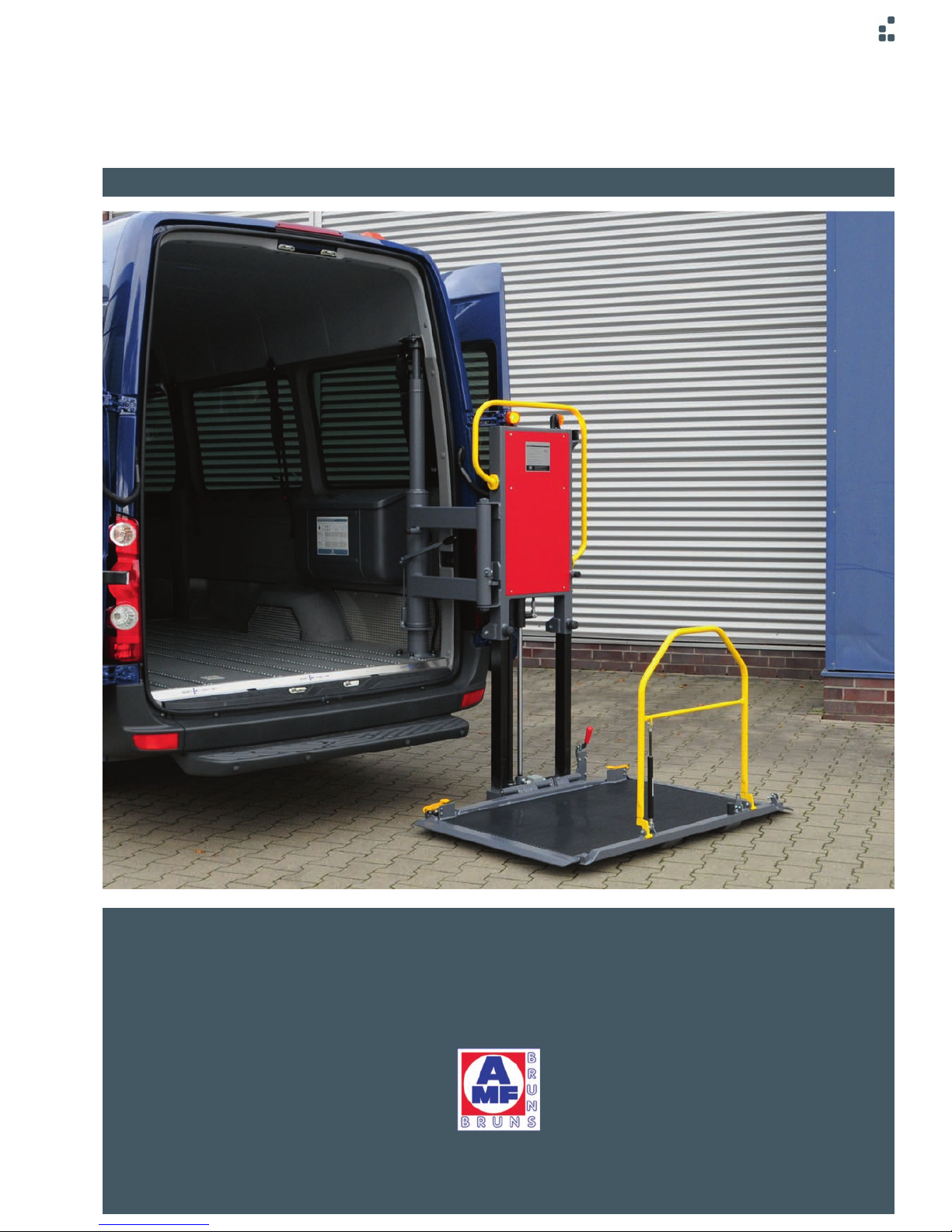

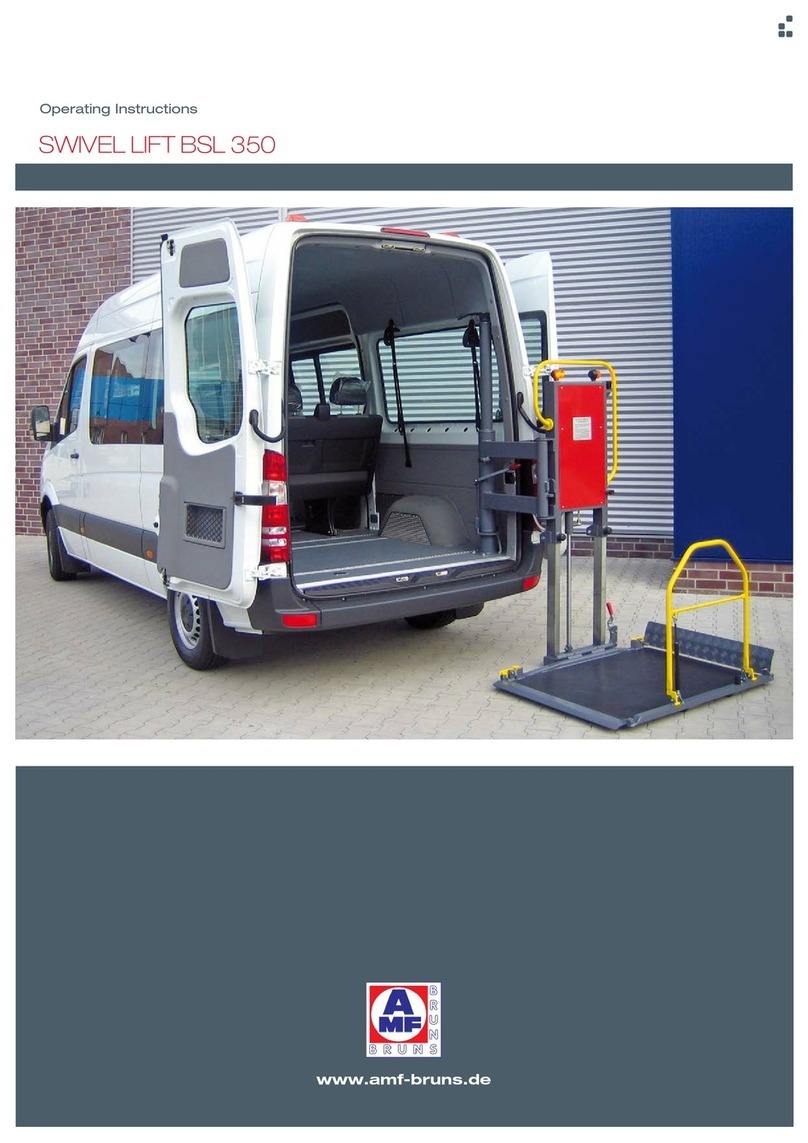

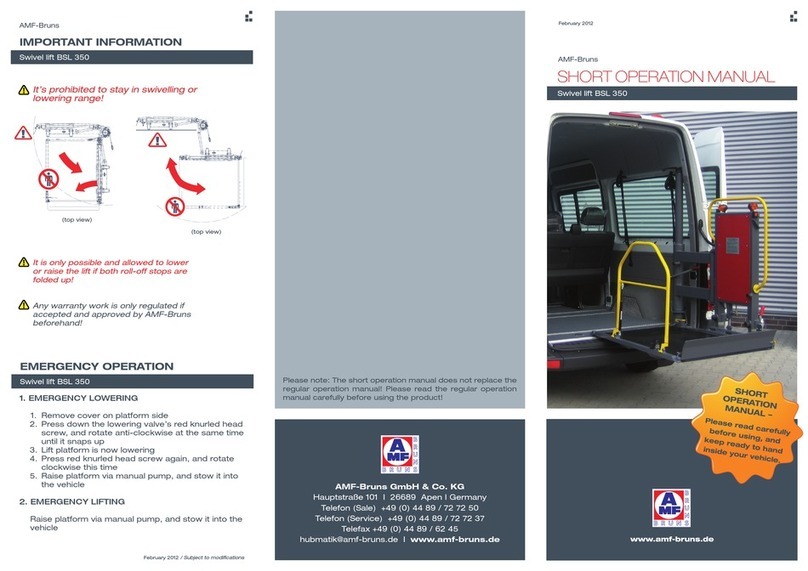

AMF-BRUNS BSL 350 User manual

Other manuals for BSL 350

2

Table of contents

Other AMF-BRUNS Lifting System manuals

AMF-BRUNS

AMF-BRUNS LINEARLIFT AL1 User manual

AMF-BRUNS

AMF-BRUNS BSL 350 User manual

AMF-BRUNS

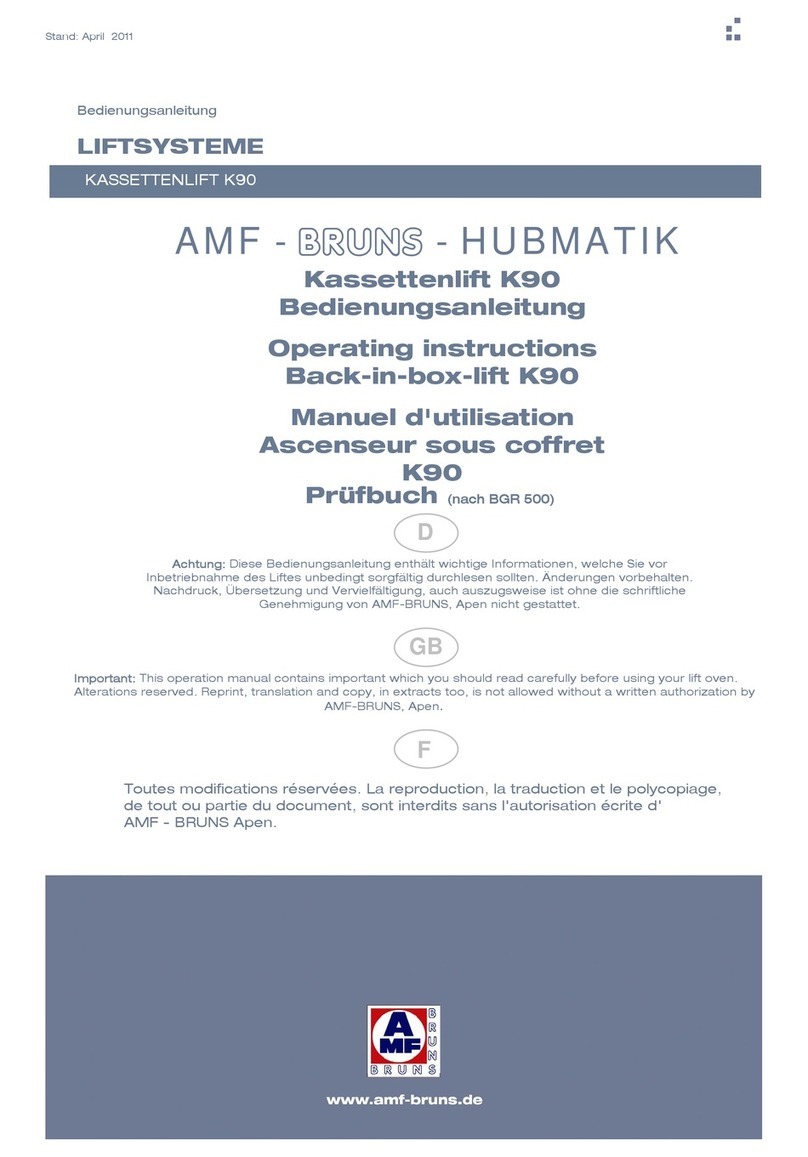

AMF-BRUNS HUBMATIK K90 User manual

AMF-BRUNS

AMF-BRUNS LINEARLIFT AL1 User manual

AMF-BRUNS

AMF-BRUNS K70 User manual

AMF-BRUNS

AMF-BRUNS Linearlift Series User manual

AMF-BRUNS

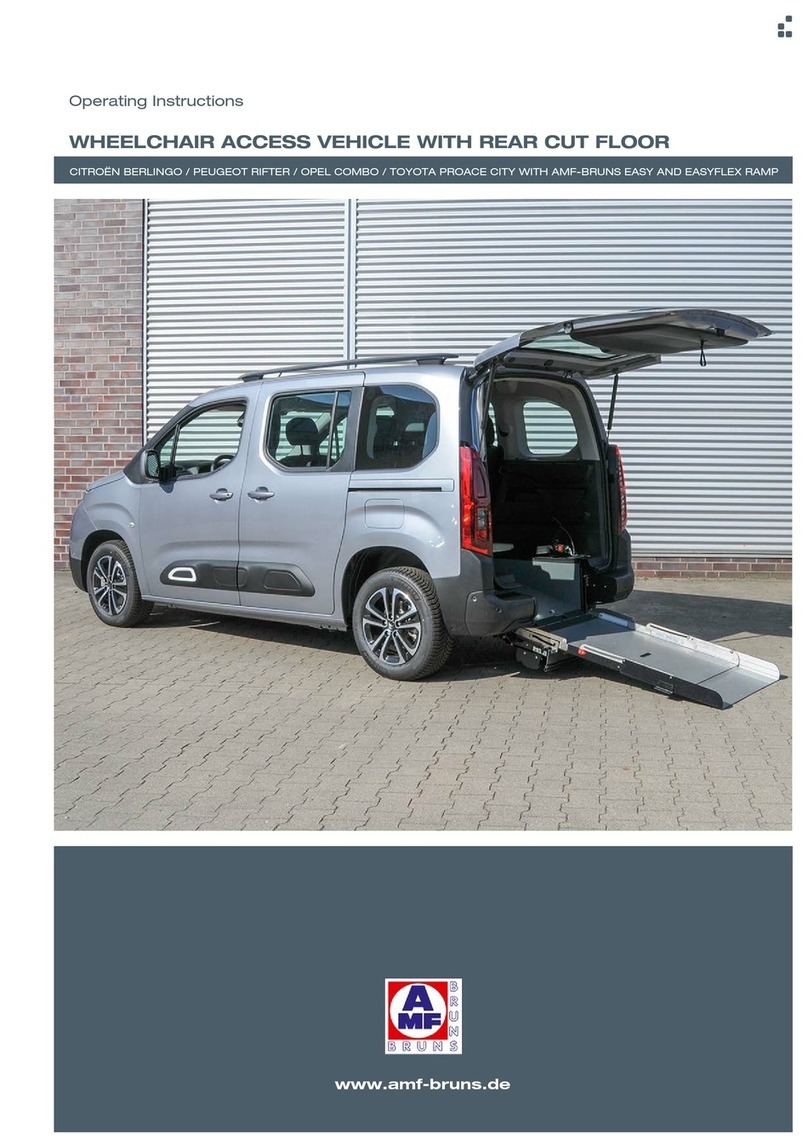

AMF-BRUNS Easy-Flex-Ramp User manual

AMF-BRUNS

AMF-BRUNS K70 User manual

AMF-BRUNS

AMF-BRUNS BSL 350 User manual

Popular Lifting System manuals by other brands

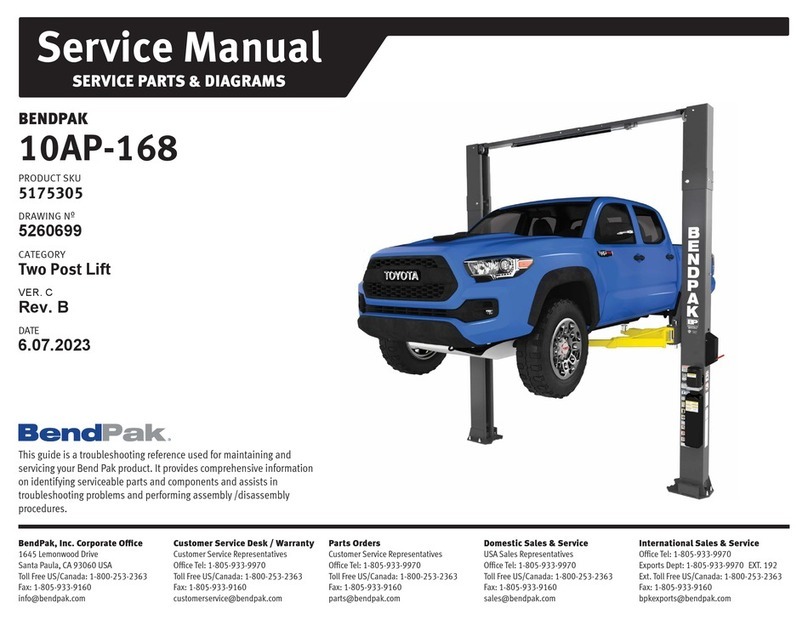

Bend-Pak

Bend-Pak XPR-10 Series Installation and operation manual

Bend-Pak

Bend-Pak HD-9 Service manual

Bend-Pak

Bend-Pak LR-5T Service manual

ARJO HUNTLEIGH

ARJO HUNTLEIGH Maxi Twin Instructions for use

Bend-Pak

Bend-Pak HD-973P Installation and operation manual

FAL

FAL VL30F230B Installation and operating instructions

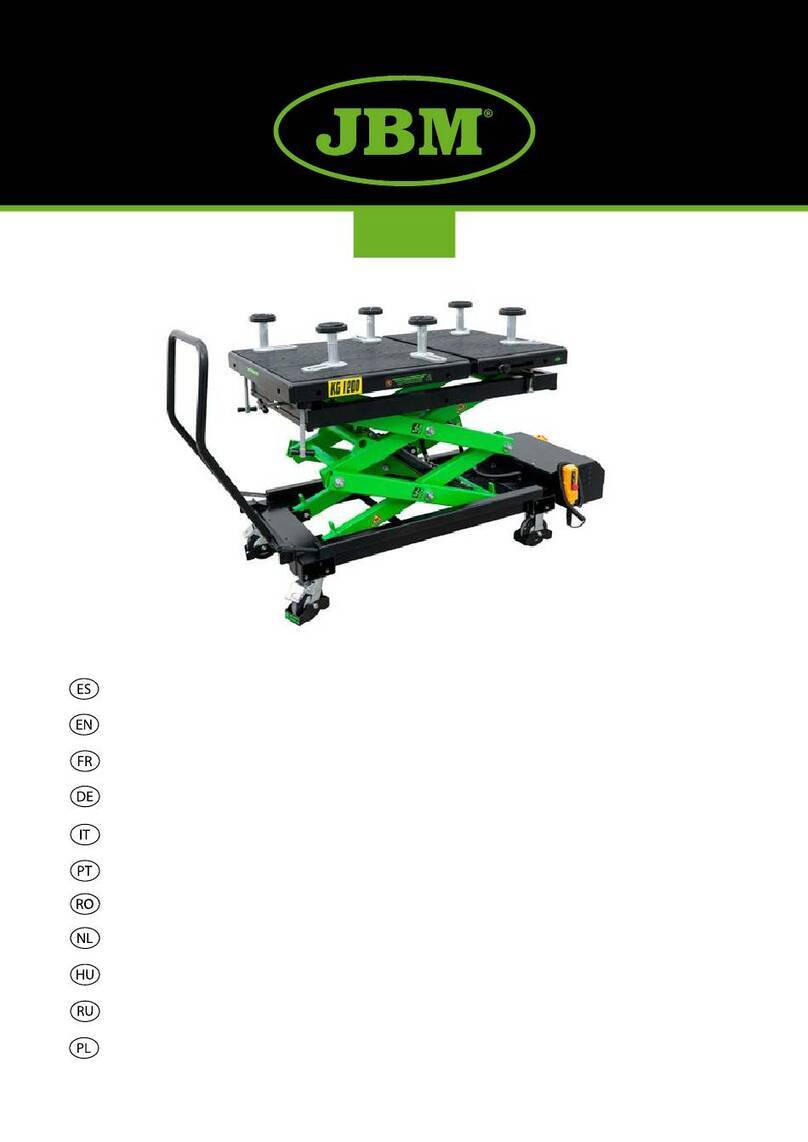

Sealey

Sealey ES502.V2 instructions

Custom Equipment

Custom Equipment HB-P830 Maintenance and troubleshooting manual

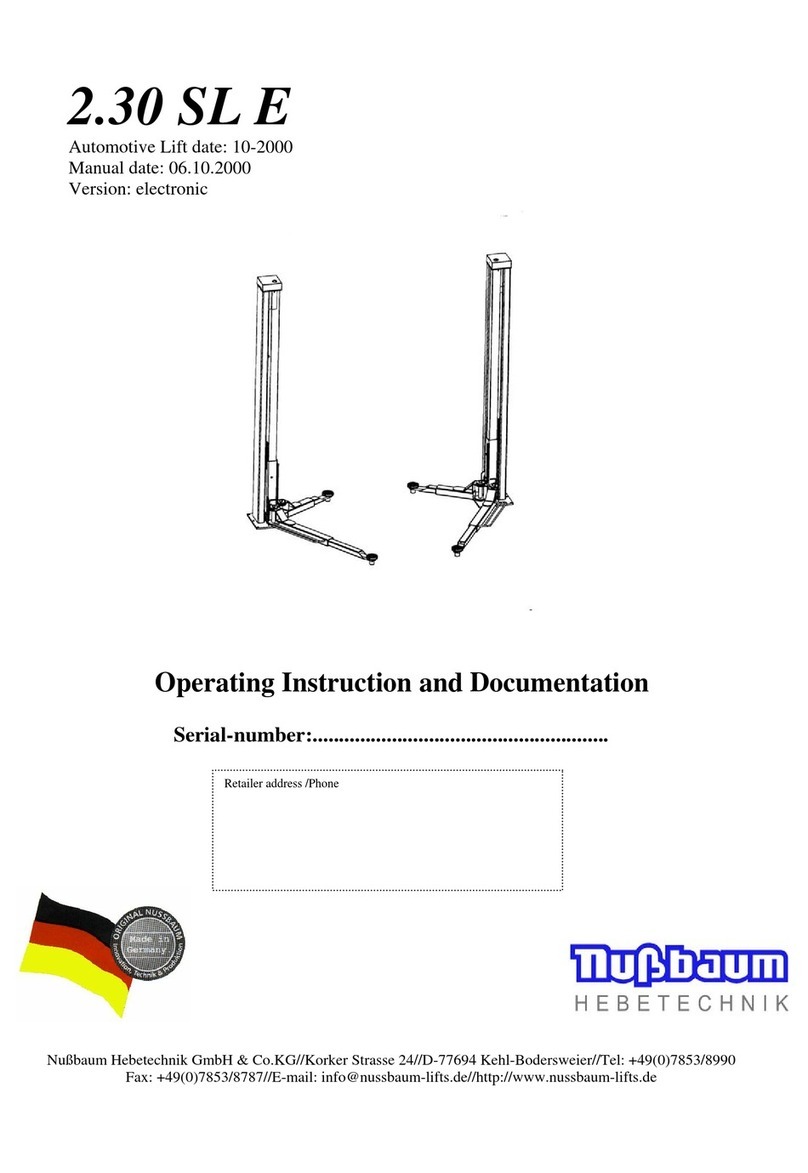

Nußbaum Hebetechnik

Nußbaum Hebetechnik 2.30 SL E Operating Instruction and Documentation

Caliber

Caliber V-Front Ramp Shield 13404 installation instructions

Grainger

Grainger 12R539 Operating instructions and parts manual

morse

morse Hydra-Lift Drum Karrier 400AM-60-124 Operator's manual