Skytech AFVK-SP Series User manual

Trouble Shooting Guide

for

AFVK-SP Series Valve Kit

(AF-4000 Series Gas Valves)

AFVK-SP, AFVK-SP-H/L, AFVK-SP-MH/L

fire-parts.com

Rev. 10/19/11

2

AFVK-SP Series Valve Kit

Trouble Shooting Guide (AF-4000 Series)

TABLE OF CONTENTS

General Information ……………………………………………………… 3

Fault Codes

Ignition Safety ……………………………………………………… 3

Sensor Safety ……………………………………………………….. 4

Thermal Safety ……………………………………………………... 4

Other Symptoms

Burner Flame Will Not Modulate Or Works Backwards ……..... 4

Flame Height Seems HI/LO ……………………………………….. 5

Module Does Not Have An Audible Beep Using Transmitter …... 5

Burner Does Not Light But Pilot Is “ON” ………………………... 6

Specifications

Main Gas Connections ……………………………………………... 6

Pilot Gas Connections & Flow …………………………………….. 6

Ambient Temperature Range ……………………………………… 6

Voltage ………………………………………………………………. 6

Approvals …………………………………………………………… 6

Maximum Pressure ………………………………………………… 6

Procedures For Qualified Technicians

Test Voltage To Gas Valve ………………………………………… 7

Test Resistance Of The Burner Coil At Gas Valve ……………… 7

Test Static And Operating Line Pressure ………………………... 7

fire-parts.com

Rev. 10/19/11

3

AFVK-SP Series Valve Kit

Trouble Shooting Guide (AF-4000 Series)

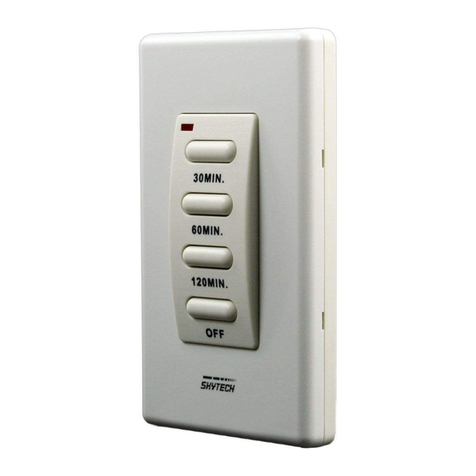

AFVK-SP –Manual ON/OFF switch, manual HI/LO flame adjustment & a ON, OFF transmitter

AFVK-SP-H/L – Manual ON/OFF switch, solenoid for HI/LO & a ON, OFF, HI, LO transmitter

AFVK-SP-MH/L –Manual ON/OFF switch, motor drive for variable flame adjustment & a ON, OFF, HI, LO

transmitter

Components that may be installed with Valve Kit:

Standard: Optional:

SP1001 ON, OFF, ON/OFF/Continuous Pilot AFVK-SP-PILOT/60 60” wire leads and pilot

SP1001 H/L ON, OFF, HI, LOW, ON/OFF/ Continuous Pilot tubing

AF-4000BP Battery Pack AF-4000ADP24 6 Volts DC Adapter

AF-4000MOD-1 Control Module (learns 3 transmitters)

In order to trouble shoot any product it is important to understand the basic operation

and functions of that product. The following information will assist you through this

process.

General Lighting Information

Lighting Procedure:

Pushing the ON button sends a radio frequency signal to the module. This sends power to the pilot assembly and the

sparking begins. The gas valve will open, sending gas to the pilot. Sparking stops after the sensor recognizes the

flame and burner ignition is complete. ON/OFF/Continuous Pilot allows you to activate the continuous pilot feature

and allows the use of a standing pilot.

Control Module (AF-4000MOD-1) “Brain” of the system; has built in fault codes:

The module, inside the valve box, controls the operation of the valve kit. If module detects a problem, it will begin

emitting a series of audible beeps (fault codes). The audible beeps indicate a fault and will assist in locating the

problem.

Fault Codes

Ignition Safety –1 beep every 1 second

Ignitor will not spark / Burner has not ignited within 60 seconds.

Check

•Gas is ON; line is purged of air and no blockage in the

pilot and main lines.

•Pilot assembly electrodes are clean, no soot build-up (clean

with steel wool if needed).

Check Wire Connections

•Pilot wires –“I” (Ignitor) and “S” (Sensor) wires connected

Igniter

“I”

Sensor

“S”

Fig. 1

fire-parts.com

Rev. 10/19/11

4

to module securely. (See Fig. 1)

•8-Pin Connector –orange/white wires to Pilot on valve

and green/white wires to Main on valve. Black wire (ground) to valve; Grounding is critical for

proper operation. (See Fig. 2)

Sensor Safety –4 beeps every second / constant beeping

Sensor detects a flame, but flame is not present. Will also occur if flame (S) sensor wire is shorted to ground.

Check

•Pilot flame is actually present when valve is turned OFF

(valve replacement necessary if yes).

•Flame sensor electrode is not touching burner pan, log

grate or pilot hood assembly.

•Flame sensor wiring is not worn, frayed, pinched or

damaged.

•Disconnect “S” wire from module and press “ON” on

transmitter.

•Is there a ticking sound at module? If Yes, module is

working as designed, check pilot assembly.

Check Pilot Assembly

•Pilot wires –“I“ (Ignitor) and “S” (Sensor) wires connected to module securely. (See Fig. 1)

•8-Pin –black (ground lead) to valve. (See Fig. 2)

•No splices to wires, cuts, crimps; these can cause shorts.

•Check spark gap at pilot assembly. Gap should be 3mm (1/8”) from hood to 1st spark electrode. Too close

will not spark, too far it will spark to the burner pan or log grate.

•Check the (white) ceramic insulators to make sure that there are no cracks at each spark electrode, if cracked,

replace pilot assembly.

•If No ticking sound, check battery voltage. Battery voltage should be a minimum of 5.3 volts DC in the

battery pack or if using a AF-4000ADP24 DC Adapter, a minimum 6.75 to maximum 8.25 volts DC. If

proper voltage is obtained, module needs to be replaced.

Thermal Safety –4 beeps every 2 seconds

Overheating –Internal module temperature exceeds 170 degrees F.

Check

•Control module must stay inside the valve box. Never move outside or other locations.

•If valve box is too close to burner, move to cooler location.

•If glass doors are installed they need to be fully opened during operation.

Other Symptoms

Burner Flame Will Not Modulate Or Works Backwards

Check

•Battery voltage should be a minimum of 5.3 volts DC in the battery pack and a minimum of 9.0 volts DC in

the transmitter.

•Red indicator light on transmitter illuminates when buttons are pressed.

•4-pin connector from module to battery pack is secure.

Fig. 1

Fig. 2

Ground screw on bottom of valve

fire-parts.com

Rev. 10/19/11

5

•Red and black wires from battery pack are connected to red and black wires on solenoid/motor. Black wire

should be on the outside and red wire should be on the inside on the terminal block. (Fig. 3)

•Battery pack is in the proper position.

oAFVK-SP-H/L should be in the latching solenoid

position

oAFVK-SP-MH/L should be in the DC motor drive

position.

Check Solenoid/Motor with a 9 volt battery

•Disconnect red and black wires from the solenoid/motor and

battery pack where they connect.

•Place one wire, from the solenoid/motor drive, on the (+)

terminal and one on the (–) terminal of the 9 volt battery. This

should adjust your flame either HI or LO.

•Reverse the wires and it should adjust the flame in the opposite direction. If this fails, the solenoid/motor

drive should be replaced.

Flame Height Seems HI/LO

IMPORTANT: Valve Kits are shipped Natural gas (NG) from

Skytech. If using LP gas, make sure that you have followed the LP

gas conversion procedure to convert from Natural (NG) to LP, before

checking the following:

Check

•Gas valve regulator is selected to proper gas being used.

Remove regulator cap located on the front of the valve.

Check to see if stem indicates proper gas type. If not, push

stem in and turn to proper gas type; replace cap. (See Fig. 4

thru 7)

•Use proper orifice for the correct type of gas being used. (Using a LP orifice while using NG gas

will cause low flame height; and using a NG orifice on LP will cause high flame and sooting).

•Low gas line pressure and blockage in the lines will affect the flame height. Contact a qualified gas

technician.

•Contact gas log manufacturer for proper burner specifications.

Module Does Not Have An Audible Beep When Using Transmitter

Check

•Battery voltage should be a minimum of 5.3 volts DC in the

battery pack and a minimum of 9.0 volts DC in the transmitter.

•Red indicator light on transmitter illuminates when buttons are

pressed.

•4-pin connector from module to battery pack is secure.

•Remote/Off switch on module is in the “Remote” position.

•Broken or frayed wires in and around box or burner assembly.

•To learn transmitter to module

oPress and immediately release the “Learn” button, on the module, you should hear an audible beep.

oIf you do not hear an audible beep, clear memory of the module. If you hear an audible beep,

continue.

Fig.

2

Fig 3

Natural Gas

Fig. 4

LP Gas

Fig. 5

fire-parts.com

Rev. 10/19/11

6

oPress and hold the “ON” button on the transmitter, you should hear a series of beeps, sparking should

occur, release the “ON” button.

•Clear memory of the module

oPress and hold the “Learn” button for 10 seconds, release;

you should hear 3 long beeps.

oPress and immediately release the “Learn” button again and

you should hear an audible beep.

oPress and hold the “ON” button on the transmitter, you

should hear a series of beeps, sparking should occur, release

the “ON” button.

Burner Does Not Light But Pilot Is “ON”

Check

•Transmitter should be within 20 -25 feet of the valve.

•Battery voltage should be a minimum of 5.3 volts DC in the battery

pack and a minimum of 9.0 volts DC in the transmitter.

•Can you turn the unit “ON” by the rocker switch on the front of the

valve box? Turn the Remote/Off switch on the valve box to the

“OFF” position. Push in (-) on the rocker switch. Does the burner

ignite?

•If Yes, the valve is working as designed manually. Turn Remote/Off

switch back to the “Remote” position. Relearn the transmitter to the module, by following the

steps to learn transmitter to module listed above.

•If No, and battery voltage is good in battery pack and transmitter relearns, check voltage on the main side of

the valve. (A qualified technician should do procedure).

Specifications

Main Gas Connections: Valve: 3/8 in. NPT thread on all Inlet and Outlet connections.

Optional: 1/2 in. NPT Side Inlet and Outlet

Pilot Gas Connections & Flow: Connection Size: 7/16-24 UNS.

Flow: ~ 5,250 Btu/hr at 7.0 in WC. Maximum.

Side & Back of valve

Ambient Temperature Range: 0 F to 175 F (-18 C to 79 C)

Voltage: 6 Volt DC Powered

Approvals: CSA International Report Number Valve: 224930-156330

Module: 224930-1998843

Maximum Pressure: 1 ⁄ 2 psi

For Technical Service Call:

U.S. Inquires

(888) 672-8929 or (260) 459-1703

Website: www.skytechsystem.com

Email: support@skytechsystem.com

Canadian Inquires: (877) 472-3923

LP Gas

Fig. 6

Natural Gas

Fig. 7

fire-parts.com

Rev. 10/19/11

7

Procedures For Qualified Technicians:

Test Voltage to Gas Valve:

•Using a multi-meter, set the test leads to VDC.

•Insert each test lead wire into the 2-pin connector on the gas

valve marked MAIN (green and white wires). (See Fig 10).

•Using the remote, turn unit on, immediately you should

see 6 VDC and then drop to 1.5 VDC. Follow the same

procedure with the 2-pin connector on gas valve marked

PILOT (orange and white wires). (See Fig. 7).

•If you do not get the 6 VDC volts, from the MAIN and PILOT,

the module should be replaced.

Test Resistance of the Burner Coil at Gas Valve:

This tests whether valve can open or close.

•Using a multi-meter, set the test leads to VDC.

•Remove the green/white 2-pin connector labeled MAIN from the gas

valve.

•Touch one lead from the volt meter to each pin on the valve. (See Fig. 8).

•Coil resistance should read 990 Ohms to 1230 Ohms.

•If resistance falls outside of these limits, the gas valve should be replaced.

Test Static and Operating Line Pressure:

Check static and operating line pressure, (should not see more than 2” water

column difference between static and operating). Static pressure is the gas pressure coming to the gas valve before the

valve is in operation.

Static Pressure: Natural Gas = 7.0” -12.0” -WC. & LP Gas 11.0” -14.0”WC.

Operating Pressure: Natural Gas = 4.7” WC. & LP = 10-14” WC.

Fig. 7

Fig. 8

fire-parts.com

This manual suits for next models

3

Table of contents

Other Skytech Control Unit manuals