SkyAzúl Krupp EKS 83 User manual

Krupp EKS 83

Service Manual

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

NOTICE

SkyAzúl makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and/or its fitness for a particular purpose.

SkyAzúl will not be liable for errors contained in this manual or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual. This document

contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of SkyAzúl.

SkyAzúl reserves proprietary rights to all drawings, photos and the data contained therein. The

drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of SkyAzúl. The drawings and/or photos are subject to technical modification without prior

notice.

All information in this document is subject to change without notice.

SkyAzúl, Inc.

16 Walnut Street

Middletown, MD 21769

Fax 301-371-0029

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

TableofContents

EKSLoadMomentIndicator.........................................................................................................................3

ThecombinedConsoleandCentralUnit..................................................................................................3

LoadMomentIndicator................................................................................................................................4

DescriptionofOperation..........................................................................................................................4

Operator’sCab–DashPanel....................................................................................................................5

Atypicalcomponentlayout..................................................................................................................5

EKS83CombinedConsoleandCentralUnit–Components....................................................................6

RemoteExternalComponents..................................................................................................................7

LMIBoom‐Lengthand‐‐Angle‐SensorsandTransmitters‐....................................................................7

Boom‐Angle‐SensorandTransmittersBox‐..........................................................................................7

ReelingDrumPotentiometer................................................................................................................8

LMI–TransmitterforPressureTransducers........................................................................................8

Selectionofliftingcapacitychart..............................................................................................................9

Selection of lifting capacity tables....................................................................................................9

Calculation of the radius....................................................................................................................9

Calculation of the reference value...................................................................................................9

Calculation of the load.......................................................................................................................9

Warning and shutdown in case of overload...................................................................................9

Data sensing.......................................................................................................................................9

Data translation and transmission...................................................................................................9

DataTranslationandTransmission.........................................................................................................10

TransmitterBoards.............................................................................................................................10

CheckingDataTransmitters................................................................................................................11

FaultDiagnosisandErrorCodeRectification......................................................................................11

FaultDiagnosisFlowCharts....................................................................................................................12

NoBuzzerorDisplays..........................................................................................................................12

LMIShutdown!RedLampon–Releasebuttondoesnotrespond...................................................13

Informationdisplayshowslettera:....................................................................................................14

Informationdisplayshowsletterb:....................................................................................................15

1

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Informationdisplayshowsletterc:....................................................................................................16

Informationdisplayshowsletterd:....................................................................................................17

Informationdisplayshowslettere:....................................................................................................19

Informationdisplayshowsletterf:.....................................................................................................20

Informationdisplayshowsletterg:....................................................................................................21

Informationdisplayshowslettert:.....................................................................................................23

2

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

EKSLoadMomentIndicator

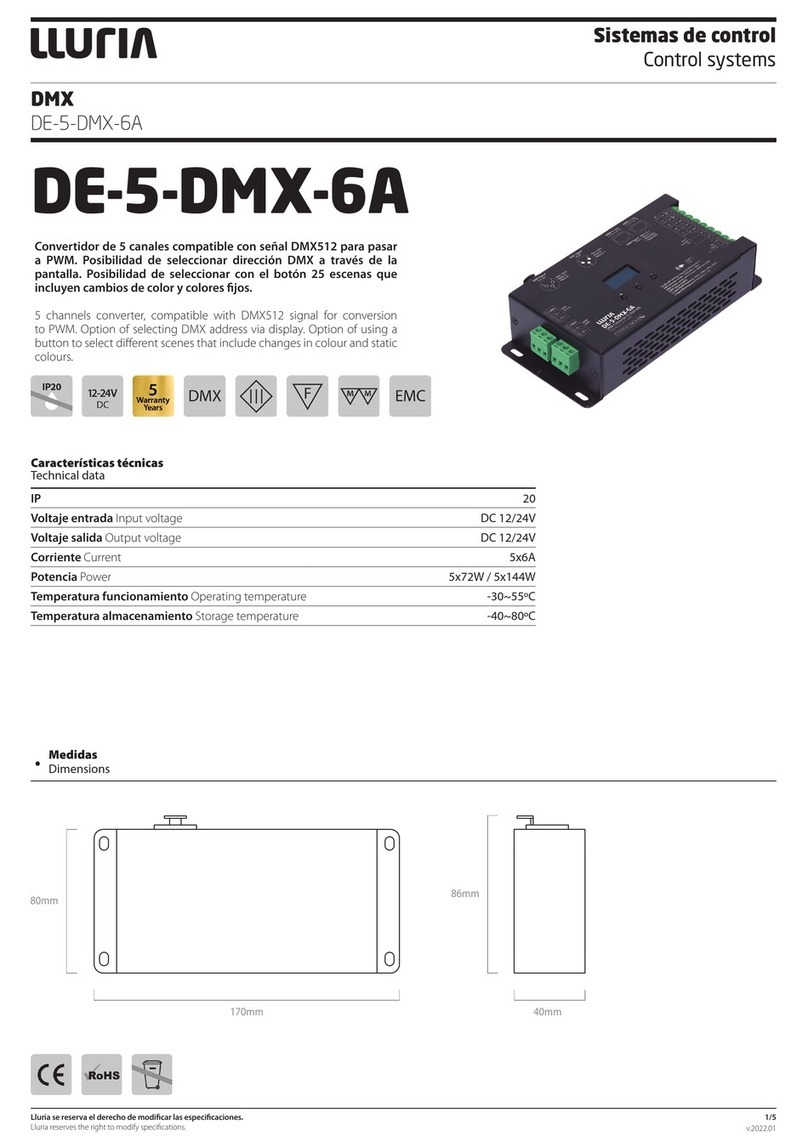

ThecombinedConsoleandCentralUnit

3

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

LoadMomentIndicator

DescriptionofOperation

1. Lifting limit switch - main boom

2. Length measuring drum with potentiometer for telescope sections III/IV

3. Length measuring drum with potentiometer for telescope sections 1/11

4. Boom unit with angle potentiometer and data transmitter for angle and length

5. Pressure sensor on derricking cylinder

6. Display unit on right-hand side of turntable

7. Data transmitter for pressure sensor on right-hand side of turntable

8. SLI central unit in the crane operator's cab

Note: This-description is for the

general layout of the EKS.83.and

does not appertain to any specific

system fitted to any Model, i.e. the

number of Boom Length reeling drums

and associated transmitters will vary

from Model to Model.

4

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Operator’sCab–DashPanel

Atypicalcomponentlayout

The dash panel shown is for a GMK407. The position of components in other models may vary

and some items might not be fitted.

1. Plug-in module lOA, fuses FI (F1/8).

2. Plug-in module 9.5A, with LMI shutdown circuit (relay K1).

3. LMI override switch.

4. EKS 83, LMI combined console and central unit.

5. Crane switch for Superstructure S 11 (Superstructure 'ON').

5

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

EKS83CombinedConsoleandCentralUnit–Components

1. Mounting screws - Instrument panel

2. “ON" light

3. Supply voltage indicator light

4. Information switch "a" to "k"

a. Capacity utilization in %

b. Hook height in m

c. Main boom length in m

d. Main boom angle in degrees

e. No function

f. Piston surface pressure in

derricking cylinder In bar

g. Piston ring surface pressure in

derricking cylinder in bar

h. (h-k) No function

5. Warning light – shutdown

6. Release button

7. Switch for setting operating mode (SLI code)

8. Switch for setting reeving mode

9. 9 SLI brief information display

10. Display – information

11. Display – radius

12. Display - shutdown value

13. Display – load

14. Status display (operating modes, fault

messages)

15. Fuse F2 (SU 2) for data bus (1.25 rnA)

16. Plug X4 for 24 V power supply

17. Fuse F1 (SU 1) (3.15A)

18. Output X3 to crane electrics (shutdown

signals)

19. Data bus connection supply Xl for data

transmitter

20. Additional outputs X5

21. Digital inputs X2

6

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

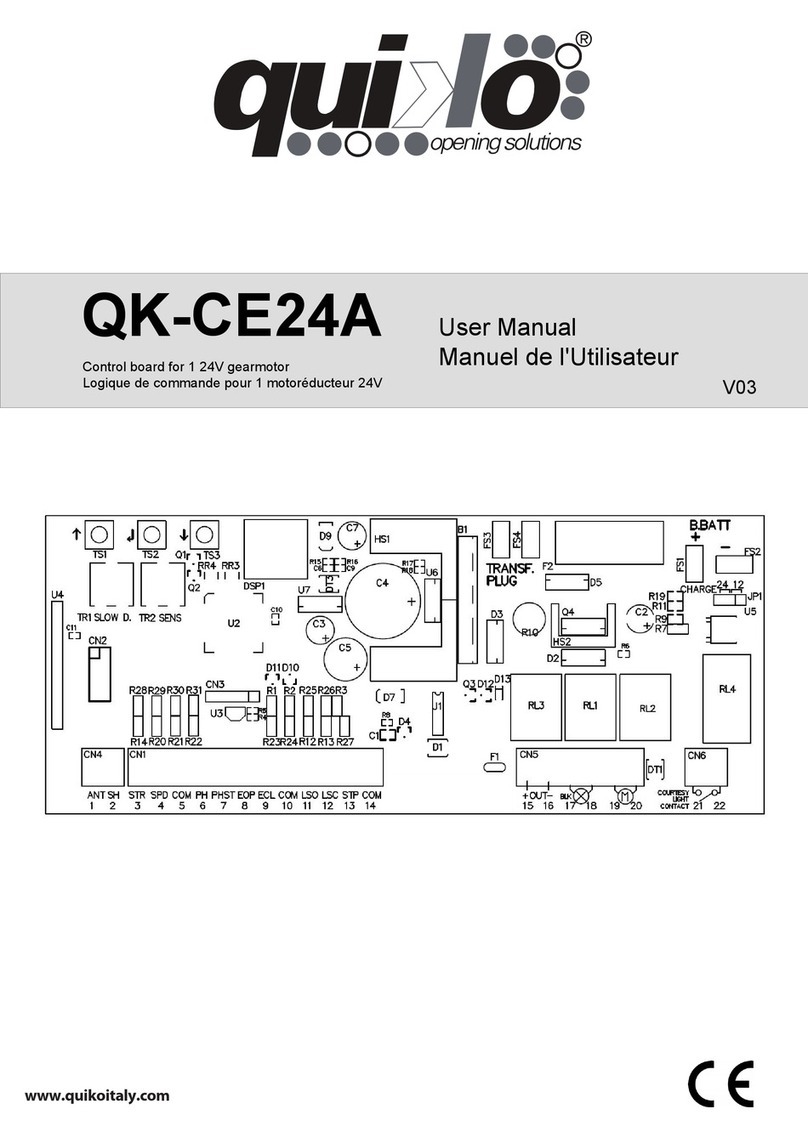

RemoteExternalComponents

Below is the layout for the length & Angle transmitters on a GMK. 4070. Other models in the GMK range

will have more length reeling drums on the side of the boom and corresponding number of transmitters.

LMIBoom‐Lengthand‐‐Angle‐SensorsandTransmitters‐

1. Cable drum with potentiometer for length -

telescope sections III and IV

2. Cable drum with potentiometer for length -

telescope sections I and II

3. Boom unit with angle measurement and

data transmitter for angle and length

Boom‐Angle‐SensorandTransmittersBox‐

1. Angle potentiometer

2. Data transmitter (lower) - boom angle

3. Data transmitter (upper) – length telescope

sections 1/11

4. Data transmitter - length telescope sections

III/IV

5. Fuse (lower) (SU 3) 0.16 A M (medium time-

lag)

6. Fuse (upper) (SU 4) 0.16 A M (medium

time-lag) 1 per board

7. Fuse (SU 5) 0.16 A M (medium time-lag)

7

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

ReelingDrumPotentiometer

1. Using-a-screwdriver to set the Length Potentiometer to the anti-clockwise position, with the

Boom fully retracted

LMI–TransmitterforPressureTransducers

2. Data Transmitter Annular/Ring side pressure

3. Data Transmitter Full/Piston side pressure

8

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Selectionofliftingcapacitychart

Selection of lifting capacity tables

The system selects the correct lifting capacity according to the operating mode set on the central

unit and current boom configuration (length, telescope status, boom length).

Calculation of the radius

The radius is calculated from the boom length and angle as well as from the boom load derived from

the hydraulic pressure measured in the derricking cylinder, taking the deflection of the boom Into

consideration. When the operating mode has been set the length of the boom and fixed angle

position of the boom extension are included in the calculation.

Calculation of the reference value

Using the radius and boom length as a reference, the corresponding reference value (= maximum

load with selected crane configuration) Is selected from the lifting capacity table. The reference value

is reduced, depending on the reeving mode set on the central unit.

Calculation of the load

The pressure measurement in the derricking cylinder produces a Signal which is proportional to the

measured load moment. After subtraction of the inherent moment of the boom, the actual load is

calculated, taking into account the reeving configuration set on the central unit.

Warning and shutdown in case of overload

Reference value and calculated load are continually monitored and compared. If the load reaches

the warning threshold (90% of the reference value). a warning is activated (Intermittent buzzer,

"Warning" relay, status indicator). If the load reaches the shutdown threshold (100% of the reference

value), shutdown is activated. A continuous buzzer sounds and the red LED warning light

"Shutdown" comes on. The "Shutdown" relay interrupts the power supply to the SU valve. The valve

switches over and blocks the control pressure for the crane functions. The shutdown is displayed on

the status display.

Measurementofvariables

Data sensing

Boom angle to the horizontal with pendulum-driven potentiometer.

Boom length with potentiometer. driven by length measuring rope or wire and gear unit

Derricking cylinder pressure with two pressure sensors in the lower chamber (piston surface

chamber) and the upper chamber (piston ring surface chamber) of the derricking cylinder.

Data translation and transmission

The measured values are digitized in the data transmitter, converted into telegrams and transmitted

time-delayed as impressed current to the central unit through the common dual-line data bus.

9

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

DataTranslationandTransmission

The measured values are digitized in the Data Transmitters, converted into signals and transmitted time-

delayed as impressed current via the common dual-line data bus to the central unit.

TransmitterBoards

All transmitter Boards fitted on a machine are the same part number. The system each board is monitoring

is identified to the CPU by the number and configuration of Links (Jumper wires).

Up to 3 Links can be placed in positions WI, W2 & W3. These correspond to positions between the

following terminals:

W1=18‐19

W2=20‐21

W3=22‐23

10

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Between 0 - 3 links (inclusive) can be fitted to each board. This will give up to 8 Permutations of

configuration. Each configuration, varies the 'Output Signal' level of the transmitter board onto the Data

Bus, thereby giving it a unique signature, therefore we can have up to 8 transmitters with different output

signals on 1 Data Bus.

A second Data Bus must be used for machines that use more than 8 transmitters, e.g. 5 section (4

telescoping section) boom machines. –

--- - - - --'-----

The CPU identifies each individual transmitter board from its unique signal off its corresponding Data

Bus. The CPU samples the Data from each transmitter in turn and if it fails to detect one or more it will

give a fault warning (audible), lock out the crane motions and display an Error code in the Status display

window (P 1).

CheckingDataTransmitters

Any data transmitter failure is registered by the central unit as a 'Missing Transmitter

Identification Signal' and displayed as a malfunction.

The CPU will react as follows:- Console 'Cut Ofr and Status display will show a code for most transmitter

failures it is prefixed with 'd='.

Note:- On a number of models a prefix of 'g=' will represent certain transmitters, i.e. machines with

4 telescoping sections. See Transmitter Identification Sheet.

See diagnosis sheets for the assistance in correcting malfunctions.

Transmitter Identification Sheet

A Transmitter Identification Sheet containing the various Models, Transmitter number, the motion they

monitor and the Error Code associated with it, is copied at the back of this publication.

FaultDiagnosisandErrorCodeRectification

The following pages are to assist you in clearing Error Codes and carrying out general Fault Diagnosis on

the EKS 83. If these steps do not help you clear the problem and it becomes necessary to contact Grove I

for assistance, a precise and detailed description of the malfunction will assist understand your problem

and could help you with future problems without having call for assistance. Such a description should

address the following points as a matter of course:

1. Exact malfunction description

2. Under what conditions does the malfunction occur

3. What is indicated on the five display windows :-

• Status Display (P 1) =

• Load(P2) =

• Load Cut-off (P3) =

• Radius (P4) =

11

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

4. Select sequentially all positions of the Information-switch (S2) and note all

information displayed in the Information display (P5)

5. What operating Code is dialed into the 3x switches

6. What Number is dialed into the 2x Reeving Switches

FaultDiagnosisFlowCharts

NoBuzzerorDisplays

SU inoperative

No buzzer signal

No displays (dark)

Power supply

switched off

Fuse F1/8 plug in module 10A

blown

Fuse F1 at back of central unit

blown

Call SkyAzul 301-748-6057

1. Switch on ignition

2. Switch on crane switch S11 on

plug-in fuse module

Replace fuse F 1/8 A

Replace fuse F1 (3.15 A)

NO

NO

NO

YES

YES

YES

Fault in system blowing fuse F1/8

or F1 again

YES

12

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

LMIShutdown!RedLampon–Releasebuttondoesnotrespond

Overload

Call up SLI fault code

Select displayed letter using

information switch

SLI displays letters “a-k” and

numbers “1-8”

Leave overload range, Press SLI

release button

See corrective action given on

the following pages.

NO

YES

YES

Press and hold release button down

One of the letters "abcdefghijk" is

displayed

13

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Informationdisplayshowslettera:

TEXT: “a=1”

Non-authorized operating mode

selected

TEXT: “a=2”

Operating mode switch faulty

TEXT: “a=7”

Non-authorized reeving mode

selected

TEXT: “a=8”

Selected operating mode code not

possible

Central unit faulty.

Call SkyAzul: 301-228-6086

Select correct operating mode

Press LMI release button (S1)

YES

YESCentral unit faulty.

Call SkyAzul: 301-228-6086

Select correct reeving mode

Press LMI release button (S1)

YES

Enter correct operating mode code

Press LMI release button (S1)

YES

NO

NO

NO

NO

14

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Informationdisplayshowsletterb:

TEXT: “b=1”

Incorrect crane model

TEXT: “b=2 & 3”

Additional operating mode switch

set incorrectl

y

TEXT: “b=8”

Incorrect country set for Rating

calibrated into CPU (75% / 85%

etc)

Central unit faulty.

Call SkyAzul: 301-228-6086

a. Customer 'Options' Not

registering with CPU.

OR

b. Telescope section No 1 not locked

(check lock system)

YES

YESCheck position of additional

operation mode switch

Contact SkyAzul to have CPU re-

calibrated to the correct percentage

for the country selected

OR Reset to original setting

YES

NO

NO

NO

15

SkyAzúl,EquipmentSolutionswww.skyazul.com301‐371‐6126

Informationdisplayshowsletterc:

TEXT: “c=1”

Customer Options not registering to

the CPU OR Telescope section Nol

not locke

d

TEXT: “c=2”

Telescope section 2 not locked

Central unit faulty.

Call SkyAzul: 301-228-6086

YES

Inspect components & bus lines

from -customer options for -damage

/ faulty connections OR Lock /

inspect locking mechanism of tele

section 1

Lock/inspect locking mechanism of

tele section 2

YES

NO

NO

NO

TEXT: “c=3”

Telescope section 3 not locked Lock/inspect locking mechanism of

tele section 3

YES

NO

TEXT: “c=4”

Telescope section 4 not locked Lock/inspect locking mechanism of

tele section 4

YES

NO

TEXT: “c=6”

Local statutory 'Options not

registering with CPU i.e.O/R's -

extended & down

(

France

)

Operate the option as required by

regulations OR inspect the monitoring

system for

fault

YES

NO

TEXT: “c=7”

Slewing angle restriction

Return crane to defined “arc” as per

load chart

YES

NO

TEXT: “c=8”

Turntable locking pin not engaged

Ensure slew lock pin is engaged

correctly with super over the rear OR

check switches & bus line for fault

YES

16

Table of contents

Popular Control System manuals by other brands

Grundfos

Grundfos PC Tool CU 300 Installation and operating instructions

Clearwater Enviro Technologies

Clearwater Enviro Technologies SCALEBLASTER AG-100 Installation & operation manual

Greenheck

Greenheck Vari-Green Air Quality VOC manual

Watts

Watts OneFlow OFPSYS EU Installation and operation manual

Advantech

Advantech AIIS-1440 user manual

Trinity

Trinity ET Plus 350 Assembly manual