Skye DataHog2+ User manual

DataHog2+

Skye Instruments Ltd

21, Ddole Enterprise Park

Llandrindod Wells

Powys, LD1 6D , UK

Tel: +44 (0) 1597 824811

Email: [email protected]

www.skyeinstruments.com

Iss. 1.0

DataHog2+

Skye Instruments Ltd

Skye Instruments is based in the UK and we are very proud to be celebrating being in

business since 1983. ur products are designed and built in the UK. We have a very wide

product base and our sensors & systems are used for plant & crop research; micro-climate,

global climate change studies; environmental monitoring and controlled environment

installations.

Products include light sensors & systems, weather monitoring sensors, automatic weather

stations, plant research systems, soil and water research systems.

Feel free to contact us via our e-mail, or any of the methods below:

Click on the icons to browse to the sites, or search for the usernames below.

Have a Smartphone? Scan this QR code to access our website for more information about

your product:

Please be aware that the information in this manual was correct at time of issue, and should be 100%

relevant to the accompanying product. We take great pride in our ever-evolving range of products, which

means that sometimes the product may change slightly due to re-design.

If you have any queries, please do not hesitate to contact our technical team by any of the methods

above.

PLEASE NOTE – SKYE, DATAHOG, SPECTROSENSE, MINIMET, HYDROSENSE, APOLLO,

ARE TRADEMARKS O SKYE INSTRUMENTS LTD

2

Skye.Instruments

Skye Instruments Ltd. @SkyeInstruments SkyeInstrumentsVideo

Skye Instruments Ltd.

DataHog2+

CONTENTS

1.0 Introduction 5

2.0 verview & Quick Start 7

2.1 Inside the enclosure _________________________________________ 7

2.2 SDHC Card verview ________________________________________ 8

2.2.1 Removing & Inserting the SDHC card ________________________ 8

2.3 Power Supply ______________________________________________9

2.3.1 Solar Power Supply _____________________________________9

2.4 Pole Mount/Bracket _____________________________________ 10

2.5 Activity LEDs _______________________________________________ 10

2.5.1 Troubleshooting of the Activity LEDs _________________________ 10

3.0 DataHog2

3.1 Memory 13

3.2 Channels 14

3.2.1 Voltage input channels 14

3.2.2 Current input channels 15

3.2.3 Internal temperature channel 16

3.2.4 Digital input channels 16

3.2.5 Internal relative humidity channel 17

3.2.6 Software channels 17

3.2.7 Relay output channels 17

3.3 Calibration 17

3.4 Firmware 18

4.0 peration 19

4.1 Initial set up 19

4.1.1 Firmware overview 19

4.1.2 Logging mode overview 19

4.1.3 Main menu mode overview 19

4.2 Main menu mode options 20

4.2.1 ption 0 - Display readings from all active channels 21

4.2.2 ption 1 - Display current setup 21

4.2.3 ption 2 - Display software version 22

4.2.4 ption 3 - ffload 24 hour data summary 22

4.2.5 ption 4 - ffload data 23

4.2.6 ption 5 - Reset memory 23

4.2.7 ption 6 - Set clock 23

4.2.8 ption 7 - Set Datafile Identifier, Plus Memory verwrite & Timed

Logging Modes 24

4.2.9 ption 8 - Set channel sample and log intervals 25

4.2.10 ption 9 - Set AX+B calibration factors 27

4.2.11 ption A - Set channel configuration 28

4.2.11a Voltage Inputs 0 – 23 29

3

DataHog2+

4.2.11b Current Inputs 25 – 40 30

4.2.11c Internal Temperature Reference – 45 31

4.2.11d Digital Count Channels 48 – 53 32

4.2.11e Internal Humidity Channel – 54 33

4.2.12 ption B - Set internal RH% sensor calibration 34

4.2.13 ption C - Set alarm relay(s) 34

4.2.14 ption D - Set channels for non zero / threshold log modes 35

4.2.15 ption E - Enter ‘Log on Demand’ mode 36

4.3 Care for your DataHog2 36

5.0 Connections 37

5.1 RS232 Connector 37

5.2 Light Sensors 38

5.3 Temperature Sensors (Thermistors) 39

5.4 Single-Ended Voltage Sensors 39

5.5 Differential Voltage Sensors 39

5.6 Digital Sensors 39

5.7 Potentiometer Sensors 40

5.8 Special Socket – RH & Air Temperature Sensors 40

5.9 Relay utputs _____________________________________________ 40

6.0 SkyeLynx Comms Software 41

7.0 Importing Data into Excel 42

8.0 Power Supply ptions 43

Fig. 1 ACC/1A RS232 Datalead 44

Fig. 2 Sub Miniature Plugs 46

Fig. 3 DataHog Sockets Pin Identification 47

Appendix 1 Summary of codes used in configuration 48

Appendix 2 Setting up Full Scale Values for Digital Channels 49

Appendix 3 Setting up Full Scale Values for Differential Voltage Channels 50

Appendix 4 Setting up Potentiometer Inputs 52

Appendix 5 Solar Panel Regulator Board __________________________________ 56

Appendix 6 Attaching the Solar Panel to a Mast _____________________________ 57

Appendix 7 Files on the SDHC Card _______________________________________ 59

4

DataHog2+

1.0 Introduction

The SDL 5000 series of DataHog2+ dataloggers comprise an electronically advanced

datalogging system for a variety of environmental sensors.

The logger is centred on a high performance generation 8 bit microprocessor (p). This

has the ability to perform all the mathematical and logging tasks and then close down to

conserve power.

Depending on the datalogger model there are one or more analogue to digital

converters which render the signals from the sensor into a digital form that can be

handled by the microprocessor. These have a resolution of 15 bits which means that

analogue signals such as light, which vary over several decades, can be properly

handled and give adequate resolution of measurement over the required range.

Many versions of the DataHog2+ are available, with different combinations of voltage,

current and digital inputs. This manual covers all models, and so will include sections that

are not applicable to individual units. Please check those parts of the manual that apply

to your model and type of your unit and ignore inapplicable sections.

In normal logging mode the p will be ‘woken up’ by the clock at regular 10 second

intervals. The p will keep track of real time by counting the number of times it is woken

up and storing the time in the RAM while the p is asleep! nce woken up, the

microprocessor will perform the tasks required of it (depending on the logging mode

previously selected) and then when these are complete will return to ‘sleep’ to conserve

power.

The microprocessor can communicate with the user’s host computer via its built in RS232

interface, and can be controlled by instructions sent via this. It also gives some feedback

to the user via the audio transducer (beeper) built in.

Immediately before the p closes down to ‘sleep’ mode, if there is a plug connected to

the 8 pin RS 232 socket, then it will ‘listen’ for a command from the user for a period of

about 1 second. During this time, preceded by an audible ‘beep’, any numeric character

sent to the DataHog2+ will cause it to enter terminal (or Main Menu) mode.

The datalogger is usually contained in a polycarbonate housing, which is sealed to IP

65. The sockets, when mated to a matching plug or blanking unit are also weatherproof

to IP65.

5

DataHog2+

Do not panic! Although some sections of this manual may at first sight appear involved and

complex, you quite probably may never need to read them. Your DataHog2+ datalogger is

supplied set up with all scaling factors configured for the sensors it is supplied with. After

connecting the power supply, the DataHog should start working. If in doubt, check the section

of the manual you think appropriate, and if trouble persists phone or email Skye or your

sales Agent. We will do our best to help. A quick phone call or email may save you hours of

pondering. Good Luck!

!!! Don't forget

A DataHog2+ needs power to operate. It cannot work with a flat battery or without being

connected to a 12v supply.

If your DataHog2+ seems unresponsive, it quite possibly just has a flat battery - so first check

the state of the 12 volt battery – see Appendix 2

DataHog2+ logger is a DataHog2 with additional electronics for extra storage of the data

on a removable multi-media card. DataHog2+ will still store data in its internal memory at the

same time, but will also store data on the Multi-Media (SDHC) card. There is no need to

offload the data from the internal memory storage, as a copy will have been made on the

SDHCHC card. If for any reason the SDHCHC card has become corrupted, then please refer

to Section 3.2.5 for instructions on how to offload the data from the internal storage module.

A datalead and SkyeLynx Comms, PC software will also have been supplied. These will only

be required if you wish to change any of the DataHog configurations, such as sample and

log times. Please refer to Section 3 for instructions on how to accomplish this task.

The logger has been set up at Skye with as much information as possible for immediate

operation. Where supplied with Skye sensors the appropriate scaling factors, zero offsets,

gains etc have already been entered, as shown on the Hardware Configuration Certificate

which is supplied with your system. The default logging interval is 30 minutes, but this can be

changed by connecting the logger to an Android mobile phone or Tablet with the FTDI UART

app installed, or to a laptop/PC running Windows.

6

DataHog2+

2.0 OVERVIEW AND QUICK START

The DataHog2+ comprises the DataHog2 datalogger with the addition of the DHLC3

electronics to provide a datalogger which stores data on a removable Multimedia (SDHC)

card.

2.1 Inside the Enclosure

1 Underneath this metal plate are the DataHog2 electronics

2 Solar Panel regulator

3 8 pin socket. For normal operation the plug – 3a – will be plugged into this

socket.

For changing any configurations & set-ups, this plug is removed and the plug

from the datalead is inserted.

4 DHLC3 electronics board

5 Row of Activity/Function LEDs

6 SDHC card holder

7 Push button for activating the blue LED for SDHC card removable

8 Blue LED

9 Power supply connection block. Connection from the 12V battery which is then

distributed to the unit

10 PSU reset. nly used on rare occasions. The main reason for pressing this will be

when the DataHog2+ is used with a PC for accessing the setup menu. After

removing the plug from the DHLC3 board (3a) and then plugging in the 8 pin

connector from the datalead (which will be connected to the PC), the PSU reset

7

1

2

3

5

4

6

7

8

910

3a

DataHog2+

will need to be pressed. A faint click will be heard. If no click is heard then there

is a problem with the power supply.

2.2 SDHC Card - overview

The SDHC card needs to be formatted (FAT 16 or 32) on a PC. The maximum size of SDHC

card that can be used is 32GB and the type is SDHC Class 4.

To insert the SDHC card hold the top of the card with the notched end at the bottom and

facing towards the inside of the enclosure

Slide the SDHC card into the holder and push down until you hear a click. The card is now in

place.

To remove the card, gently press down on the card and then let go. This will release it from

the locking mechanism

2.2.1 Removing & Inserting the SDHC Card in Use

The SDHC card is located inside the enclosure and is quite visible when the lid has been

removed.

PLEASE D N T ATTEMPT T REM VE THE SDHC CARD WITH UT F LL WING THESE

INSTRUCTI NS

1) Press the button next to the SDHC card/SDHC card holder.

2) A blue LED will light up. This will be alight for 1 minute and 20 seconds, which

should be ample time to remove the SDHC card and insert a new one. nly

remove the SDHC card when the LED is alight. If you attempt to remove the

SDHC card while the blue LED is off, then you can damage or corrupt the SDHC

card.

8

Notched end

DataHog2+

The DHLC3 buffers datastrings whilst this LED is alight so no data is lost. Data in the buffer will

be sent to the SDHC card 5 seconds after the LED goes out.

At the configured logging interval the DataHog sends a 'datastring'. This datastring contains

the date and time of the stored data, channel number and data:

This 'datastring' is stored on the SDHCHC card in a 'day file'. A new day file is automatically

created at midnight. Day files are a space delimited text file and easily read by any

spreadsheet software. Please refer to Appendix 7 for details of the SDHC card structure.

2.3 Power Supply

The unit requires an external 12 volt power supply for operation. The white cable from the

enclosure should be connected to the battery terminals

2.3.1 Solar Power

9

To negative terminal of the battery

To positive terminal of the battery

Connectors from the solar panel click

into these connectors on the enclosure.

A tool is supplied to aid the removal of

these connectors should it be

necessary

DataHog2+

Please refer to Appendix 6 for instructions on how to mount the solar panel on a pole.

2.4 Pole Mount/Bracket for the DataHog2+ SKM 225A

If a pole mount has been ordered at the same time as the DataHog2+, then the enclosure

will be pre-mounted on the bracket. Connection holes, accessible by removing the lid of the

enclosure, line up with holes in the mounting plate. A pair of 'V' bolts plus nuts etc are

supplied so that the unit can be fixed to a pole.

2.5 Activity LED Lights

There are 8 coloured LED lights which light up and flash in different sequences depending on

the intended function or activity.

When the power supply is first connected all the LEDs will continually flash in turn, until the

DataHog has undergone its setup routine. When this has happened the DataHog will settle

into its normal operating routine as follows:

LED 1 - DataHog 'wake-up' string is detected

LED 2 - DataHog 'datastring' detected

LED 3 - Complete 'datastring' successfully received

LED 4 - 'Datastring' stored on the SDHC card successfully

LED 5 - Indicates a search is being made for the 'datastring' but none was found

LED 6, 7 & 8 – SDHC card storage attempt failed.

10

'V' bolts for fixing bracket to a pole

through these holes

DataHog2+

2.5.1 Trouble-shooting LED Sequences

LEDs 6, 7 & 8 continuously flash

Indicates a full SDHC card.

In this scenario, LEDs 1,2,3,4 & 5 will not light even though the DataHog is still running. No

storage will be taking place on the SDHC card as it is full, but the DataHog will continue to

store to its internal memory as long as that isn't also full.

No buffering will be taking place and all datastrings will be lost until a new card is inserted.

If, by mistake, a full SDHC card is inserted instead of a blank one, then the above LED

sequence will occur.

LEDS 6,7 & 8 continuously flash and LEDS 1,2,3,4 & 5 flash according to the datastrings

generated by the DataHog

This indicates either no SDHC card is present or the SDHC card is faulty.

No buffering occurs and all datastrings will be lost until a new card is inserted.

LEDs 6,7,& 8 giving a single flash and LEDs 1,2,3,4 & 5 flash according to datastrings

generated by the DataHog.

This sequence occurs if the SDHC card is removed whilst the unit is running. Please note that in

this situation the SDHC card could have been corrupted. See section 2.2 for details on how

to remove the SDHC card safely.

No buffering occurs and all datastrings are lost until an SDHC card is inserted.

11

DataHog2+

The rest of this manual is a very detailed description of the

DataHog2 how it operates how to configure the many settings

plus wiring information of the many sensors which can be used.

Some parts will not be applicable to the DataHog2+. DataHog2+

does not have any internal batteries so please disregard any

reference to internal batteries in the following pages.

Changing any of the configuration settings can be achieved by

using the SkyeLynxComms software and datalead supplied with

your system. Unplug the connector shown as no. 3 in the photo

above and plug in the 8 pin plug on the end of the datalead

Please note. The DataHog2+ must be powered before connecting a

datalead and pc.

12

DataHog2+

3.0 DataHog2

3.1 Internal (on-board) Memory

The DataHog2+ loggers all have solid state, battery backed Random Access Memory.(RAM).

This stores all the logged data and also calibration factors etc. The on-board lithium cell

should provide back-up power for approximately ten years. Because of this memory back-

up, data is retained when the main batteries are flat or disconnected for replacement, but no

logging is possible from this back-up power. It should be noted though that it is good

practice to offload data from the unit before the main batteries are exhausted if at all

possible.

Depending on the model of 5000 series, the RAM may hold up to 11,001 records of data and

time (1 record includes date, time and a measurement of each channel) or nearly 30,000

measurements each with a time and date stamp, in 121,020 bytes. The amount of spare

memory can be checked in ptions 1 then 5 from the Main Menu. The following table gives a

useful guide to the number of bytes used per channel and records available at different

logging intervals:

TABLE F INTERNAL ( N-B ARD) MEM RY SIZE AND USAGE

The internal memory of your DataHog2+ is split between a few locations required for housekeeping

and the bulk of the storage capacity which is devoted to data storage. The data is stored in a format

that is constant. Basically the data from each channel that has been gathered at one time is stored

together with the date and time at which the data was obtained. Thus the channel data (from 1 to 8

channels) plus the time is a set number of records. Clearly the fewer the number of channels in use, the

greater the number of records available for storage. The table below shows the maximum number of

records for different numbers of channels in use and illustrates the time before memory is full at different

logging intervals.

Channels Bytes per

record

Records

available

Logging

1 min.

Interval

10 min 30 min 2 hrs

1 11 11,001 7.6 days 10.9 wks 32.7 wks 2.5 yrs

2 15 8,068 5.6 days 8.0 wks 24.0 wks 1.8 yrs

3 19 6,369 4.4 days 6.3 wks 18.9 wks 1.5 yrs

4 23 5,261 3.6 days 5.2 wks 15.6 wks 1.2 yrs

5 27 4,482 3.1 days 4.4 wks 13.3 wks 1.0 yrs

6 31 3,903 2.7 days 3.8 wks 11.6 wks 46 wks

7 35 3,457 2.4 days 3.4 wks 10.2 wks 41wks

8 39 3,103 2.1 days 3.0 wks 9.2 wks 37 wks

9 43 2,814 1.95 days 2.8 wks 8.3 wks 33 wks

10 47 2,574 0.78 days 2.5 wks 7.6 wks 30 wks

11 51 2,372 1.64 days 2.3 wks 7.0 wks 28 wks

12 55 2,200 1.52 days 2.2 wks 6.5 wks 26 wks

16 71 1,904 1.18 days 1.4 wks 5.0 wks 20 wks

13

DataHog2+

25 103 1,175 19.6 hours 8.1 days 3.5 wks 14 wks

3.2 Channels

There are two ‘types’ of channels with DataHog2+, hardware channels and software

channels. The former is the electronic hardware that is fitted to your DataHog2+. The

hardware that you have will be shown in the front of this manual in the “Hardware

Configuration Certificate”. There are potentially 54 hardware channels, though only a total of

16 can ever be in any one DataHog2+. Channels can be used for a variety of inputs as is

shown on your certificate, eg. voltage, current, digital, etc. The electronic components will be

different in each case according to which input type that channel has been dedicated.

The connections for external sensors to the hardware channels will be marked on the

Hardware Configuration Certificate located in the Calibration Certificates booklet provided

with each logger. The connections and calibration for those sensors that require it, will be

covered in subsequent sections of the manual.

3.2.1 Voltage Input Channels

In reality each is a differential amplifier (that is an amplifier which measures the voltage

difference between both its inputs) but which has been has been arranged so that each of

its inputs may be used as a separate channel if required. Usually only one or two of these

channels will be fitted on any logger, though the full list is shown below.

Hardware Channel Number Function and Description

0 Single ended Voltage Input, gain = 1, 10,100, or 1000

1 Single ended Voltage Input, gain = 1, 10,100, or 1000

2 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 2 uses the connections of channels 0 and 1)

3 Single ended Voltage Input, gain = 1, 10,100, or 1000

4 Single ended Voltage Input, gain = 1, 10,100, or 1000

5 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 5 uses the connections of channels 3 and 4)

6 Single ended Voltage Input, gain = 1, 10,100, or 1000

7 Single ended Voltage Input, gain = 1, 10,100, or 1000

8 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 8 uses the connections of channels 6 and 7)

9 Single ended Voltage Input, gain = 1, 10,100, or 1000

10 Single ended Voltage Input, gain = 1, 10,100, or 1000

11 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 11 uses the connections of channels 9 and 10)

12 Single ended Voltage Input, gain = 1, 10,100, or 1000

13 Single ended Voltage Input, gain = 1, 10,100, or 1000

14 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 14 uses the connections of channels 12 and 13)

14

DataHog2+

15 Single ended Voltage Input, gain = 1, 10,100, or 1000

16 Single ended Voltage Input, gain = 1, 10,100, or 1000

17 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 17 uses the connections of channels 15 and 16)

18 Single ended Voltage Input, gain = 1, 10,100, or 1000

19 Single ended Voltage Input, gain = 1, 10,100, or 1000

20 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 20 uses the connections of channels 18 and 19)

21 Single ended Voltage Input, gain = 1, 10,100, or 1000

22 Single ended Voltage Input, gain = 1, 10,100, or 1000

23 Differential Voltage Input, gain = 1, 10,100, or 1000

(note that channel 23 uses the connections of channels 21 and 22)

3.2.2 Current Input Channels

Note that each of these is a separate input to a current amplifier which can have any of

eight different feedback resistors. The effect of these resistors is to set the scaling of the

channel. The full scale of the DataHog2 is reached when 2.000 volts is applied to the

Analogue to Digital converter by this current amplifier. The ratio of current in to voltage out

(to the A/D converter) is set by this feedback resistor. It’s precise value is given in the

configuration certificate for each DataHog2. The ratio of current in to voltage out is given by

the following:-

Current in for F/S voltage out (2.000) = 2.0000 volts / feedback resistor value (Megohms)

The individual resistors fitted are very stable in value, but each has a slightly different value.

See the configuration certificate for the actual values fitted, but nominal values for each

‘current gain’ setting (resistor value Megohms / F/S input currents) are as follows:-

0) 0.005M / 400uA 1) 0.01M / 200 A 2) 0.05M/ 40uA 3) 0.1M / 20uA

4) 0.5M / 4uA 5) 1.0M/ 2uA 6) 5.0M/ 0.4uA 7) 10.0M / 0.2uA

Again, only one or two of these are usually fitted, but the full list is as follows:-

Hardware Channels Number Function and Description

25 Current Input - ‘current gain’ settable as above, 0) to 7)

26 Current Input - ‘current gain’ settable as above, 0) to 7)

27 Current Input - ‘current gain’ settable as above, 0) to 7)

28 Current Input - ‘current gain’ settable as above, 0) to 7)

29 Current Input - ‘current gain’ settable as above, 0) to 7)

30 Current Input - ‘current gain’ settable as above, 0) to 7)

31 Current Input - ‘current gain’ settable as above, 0) to 7)

32 Current Input - ‘current gain’ settable as above, 0) to 7)

33 Current Input - ‘current gain’ settable as above, 0) to 7)

34 Current Input - ‘current gain’ settable as above, 0) to 7)

15

DataHog2+

35 Current Input - ‘current gain’ settable as above, 0) to 7)

36 Current Input - ‘current gain’ settable as above, 0) to 7)

37 Current Input - ‘current gain’ settable as above, 0) to 7)

38 Current Input - ‘current gain’ settable as above, 0) to 7)

39 Current Input - ‘current gain’ settable as above, 0) to 7)

40 Current Input - ‘current gain’ settable as above, 0) to 7)

N.B. a) Current channel inputs are intended for use with Skye Instruments light sensors and so

show a positive reading for a negative current input with respect to ground. If these channels

are used with a sensor giving a positive current output with respect to ground, then the

DataHog will show a negative current.

b) Current sourcing sensors that can apply greater than 2 volts to these inputs when they are

not active, may cause errors on other channels.

3.2.3 Internal Temperature Channel

This is fitted only as an integral air temperature sensor, or as the 12th thermistor channel

where 12 thermistor channels are required. If it is fitted, it may be addressed as channel 45,

and will give an output as per a standard thermistor channel

Hardware Channel Number Function and Description

45 Thermistor only channel. Scale as a thermistor (10K)

3.2.4 Digital Input Channels

Low speed inputs. These accept switch closure inputs or 5 volt pulse inputs. The maximum

counting rate is 300 pulses per second.

N.B. Digital channels may only be ascribed to one software channel.

Hardware Channel Number Function and Description

48 Counting channel. Max count = 65535 before rollover

49 Counting channel. Max count = 65535 before rollover

50 Counting channel. Max count = 65535 before rollover

51 Counting channel. Max count = 65535 before rollover

52 Counting channel. Max count = 65535 before rollover

53 Counting channel. Max count = 65535 before rollover

Note that with a sampling time of 1 hour, the maximum count rate is approximately 18 per

second if a rollover is to be avoided with a sensor such as windspeed, sample times should

be kept below 10 mins to avoid rollover.

3.2.5 Internal Relative Humidity Channel – earlier models of DataHog2 only

16

DataHog2+

This hardware is simply addressed as hardware channel 54. As for all other hardware

channels it may be ascribed to any or all of the 25 software channels.

Hardware Channel Number Function and Description

54 ‘Built in’ Relative Humidity Channel.

3.2.6 Software Channels

The second type of channel or rather use of the word ‘channel’ is the software channel. This

simply refers to the way that the software has been configured to look at the hardware. For

example, if a hardware channel is fitted to the DataHog2+ it may be treated and read from

the software as software channel 0 - 24 depending on how the software is configured. Many

DataHog2+ s use a preset configuration option, but all can be individually configured to use

available hardware channels as the user desires.

e.g. more than one software channel can read from a single hardware channel, this is

especially useful if each software channel is set with a different gain for readings over a wide

range.

N TE - each digital hardware channel should not have more than one software channel

assigned to them, as once they have been ‘read’ by the first software channel the counter is

returned to zero.

3.2.7 Relay utput Channels

These channels can be fitted at the time of ordering your DataHog2+. Up to 4 relay outputs

are available, which can be assigned to any software channel. More than one can be

assigned to a single software channel if a “window” threshold is required.

The relay contacts are gold plated for low level relay switching and hence are for light duty,

low inrush switching only. They are not suitable for direct mains connection, inductive loads or

loads over 0.5amps. Slave relays should be used if these ratings are to be exceeded. The

built-in relays have a very low contact resistance, and are suitable for dry switching circuits.

3.3Calibration

Calibration of the sensor depends on the model in question, some units, for example with

curve matched thermistor temperature sensors, will not need specific calibration, this being set

at the time of manufacture. thers with external light sensors, or RH probes can be easily

calibrated in software.

17

DataHog2+

Sections later in this manual give specific details for calibration of the various channel and

sensor options. Please note that this manual contains the instructions for all models and

options. Please ignore those that do not apply to your specific unit.

3.8 Firmware

As previously mentioned, the units are designed for low power operation, and this is at least

in part achieved by switching off as much of the circuitry for as long as possible. This means,

amongst other parts of the unit, the RS232 interface (which has a high current requirement),

and hence the communication channel with you, the user, is switched off for most of the time.

However the software has been arranged so that in most modes there is a period of

‘listening’ on the RS232 to see if you wish to ‘talk’ to the unit. This period is generally

immediately after the microprocessor has done the tasks required of it during each ‘wake up’

period (every ten seconds). In most cases a message is sent from the DataHog2+ via RS232

requesting a response. An audible beep generally precedes the second or so that the unit

spends listening.

The DataHog2+ will only spend this extra time with the RS232 interface switched on if it

‘thinks’ that there is someone likely to want to ‘talk’ to it. The microprocessor monitors the

‘plug detect’ line - pin 6 socket 1 - and if this is shorted to ground, as by a suitably wired

datalead connected to the RS232 input, then it will ‘listen’.

************************************************************************************

N.B. If for any reason a connection lead is used without the ‘plug detect’ pin connected to

ground, then, although in most modes some data will be sent FR M the 5000 series

DataHog2+, it will not respond to characters sent from the host computer T the DataHog2+.

************************************************************************************

During the listening period if any numeric character is sent to the unit at the correct baud rate

it will immediately stop what it is doing and enter ‘terminal’ or Main Menu mode. The unit will

then send a ‘menu’ to the host with various options These options are listed in subsequent

sections

The baud rate for current software versions is 9600 Baud. ther details are 8 data bits, stop

bits, no parity, and xon/xoff flow control.

18

DataHog2+

4.0 OPERATION

4.1 Initial Set Up

The logger has been set up at Skye with as much information as possible for immediate

operation. Where supplied with Skye sensors the appropriate scaling factors, zero offsets,

gains etc have already been entered, as shown on the Hardware Configuration Certificate at

the front of this manual. In many cases the user simply needs to set the sampling and storing

periods desired and start logging.

4.1.1 Firmware verview

Firmware means the programme that is running within the DataHog2+ itself, not on the PC.

This programme is stored in a ‘R M’ (Non-volatile Read nly Memory) chip.

The DataHog2+, as previously mentioned, is designed to save power when

possible, and thus will ‘sleep’ for long periods compared to the time it spends

working. Essentially, it has two modes of operation which are referred to as

Logging Mode and Main Menu mode.

4.1.2 Logging Mode verview

To conserve power the DataHog2+ shuts down circuits not currently in use whenever possible.

In Logging Mode the operation is cyclic. It is ‘woken’ after approx. 8 seconds by the internal

clock, it will collect and store data from channels according to the various settings made by

the user in Main Menu mode.

‘Listening’ is a strange term, but the DataHog2+ is simply monitoring its RS232 input for any

numeric character sent by a computer connected to it. As soon as the DataHog2+ receives

such a character (assuming it arrives within the one second listening period) the DataHog2+

will leave logging mode and enter the Main Menu mode. If the character arrives too late,

then the DataHog2+ will simply go back to ‘sleep’ and listen again about 10 seconds later.

4.1.3 Main Menu Mode verview

Main Menu mode is entered when a character is received as described above. This can be

achieved by using the SkyeLynx Comms software and choose Wake Up Logger.

The DataHog2+ transmits the Main Menu showing the various functions and setup choices it

has to offer. These are described further in section 3.2. In essence, each option will either

19

DataHog2+

display status, offload data, configure and calibrate the logger, etc, returning the user to the

Main Menu when the individual task is completed.

Main Menu mode can only normally be left and Logging Mode re-entered by pressing

Escape on the PC keyboard.

N TE – always press Escape to leave Main Menu mode and return to Log Mode. Else the

logger will not record any data and batteries will drain quickly.

4.2 Main Menu Mode ptions

This is accessible from the SkyeLynxComms software

Main Menu mode is entered from Logging Mode by choosing File and Wake Up Logger, or

by pressing a numeric key on the keyboard during the ‘listening’ period of the DataHog2+, 1

second after the ANY NUMERIC KEY T WAKE UP message is seen. A menu of options is

displayed as below and may be selected from by typing the menu option number or letter:

SKYE INSTRUMENTS LTD. MINIMET SERIES

SEND CHARACTER SH WN T SELECT ITEM

<ESC> RETURNS T L GGING

-MAIN MENU -

0) DISPLAY READINGS FR M ALL ACTIVE CHANNELS

1) DISPLAY CURRENT SETUP

2) DISPLAY S FTWARE VERSI N

3) FFL AD 24H UR DATA SUSDHCHCARY

4) FFL AD DATA

5) RESET MEM RY

6) SET CL CK

7) SET DATAFILE I/D, PLUS MEM VERWRITE & TIMED L GGING M DES

8) SET CHANNEL SAMPLE & L G INTERVALS

9) SET AX+B CALIBRATI N FACT RS

A) SET CHANNEL C NFIGUR’NS

B) SET INT’NL RH% SENS R CALIB’N

C) SET ALARM RELAY(S)

D) SET CHANNELS F R N NZER / THRESH LD L G M DES

E) ENTER ‘L G N DEMAND’ M DE

In general upper case characters are expected. <Escape> will cancel almost all operations

before changes take effect!

Not all of these options apply to all models of the DataHog2+ family and consequently,

those functions that do not apply to a particular unit will be found to be inoperative.

20

This manual suits for next models

1

Table of contents

Other Skye Data Logger manuals

Popular Data Logger manuals by other brands

Capetti Elettronica

Capetti Elettronica WSD12PS-4AI user manual

Dickson

Dickson SP100 Getting started

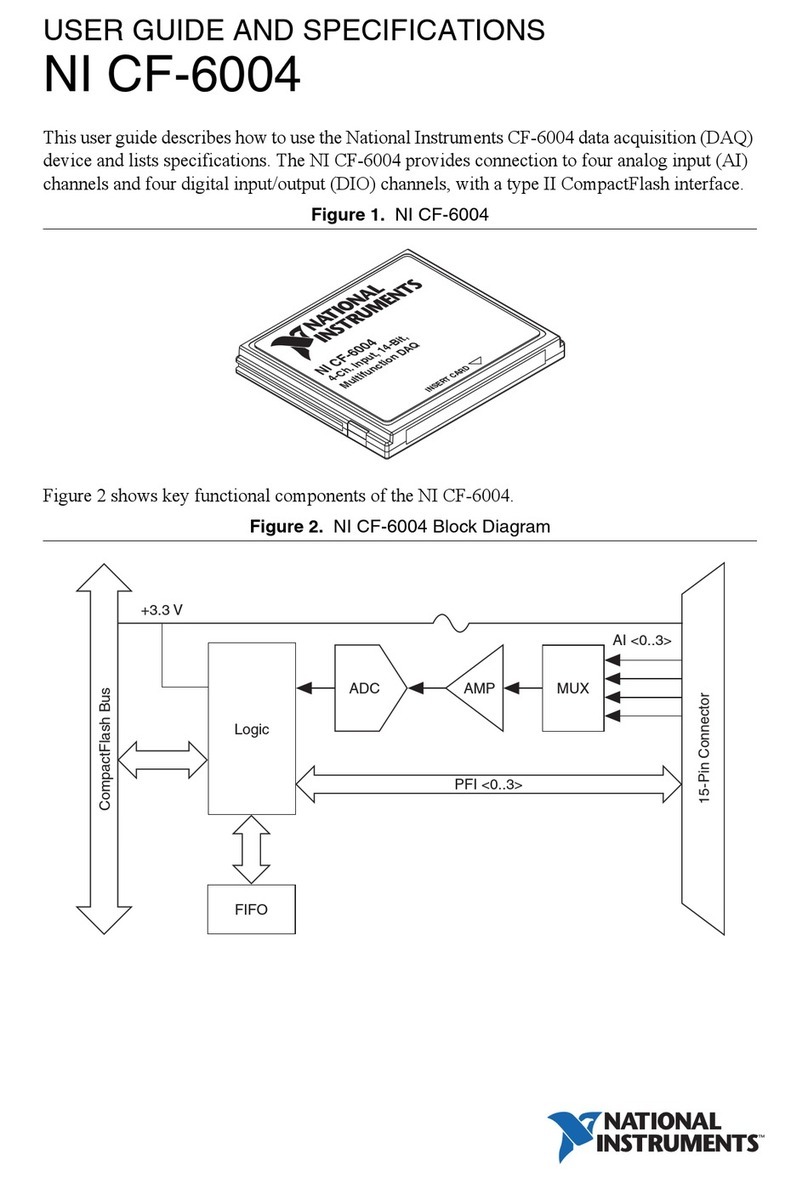

National Instruments

National Instruments CF-6004 USER GUIDE AND SPECIFICATIONS

National Instruments

National Instruments NI 781 R Series user manual

Aim

Aim MyChron 3 660 Technical documentation

Huawei

Huawei FusionModule 1000B Maintenance Guide