Sky Climber SKYMASTER User manual

SKY CLIMBER LLC –1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

N.V. SKY CLIMBER EUROPE S.A. - Boomsesteenweg 14 - 2630 Aartselaar - Belgium

Artesia Bank 550 33 14700 09 - BTW: BE 407 249 055 - HRA 185.015

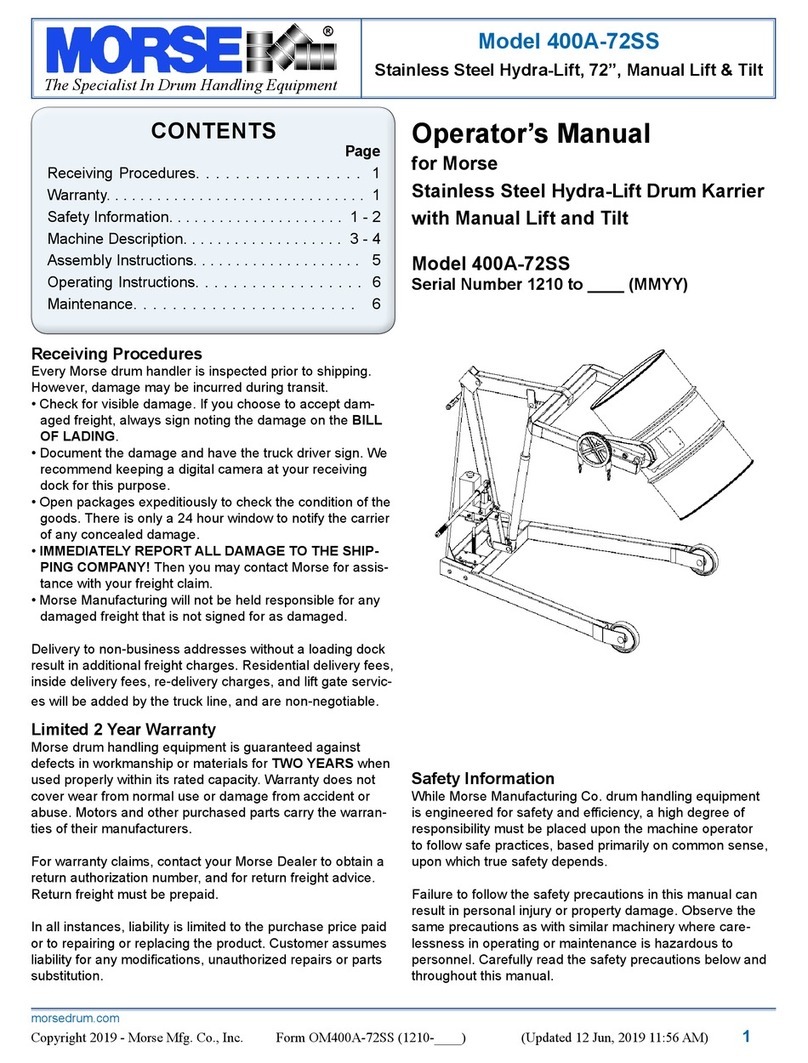

SKYMASTER®

Owners Manual

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

2

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Revision History:

Revision #

Description

06/24/09

Draft Review

08/1/09

Initial Release

09/11/09

Clarification to Page 34, Connecting Rod Installation

12/3/09

Updated Images with New Dog Design

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

3

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

FOREWORD

Welcome to Sky Climber.

Congratulations on your new Sky Climberproduct. All Sky Climber

products are designed and certified to the highest worldwide industry

standards. Our continuous quality control ensures this product is

manufactured to relevant codes.

It is your responsibility to READ AND UNDERSTAND the contents of

this manual. If you have any questions whatsoever, contact your dealer

or Sky Climbercustomer service.

Sky Climber“Owners Manuals” are designed for easy and efficient

use. Each part can be recognized easily with the use of exploded views.

Part numbers are shown near the assembly. The parts list, with part

numbers and descriptions, are in chronological order.

Sky Climberreserves the right to continually improve its products.

Every effort has been made to make this manual as accurate as possible

at the time of production; however there may be product changes, which

are not detailed in this manual.

We remind you to always wear personal fall protection equipment.

You’re Sky ClimberTeam

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

4

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

CONTENTS: SKYMASTER®

COVER PAGE

........................................

1

REVISION HISTORY

........................................

2

FOREWORD

........................................

3

CONTENTS

........................................

4

SAFETY GENERAL

GUIDELINES

........................................

5-13

OPERATOR & OPERATION

SAFETY

........................................

14-20

INSPECTIONS

........................................

21-24

PRODUCT DESCRIPTION

........................................

25

ASSEMBLY METHODS

........................................

26-38

PRODUCT OPERATION

........................................

39-41

DISASSEMBLY

METHODS

........................................

42-44

CHECK LIST

........................................

45-46

OSHA AND ANSI

........................................

47

LOG BOOK REQUIREMENTS

........................................

48

GUIDE TO ORDER SPARE

PARTS - SKYMASTER

........................................

49

QUESTIONS / CONTACTS

........................................

50

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

5

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

GUIDELINES

The SKYMASTER® System was designed and integrated using Sky

Climber products. The entire functionality, design intent, integrity and

performance were built around the SSU Staging and Sky Climber

Hoists.

•Maximum Height = 200 Feet

•Maximum SSU Width Between Masts = 15 Meters

TO EMPLOYER AND/OR RENTAL AGENCY

It is imperative that this manual be given to the operator of Sky Climber

equipment and that they read, fully understand, and follow all

instructions contained herein.

WARNING

Any use of this equipment, other than in strict accordance with

these instructions, shall be at the Operator's risk and

may result in serious injury to themselves or others.

REMEMBER SAFETY IS THE RESPONSIBILITY

OF BOTH YOU AND THE OPERATOR.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

6

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Safety is of the utmost importance when installing and

using the SKYMASTER® System equipment.

This section covers general guidelines. Follow your Manufacturer's

Instructions for proper equipment assembly. Follow all applicable

Federal, State, and Local rules and regulations.

Test your system before going aloft.

Continue to check to be sure your system remains safe throughout

the entire use on the job.

Make certain there are no obstructions to the vertical platform

travel.

RIGGING:

WARNING Rigging is the responsibility of the user. Do not

attempt to rig a job unless you are qualified. Failure of rigging may

result in serious injury or death.

Consult a professional structural engineer or the building owner to

verify safety of the Building or Structure to be rigged. Have them

clearly identify the construction and strength of all components used

in the rigging process.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

7

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Wire Rope Handling and Storage:

Always wear gloves to protect your hands when working with wire

rope.

Store wire rope in a coil or on a spool.

Protect rope from physical abuse, inclement weather, and corrosive

materials.

Do not drop wire rope from any height.

Uncoil wire rope carefully to avoid kinking or inducing a twist.

Do not uncoil by tossing coil over the edge of a structure.

Avoid dragging wire rope in dirt or around objects that could

scrape, crush, bend, or damage it.

Galvanized wire rope specified by Sky Climber, LLC is lubricated

at the factory and under normal conditions does not require further

lubrication.

Wire Rope Preparation:

Always use 5/16 inch wire rope of the proper length and

construction.

5/16 inch, G, XIP, RL, PRF**

Braze both ends a maximum of ½ inch in length.

WARNING:Wire rope is an expendable item. It begins

to wear when it is put into use. Do not use kinked, bird-

caged, excessively worn or damaged wire rope. Such use

may result in injury or death to yourself or others.

WIRE ROPE:

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

8

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Air cool, then grind the tip to a blunted point.

G=Galvanized

XIP= Extra Improved Plow

RL=Right Lay

PRF= Preformed

Wire Rope Rigging:

Sky Climber only recommends a hand-tucked eye splice with

protective thimble, poured zinc socket, swaged socket or

compression fitting should be used to connect the suspension

cable to the anchorage point ofthe “Carriage”connection on the

SKYMASTER® System.

NEVER use U-type clamps which can crush wires and reduce wire

rope strength.

NEVER use J-clamps or Fistgrips at the Carriage connection

point.

These style Clamps will loosen; and require being torque at the

beginning of each shift.

Use a 5/16 inch thimble and a 5/8 inch shackle.

Use insulated thimbles when welding from platform. Minimum of

four J-type clamps, evenly spaced, are required.

Wire rope must support 6:1 safety factor.

A properly made 5/16 inch wire rope will have a minimum

breaking strength of least 9,400 lbs.

Store extra rope neatly coiled, tied, and protected from the

weather.

Wire rope must be rigged to remain vertical with suspension points

directly above the hoist entry guide or lead-in device.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

9

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Wire Rope Replacement:

Wire rope is critical to safe and trouble-free operation.

Replacement rope shall be to Sky Climber’s specifications. Use of

wire rope obtained from sources other than those specified by Sky

Climber could result in serious personal injury, property damage,

and/or equipment breakdown.

SSU PLATFORMS:

Follow the platform load specification.

Check stirrup bolts daily for soundness and tightness.

Use toe boards, handrails and mid-rails on all open sides.

Acids can destroy aluminum platforms. Replace platform

immediately if exposed to acids or corrosive materials.

Operate platform in level position only.

Work from deck of platform only. Do not stand on guardrails, toe

boards, platform/work cage supported objects or lean out from

ends of the platform. Do not use ladders etc. to get at higher

elevations.

Do not bridge from one platform to another, or to any structure or

other equipment.

Do not horizontally transfer a work platform while it is suspended

in the air. Perform all transfer operations ONLY with the platform

resting on a safe surface.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

10

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

WELDING:

Use the following precautions when welding to prevent the possibility of

electric shock to personnel and/or the possibility of welding current

passing through the wire rope.

Attach each wire rope to its suspension point with a suitable

insulated thimble. Insulate extra rope stored on the roof to prevent

grounding, or terminate the suspension rope at the insulated

thimble.

Cover the supporting wire rope with insulating material above and

below the Sky Climber® Hoist.

Use a length of split rubber tube taped in place around the cable as

follows:

oExtend above the Sky Lock brake for 4 to 5 feet (more if

required by local codes).

oExtend below the Sky Climber® Hoist, far enough to insulate

the tail line from the platform. Guide and/or retain the

portion of the tail line below the platform so that it does not

become grounded.

Cover each Sky Climber Hoist, Sky Lock Brake, and Wire Winder

with protective covers made from insulating material.

Connect a grounding conductor from the platform to the work

piece. The size of this conductor must be equal to or greater than

the size of the stinger lead.

NOTE: This must be a secondary conductor and must not be in series

with the primary conductor between the welder and the work piece.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

11

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

SAFETY:

Accidents can be prevented if you follow the instructions in this

manual. Once the equipment leaves Sky Climber’s control, the

Operator is responsible for its safe use, operation, and maintenance.

Safety Prevents Accidents:

Know and understand the operation of this equipment.

All Federal, State, and local codes and regulations that apply to

this equipment and its safe use must be followed.

Do not alter any Sky Climber Hoists, Sky Locks, SKYMASTER

parts or Accessories. Use only Sky Climber original parts in your

Sky Climber equipment.

Thoroughly inspect all equipment before use. Do not use any

equipment that has any apparent difficulty.

Wear hard hats at all times when servicing, erecting,

disassembling, or using this equipment.

Provide protection for workers from falling objects both above and

below the equipment.

Keep all persons from beneath SKYMASTER® System

equipment.

Never work alone on the SKYMASTER® platform, and ensure

help is available in an emergency.

Do not overload the equipment or exceed the maximum rated

capacity as noted in this manual.

Do not wear loose clothing while operating this equipment.

Always disconnect the AC power, when not in use.

SAFETY IS IMPORTANT

Use Commons Sense … Do NOT Take Chances!

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

12

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Safety Guidelines

Operator’s Safety:

•All persons who service, install, dismantle or use SKYMASTER®

access equipment must fully comprehend and act in accordance with this

manual and all appropriate regulations. A competent person is a

designated person, suitably trained, and qualified by knowledge and

practical experience to carry out the required task safely.

Training, manuals and other documentation are available at Sky

Climber®. Do not hesitate to contact us for more details.

•Operators must be emotionally and physically able to withstand the

stress of working at elevations. Do not work at elevations if subject to

seizures or loss of physical control. Operators must be safety conscious,

responsible and not under the influence of alcohol, drugs or other

substances.

WARNING: Do NOT use the SKYMASTER® System,

Sky Climber Hoists, Sky Locks, or any other equipment that

is damaged or worn beyond normal tolerances.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

13

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

•All persons using SKYMASTER® access systems must at all times

wear safety harnesses attached by lanyards and rope grabs to

independent anchorage point. Lifelines shall be fastened to an

independent anchorage point rated at 5000 lbs. or the use of a pre-

engineered “Dog Line” system affixed to a modified SSU stage. Do not

disconnect or remove harnesses or lanyards until safely on the ground or

until completely disembarked from SKYMASTER® System at a safe

location.

•Safety helmets should be worn at all times when servicing,

disassembling or using the equipment.

•Provide protection for operators from collision with overhead obstacles

and falling objects.

•Provide adequate protection below the SKYMASTER® system to

prevent injury to persons from falling objects. Keep all persons from

beneath suspended platforms.

•Maintain contact with your supervisor at all times.

•Make a copy of this manual available to every person using, erecting

and assembling this equipment.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

14

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Operation Safety:

•All SKYMASTER® access equipment must be handled with care:

during handling of equipment, installation and use (place loads gently on

platform).

•Inspect and test the equipment before use, rigging, re-rigging, after de-

rigging and at regular intervals to make sure that it is maintained in a

safe workable condition. The supervisor should assign a competent

person for inspection purposes. In case of equipment failures or

difficulties noticed during testing and inspection prior to use, contact

your nearest Sky Climber® representative and do not use the

equipment until it is repaired or replaced. Only use Sky Climber®

spare parts. Do not alter any equipment. Maintenance may only be

carried out by Sky Climber® representatives.

•Ensure that the electrical cable connection is routed safely. Make

certain that it can not get snagged or caught on any obstructions. Also

be sure that no materials could be dropped on the cable and cause

damage.

•Verify if all decals and nameplates are properly affixed and legible. If

they are obscured or missing, replacements are available from Sky

Climber®.

•Always verify the entire SKYMASTER® system is safe for use prior

to and during each shift. This would include but not limited to the safety

of the Mudsills, Base, Masts, Wall-Ties, Mast-Ties, Carriage, Wirerope,

SSU Staging & Components, Wall Anchor Bolts, and any other

Components included as part of the erected System. This includes the

inspection of all components listed.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

15

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

•Never overload the platform above the indicated safe working load.

SEE SSU STAGING LIMITATIONS AND SAFE LOADING DECALS

INCLUDED IN THIS MANUAL.

•In case of an emergency during operation press the red emergency stop

button on the hoist or control unit. The platform will halt immediately

power is cut off, brakes are activated). Always solve the problem first,

prior to further use.

•Do not use hoists in conjunction with cableless control systems.

•Never use the SKYMASTER® System for transportation of passengers

from one level to another.

•Keep the vertical travel zone of the platform free of obstructions. When

running into an obstruction immediately stop the platform. Inspect the

platform and the obstruction for possible damage and/or hang-up.

Proceed in a safe direction. Take care not to overload the system or get

in slack rope situations when running into an obstacle.

•Beware of obstacles when there is too small of a clearance between

platform and façade. Use long-handled tools when working at large

distances between platform and facade.

•Do not handle suspended loads in conjunction with suspended

platforms.

•Never attempt to leave a SKYMASTER® platform in mid-air, always

return the system to the safety of ground level before exiting the system.

Otherwise; serious injuries and/or damage can occur.

•Hazardous situations occur when it is not possible to lower the

SKYMASTER® System to a safe position, over water and public roads.

•Never alter equipment once the SKYMASTER® System is suspended.

Keep all equipment out of reach of unauthorized persons.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

16

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

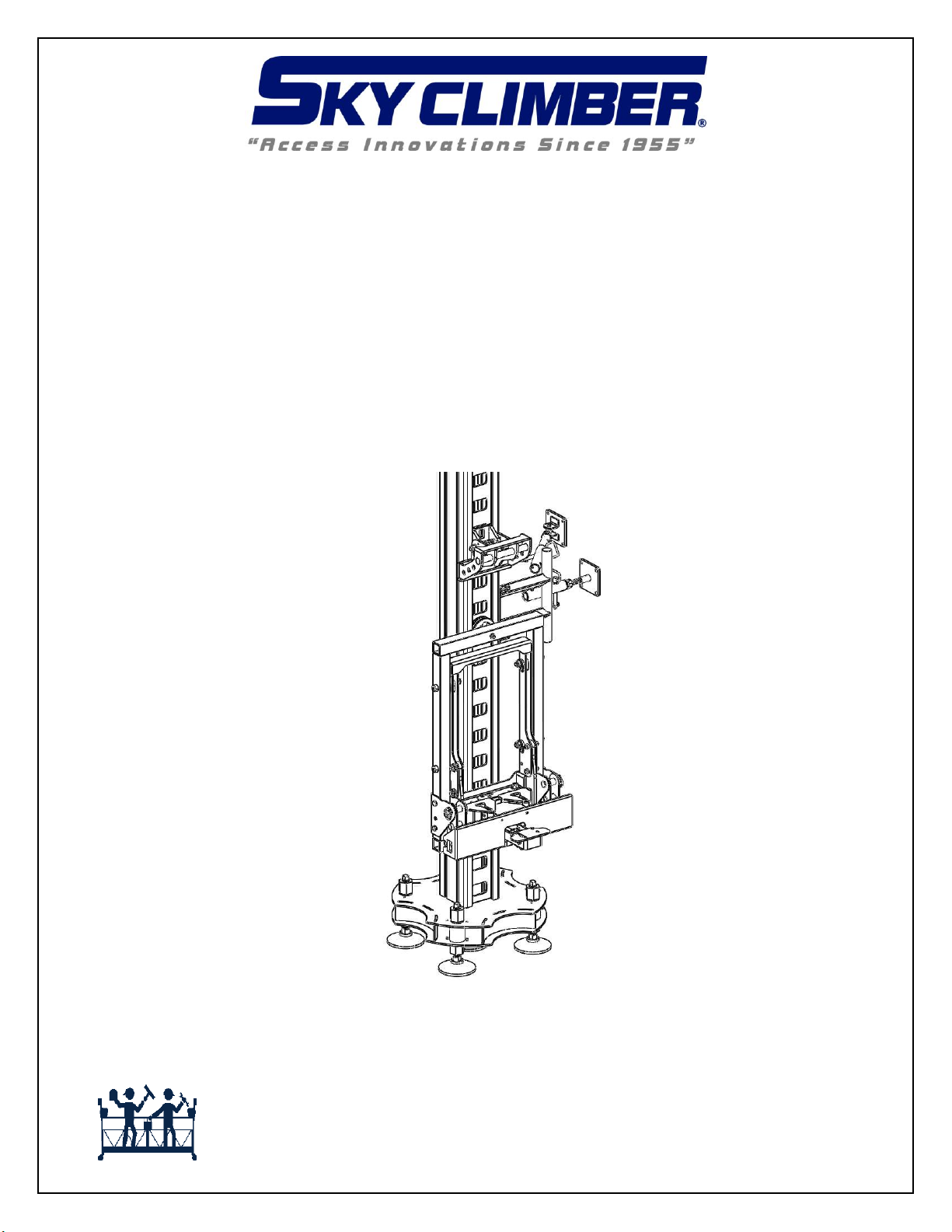

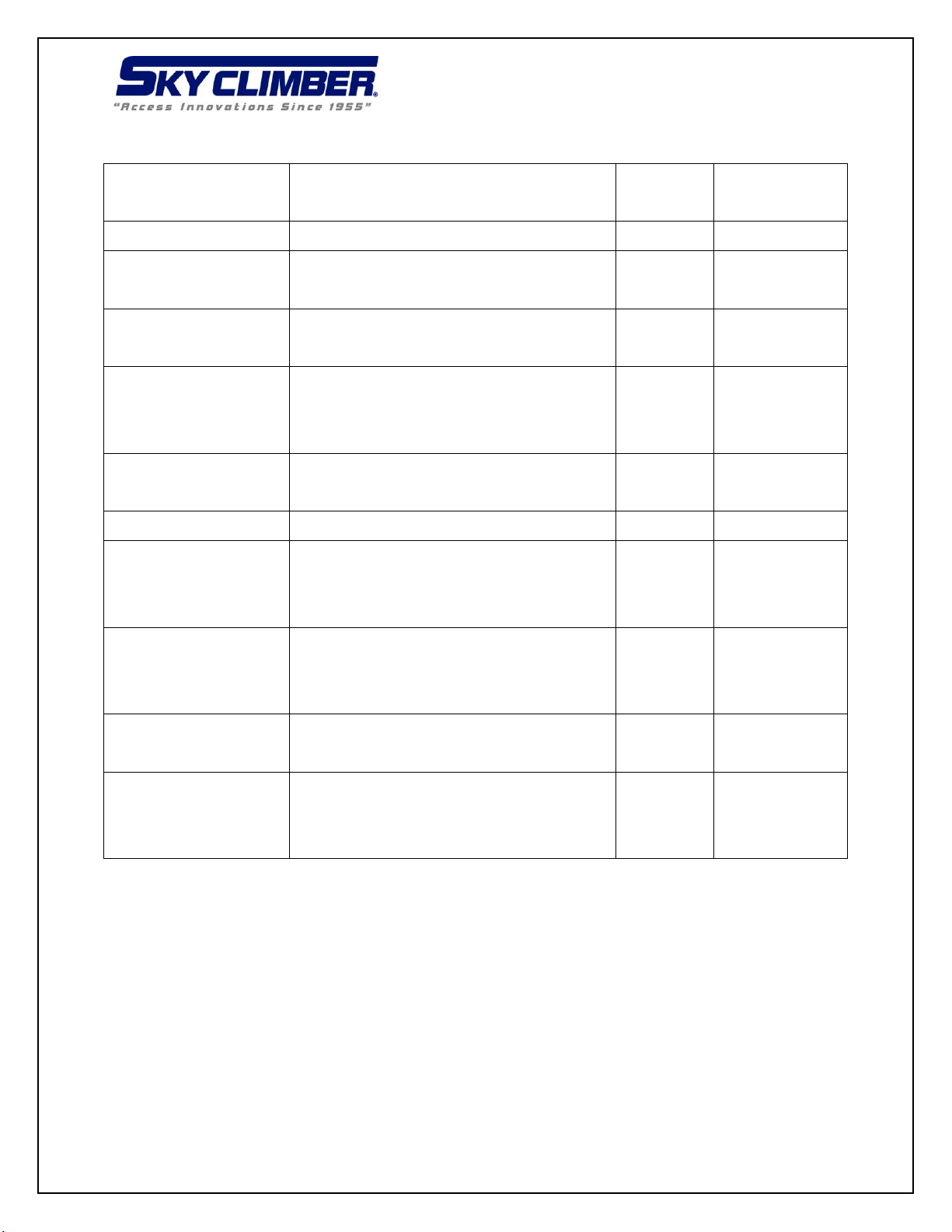

Group

Category

Condition

Temp

Application

Inspection

1

-

Normal

>0C/32F

Inspections, light

maintenance,

window washing.

Prior to each work shift.

2

A

B

C

Contaminated

Contaminated

Contaminated

>0C/32F

>0C/32F

>0C/32F

Abrasive

materials; sand

grit, dust,

welding.

Caustic materials;

corrosive

chemicals

Adhesive

materials; cement,

plaster, paint,

caulking,

compound

Prior to each work shift.

Service Every 3 months

Service Every 3 months

3

-

Freezing

0C/32F

All

Prior to each work shift.

Every hour.

•Do not use the SKYMASTER® System in severe conditions: extreme

environmental conditions, corrosive environment, strong magnetic

fields, and explosive atmospheres.

•Do not use the SKYMASTER® System when handling loads that

could lead to dangerous situations: molten metal, acids/bases,

radioactive materials, brittle loads.

Hoist Service & Inspections

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

17

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

•Always read your MSDS sheets on any product that will cause

Corrosion to Aluminum, Steel, or Rubber. Immediately clean and care

for any corrosive or caustic attacks on any of the materials used within

the SKYMASTER® System.

WIND SPEED CONDITIONS:

•NEVER use the SKYMASTER® System when wind speeds exceed

(31) MPH, (50km/h or 14m/s). The entire SKYMASTER® System is to

be lowered to the ground level and parked until weather conditions

improve. You may want to tether the SSU to the ground, so as to prevent

possible damage. Always unplug the Electrical supply when not in use!

•Do not use the SKYMASTER® System when hazards could arise from

wind pressure acting on loads having a surface area in excess of 2m²

(21.5 SQFT).

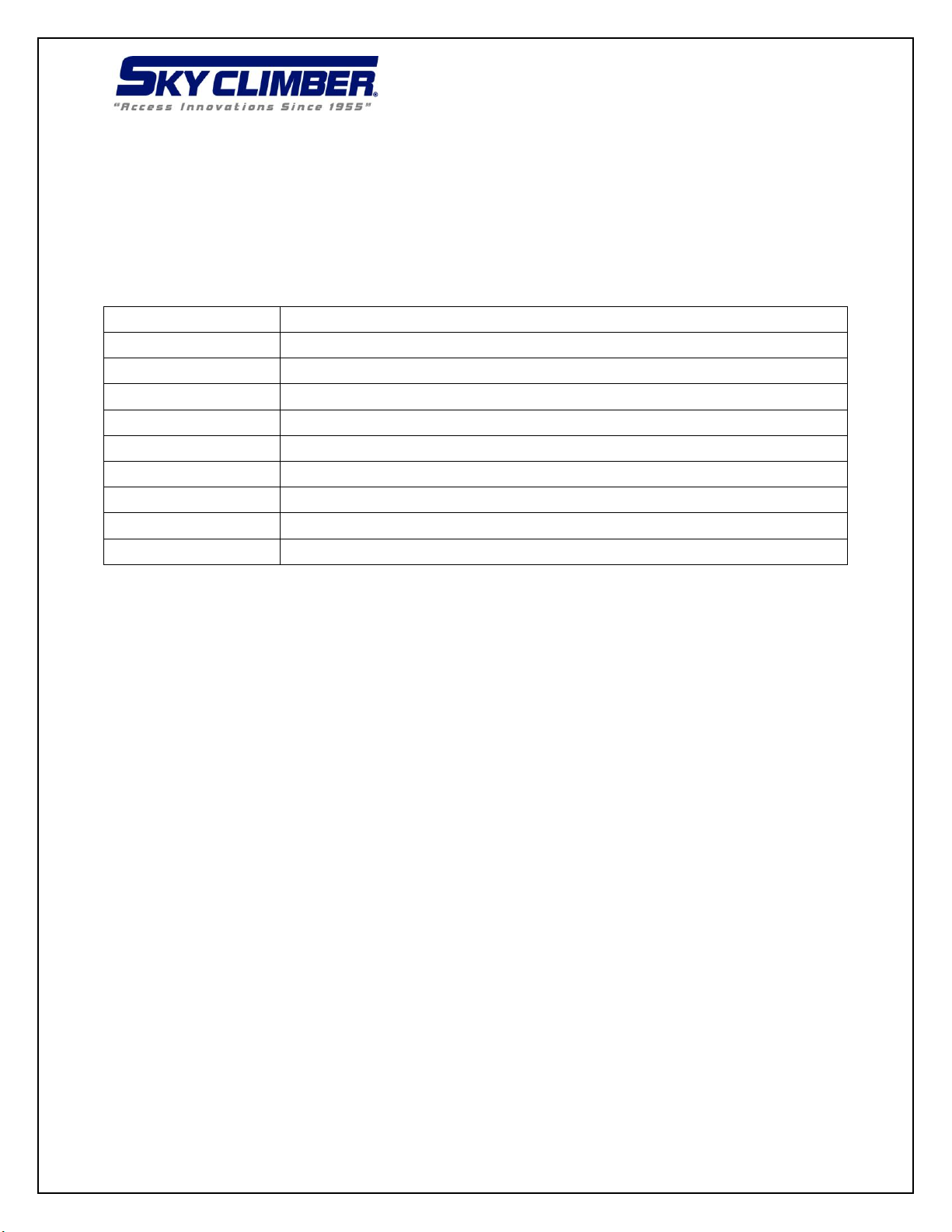

•There are scales of wind forces which are accepted internationally and

used when communicating weather conditions. These scales represent

certain strength and velocity of wind at 33ft. above ground level in open

spaces.

•A typical representation of wind conditions is shown in Table 18.1

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

18

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Wind

Description

Results

mph

m/s

Calm

Smoke rises vertically

0-1

0-0.2

Light Air

Direction of wind shown by

smoke

1-3

0.3-1.5

Light Breeze

Wind felt on face, leaves

rustle

4-7

1.6-3.3

Gentle Breeze

Leaves and small twigs in

constant motion, wind extends

light flag

8-12

3.4-5.4

Moderate

Breeze

Raises dust and loose papers,

small branches move

13-18

5.5-7.9

Fresh Breeze

Small Trees begin to sway

19-24

8.0-10.7

Strong Breeze

Large branches in motion,

whistling heard in telephone

lines

25-31

10.8-13.8

Near Gale

Whole Trees in motion,

resistance felt when walking

into the wind

32-38

13.9-17.1

Gale

Breaks twigs off trees,

impedes progress

39-46

17.2-20.7

Strong Gale

Slight structural damage

occurs, slate or shingles could

be removed

47-54

20.8-24.4

Table 18.1

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

19

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

NOTE:

Remove the SSU staging from the SKYMASTER® System when wind

speeds are expected to exceed the Strong Gale force wind speeds of 54

MPH.

High Voltage Power-lines:

•Refer to regulations, federal, state and local codes when working in the

vicinity of electrical overhead power-lines. Consult the local power

company for safe operating procedures.

•The minimum separation between live power lines and

SKYMASTER® System platform is 3m (10’).

•Touching live power-lines may result in death or serious injury.

Welding:

•During welding, the electrocution hazard and the risk of the welding

current passing through the steel wire ropes shall be eliminated by taking

the following precautions:

Use insulated thimbles at each suspension point. Insulate surplus steel

wire rope stored on roof to prevent grounding or, terminate steel wire

rope at insulated thimble.

SKY CLIMBER LLC

1800 Pittsburgh Drive - Delaware - Ohio 43015 - U.S.A

Email: [email protected] - Tel: +1 740 203 3900 - Fax: +1 740 203 3901

Website: http://www.skyclimber.com

20

© Sky Climber, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

•Cover steel wire rope above hoist and Sky Lock for a distance of ±

1.2m (4’) with insulating material: rubber hose taped in place. Insulate

tail line below hoist: extend downward sufficiently to prevent contact

with platform. The portion of tail line hanging free below platform must

be guided and/or retained so that it does not become grounded.

•Cover each hoist, Sky Lock and wire winder with protective covers

made out of insulating material.

•Connect a ground conductor from platform to work piece. The size of

this conductor shall be equal to or greater than the size of the stinger

lead. It must be a secondary conductor and shall not be in series with the

primary conductor between welder and work piece.

Marine Environment:

• Salty environments may deteriorate aluminum & steel components.

Frequently inspect equipment.

• Excess material accumulation; Make sure that excess material does not

clutter up the any of the working parts on the SKYMASTER® System,

Hoist, Sky Lock, Wirerope or Platform.

Table of contents

Other Sky Climber Lifting System manuals

Popular Lifting System manuals by other brands

Wabtec

Wabtec Ricon S Series Service manual

AMGO

AMGO SL-7 Installation and service manual

TradeQuip

TradeQuip 2057T owner's manual

HAWEKA

HAWEKA AirgoLift operating instructions

probst

probst EL-SDH operating instructions

Powerlift Dumbwaiters Corporation

Powerlift Dumbwaiters Corporation P-100 owner's manual

POP UP

POP UP EIGER 200 instruction manual

HESHBON

HESHBON HL-26K Installation, operation and maintenance manual

Anthony Liftgates

Anthony Liftgates ALB-1500 Installation, operation, and parts manual

Sealey

Sealey MC454 instructions

MSA

MSA Lynx Hoist User instructions

Kasco

Kasco HYDRAFORCE LS-100 Installation & operation manual