2

308–607

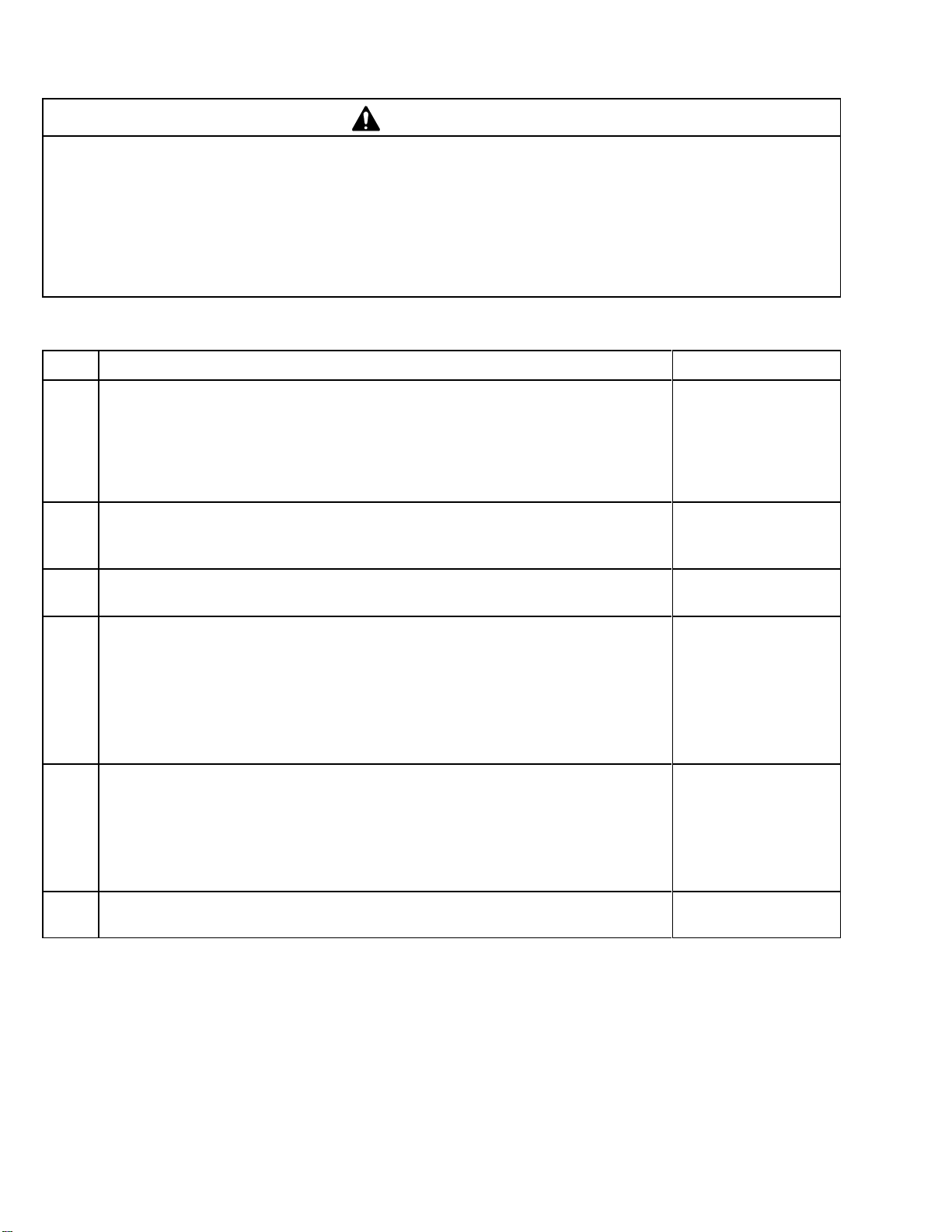

Table

of Contents

Terms 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-installation

Checklist

4.

. . . . . . . . . . . . . . . . . . . . .

Installation

Checklist

6.

. . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Installation 8.

. . . . . . . . . . . . . . . . . . . . . . . . .

Flush

the System

8.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Install

Solenoids and Meters

8.

. . . . . . . . . . . . . . . .

Set

Control Module Addresses

8.

. . . . . . . . . . . . . .

To

Change from 120 V

AC to 240 V

AC 9.

. . . . . . . .

Mount

the Control Module and Keypad Bracket

10

Cable Routing and Connection 11.

. . . . . . . . . . . . . . .

Connect

the AC Electrical Power

11.

. . . . . . . . . . .

Route

the Solenoid and Meter Cables

12.

. . . . . . .

Connect

the Solenoid and Meter Cables

12.

. . . . .

Connect

the Control Modules to the CAN

13.

. . . .

Connect

the Keypad Cable

14.

. . . . . . . . . . . . . . . .

Connect

the Printer or Computer Cable

14.

. . . . . .

Visually

Check the Wire Connections

14.

. . . . . . . .

System

Setup

15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modify

or New

17.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear

Setup

18.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print

Setup

19.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update Tables 20.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time

and Date

24.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator

Access

24.

. . . . . . . . . . . . . . . . . . . . . . . . .

Save

Setup

25.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control

Modules

25.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Fluids 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dispense

Areas

27.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Connection

Assignments

28.

. . . . . . . . . . . . . . . . . .

Meter

Calibration

29.

. . . . . . . . . . . . . . . . . . . . . . . . .

Inventory 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Report

Options

31.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Run

Options

31.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System T

ime Outs

31.

. . . . . . . . . . . . . . . . . . . . . . . .

Run Mode 32.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dispensing 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Review

Jobs

36.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown

Procedure

39.

. . . . . . . . . . . . . . . . . . . . . .

Power

Failure

39.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control

Module is Not User Repairable

39.

. . . . . .

To

Clean The Keypad

39.

. . . . . . . . . . . . . . . . . . . . .

To

Install New Software

39.

. . . . . . . . . . . . . . . . . . .

To

Replace the Complete Pulse Meter

40.

. . . . . . .

To

Replace the Electronic Pulse Module

40.

. . . . .

To

Replace the Metering Unit

40.

. . . . . . . . . . . . . . .

To

Clean the Solenoid V

alve 41.

. . . . . . . . . . . . . . .

Horizon

System Components

42.

. . . . . . . . . . . . . . . .

Control

Modules

42.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Keypads 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad

W

all-mount Bracket

45.

. . . . . . . . . . . . . . . .

Fluid

Solenoid V

alves 46.

. . . . . . . . . . . . . . . . . . . . .

Air

Solenoid V

alves 46.

. . . . . . . . . . . . . . . . . . . . . . .

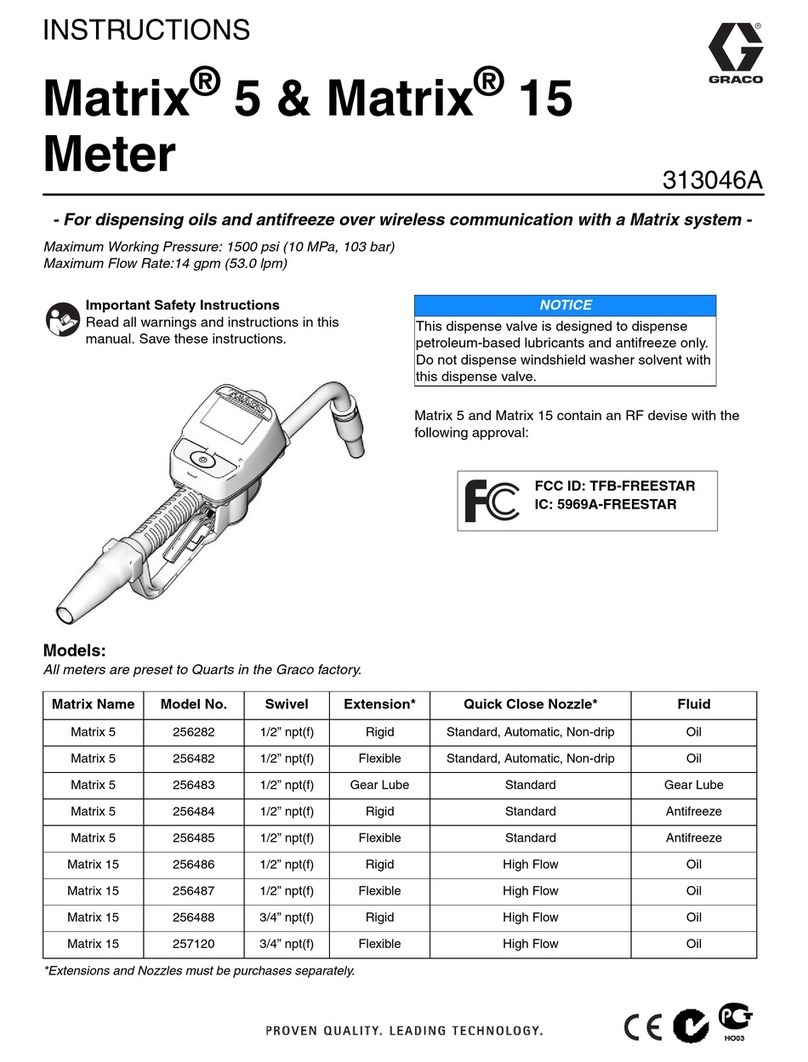

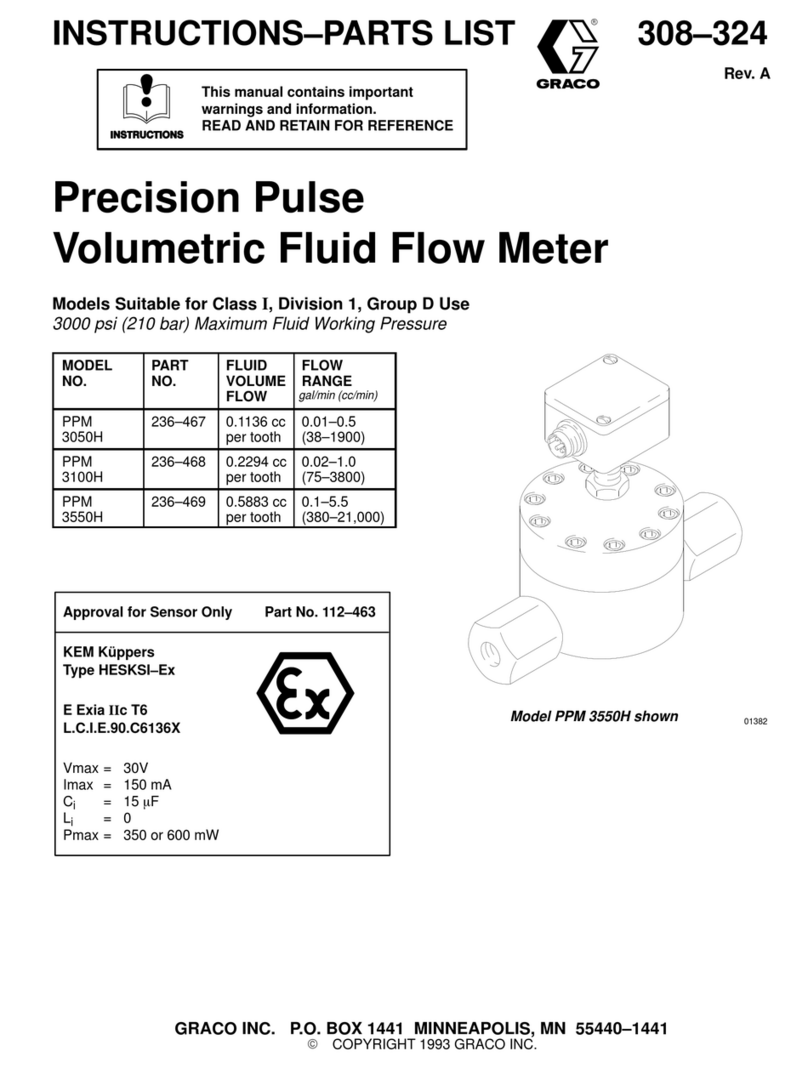

Pulse

Meters

47.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System

Cables

48.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Relief Kit

50.

. . . . . . . . . . . . . . . . . . . . . . . .

Fluid

Check V

alve 50.

. . . . . . . . . . . . . . . . . . . . . . . .

40

Column Thermal Printer

50.

. . . . . . . . . . . . . . . .

Appendix

Horizon

Software Features

52.

. . . . . . . . . . . . . . . . . . .

System Configuration 53.

. . . . . . . . . . . . . . . . . . . . . . .

Installation

Considerations

53.

. . . . . . . . . . . . . . . . .

Steps

For Configuring A System

53.

. . . . . . . . . . . .

System

Design Suggestions

53.

. . . . . . . . . . . . . . .

System

Configuration Examples

54.

. . . . . . . . . . . .

Horizon

Forms #1–6

(Guide to Initial Setup)

56.

System

Dynamics And Design Factors

67.

. . . . . . .

Pressure

Relief Kit

67.

. . . . . . . . . . . . . . . . . . . . . . . .

Dispense

Fluid During System Failure

67.

. . . . . . .

Avoiding

Pulsation

69.

. . . . . . . . . . . . . . . . . . . . . . . .

Selecting

a Supply Pump

69.

. . . . . . . . . . . . . . . . . .

Technical

Data

70.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

W

arranty and Limitation of Liability 72.

. . . .

Graco

Phone Number

72.

. . . . . . . . . . . . . . . . . . . . . . .

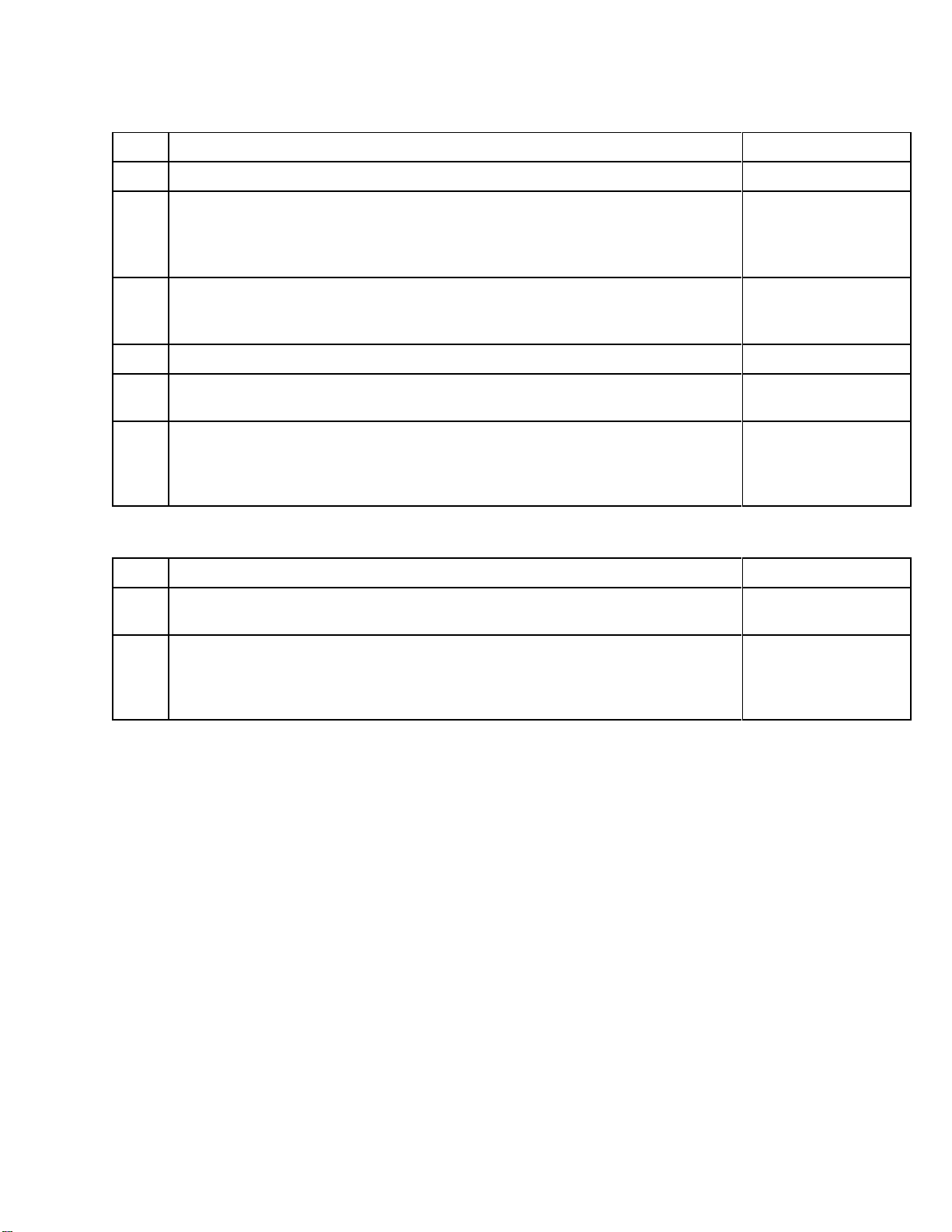

Terms

CAN:

Controller Area Network; network that

interconnects the control modules in the system.

Dispense Point:

The combined designation of the

dispense area and fluid number

.

Fluid Zone:

The groups of reels that share a pulse

meter.

Keypad:

Hand-held device with display screen and

keys that communicates with the control module it is

connected to.

Master Control Module:

In addition to the functions of

a

Slave Control Module

, it controls activity over the

CAN

, has additional memory

, provides printer or

computer interface, and continuously tracks the time

and date.

Non-volatile Memory:

Data is retained when the

power is shut of

f.

Simultaneous Dispensing:

The ability for more than

one hose reel in the Horizon system to be dispensing

fluid at the same time. The Horizon allows up to 12

dispenses to take place at a time.

Slave Control Module:

Drives air and fluid solenoids

and counts pulses of the meters that are connected

to it.