Sky Way Swing User manual

3. Layout ofGateOpener and Wiring forControl Unit

4.Standar d Installation

5.Clutch Release

7 .Opening and Closing Travel Limit Setting

8 .Transmitter Programming 13-14

9. Function Introduction 14-16

10

11.Trouble Shooting

12.Recycling and Manipulation

IMPORTANT SAFETY INSTRUCTIONS

WARNING: It is important for the safety of persons to follow

these instructions. Savethese instructions.

- Do not allow children to play with fixed controls. Keep transmitters

away from children.

- Activation of the manualrelease may cause uncontrolled movement of the driven

part due to mechanical failures or an out - of - balance condition.

- When operating a biased-off switch, make sure that other persons

are kept away.

- When closing agate that has been opened by afire-sensing system, make sure that

other persons are kept away.

- Frequently examine the installation for imbalance and signs of wear or damage of

cables, springs and mounting. Do not use if repair or adjustment is necessary.

- The supply must be disconnected when cleaning or other maintenance is being carried out.

- This appliance is not intended for using by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

- The means for disconnection must be incorporated in the fixed wiring in accordance with

the wiring rules. An ON/OFF switch with a minimum distance of 3mm between contacts

in all poles must also be connected to the power supply.

- If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

- Only power cord with H05RN-F2×0.75mm2 type can be used.

- The replacement of battery should be carried out by professional people.

Correct disposal of this product:

This marking indicates that this product should not be disposed with other household

wastes throughout the E U . To prevent possible harm to the environment or human health

from uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse

of material resources. To return your used device, pleas e use the return and collection

systemsor contact theretailer where the product was purchased.

They cantake this product forenvironmental safe recycling.

Instruction manual

1

1

Optional

Optional

Optional

(Make sure you have all the following tools and they are in good conditions

and serviceable according to the safety standards)

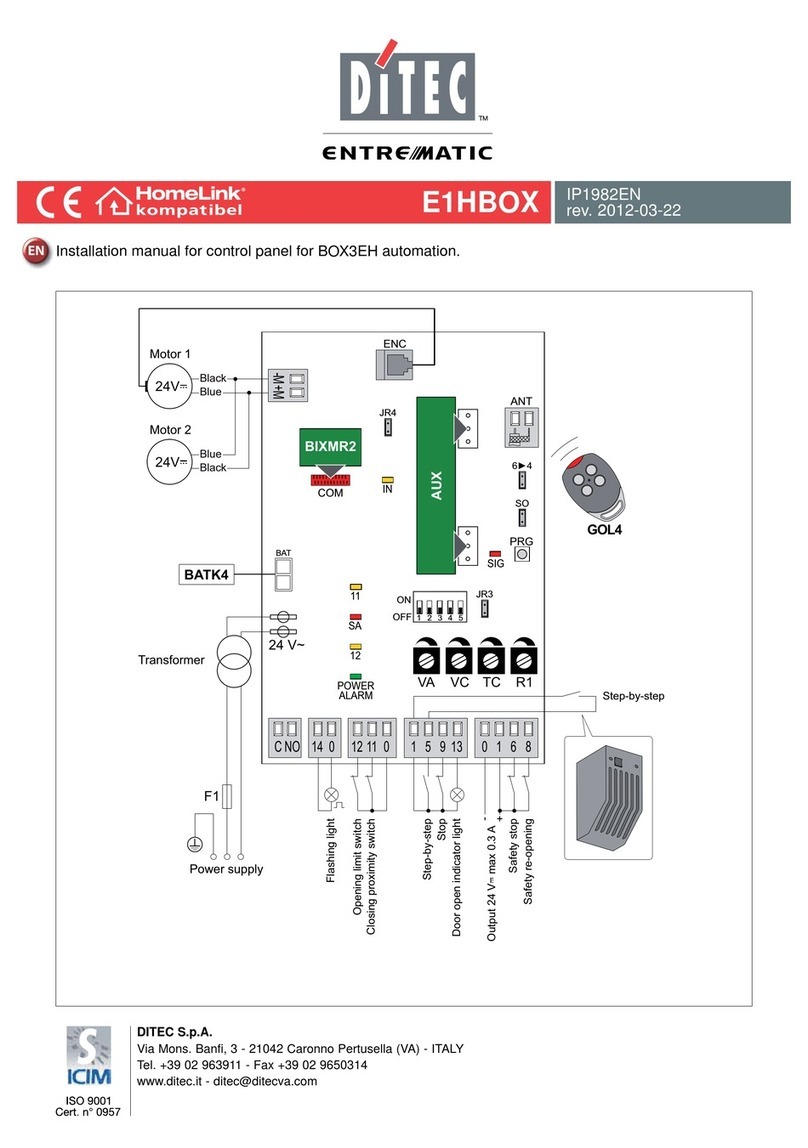

3. Layout ofGateOpener andWiring forControl

Unit (Fig.1)

F-600 Gate Opener FA30 Photocell

WARNGING: Make sure the cables youused meet withthe above installation

types and the wiringsystem is in a safety ground surrounding.

WARNING: Important safety instructions. Follow all instructions

since incorrect installation can lead to severe injury.

- Before installing thedrive ,check whether thedriven part is in goodmechanical condition,

correctly balanced and open or close properly.

- The drive cannot be used with a driven part incorporating a wicket door.

- Whether the actuating member of a biased-off switch is to be located within direct sight of

the driven part but away from moving parts. Unless it is key operated, it is to be installed

at a minimum height of 1.5 m and not accessible to the public.

Measurement gearmo tor

rear brackets

Please refer to Table 1 on page 7, Value B will depend on Value A and the

Maximum Opening Angle of the gate leaf.

rear brackets Use

rear bracket.

front bracket

rear bracket

rear bracket

front bracket front bracket

cotter pin and then insert the clevis pin into the

rear bracket

cotter pin.

⑺Fix the gearmotor to the front bracket and anchor it with the appendant

screws (D) and washers (C) with the gearmotor,fully tighten the

screw.(Fig9)

P10

front bracket w

P1

0

5.Clutch Release

(Fig.11 &Fig.12) Release the clutch: Insert the release key and turn

it clockwise for 180°. Engage the clutch: Insert the release key and

turn it 180°in an opposite direction.

control box

(unit: mm)

control box

3.The structure of control box (Fig. 15:)

24V Control board

Power panel

diagram

7 . Opening and Closing Travel Limit Setting

⑴ Release the clutches of both gearmotors with a release key, open

both gate leaves completely, then engage the clutches.

⑵ Put DIP switch SW2 No.8 to ON position.

ST

main board

ST

switch

8 . Transmitter programming

1.Memorizing a new transmitter

Put DIP switch 4 on SW1 to ON:

a.Programming transmitter button for both leaves:

CODE

Press and hold for 2S, the code LED DL6 is on, press button 1

Button1

Button2

of the transmitter twice, the code LED DL6

is off, button 1 can operate both leaves.

b.Programming transmitter button for single leaf :

CODE CODE

Press and hold for 2S, the code LED DL6 is on, press again,

Button 1

Button 2

the code LED DL6 is flashing, press button 2 of the

transmitter twice, the code LED DL6 is off, button 2

can operate one of the leaves.

Note: 1. When the code LED DL6 is flashing, if the user does not need to

CODE

programme transmitter button for single leaf, press

to exit the programming.button

2.The control unit can memorize Max. 25 pcs transmitters.

3.If button 1 is for both leaves, button 2 is for single leaf, it is invalid

to code button 1 for single leaf.

4.If button 1 is for both leaves, button 2 is for single leaf, now the

user programmes button 2 for both leaves, then button 1 will be

invaild at the same time.

2 . Deleting all transmitters:

CODE

Press and hold for 10S to delete all transmitter

s.

(Note: If the procedure is performed correctly, press the buttons of a

ny transmitters cannot operate the unit).

9 . Function Introduction

(1)

( The delay time is set at 2 seconds in factory)

1-3 1

3

2

1 second 3S

If without any opening/closing delay setting, the default delay time is 1S.

Note:Switch 3 on SW2 is for reservation.

(2) Opening /closing delay setting

(Default: MOT2 gearmotor will open first ).

4 ON= MOT2 gearmotor will open first

4 OFF=MOT1 gearmotor will open first MOT 2 open first

(3) Single gate leaf operation setting

5 ON= Only MOT1 gearmotor is avaliable

5 OFF=Both MOT1 and MOT 2 gearmotors are avaliable MOT 1 only

(4) Operation mode setting

6 ON= The operation mode is : OPEN-

CLOSE- OPEN

6 OFF= The operation mode is:

OPEN-STOP- CLOSE-STOP- OPEN OPEN- CLOSE-OPEN

(5) Auto closing setting:

7 ON= The unit can not receive any operating commands

before automatically closing.

7 OFF= The unit can receive operating commands beforeau

tomatically closing.

Auto closing time setting:(This funtion is set OFF in

factory ).

s

s

s

(6)

Tur n butt on FO RCE clockwise, the driving force will

become stronger. Turn it anticlockwise, the driving

force will become weaker. Weaker Stronger

(7)Turn button LV

Slower Fast er

(8)

Slower Fast er

(9) Operating time setting:

Turn button TIMER clockwise, the operating time

will be longer;

Turn button TIMER anticlockwise, the operating

time will be shorter;

The time can be set from Max.63S to Min. 30S Shorter Longer

(10) Electric lock(optional)

LOCK and –are connectors for electric lock, F-600 (12V/DC-A) and F-600(12V/DC-B)

match with 12V/500mA elctric lock; F-600(24V/DC-A) matches with 24V/500 mA

electric lock. Whe n the electric lock is connected, it will open before the gate leaf opens.

(11) The wired control connectors( Key switch)

DOOR1, - and DOOR 2 are the connectors for wired control(for normalopenonly.)

When DOOR1 and–are connected, only MOT1 gearmotor will work and DL5 LEDwill turn

on; When DOOR2 and–are connected, both gearmotors will work and DL4 LED will turn on.

(12)The connect ors for phot ocell are normal closed.I f the cont rol unit is installed without

photocell, connect terminals IR1 , IR2 and- with a short cable, othewise the unit will

not be operat ed( these 3 connectors have been connected in factory). If only IR1 is used,

please connect IR2 and ter minals with a short cable. When the beam of photocell

IR1 is interrupted by obst acles, the gate leaf will stop and reverse. DL2 LED on the main

panel will turn off . If only IR2 is used, connect IR1 and- with a short cable.

When the beam of infrared IR2 is interrupted byobstacles, the gate leaf willstop. DL3

LED on the main panel will turn off .

10

F-600

220~240 Vac @ 50/60Hz

Model

Working power ( vac )

Ambient temperature range

.

(m)

Max.Open Angle (with electric lock)

320

Gearmotor

Motor voltage ( vdc )

1 1.Trouble Shooting

connected securely by

2.Replace with a new fuse of

referringto 8 on P 13.

of the same type .

of the same type .

photocell sensor is not shielded.

2.Set the operating time referring

to (9) on P16.

referring to (5) on P 15.

to the wiring diagram on P 12

.

Troubles Causes Solutions

The gear mot or

do esn't work.

1.The plug is not securely

connected.

2.The fuse on the pcb is

blown.

The gearmotor doesn't

work when operating

the transmitter.

1.The transmitter has not

been memorized.

2.The battery of the

transmitter has not

enough power.

3.The clutch is dis-engaged.

1. Memori ze the transmitter

The trans mitter

distance is short .

The battery of the

transmitter has not enough

power after long time use.

Replace with a new bat tery

The moving speed of

the gate leaf is slow.

1.The installation of the gate is

not proper, so the moving

become not smooth .

2.The moving speed of the

gearmotor is not adjusted

properly.

1.Release the gearmotor and

move the gate leaf by hand

to see if it can move smoothly.

2.Set the moving speed referring

to (8) on P 15 .

The gate leaf can not

open or close completely

or it does not move .

1.The photocell sensor is

shielded.

2.The operating time of the

gearmotor is not adjusted

properly.

1.Check and make sure the

The gate leaf can not

close automatically .

1. The auto closing function

is set OFF .

2.The wire connection of the

unit is not correct .

1. Set the auto closing time

2. Connect the wire referring

2.Replace with a new battery

3.Eng age the clutch

with the release key .

1 2. Recycling and Manipulation

Ther e are differ ent k ind s of m ateri al in a swing gate o pener . So me can be

recyclable, s uch as alumini um , iron, plastic, w ires etc., bu t some of them

can't.

Warning: Lead-acid backup batteryand some electronic material are

harmful substanc es. In order not to get the environment polluted, they

should be recycled or disc arded acco rd ing to requirements of the l ocal

law regulation.

1 . Completely cut off the power supp ly.

2 . Disassemble all the equipments and accessories.

3 . Take out the backup battery from the control box and the battery

from transmi tters.

4 . Take out the PCB.

5. Recyclable materials should be handled by the local qualified company.

6 . Backup battery, battery from transmitter and control board,etc .

with harmful substances shoul d be hand led by the local quali fied

company so that they won't cause any polluti on to the environment.

Table of contents

Popular Gate Opener manuals by other brands

D.A.C.E

D.A.C.E Compact 300 owner's manual

Accessmatic

Accessmatic Bulldozer 850 manual

fadini

fadini MEC 800 Special instruction manual

BFT

BFT PHOBOS N BT installation manual

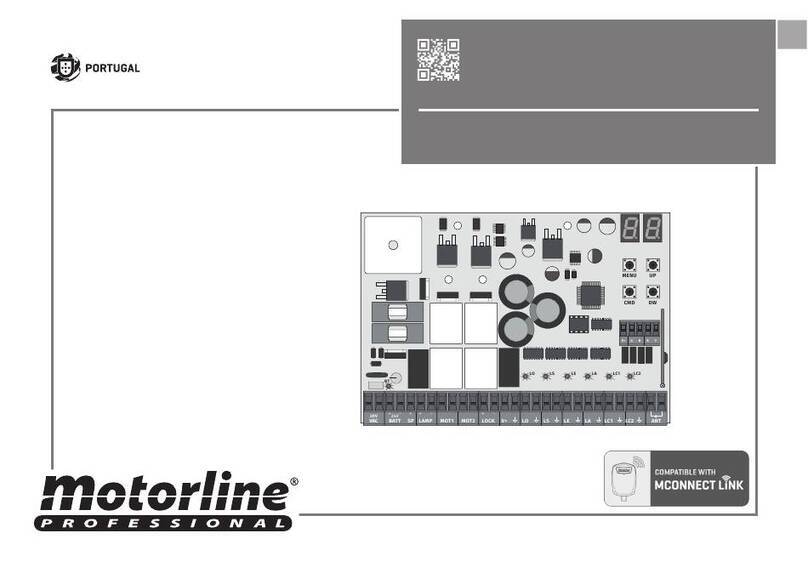

Motorline professional

Motorline professional MC62 User's and installer's manual

tousek

tousek FOLD 330/L Connection and Installation Guide