Skyteam SKYMAX ST126-6 Instruction manual

ST125-6

E4

approved

:

WORKSHOP

MANUAL

m

n

PREFACE

ST125-6

This

workshop

man al

is

to

s pply

the

reference

and

help

for

the

correct

maintenance

and

repair

of

SKYTEAM

SKYMAX

ST125-6

MODEL.

ST125-6

hkmmni

SKYTEAM

SKYMAX

ST125-6

MODEL

can

s it

the

general

needs

of

the

motorcycle

sers,

so

the

mechanics

sho ld

read

and

st dy

this

man al

caref lly

before

processing

the

maintenance

or

repair.

If

the

information

on

this

workshop

man al

is

different

from

the

ser's

man al,

please

take

this

workshop

man al

as

standard.

^Ti^l

CONTENT

GUIDE

2

PART

2

REGULAR

MAINTENANCE

AND

CHECK

3

PARTS

ENGINE

REPAIR

mmut:

4

PART

4

ELECTRICAL

SYSTEM

PART

5

EFI

SYSTEM

5

sa

*

;

MMœièmm 6

*

:

J

J

PART

6

FUEL

SUPPLY

SYSTEM

1

PART

1

GENERAL

INFORMATION

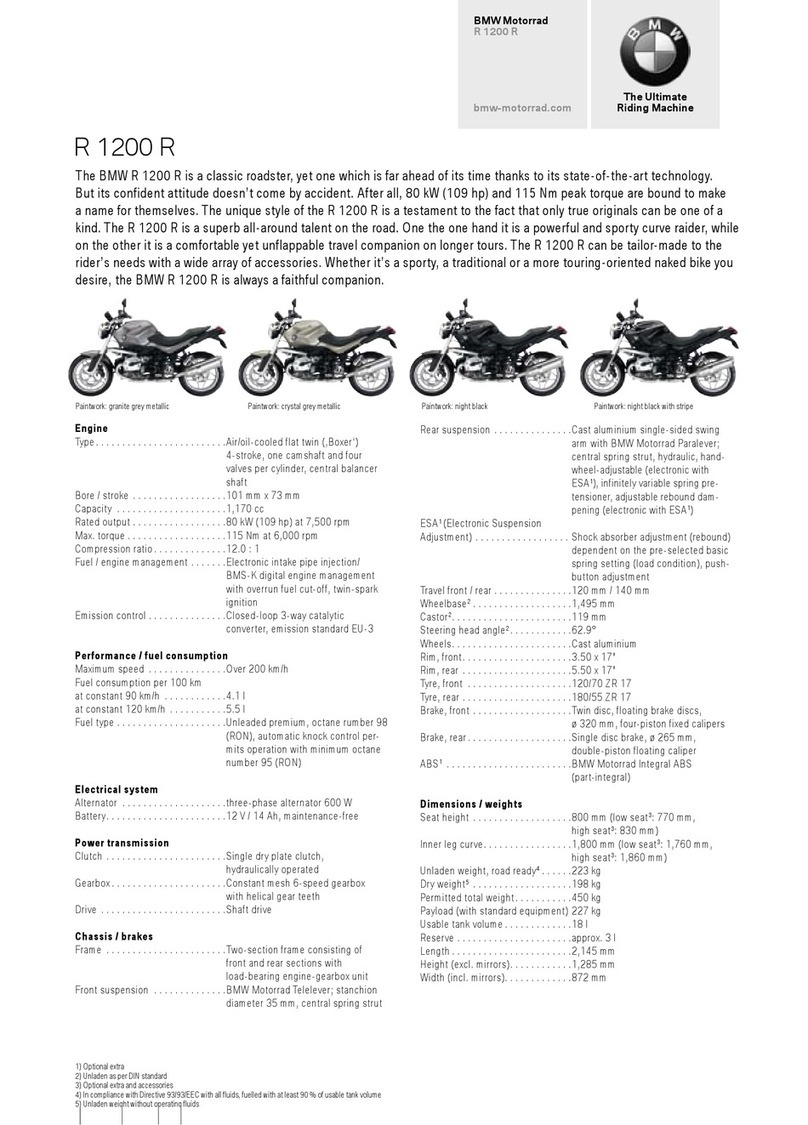

VEHICLE

APPEARANCE

1-1

VIN

NUMBER

POSITION

1-2

RECOMMENDED

FUEL

AND

MACHINE

OILTYPE...1

-3

PARAMETER

1-4

GENERAL

INFORMATION

1-1

ST125-6^hH

APPEARANCE

Rear

Carrier

Speedometer

Headlamp -Tail

Lamp

■Rear

Wheel

Front

Wheel

Engine

Handlebar

iew

Mirror

M ffler

Comp

Shock

Absorber,

Front

Rear

Shock

Absorber-

Brake

Rod

W

l

GENERAL

INFORMATION

1-2

■

\

.

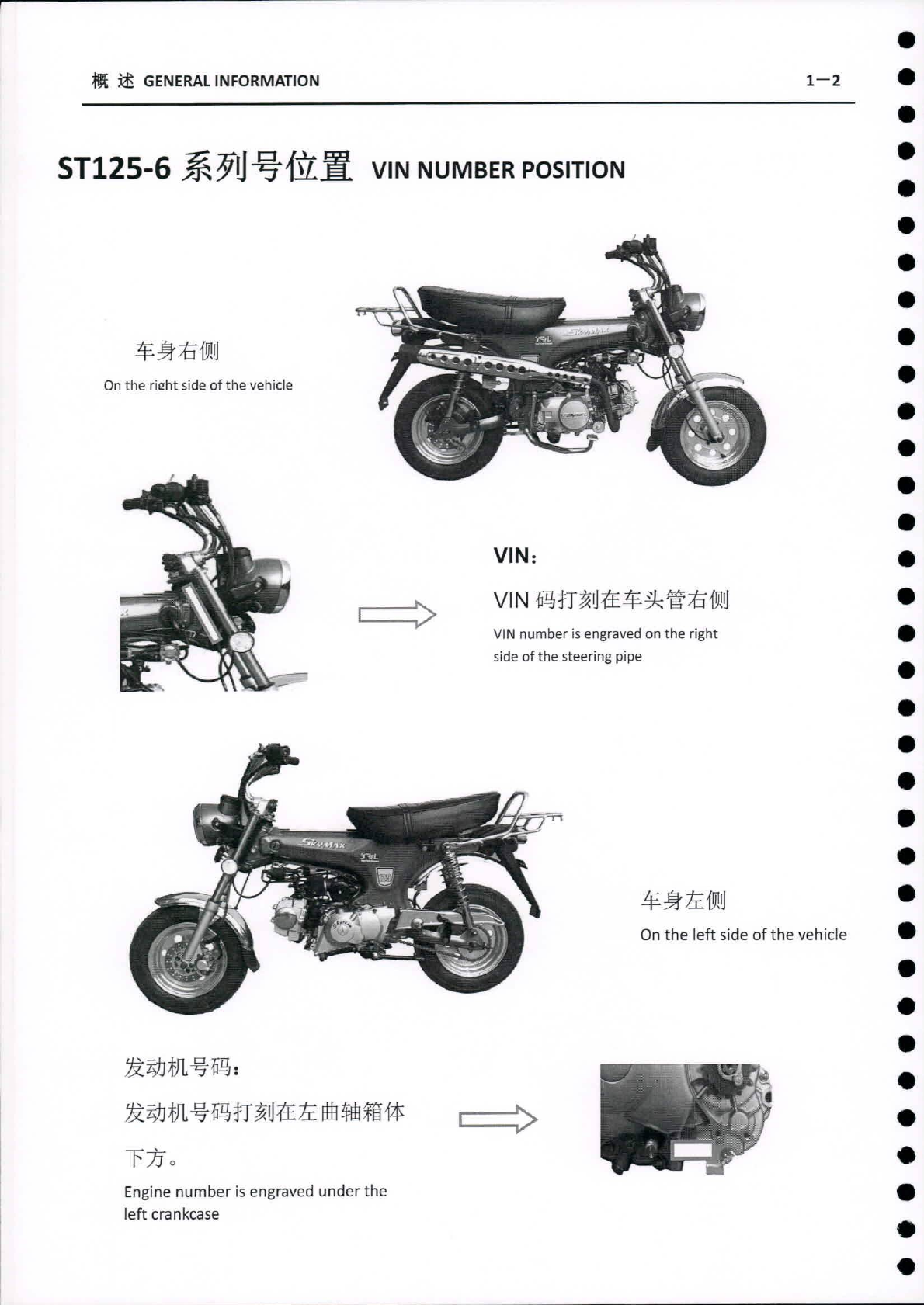

ST125-6

\r

VIN

NUMBER

POSITION

On

the

rieht

side

of

the

vehicle

VIN:

vin

>

[

VIN

n mber

is

engraved

on

the

right

side

of

the

steering

pipe

On

the

left

side

of

the

vehicle

>

T^o

Engine

n mber

is

engraved

nder

the

left

crankcase

H

3^

GENERAL

INFORMATION

1-3

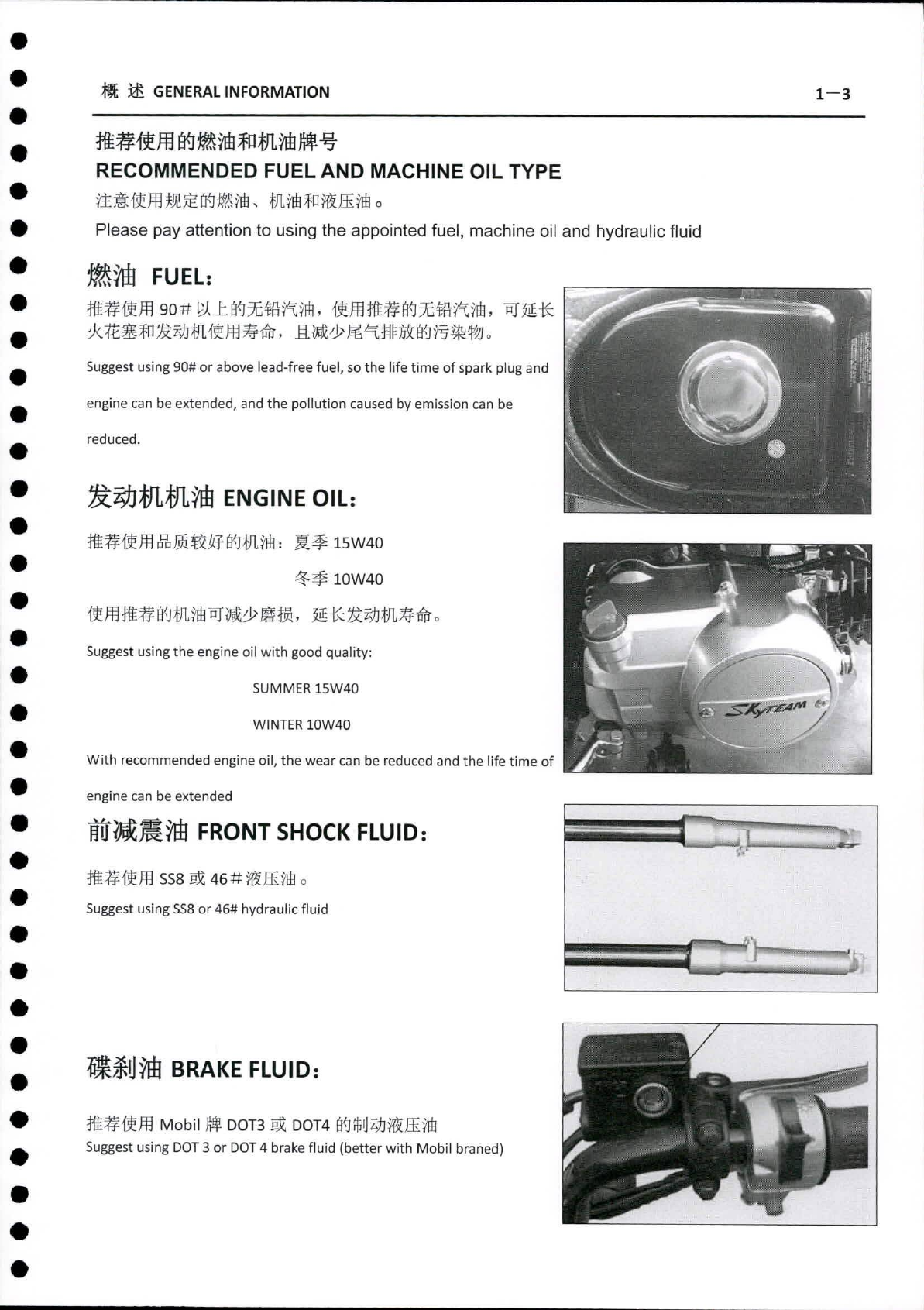

RECOMMENDED

FUEL

AND

MACHINE

OIL

TYPE

Please

pay

attention

to

sing

the

appointed

f el,

machine

oil

and

hydra lic

fl id

M

FUEL:

S ggest

sing

90#

or

above

lead-free

f el,

so

the

life

time

of

spark

pl g

and

engine

can

be

exten e ,

an

the

pollution

cause

by

emission

can

be

red ced.

ENGINE

OIL:

mmm&mmmm:

M^i5W4o

^

10W40

Suggest

using

the

engine

oil

with

goo

quality:

SUMMER

15W40

WINTER

10W40

With

recommended

engine

oil,

the

wear

can

be

red ced

and

the

life

time

of

engine

can

be

exten e

BUMMîÆ

FRONT

SHOCK

FLUID:

SS8

«£

46

#

m&'tâ

o

S ggest

sing

SS8

or

46#

hydra lic fl id

îfiljÿÈ

BRAKE

FLUID:

Mobil

J#

DOTS

Si

DOT4

ËlîM^jïïlii

S ggest

sing

DOT

3

or

DOT

4

brake

fl id

(better

with

Mobil

braned)

SE

GENERAL

INFORMATION

1-4

ST125-6^#it

PARAMETER

SIZE

AND

WEIGHT:

±S#SSC

MAIN

PARAMETER:

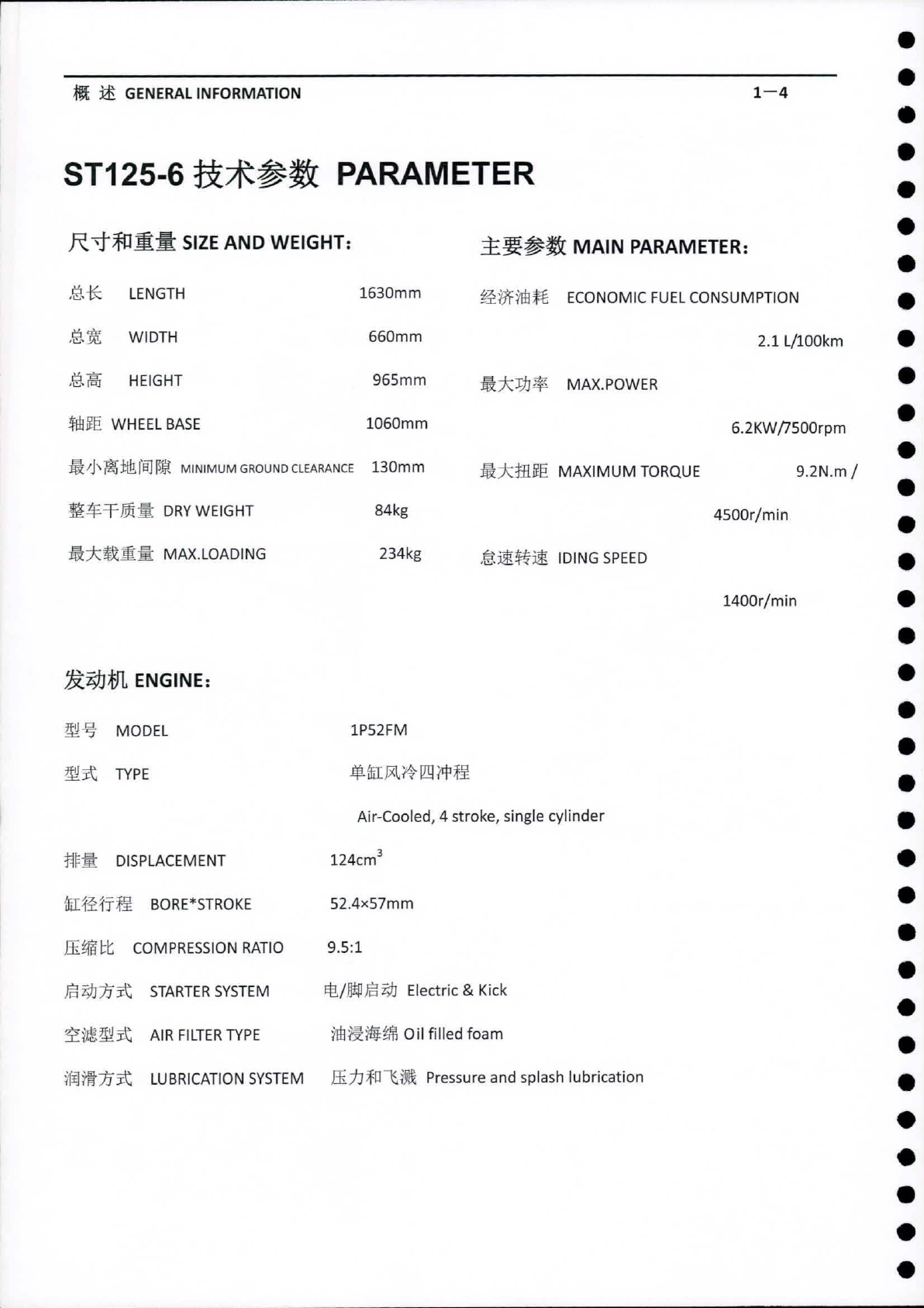

LENGTH

1630mm

ECONOMIC

FUEL

CONSUMPTION

WIDTH

660mm

2.1

L/l

00

km

HEIGHT

965mm

MAX.POWER

WHEELBASE

1060mm

6.2KW/7500rpm

MINIMUM

GROUND

CLEARANCE

130mm

MAXIMUM

TORQUE

9.2N.m

/

DRY

WEIGHT

84kg

4500r/min

234kg

MAX.LOADING

IDING

SPEED

1400r/min

ENGINE:

MODEL 1P52FM

Sït

TYPE

Air-Cooled,

4

stroke,

single

cylinder

124cm

3

W

DISPLACEMENT

fcLfèMï

BORE*STROKE

52.4x57mm

BUfâtt

COMPRESSION

RATIO

9.5:1

%/f$P/nAÙ

Electric

&

Kick

STARTER

SYSTEM

Oil

filled

foam

AIR

FILTER

TYPE

LUBRICATION

SYSTEM

Press re

and

splash

l brication

$E

&

GENERAL

INFORMATION

1-5

ELECTRICAL

SYSTEM:

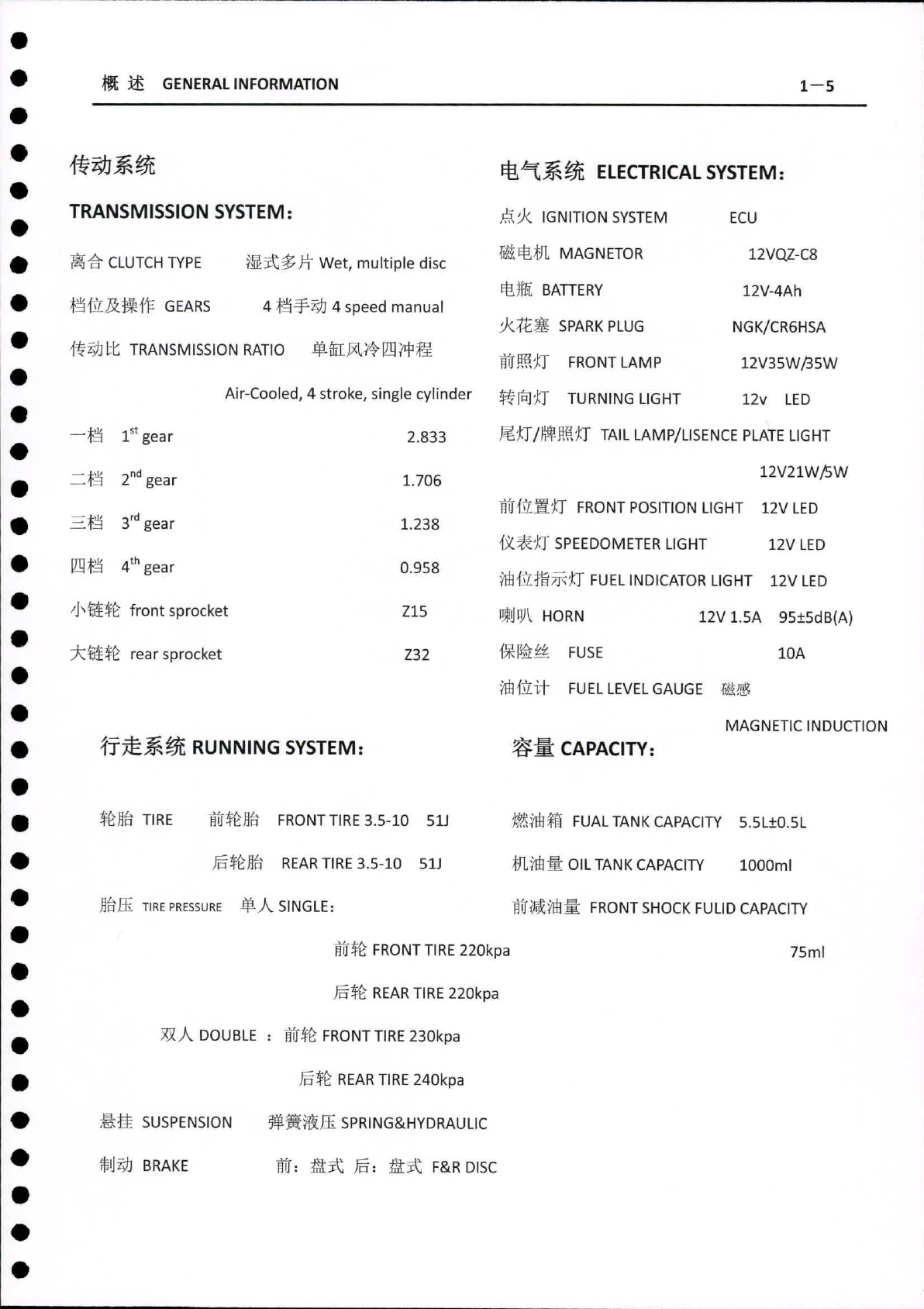

TRANSMISSION

SYSTEM:

IGNITION

SYSTEM

ECU

MAGNETOR 12VQZ-C8

CLUTCH

TYPE

Wet,

m ltiple

dise

BATTERY

12V-4AH

GEARS

4

4

speed

man al J

KVcU

SPARKPLUG

NGK/CR6HSA

'ffAÜtk

TRANSMISSION

RATIO

lüM'j:!

FRONT

LAMP

TURNING

LIGHT

®T/J$PI'J:T

TAIL

LAMP/LISENCE

PLATE

LIGHT

12V35W/35W

Air-Cooled,

4

stroke,

single

cylinder

12v

LED

1

st

gear 2.833

12V21W/5W

ItlfÈfi'j:!

FRONT

POSITION

LIGHT

12V

LED

SPEEDOMETER

LIGHT

fuel

indicator

light

12V

led

2

nd

gear

1.706

jnfê

3

rd

gear

1.238

12V

LED

4

th

gear

mm

0.958

front

sprocket

Z15

ii]nA

HORN

12V

1.5A

95±5dB(A)

FUSE

yÉIÈit

FUEL

LEVEL

GAUGE

mm

rear

sprocket

10A

Z32

MAGNETIC

INDUCTION

RUNNING

SYSTEM:

CAPACITY:

fèlp

TIRE

fjMn

FRONTTIRE

3.5-10

51J

FUAL

TANK

CAPACITY

5.5L±0.5L

REAR

TIRE

3.5-10

51J

OIL

TANK

CAPACITY

1000ml

Ipffi

TIRE

PRESSURE

ip-A

SINGLE:

FRONT

SHOCK

FULID

CAPACITY

itM

FRONT

TIRE

220kpa

75ml

REAR

TIRE

220kpa

MA.

DOUBLE

:

iiffÈ

FRONTTIRE

230kpa

REAR

TIRE

240kpa

Mm

SUSPENSION

#

if

SPRING&HYDRAULIC

fljsj]

BRAKE

fj:

/5:

F&R

DISC

2

PART

2

REGULAR

MAINTENANCE

AND

CHECK

BREAKING-IN

PERIOD

AND

MAINTENANCE

PERIOD..

.2-1

maintenance

and

ADJUSTING

PROCESS..

.2-2

ENGINE

MACHINE

OIL

2-2

AIL

FILTER

2-3

CLUTCH

2-4

SPARK

PLUG

2-5

DRIVE

CHAIN

2-6

mà

TIRE

2-7

STEERING

SYSTEM

2-8

FASTNERS

2-8

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-1

REAKING-IN

PERIOD

AND

MAINTANENCE

PERIOD

ll'nlfj

REAKING-IN

PERIOD:

•

ST125-6

1000km;

1000km

for

125-6

•

300km

&

1000km

Need

to

change

the

machine

oil

at

300km

and

1000km

within

the

breaking-in

period

;

The

max.

speed

cannot

be

over

60km/h

d ring

the

breaking-in

period,

f ll

throttle

is

not

allowed.

MAINTENANCE

INTERVALS:

.

$

1000km

^

6

The

vehicle

sho ld

be

maintained

every

1000km

or

6

months,

take

the

earlier

one

as

the

standard

ÆSBÆIrMfflïï

REGULAR

MAINTANENCE

PERIOD

CHART

SC

#

PARTS

1000km

3000km 5000km

lOOOOkn

Ml

W

PERIOD

f/UÉ

ENGINE

OIL CHANGE

—

tÇ-Wk

2

TIMES

EVERY

YEAR

Sill

AIR

FILTER

CLEAN

M'iii

FUEL

FILTER

--Mm

CHANGE

CLUTCH

ADJUST

‘

kVcU

SPARKPLUG

Min

CHECK,

CLEAN

fèit

CHECK

CHECK

Mm

CHANGE

FUEL

HOSE

2

¥Mm-ft

CHANGE

EVERY

2

YEARS

TRANSMISSION

CHAIN

iüS

ADJUST

ffl

LUBRICATE

îèün'

TIRE

fèg

CHECK

3¥Mm-&

CHANGE

EVERY

3

YEARS

I^f/lf^I

STEERING

SYSTEM

IÈS.

SS

CHECK,

ADJUST

VEHICLE

FASTNERS

iMfê

CHECK,

ADJUST

fig

CHECK

BRAKE

FLUID

2

CHANGE

EVERY

2

YEARS

f5$l]Z>]$$

REAR

BRAKE

fèg.

iflg

CHECK,

ADJUST

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2

—

2

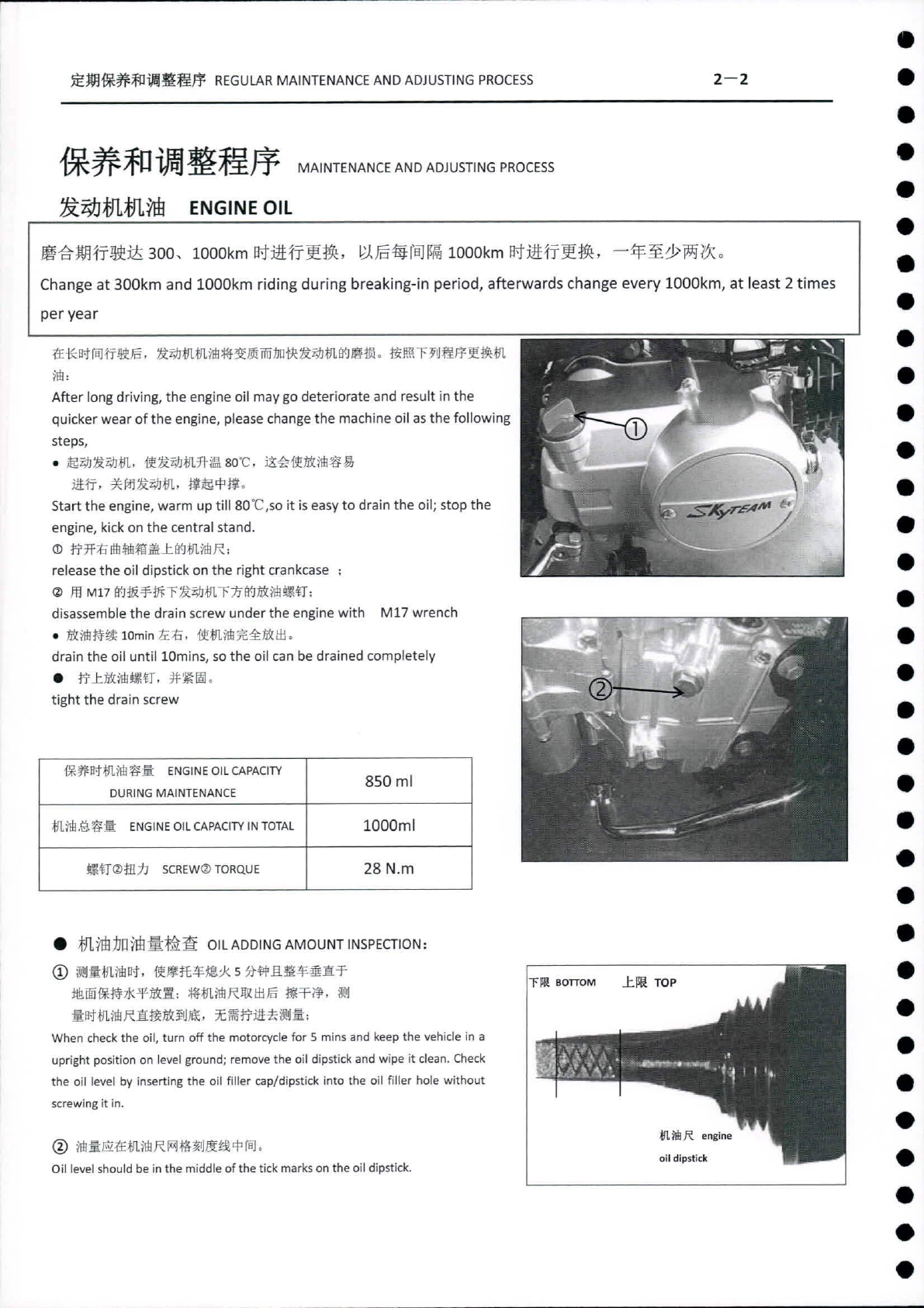

ENGINE

OIL

MAINTENANCE

AND

ADJUSTING

PROCESS

300,

1000km

1000km

Change

at

300km

and

1000km

riding

d ring

breaking-in

period,

afterwards

change

every

1000km,

at

least

2

times

per

year

S-feBTfgJtriiJg,

>4

After

long

driving,

the

engine

oil

may

go

deteriorate

and

res lt

in

the

q icker wear

of

the

engine,

please

change

the

machine

oil

as

the

following

steps,

Start

the

engine,

warm

p

till

80°C,so

it

is

easy

to

drain

the

oil;

stop

the

engine,

kick

on

the

central

stand.

©

ff?F£MM±lftÜltàR;

release

the

oil

dipstick

on

the

right

crankcase

;

®

ffl

Mi?

disassemble

the

drain

screw

nder

the

engine

with

M17

wrench

•

10min

drain

the

oil

ntil

lOmins,

so

the

oil

can

be

drained

completely

tight

the

drain

screw

ENGINE

OIL

CAPACITY

DURING

MAINTENANCE

850

ml

1000ml

ENGINE

OIL

CAPACITY

IN

TOTAL

28

N.m

SCREW©

TORQUE

•

tAyÉ^CI'/Èmltê

OIL

ADDING

AMOUNT

INSPECTION:

When

check

the

oil,

t rn

off

the

motorcycle

for

5

mins

and

keep

the

vehicle

in

a

pright

position

on

level

gro nd;

remove

the

oil

dipstick

and

wipe

it

clean.

Check

the

oil

level

by

inserting

the

oil

filler

cap/dipstick

into the

oil

filler

hole

witho t

screwing

it

in.

(2)

Oil

level

sho ld

be

in

the

middle

of

the

tick

marks

on

the

oil

dipstick.

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-3

air

filter

§

3000km

Check

and

clean

every

3000km

If

the

air

filter

is

st ck

by

the

d st,

then

the

resistance

of

air

inlet

will

be

increased,

which

will

res lt

in

low

o tp t

power,

increased

f el

cons mption

and

air

poll tion.

im-FWj&fa&xm'mm*

Please

check

and

clean

the

parts

as

follows,

Loosen

the

screw

of

the

air

filter

clip,

remove

the

air

filter

•

fôJFSMiiï,

Loosen

the

screw,

and

remove

the

air

filter

cover

(D

a

.

Fill

the

incomb stible

detergent

A

in

the

washing

plate

Immerse

the

foam

filter

core

in

the

detergent

and

wash

Press

the

foam

filter

core

by

the

two

palms

instead

of

twisting,

otherwise,

the

filter

core

will

be

damaged

(3)

+

o

Immerse

the

filter

core

in

the

engine

oil

(D

EEtjmCTMM.

Press

the

engine

oil

from

the

filter

core,

and

keep

the

core

slightly

wet

with

oily

WARNING:

After

washing,

please

check

whether

the

filter

core

is

broken

or

cracked,

if

so,

please

change

the

filter

core.

Fix

the

filter

core

correctly,

so

the

air

can

go

thro gh

the

filter

core,

and

the

d st

will

not

enter

the

cylinder

to

q icken

the

wear

of

the

piston

and

cylinder.

Throttle

Cable

adj stment

ÿénm&w

i~2mm

w

g

èm

,

T^îéüiïïÉn^^Mri]i®.

l-2mm

free

play

sho ld

be

kept

for

throttle

cable,

please

adj st

the

cable

free

play

as

follows:

•

fèlêÉI'àMl::

Check

the

free

play

by

rotating

the

throttle

grip

slightly

Loosen

the

locking

n t©,

and

t rn

the

adj sting

n t

©

inwards

or

o twards

ntil

get

a

s itable

free

play

•

mmmm,

@

æ

««©=

Keep

the

position

of

the

adj ster,

and

fix

the

locking

n t

©

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2

—

4

ï^-ê-3£

CLUTCH

^

5000km

CHECK

EVERY

5000KM

AND

ADJUST

•

remove

the

cl tch

cover;

•

3mm

£

T

j

;

Loosen

the

cl tch

adj ster

lock

n t

on

the

cl tch

cable(î),

t rn

the

adj sting

n t(?)

ntil

the

adj ster

screw

at

aro nd

3mm

V4~V2ffl;

Loosen

the

cl tch

lock

n t®,

t rn

the

adj sting

bolt

®

ntil

resistance

is

felt

by

flat-blade

screw

driver,

then

loosen

l/4~J/2

t rn

•

tighten

the

locking

n t®

Fix

the

free

play

of

the

cl tch

lever

to

3mm

by

the

adj ster

on

the

cl tch

cable

Tighten

the

adj ster

lock

n t

on

the

cl tch

cable

^1:

WARNING:

If

there

is

no

free

play

of

the

cl tch,

then

the

cl tch

may

separate

slightly,

which

will

res lt

in

the

q icker

wear

of

the

cl tch,

even

b rning

the

cl tch

plate,

and

conseq ently

decrease

the

power

and

increase

the

f el

cons mption

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-5

SPARKPLUG

M

10000km

Check,

adj st

and

change

every

10000km

tern.

mmpikttm&m,

If

ignore

the

spark

pl g,

the

vehicle

will

be

diffic lt

to

get

started

and

perform

badly.

After

sing

the

spark

pl g

for

some

while,

the

electrodes

will

be

b rned

grad ally

and

th s

prod ce

the

carbon

inside.

According

to

the

reg lar

check

list,

the

spark

pl g

sho ld

be

removed,

inspected,

washed

and

adj sted(clearance).

K'X

The

carbon

inside

can

stop

the

good

spark,

and

res lt

in

bad

ignition

or

b rning,

so

please

clean

the

carbon

reg larly

Mo

If

the

electrodes

in

the

middle

are

damaged

badly,

please

change

the

spark

pl g,

and

se

the

depth

r ler

to

adj st

the

clearance

correctly

:

NGK

CR6HSA

SPARK

PLUG

'Xi mm

0.6~0.7mm

SPARK

PLUG

CLERANCE

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-6

DRIVE

CHAIN

#

1000km

CHECK

EVERY

1000KM

AND

ADJUST

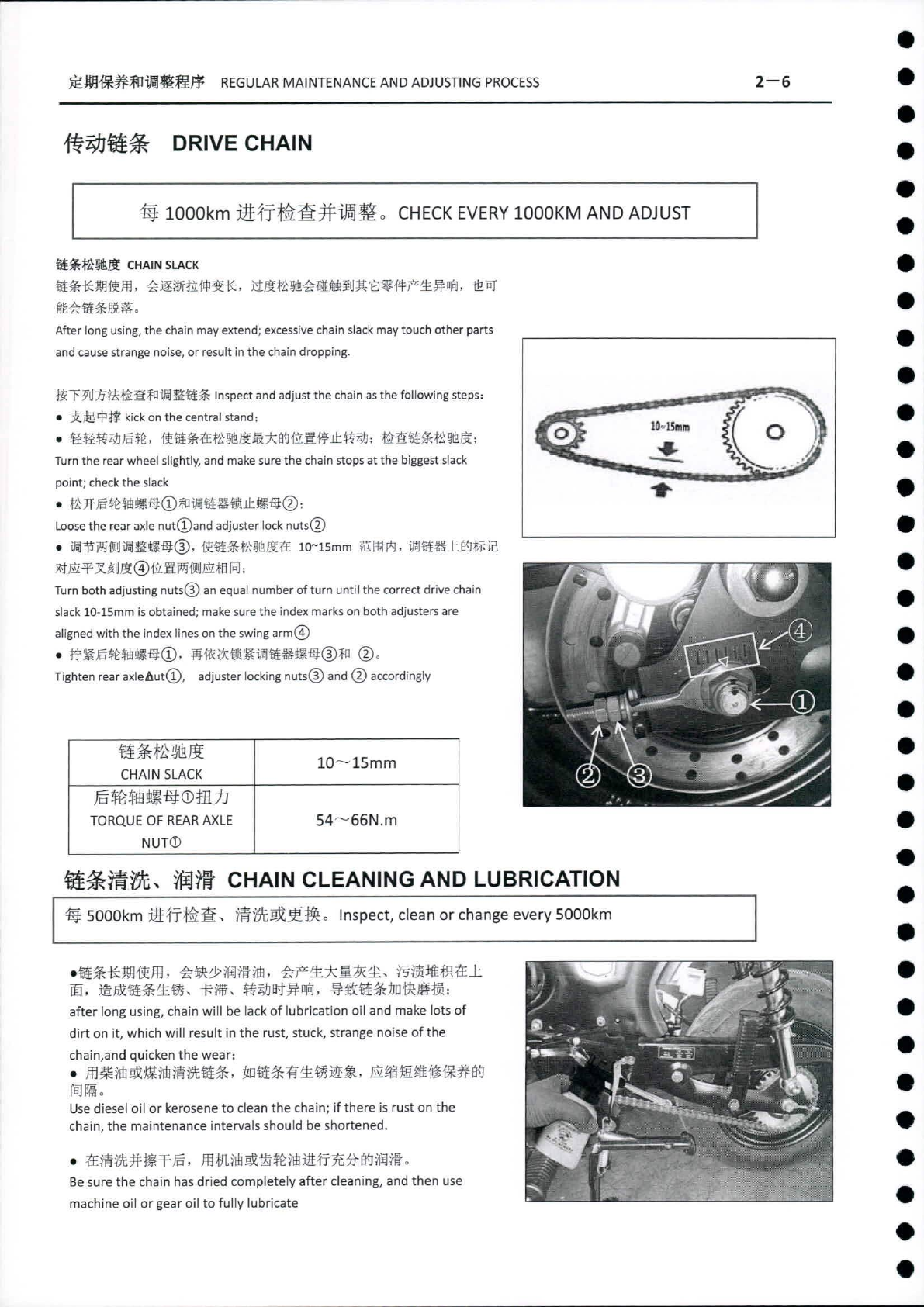

CHAIN

SLACK

After

long

sing,

the

chain

may

extend;

excessive

chain

slack

may

to ch

other

parts

and

ca se

strange

noise,

or

res lt

in

the

chain

dropping.

Inspect

and

adj st

the

chain

as

the

following

steps

•

jtîë'T'J#

kick

on

the

central

stand:

T rn

the

rear

wheel

slightly,

and

make

s re

the

chain

stops

at

the

biggest

slack

point;

check

the

slack

Loose

the

rear

axle

n t(T)and

adj ster

lock

n ts@

•

«MMÆ

10~15mm

îÊiart.

2T

|11

:

T rn

both

adj sting

n ts®

an

eq al

n mber

of

t rn

ntil

the

correct

drive

chain

slack

10-15mm

is

obtained;

make

s re

the

index

marks

on

both

adj sters

are

aligned

with

the

index

lines

on

the

swing

arm®

Tighten

rear

axle

A t®,

adj ster

locking

n ts®

and

@

accordingly

CHAIN

SLACK

10~15mm

54—

66N.m

TORQUE

OF

REAR

AXLE

NUT©

fê&?#î5fc.

'MW

CHAIN

CLEANING

AND

LUBRICATION

^

5000km

Inspect,

clean

or

change

every

5000km

after

long

sing,

chain

will

be

lack

of

l brication

oil

and

make

lots

of

dirt

on

it,

which

will

res lt

in

the

r st,

st ck,

strange

noise

of

the

chain,and

q icken

the

wear;

IS]

n.

Use

diesel

oil

or

kerosene

to

clean

the

chain;

if

there

is

r st

on

the

chain,

the

maintenance

intervals

sho ld

be

shortened.

Be

s re

the

chain

has

dried

completely

after

cleaning,

and

then

se

machine

oil

or

gear

oil

to

f lly

l bricate

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-7

WARNING:

As

the

photo

shows,

install

the

circlip

so

that

its

open

end

is

opposite

the

normal

rotation

of

the

chain.

chain

dr

dtp

0

0

0

0

check

whether

the

chain

sho ld

be

changed

according

to

the

following

steps:

moving

chirwtwn

fix

the

chain

on

the

flatform,

and

make

s re

the

chain

is

aligned;

,

mB-tRmm. mfà&jË,

Saji

259.0mm,

o

Check

the

length

of

the

21

rolling

balls(eq al

to

20

links)

by

the

vernier

caliper,

if

the

length

is

over

259.0mm,

then

the

chain

sho ld

be

replaced

123

19

20

21

'«

«I»

cje

ojc

aye

oJa

ela

aX°

<>

Tt

0

«X

m,

71

If

the

chain

is

with

distorted

or

damaged

rolling

balls,

or

r sty

badly,

or

st ck

by

several

links,

over

worn,

then

it

sho ld

be

replaced.

lâ

TIRES

'at

5000km

Mr

CHECK

EVERY

5000KM

If

se

over

worn

tire,

the

driving

stability

will

be

red ce,

and

res lt

in

dangero s

driving

œ

If

the

tire

press re

is

too

high

or

too

low,

the

steering

system

will

be

infl enced

badly,

and

the

tire

will

be

also

worn

more

q ickly;

Therefore,

we

sho ld

keep

the

correct

tire

press re

to

ens re

the

stability

and

safety

of

the

driving.

,

fSMI&fèJjp

Please

change

the

tire

if

any

of

the

following

sit ation

happens:

the

depth

of

the

tire

thread

is

below

the

limit;

2.fèIpjPJjMW

crack

at

the

side

of

the

tire,-

B.fèlp^'Ë.

b mp

on

the

tire;

3

^

the

inner

t be

has

been

repaired

for

3

times;

S.fèljpflîfflÆiÜ'

3

^

the

tire

has

been

sed

for

more

than

3

years,,

BUffcjjn

FRONT

TIRE

1.6

mm

ÆîfkHn

REAR

TIRE

2.0

mm

fèln^Ëfê-

TIRE

SIZE

3.50-10

ÜZfc^fc^Ji

MAX.

LOADING

PRESSURE

250kpa

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2

—

8

STEERING

SYSTEM

^

5000km

10000km

jatTV^Vto

Check

every

5000km,

and

l bricate

every

10000km

To

handle

easily

and

drive

safely,

the

steering

system

sho ld

be

adj sted

correctly.

Check

req irement:

the

front

fork

is

tightened

correctly,

and

the

steering

moves

freely

from

side

to

side.

Check

method:

kick

on

the

central

stand,

grab

the

lower

part

of

the

front

shock

absorber,

and

then

move

front

and

rear,

to

check

whether

it's

loose.

•

ijfiETjvi

Adj sting

steps

Loosen

the

steering

head

n t(T)

and

the

steering

stem

bolt(2)

Use

professional

wrench(3)

to

tight

the

steering

stem

self-lock

n t(4)

Then

tighten

the

n t(T)

and

steering

stem

bolt(2)

in

seq ence.

Tighten

the

bolt

to

the

following

torq e

val e,

N t®

81

—

99

N.m

Steering

stem

bolt©

22.5

—

27.5

N.m

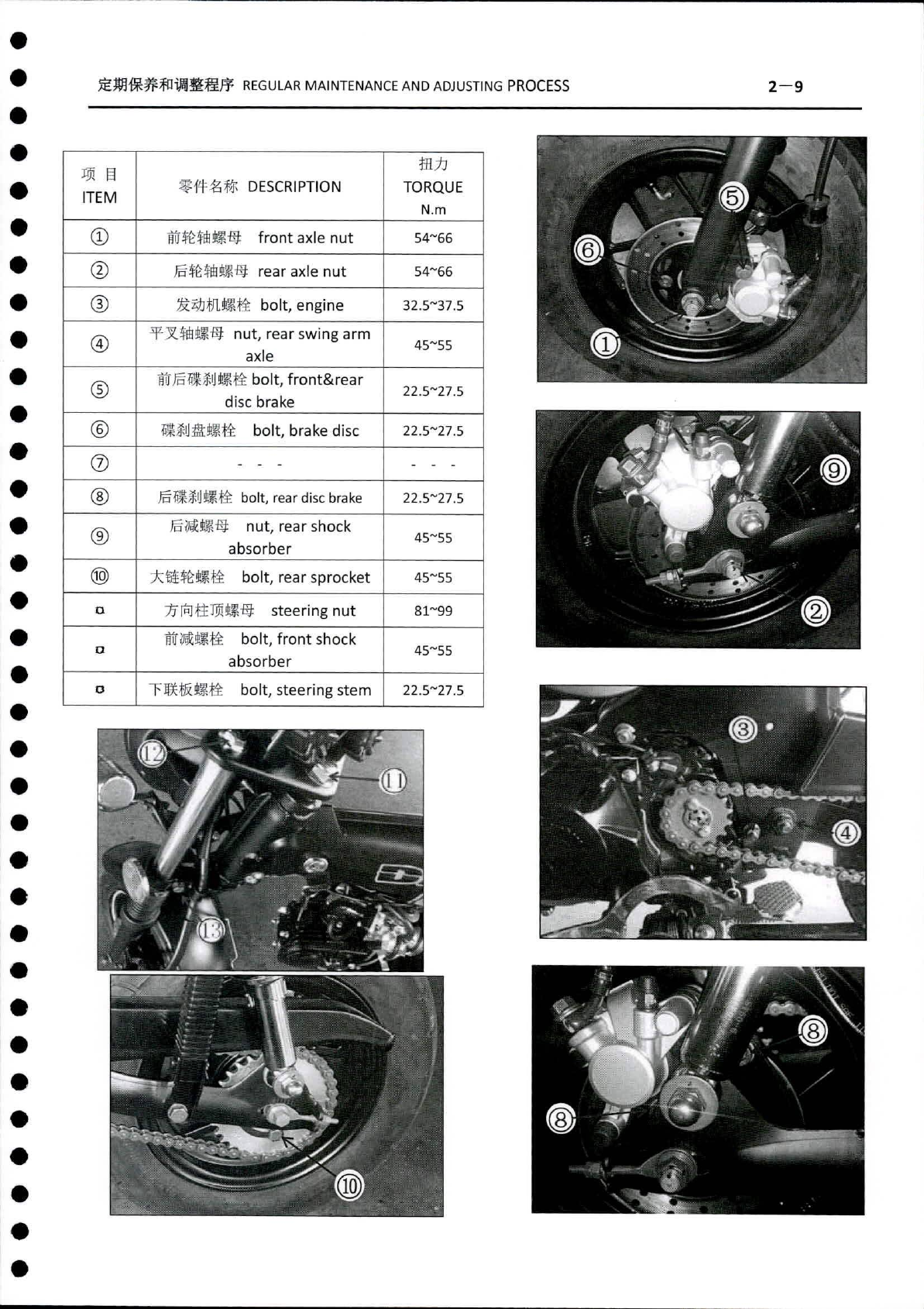

FASTENERS

5000km

Check

and

tighten

every

5000km

The

following

bolts

and

n ts

are

the

fasteners

for

important

parts;

to

ens re

the

driving

safety,

they

sho ld

be

tightened

and

properly

sec red.

Sho ld

se

the

torq e

wrench

and

tight

to

the

correct

torq e

val e.

REGULAR

MAINTENANCE

AND

ADJUSTING

PROCESS

2-9

^

S

DESCRIPTION

TORQUE

ITEM

N.m

front

axle

n t

54~66

©

rear

axle

n t

54-66

©

fèz&fcniifè

bolt,

engine

32.5-37.5

n t,

rear

swing

arm

axle

45~55

bolt,

front&rear

disc

brake

©

22.5~27.5

©

bolt,

brake

disc

22.5-27.5

©

bolt,

rear

disc

brake

22.5~27.5

n t,

rear

shock

absorber

©

45~55

bolt,

rear

sprocket

45~55

Æ'iRlttlIlti#

steering

n t 8l~99

o

t iiiilfê

bolt,

front

shock

absorber

45~55

a

TSctMfê

bolt,

steering

stem

22.5~27.5

o

3

PARTS

ENGINE

ENGINE

OPERATION

PRINCIPLE

3-1

ENGINE

DISMANTLING

AND

ASSEMBLY

3-2

frMRM

ENGINE

PARTS

3-6

CYLINDER

HEAD

3-6

CYLINDER

3-14

ÆftSjfIMSP#

LEFT

CRANKCASE

COVER

3-19

RIGHT

CRANKCASE

COVER

3-24

CRANKCASE

3-31

Other Skyteam Motorcycle manuals