SKYSHL SS413F Series User manual

Optical Fiber Fusion Splicer

SS413F Series User’s Manual

Shenzhen SKYSHL Technology Co.,LTD.

V2019.08

Please read carefully this manual

before operating this model of the splicer.

Please follow all safety warnings and cautions in this manual.

Warning (Ignoring this warning, Incorrect use of fusion splicer may cause fatal and serious injury):

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

Warning!

1.The input voltage range of SS413F series fusion splicer is fixed. Do

not use the power voltage outside the range specified. Please use correct

AC and DC power supply.

2.Avoid the operation which may cause electrical shock, equipment

damage, or even fire disaster, personal injury or death. Please use a

dedicated three-wire grounded AC power line and AC / DC power

adapter.When the adapter input cable is connected to AC220V, 50 /

60HZ power supply, an effectively grounded three-holes socket must be

used.

3.Strictly prohibit to handle AC power cable, adapter and fusion splicer

with wet hand, or an electrical shock may occur.

4.When the fusion splicer encounters following faults, please unplug

immediately the power output cable of the adapter from the fusion

splicer power supply input port and shut down the fusion splicer,

otherwise, it will cause the fusion splicer unable to be repaired, even

cause bodily injury, death and fire.

*Smoke, smell, sound or abnormal heating up;

*Liquid, foreign matter go into the machine;

*Machine damage or falling down.

5. Do not use gas cleanser to clean the fusion splicer, otherwise the arc

of the machine electrode during arc will ignite combustibles, cause fires.

6.Do not operate the fusion splicer in flammable liquid or flammable

gas environment, Otherwise it will lead to serious consequences of fire,

explosion and so on.

7.Never touch the electrode of this model fusion splicer at work,

otherwise, the people will suffer a serious arc electric shock and burn.

Shut down the fusion splicer and disconnect the power supply before

replacing electrode.

8.Meet proper personal protection requirements in operation, in case the

fiber debris get into the eyes, mouth, skin or mouth, causing personal

injury.

SS413F Optical Fiber Fusion Splicer User’s Manual

V

2

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

Warning!

9.There are no parts required for maintenance in this model of fusion

splicer. Prohibit dismantling the fusion splicer and power module

(lithium batteries). Repair in any errors will cause the machine unable

repair even causing personal injury.

10.The power module (lithium battery) is strictly limited in this manual.

Wrong use will result in battery explosion, fires and personal injury.

Please strictly implement "Battery Precautions" in the manual, "Battery

Danger Warning" and other related requirements.

11.If the battery charging can not be completed or charge indicator can

not be converted within five hours, please stop charging immediately

and contact with our customer service center.

12.The fusion splicer battery is a consumable item. There is a safe

period of use. Extended use is strictly prohibited(Safe service life

means: The charge-discharge in normal use are less than 300 times).

Note (Ignoring this warning and improper use may cause personal injury and material

damage):

NOTE!

1.Not to touch the fusion splicer heater and heat-shrink sleeve with

splicing process just completed, otherwise burn hazard will occur.

2.In routine maintenance, the ear syringe may be used for blowing off

the dust from the surface of the mirror and the objective lens of the

fusion splicer. The operator can also use special lens paper to clean. It is

recommended in principle not using alcohol to clean the mirror surface.

Please strictly implement the relevant requirement of the manual.

3.Do not store the fusion splicer at a high temperature or high humidity

environment.

SS413F Optical Fiber Fusion Splicer User’s Manual

V

3

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

NOTE!

4.In a dusty environment, the fusion splicer shall avoid dust.

5.When the fusion splicer is moved from a cold environment to a high

temperature environment, try to have a heating up process to eliminate

condensation.

6.In order to maintain fusion splicer performance and stability, the

machine maintenance in factory is recommended once a year.

7.The fusion splicers are accurately calibrated, try to avoid intense

shock and collision, and use a dedicated carrying case for transportation

and storage.

8.The repair and commissioning of the fusion splicer must be

performed by professional and technical personnel. Incorrect use

methods or undesirable devices can cause bad damage to the

equipment. If a problem occurs, please contact in time the

manufacturer.

★Exemption clauses:

For alllosses caused by using non-original battery,battery

charger, power adapter and so onnot provided by our company,the

Company will not accept any liability.

★Symbols and logo

Please give full attention to the safety warning signs used on this

model fusion splicer.

High voltage warning signs: High voltage; no touch.

High temperature warning signs: High temperature; no touch.

SS413F Optical Fiber Fusion Splicer User’s Manual

V

4

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

1 Overview…………………………………………………………………………1

1.1 Product specifications ................................................................................................................... 2

1.2 Standard configuration of fusion splicer ...................................................................................... 5

1.3 Name of main components of fusion splicer ................................................................................6

1.4 Keypad instruction of fusion splicer...............................................................................................7

1.5 Description of readiness window of fusion splicer ...................................................................... 8

2 Basic operation …………………………………………………………………..9

2.1 Power supply of fusion splicer....................................................................................................... 9

2.1.1 Power supply of power adapter .................................................................................................. 10

2.1.2 Power supply of Lithium battery ................................................................................................ 12

2.2 Battery operation precautions .....................................................................................................16

2.3 Battery hazard warning ...............................................................................................................17

2.4 Power-saving mode operation .................................................................................................... 19

2.5 Undervoltage alarm .....................................................................................................................19

2.6 Start up and shut down ................................................................................................................20

2.7 Display brightness adjustment ....................................................................................................20

2.8 Preparation of optical fiber end face ...........................................................................................22

2.8.1 Installing optical fiber heat shrink sleeve ...................................................................................22

2.8.2 Production of single-mode and multimode fiber end face............................................................22

2.8.3 Production of the fusion splicing end face of covered optical cable............................................24

2.8.4 Production of end face of tail optical cable.................................................................................. 26

2..9 Placement of optical fiber ...........................................................................................................26

3 Management menu ……………………………………………………………28

3.1 Overview of first-level menu ......................................................................................................28

3.2 [Splice mode] operation ..............................................................................................................31

3.2.1 Overview.......................................................................................................................................31

3.2.2 Edit / Select /restore.....................................................................................................................39

3.3 [Heating mode] operation ........................................................................................................... 43

3.3.1 Overview......................................................................................................................................43

3.3.2 Edit / Select ...............................................................................................................................45

3.4 [Calibration] operation ................................................................................................................50

3.5 [Splice options] operation ...........................................................................................................51

3.5.1 Fusion splicing operation ...........................................................................................................51

3.5.2 Data display ............................................................................................................................... 52

3.5.3 Ignored options .......................................................................................................................... 53

SS413F Optical Fiber Fusion Splicer User’s Manual

V

5

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

3.5.4 [Arc compensation ]operation ....................................................................................................... 54

3.5.5 Display fiber image:.........................................................................................................................55

3.5.6 Others ............................................................................................................................................. 55

3.6 [Maintenance] operation ...............................................................................................................57

3.6.1 Splice records .................................................................................................................................58

3.6.2 Splice images ................................................................................................................................. 60

3.6.3 Electrode ........................................................................................................................................ 61

3.6.4 Dust check ......................................................................................................................................61

3.6.5 Manufacture adjust 1 ......................................................................................................................61

3.6.6 Real-time revise............................................................................................................................... 62

3.6.7 Clear real-time revise.......................................................................................................................63

3.6.8 Open arc calibration.........................................................................................................................65

3.6.9 Status................................................................................................................................................66

3.6.10 System update .............................................................................................................................. 67

3.6.11 About .............................................................................................................................................72

3.7 [Settings] operation .........................................................................................................................73

3.7.1 Time ................................................................................................................................................73

3.7.2 Language ........................................................................................................................................74

3.7.3 Monitor position .............................................................................................................................74

3.7.4 LCD brightness .............................................................................................................................. 75

3.7.5 Power save menu ........................................................................................................................... 75

3.7.6 Menu lock ...................................................................................................................................... 78

3.7.7 Factory settings................................................................................................................................ 81

4 High level operation……………………………………………………………81

4.1 "Real-time revise".............................................................................................................................81

4.1.1 Preheat splicing................................................................................................................................82

4.1.2 Special precaution............................................................................................................................83

4.2 Select splice mode according to the type of optical fibers............................................................... 84

4.3 Selecting / editing splice mode......................................................................................................... 86

4.4 Fusion splicing operation ................................................................................................................87

4.4.1 Inspection on cutting angle and end face of the optical fiber ........................................................87

4.4.2 Automatic alignment and splicing ................................................................................................. 89

4.4.3 Estimation of splice loss ................................................................................................................ 90

4.5 Tension test ......................................................................................................................................93

4.6 Storage of spliced fiber..................................................................................................................... 94

4.7 Reinforcement of fiber splice point.................................................................................................. 95

4.7.1 Selecting heating mode according to heat-shrink sleeve material.................................................. 95

4.7.2 Selecting / Editing heating mode.....................................................................................................96

SS413F Optical Fiber Fusion Splicer User’s Manual

V

6

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

4.7.3 Heating operation.............................................................................................................................97

4.8 Motors operated manually ...........................................................................................................100

5 Inspection and maintenance …………………………………………………103

5.1 Cleaning V-groove ...................................................................................................................... 103

5.2 Cleaning fiber clamp ...................................................................................................................104

5.3 Cleaning LED in light bracket ....................................................................................................105

5.4 Cleaning objective lens ...............................................................................................................105

5.5 Replacement of electrodes ..........................................................................................................107

5.6 Stabilizing electrodes ..................................................................................................................109

5.7 Clear arc times ............................................................................................................................ 110

5.8 Dust check ...................................................................................................................................111

5.9 Maintenance of cutter ................................................................................................................. 113

5.9.1 Cleaning fiber cleaver .................................................................................................................113

5.9.2 Adjustment of blade height .........................................................................................................114

5.9.3 Changing blade position ............................................................................................................. 114

5.9.4 Replacement of blade ..................................................................................................................114

5.9.5 Precautions in cleaver operation .................................................................................................115

5.10 Calendar setting .......................................................................................................................... 116

5.11 Heater / battery / environment .................................................................................................... 116

5.12 Replacement of spare lithium batteries ...................................................................................... 117

6 Problems and troubleshoot …………………………………………………117

6.1 Power supply ...............................................................................................................................117

6.2 Fusion splicing operation..............................................................................................................118

6.3 Heating operation ........................................................................................................................120

6.4 High lever settings........................................................................................................................ 120

Appendix A Warranty period and conditions ………………………………120

Appendix B Contact us………………………………………………………...122

1

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1.Overview

Thank you for choosing our products. This user manual describes mainly the detailed

operation steps of SS413F automatic, high-performance optical fiber fusion splicers

which are the latest products made by our company. The machine adopts a high-speed

image processing technology and special precision positioning technology. The whole

process of fiber fusion splicing can be completed automatically within 9 seconds.

Provided with TFT color 4.3 LCD display, the screen is protected by high strength

protective panel. User-friendly graphical interface is convenient for efficient and quick

operation by the user. High performance battery can realize online charging continuously

in the work, to get a longer battery life. No manual arc calibration operation is needed.

The machine has real time splice arc control and correction functions. In extreme

environment, the machine can alsoeffectively ensure the splice quality of optical fiber.

The machine is featured with fast splice speed, less splice loss, light weight, portable,

applicable to backbone network, metropolitan network and FTTH project. In order to

complete accurately the splice operation, please read carefully this user's manual.

2

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1.1 Product specifications

Applicable optical

fibers

SM (G.652 & G.657), MM (G.651), DS (G.653),

NZDS (G.655) and user-defined optical fibers

Splice loss

0.02 dB (SM), 0.01 dB (MM), 0.04 dB (DS/NZDS)

Return loss

Better than 60dB

Control technology

Real time splice arc control and correction; Self adaptive in

working environment scope; Electrode oxidation self

adaptive.

Splicing time

<9 seconds (standard SM).

Heat time

<25 seconds (The Heat time can be set and the heater

temperature can be adjusted.); Fast heat function, functions of

automatic or manual heating selection.

Splicing function

Step-by-step splicing or automatic splicing optional

Fiber alignment

Fine alignment, fiber core alignment, cladalignment, manual

alignment

Fiber diameter

Cladding diameter 80~150μm,coating diameter 100~1000μm

Cleave length

Coating less than 250μm: 5 ~ 16 mm;

Coating 250 ~ 1000μm: 16 mm.

Tension test

Standard 2N (optional)

Fiber clamp

Multifunctional clamp is applicable to bare fiber, tail fiber,

jumper, covered fiber and stealth fiber. The clamp meets the

requirement of industry standard FTTH fusion quick splicer.

3

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

Magnification

times

310 times (X-axis or Y-axis);150 times (X-axis and Y-axis).

Heat-shrink sleeve

60mm, 40mm and a series of micro- shrink sleeves (some

features are optional)

Display

Provided with TFT color 4.3 LCD display. The screen is

protected by high strength protective panel. Contents (image)

can be flipped, easy for two-way operation.

External Interface

USB2.0 Interface: convenient data download,

USB flash disk upgrade software.

Splicing mode

100 groups user mode, 53 groups factory mode.

Heater mode

40 groups user mode, 11 groups factory mode.

Connection

storage

Built-in memory is capable to save latest 10000 splices.

Store 100 groups of splice images (X, Y fiber splicing

images).

Electrode life

> 3000 times (times of arc).

Built-in battery

Continuous splicing, heating more than 350 times (typical

environment).

Power saving

function

In “Power Save Mode" Under typical circumstances can

save 15% battery power

4

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

Power supply

Lithium battery provides 12.5 V power (charging in 10.8V)

and can be charged continuously when the splicer works.

When the charging time ≤3.5, the battery charging times are

not less than 300 times. (Charging) Power adapter: Input

AC100-240V 50 / 60HZ, Output DC13.5V / 4.8A. The

present power mode can be identified, real-time monitoring

the present battery capacity.

Work environment

Operating environment: -10~+50℃; Storage temperature:

-40~+ 60℃;Humidity:<95% RH (non-condensing);

Operating altitude: 0~5000m. Maximum wind speed:15m/s.

External

dimension

133(length)*163(width)*140(height)

Weight

1.6Kg(not including battery)

□ SKYSHL splicer, powerful core, service oriented.

□ Battery charging online, lasting longer.

□ Splicing arc real-time control, no manual

correction needed.

□ 4.3" color LCD display, high strength panel.

5

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1. 2 Standard configuration of splicer

The following is the standard configuration of splicer:

No.

Name

Thumbnail

Quantity

Remark

1

Fusion splicer

1 set

Host

2

Carrying case

1 piece

Parts

3

Lithium battery

1 piece

Parts

4

Spare electrode

1 pair

Parts

5

Power adapter

1 piece

Parts

6

AC power cable

1 piece

Parts

7

Plastic tweezers

1 piece

Parts

8

Cleaning brush

1 piece

Parts

9

Inspection report

—

1 copy

Accessories

10

Certificate of quality,

warranty card

—

1 copy

Accessories

11

Packing List

1 copy

Accessories

The following is optional parts of splicer.

1

Hot joint clamp

1 piece

Optional

2

Heater clamp

1 piece

Optional

6

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1. 3 Name of main components of fusion splicer

Remarks:

1.The standard configuration above is the configuration

recommended by our company. The configuration of the machine in packing

box is based on the packing documents, i.e. "packing list" in the packing

box and is not described in detail.

2.Theoptional parts are not the basic parts of the fusion splicer in the

packing box and shall be ordered by the user separately.

Heater transparent window cover

Heating groove

Heater right press plate

Heater left press plate

V-groov

Electrode

Left fiber clamp

Right fiber clamp

7

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

1.4 Keypad instruction of fusion splicer

Button

Readiness

Manual mode

Automatic mode

Parameters menu

Power switch

Power switch

Power switch

Power switch

Moving

cursor

Upward movement

of fiber

In valid

Increasing the amount of

parameters

/ moving cursor

Moving

cursor

Downward

movement of fiber

In valid

Reducing the amount of

parameters

/ moving cursor

Moving

cursor

Leftward

movement of fiber

In valid

Reducing the amount of

parameters

/ moving cursor

Moving

cursor

Rightward

movement of fiber

In valid

Increasing the amount of

parameters

/ moving cursor

Entering

splicing mode

menu

Open manual drive

motor function at

pause

In valid

Entering lower level

menu

/operation screen

8

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

Start splicing

Continue forward

/ Start splicing

Start splicing

Confirming Option

Function

/ Parameter modification

In valid

Motor Reset

/ Return to

readiness screen

Motor Reset

/ Return to

readiness screen

Return to higher level

menu

/ readiness screen

Heater

Switch

Heater switch

Heater

Switch

Heater switch

In valid

Next step

/Arc

Repeating arc

In valid

In valid

Switching over X /

Y display screen

Switching over X /

Y display screen

In valid

1. 5 Description of readiness screen of fusion splicer

Remarks:

①. "power switch" button is installed at the lower left side of

the machine panel.

②. For the detailed operation of [step by step splicing mode], please read "4.8

Motors operated manually " in this manual.

9

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

●Top right corner of the screen : Indicating the present power supply mode of

"power adapter".

●Top right corner of the screen : Indicating "Heater" is "warming up" at current.

●Bottom of screen : Indicating "Keypad operation" on

current screen.

LCD display

SS143F series of fusion splicers are equipped with a liquid crystal display. It is a

precision device manufactured in factory environment with quality controlled strictly.

Nevertheless, there may be also some individual black, red, blue, green dots on the

screen. The brightness of the display will be different at different viewing angle to the

screen. These symptoms are not the defects of LCD display, but natural

phenomenon.

2. Basic operation

2.1 Power supply of fusion splicer

The power supply modes of SS413F optical fiber fusion splicer are divided into

"external power adapter" or “removable lithium battery". Built-in high-performance

battery panels can be charged online continuously in the work in lithium battery

power mode to get a longer battery life. To correctly and safely use this type of fiber

splicer, the operator shall use the built-in high-performance battery and parts (power

adapter and lithium battery)provided by our companyand read carefully the operation

description in detail.

2.1.1Po

10

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

wer supply by power adapter

<1>The basic parameters of the exclusive AC/DC power adapter of the fusion

splicer produced by our company :

INPUT: AC100-240V ~ 1.8A 50 / 60HZ OUTPUT: DC13.5V / 4.8A

<2>Power supply of the power adapter is shown as follows:No power connector is

required at the bottom of the splicer. The power adapter is connected to AC

mains power.Finally, DC output power cable is connected to "DC IN" inlet of

the power supply at the right side of the fusion splicer. The fusion splicer is

powered then by the power adapter.

●Use only AC adapter power cable supplied with the machine.

●The ground terminal of AC input power cable must be effectively

grounded.

●When using AC generator, the operator shall check regularly whether

it conforms to AC input requirements of the output voltage.

●Use only DC output power cable supplied with the adapter.

●Strictly prohibit to handle AC power cable, adapter and fusion

splicerwith wet hand,or an electrical shock may be caused.

11

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

<3>When the fusion splicer is powered by the power adapter, the indicator flashes

at "DC IN" input at the right side of the splicer as shown in following

drawing.

Insert to the power

adapter, power on.

No power connector is needed.

12

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

●If AC voltage of the mains power (or generator) is lower than 100V or higher

than 240V or unstable, AC / DC power adapter will not provide normal DC

output. DC output cable of the power adapter can not be connected to "DC IN"

input of the fusion splicer.

2.1.2 Power supply by lithium battery

The lithium battery in this machine is an "independent removable battery":If the

fusion splicer will not be used for a long time, the battery must be removed from

the splicer for safety concern. When the splicer is going to be used again, the

battery can be installed to the splicer quickly, realizing "charging battery while

working". The battery can always be charged directly on-line and the service life

of the battery can be prolonged thereby.

A.Lithium battery installation and power supply

As shown in the figure below, hold the splicer with and with the bottom facing

upward, "independent removable battery" is installed at the bottom of the

splicer. As indicated by the arrow, the splicer is powered by the "independent

Do not use external power supply which does not meet the

requirements of our company,otherwise it will burnout fusion splicer

or cause personal injury. When the AC/DC power supply adapter input

cable is connected to AC220V, 50 / 60HZ power supply, the user must

use an effectively grounded three-holes socket.

13

Shenzhen Skyshl Technology Co.,LTD.

Sales email: sales1@skyshl.net After Sales email:af@skyshl.net Website:www.skyshl.net

SS413F Optical Fiber Fusion Splicer User’s Manual

V

removable battery".

B.Lithium battery capacity check

After "independent removable battery" is installed in accordance with the steps

above, the check operation is as follows.

Start work

Install"independent

removable battery"

Other manuals for SS413F Series

1

Table of contents

Other SKYSHL Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

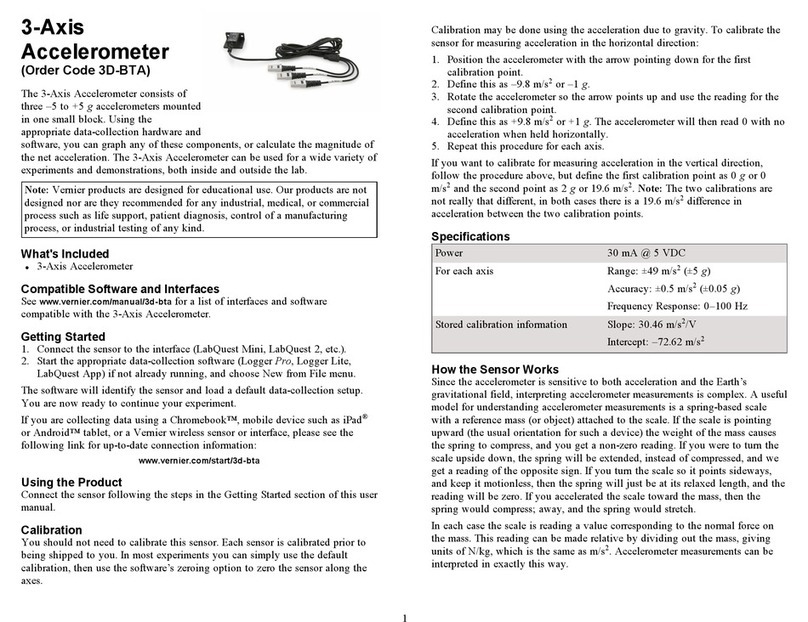

Vernier

Vernier 3D-BTA quick start guide

Extech Instruments

Extech Instruments AN100 user manual

Micro Audiometrics

Micro Audiometrics ES3S user guide

Rohde & Schwarz

Rohde & Schwarz R&S LCX200 Getting started

X-Vision Optics

X-Vision Optics ROC 8X user manual

EA Technology

EA Technology UltraTEV Plus2 operating manual