AUTEC AL4044 User manual

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

•4-Colomn lifts – electro hydraulic

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-01

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

INHOUDSOPGAVE PAG

1 Introduction 02

2 Packing, transport and storage 02

3 Safety specifications 02

4 Description of the lift 02

5 Installation 03

6 Connection to electrical mains 05

7 Safety checks 05

8 Goods received report 06

9 Electrical diagram 07

1. INTRODUCTION

CAUTION

This instruction manual is intended

for the assembly personnel who are

going to carry out the installation of

the lift.

2. PACKING, TRANSPORT

AND STORAGE

Every action involving the operation,

transportation or unpacking of the

equipment must only be done by

trained personnel who have a proper

knowledge of the lift, and who are

familiar with the contents of this

operating manual.

LIFTING AND MOVING THE

PACKING CRATES CONTAINING

THE EQUIPMENT

The wooden crates must be lifted and

moved with the help of a fork lift truck or

a lift crane. (Fig. 1)

Fig. 1

The equipment chosen must be

capable of lifting and moving the

equipment safely, keeping in mind

the dimensions of the vehicle, the

weight, the centre of gravity and

projecting and fragile parts.

STORAGE

The packed lift must always the placed

in a covered area at a temperature

between -10 oC and + 40 oC and must

not be exposed to direct sunlight.

OPENING THE CRATES

Check whether the machine have been

damaged during transportation, and

whether all the components as

mentioned in the Packing List are

physically present.

REMOVAL OF CRATES

The wood of the crates may be re-used.

It is strongly recommended

that you should first carefully read

the safety instructions.

3. SAFETY REGULATIONS

The manufacturer hereby refuses to

accept any responsibility for injury to

persons or damage to equipment or

property if it appears that incorrect

handling of the lift has taken place. This

instructions manual only describes the

operating- and safety aspects which

persons who are installing the machine

need to know. In order to understand

the terminology used in this manual, it is

necessary that the person performing

the installation work should have

specific experience in industrial work,

service, maintenance and repair

activities, and must also possess the

ability to explain the drawings and the

descriptions contained in this manual to

other people. At the same time he must

also be aware of the general and

specific safety regulations which apply

in the country where the lift is being

installed.

4. DESCRIPTION OF THE LIFT

(Fig.2)

The lift consists of the following :

Two platforms and four posts. The

columns are fixed to the floor with bolts.

The liftingsystem consists of a hydraulic

cilinder which converts the horizontal

movement by cabels and pulleys into a

vertical movement. The lift is controlled

by a controlbox mounted on the

controlpost.

Fig.2

CONTROL BOX (FIG.3)

The controlpanel of the controlbox

consists of the following:

11. Mainswitch

12. Lifting motion button

13. Descend button

14. Locking

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-02

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

Fig.3

5. INSTALLATION

Installation may only be done

by persons authorised to do so.

BEFORE STARTING INSTALLATION,

PLEASE RECHECK ALL THE

CONTROL POINTS.

The lift must be installed in an enclosed

space where weather influences do not

have any effect. The place of installation

must be at a sufficient distance from the

storage locations of paint and wax, and

also rooms where there is a danger of

explosion.

ELECTRICAL POWER SUPPLY

POINT.

The client must ensure that there is a

power supply point near the installation

site, which satisfies all the applicable

legal requirements (see page 4). If such

power supply is not available, the

installation technician will arrange for

an emergency cable. The lift shall be

tested after the emergency power

supply has been dismantled. The client

must then arrange for a duly qualified

and recognised installation technician to

lay the final wiring.

IMPORTANT INSTALLATION

MEASURES

The lift must be installed taking into

account the dimensions of other objects

(Fig. 4), and the rules and regulations

applicable in the country where the lift is

installed.

In particular, attention should be paid to

the following :

The minimum height from the floor,

at the installation location, must be

5000 mm

The minimum distance from the

walls must be 1 m.

The minimum working area is 500

mm

Adequate room for working

Adequate room for maintenance,

access-/ and exit routes.

Position with respect to other

machines

In the neighbourhood of the power

supply point to ensure problem-free

connection.

Fig.4

During the installation no

unauthorized persons may be

present in the safety zone around the

lift.

•Remove the packaging from the

driving plates.

Place the driving tracks on dollies and

convey them to the general location of

installation. The driving track with the

cabling / hydraulics under the driving

plate must be installed on the same side

as the operating column (fig. 5)

Fig.5

Open the packaging of the columns and

place the columns on the installation

location. Fit the locking strips in the

columns. Take care: that this strip runs

behind the strip (1) in the centre of the

column (Fig.6).

Fig.6

Place the crossbeams on dollies. Take

care: that the crossbeam with the fuse

box is placed on the same side as the

operating column (Fig.7).

Fig.7

Remove the steel cable from under the

driving plate (Fig.8).

Fig.8

Lead the cables to the non-operating

side through the crossbeam. The cable

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-03

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

in the 2nd duct should seen from below

pass through the short section of the

crossbeam. The cable in the 3rd duct

should seen from below pass through

the long section of the crossbeam

(Fig.9). Use for this purpose the string

supplied.

Through short part of the

crossbeam (2egroove)

Through long part of the

crossbeam (3egroove)

Fig.9

Short part

crossbeam

Long part

crossbeam

Fig.10

Lead 2 electricity cables from the rear

crossbeam to the front crossbeam. In

doing so lead the cable through the

same passage as the air hose (over the

I-profile).

Secure the crossbeam to the driving

plates with bolts and turn these hand-

tight (Fig.11).

Fig.11

Now lead the steel cables to the side of

the control unit in the same way through

the crossbeam as to the non-control

side.

Secure now the protective device on the

fixed driving plate.

Fig.12

Align the riding plates and secure the

bolts.

Connect the air hose that runs through

the driveway on both sides to the

locking cylinders.

Connect the air hose that emerges from

the crossbeam on the control side to the

compressed air supply.

Now fit the runners in the crossbeams.

Take care that the spring rings are fitted

to the bolts to secure the blocking plate

(Fig.13).

Fig.13

Fit the open guidance blocks to the

crossbeams. Take care that the

assembly bolt is in the centre to allow

for later adjustment. (Fig. 14).

Fig.14

Connect the electrical wiring to the

contact box on the crossbeam.

Place the columns by sliding them

against the crossbeams.

Fit the closed guidance blocks on the

exteriors of the crossbeams (Fig.15).

Fig.15

Now secure the lifting cables in the

column

Fig.16

FITTING THE CONTROL UNIT

Fit the control unit to the column.

Connect the cabling to the column as

detailed in diagram Fig.23

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-04

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

Fit the safety switch at the bottom of the

column and connect it.

Remove the hydraulic hose from under

the platform and lead this together with

the pneumatic hose, the electrical cable

of the control unit, the return pipe and

any electrical cable for the lighting

through the flexible hose to the control

column (Fig.17).

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Fig.17

Fill the oil reservoir.

Connect the electrical power to the

control unit

Align the columns, using if necessary

spacers secured with M12x100.

Suspend the safety bars in the column.

Fit the catch bars at the tops of the

columns with double nuts. 1 nut must be

located under the top plate. Caution:

the catch bar must be suspended loose

in the column (Fig. 18+19)

Fig.18

Fig.19

1. Adjust the column cables. Ensure

that the cables are taut when the

driving plates are on the floor.

2. Adjust the safety switches (cable

breach/weakness) to

approximately 1.5/ 2 mm (Fig.20)

Fig.20

Fit the pin that is to serve the switch at

the bottom of the column. Then adjust

the final switch at the bottom of the

column (Fig.21).

Fig.21

6. CONNECTING TO THE

MAINS

WARNING

The following actions must only be

carried out by duly authorised

personnel :

First check the following points before

connecting to the mains:

-

-

-

The electrical system at the

workplace must be protected

according to the applicable

standards.

The wires must be of the following

sizes : in the case of 400 V they

must be at least 2.5 mm2fuse max

16A. In the case of 230V 3-phase

supply, the wire size must be at

least 4 mm2.

-The supply cable must be provided

with an earthing wire, and must be

suitable for a firm and final

connection.

Connect the power supply cable to

the control cabinet according to

Fig. 23.

Put the main switch in the “1” position.

Check the direction of rotation of the

motor by pressing the lifting-motion

button.

7. SAFETY CHECKS

After the complete installation of the lift,

the responsible installation engineer

must check all the safety arrangements

on the lift to check whether they are

working properly.

CLEANING OF THE LIFT (Fig. 17)

The installation engineer responsible

must take care to see that the lift which

is installed is delivered to the client in a

'squeaky clean' condition.

en/TD-AL4044-05

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Fig.22

8. GOODS RECEIPT REPORT

The concerned installation engineer

must prepare a goods receipt report

after completion of the installation. The

goods receipt report must be prepared

as carefully as possible. Any complaints

and/or observations of the client will

also be noted in the report under the

heading ‘Remarks’. The report must be

signed by the responsible installation

engineer, and by the client. The

installation engineer will deliver the

report to the technical department. The

installation engineer must see to it that

the report are filled-in in time in the

service box.

en/TD-AL4044-06

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

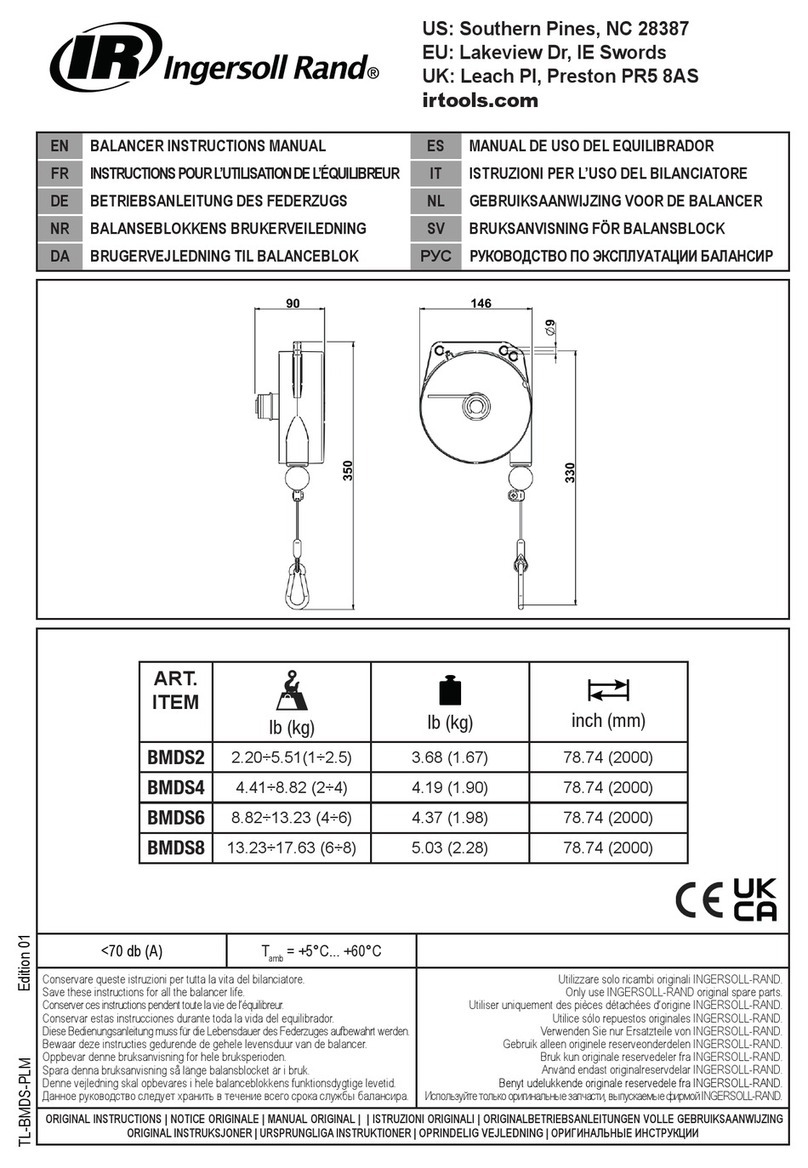

F1 = 2 Amp. Fuse

S1/S2 = Lift / descendlknop

Z1 = Buffe

r

S3 = Locking button

FC1-2-3-4 = Microswitch

FC5 = Microswitch

KM = Contact

Y1 = Hydr. solenoid valve

Y2 = Pneum. solenoid valve

Tem

p

= Time relais unlockin

g

Fig.23

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-07

INSTALLATION-MANUAL

4-Colomn AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

Fig.24

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-AL4044-08

This manual suits for next models

5

Table of contents

Other AUTEC Lifting System manuals

Popular Lifting System manuals by other brands

Fleece

Fleece Duramax PowerFlo LB7 installation instructions

S.R.Smith

S.R.Smith MultiLift Owner's Manual and Maintenance Instructions

MINN KOTA

MINN KOTA 1854073 manual

Golden

Golden Tornado 4-CYLINDER installation manual

USM

USM QuickServe II installation manual

Ravaglioli

Ravaglioli G1000A99NP instruction manual

Haklift

Haklift MAGPML100 Original instructions

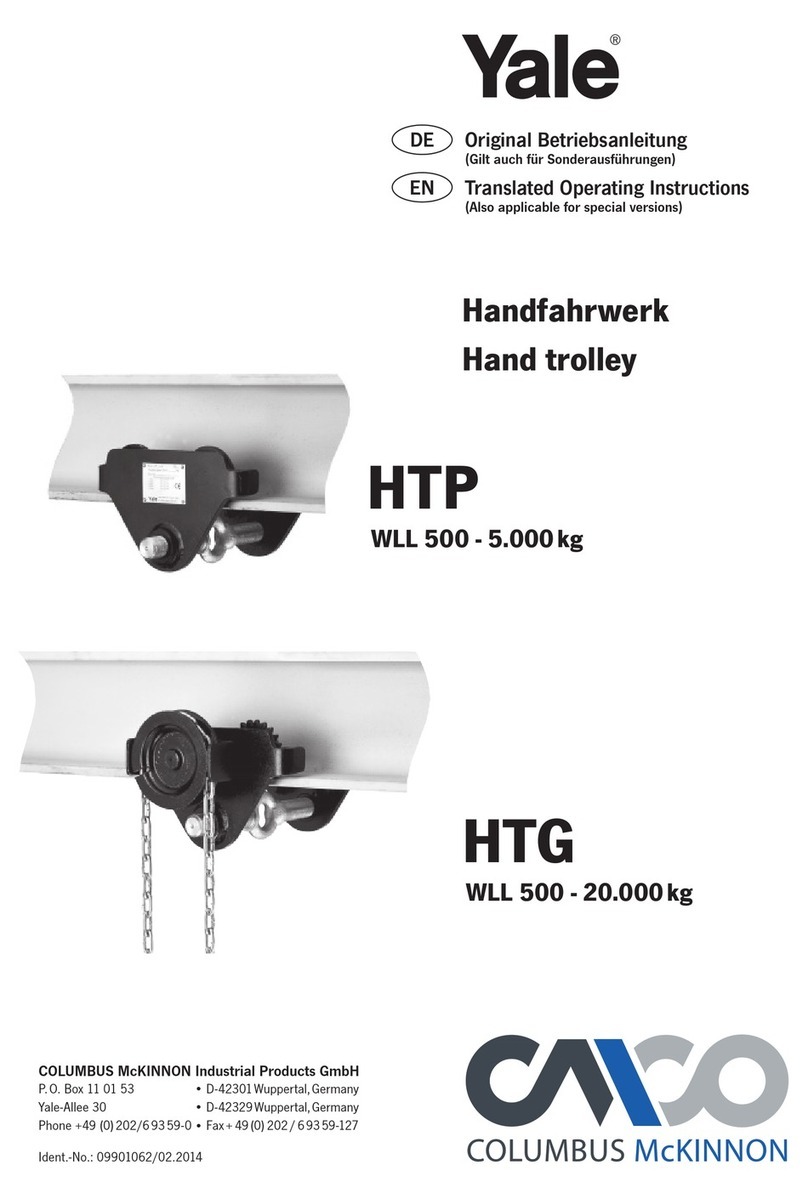

Columbus McKinnon

Columbus McKinnon Yale HTP Series operating instructions

DÖRR

DÖRR B-4WE 2.4G instruction manual

Atlas

Atlas BP10000X Installation & operation manual

Thiele

Thiele TWN 1884 operating instructions

Tuxedo

Tuxedo TP9KF ASSEMBLY & OPERATION INSTRUCTION MANUAL