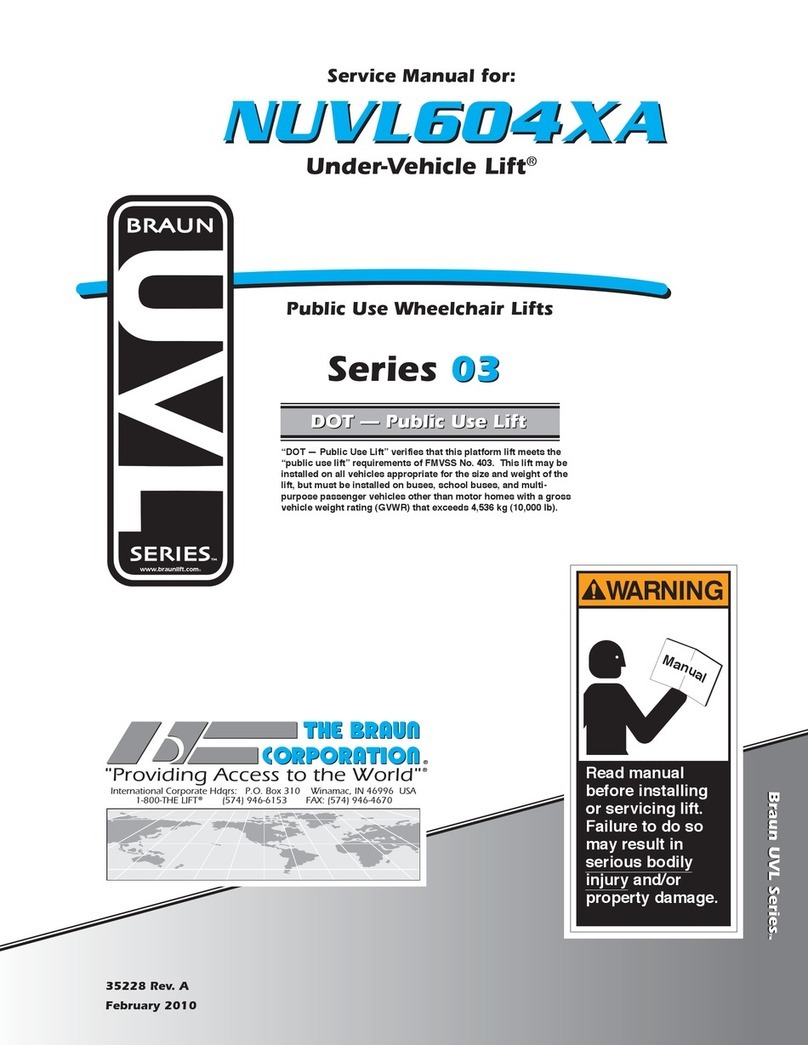

Sky Climber Rolling Roof Rig User manual

Rolling Roof Rig

Assembly Instructions

Rolling Roof Rig, Corner Adaptor, and Beam Splice Tube Packages

Sky Climber LLC.

1800 Pittsburgh Dr.

Delaware, OH 43015

Tel. 1 800-255-4629

www.skyclimber.com

Tel. 1 800-255-4629 | info@skyclimber.com | www.skyclimber.com 2

Print Date: 11/18/2019

SCL_AssemblyInstructions_RRR_RevAA_2019-11-

18

SAFETY CHECKLIST

TO OWNERS AND DISTRIBUTORS

It is imperative that this manual be given to the erector and/or operator of Sky Climber equipment and that

they read, fully understand, and follow all instructions contained herein.

WARNING

Any use of this equipment, other than in strict accordance with these instructions, shall be at the Operator's

risk and may result in serious injury to themselves or others.

DAILY CHECKLIST

Prior to use, check Sky Climber Hoists, Sky Locks, wire rope and other equipment for wear. DO NOT use hoists or

Sky Locks which are damaged or worn beyond normal tolerances.

Ascertain that:

•Instructions are kept with the unit at all times. Additional copies are available – contact Sky Climber.

•All Warning and Rating labels are in place, legible, and have been read.

•Roof rigging load is adequately distributed over the roof or parapet.

•Counterweights are non-flowable type, secure and in the correct quantities.

•Cornice hooks, parapet clamps, or outriggers are secured and tied back. Tiebacks are tight and straight back

or two opposing tie-backs are used (contact Sky Climber Engineering for details.

•Wire rope inspected and is not kinked, bird-caged, or otherwise damaged or overly worn.

•Minimum of three (3) J-Clamps / fist grips are used and are properly torqued. (Four J-Clamps are required

for round thimbles).

•Suspended platform hoist is connected to proper power source.

•Hoist drain holes on bottom are open. Check that fasteners are properly installed and air hoist oil level in

lubricator of hoist is acceptable.

•Sky Lock, Hoist Load, Controlled Descent, and Emergency Stop tests performed and acceptable.

•Make sure ALL fall protection equipment is damage-free and in good condition.

© Sky Climber, 2019. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of the publisher.

SAFETY IS THE RESPONSIBILITY OF BOTH OWNERS AND

OPERATORS OF THIS EQUIPMENT.

Tel. 1 800-255-4629 | info@skyclimber.com | www.skyclimber.com 3

Print Date: 11/18/2019

SCL_AssemblyInstructions_RRR_RevAA_2019-11-

18

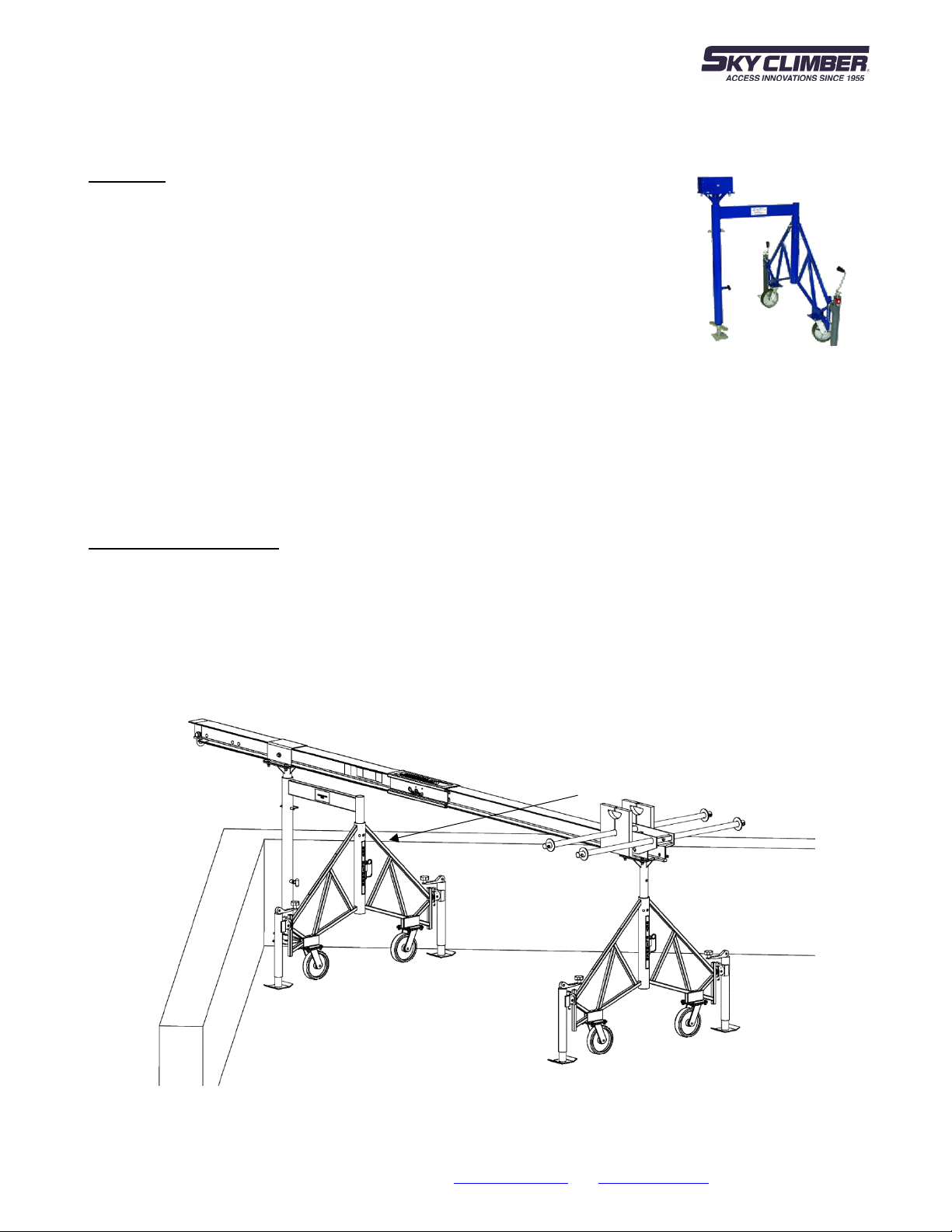

ASSEMBLY INSTRUCTIONS

Sky Climber Rolling Roof Rig

1. Assemble beam using 2 splice plates and 8 bolts and nuts per joint. Rolling Roof Rig Package 154-24-A

consists of 2 end beams. Package 154-24-Bconsists of 2 end beams and 1 mid-beam.

2. Raise the mast to the desired height and insert the retaining pin. Loosen the 4 nuts and bolts connecting the

hat bracket to the mast. Insert and pin a jack on each side of the stanchion. Repeat with second mast.

3. Insert the assembled I-beam through the hat bracket of the front stanchion until you reach the desired amount

of outreach. Tighten the four hat bracket nuts and bolts. Insert other end of I-beam through rear stanchion

until about 3 inches of the beam extends beyond the hat bracket (packages 154-24-A and 154-24-B).

4. Remove the two bolts on either side of the rear hat bracket. Set the Longhorn on top of the rear hat bracket

and secure it using the two bolts.

5. Check chart to determine maximum amount of outreach for your application. If a strongback is required see

package 154-24-C or 154-24-CBT.

6. Roll the assembled roof rig into the desired location. Crank the jacks until the load is removed from the casters

and the roof rig is level.

7. Slide the correct number of counterweights (see chart on page 6) onto the longhorn rods. Slide the large

washers onto the rods and place a bale clip or nut and bolt through the ends of the rods to retain the

counterweights.

8. Attach the tie back wire rope to the hole in the rear of the I-beam or the shackle of the suspension rope and

tie back to a substantial building structure*.

*Substantial building structures are defined and verified as an anchor point designed and confirmed in writing by an engineer,

with a 4:1 safety factor versus the rating of the hoist being used.

9. Attach the suspension wire rope assembly counterweights to the hole in the front of the I-beam.

16-foot Rolling Roof Rig

(plus counterweights)

8-foot End

Beam

Double

LongHorn

Beam Tube

(or splice plates)

Rolling Roof

Rig Stands

Rolling

Roof Rig

Stands

Splice Plate

alternative to beam tubes

Tel. 1 800-255-4629 | info@skyclimber.com | www.skyclimber.com 4

Print Date: 11/18/2019

SCL_AssemblyInstructions_RRR_RevAA_2019

-11-18

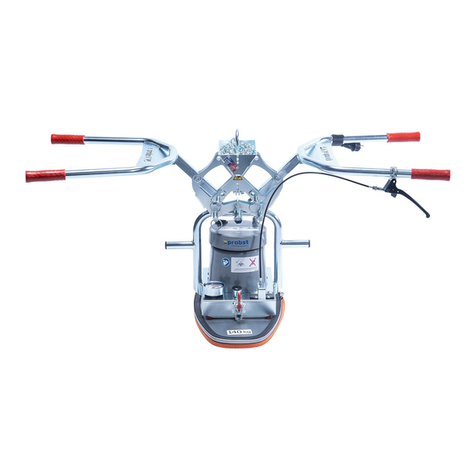

Rigging Collar Instructions

•The Rigging Collar is designed to be used when intermediate and additional

suspension points are required on the Sky Climber Rolling Roof Rig beam. For

example: it may be used to reduce the outreach without moving the entire rolling

roof rig.

•The Rigging Collar may only be used when precautions have been taken to

ensure a shackle, stop bolt or other hardware is placed in the hole at the end of

the beam. Locate the Rigging Collar between the rolling roof rig stanchion and

the end of the beam.

•Counterweight calculations should be based upon the rolling roof rig position i.e. the Rigging Collar may not

be used to reduce outreach with the goal of reducing the number of counterweights required.

Beam Tube Instructions

•Follow normal Rolling Roof Rig instructions but use the Beam Tube in place

of splice plates, nuts and bolts. Insert Pins in the outermost holes of the

beam allowing for assembly without tools.

•Look through the inspection slot to verify that beam is fully inserted into the

beam tube. If you can see through to the inspection slot on the opposite

side of the beam tube, then the beam is not fully inserted.

•Some beams also feature a label that will be partially visible once inserted into

the beam tube. If the green portion of the label is visible but not the red

portion, the beam has been properly inserted. If the red portion of the label is

visible, the beam has NOT been fully inserted into beam tube.

If a strongback is required, move the rear stanchion 8 inches

from the end of the beam. Remove the two bolts on the sides

of the front stanchion hat bracket. Attach the strongback mast

to the top of the front stanchion hat bracket and secure with

the two bolts. Place the telescoping section on top of the mast.

Hook the finger hooks on each end of the cable to the flange

on either end of the I-beam. Turn the wing nut on the

telescoping mast, raising it until the cable is tight.

Strongback

Cable

End Hook

Telescoping

Mast

24-foot Rolling Roof Rig WITH

Strongback (plus counterweights)

Counterweight

Beam Tube

Beam insertion label

Tel. 1 800-255-4629 | info@skyclimber.com | www.skyclimber.com 5

Print Date: 11/18/2019

SCL_AssemblyInstructions_RRR_RevAA_2019

-11-18

Corner Adaptors

The Corner Adapter reduces outreach by moving fulcrum closer to parapet. It also reduces the quantity of

counterweights needed and can eliminate the need for a cable-truss/strongback.

Instructions

•Remove the mast from the front Rolling Roof Rig stand.

•Insert the short tube of the Corner Adaptor into the front Rolling Roof Rig

(RRR) stand and pin in place so that the tube is perpendicular to the front RRR

stand (as shown in the diagram on the right).

•Adjust the height of the screw jack by releasing the Jack Holding Pin, allowing

the jack to be moved to the floor. Complete a final adjustment using the

screw jack wing nut. Note that the load should be spread on the roof/floor

with the use of appropriate cribbing.

•Tighten the wing nut to secure the screw jack height.

•Insert the mast of the front RRR stand in to the long tube of the Corner Adapter and adjust the height as

required.

•Assure the rear Rolling Roof Rig stand is set to the correct height to ensure a level beam. Install the beam as

usual.

To move the Corner Adaptor

•Move the Rolling Roof Rig as normal.

•To avoid dragging the screw jack, screw the wing nut to the bottom of the jack:

oLift the jack to the bottom of the Corner Adapter tube

oPull the Holding Pin out and release the Holding Pin to hold the screw jack in place off the ground.

oReverse the procedure to properly reset the corner adaptor in its new location.

Corner Adapter with

16-foot Rolling Roof Rig

plus counterweights.

Corner Adapter

Corner

Adapter

Table of contents

Other Sky Climber Lifting System manuals