HIMA HIMax X-SB 01 User manual

X-SB 01

HIMax®

System Bus Module

Manual

HI 801 007 E Rev. 4.00 (1117)

All HIMA products mentioned in this manual are protected by the HIMA trade-mark. Unless noted

otherwise, this also applies to other manufacturers and their respective products referred to herein.

All of the instructions and technical specifications in this manual have been written with great care and

effective quality assurance measures have been implemented to ensure their validity. For questions,

please contact HIMA directly. HIMA appreciates any suggestion on which information should be

included in the manual.

Equipment subject to change without notice. HIMA also reserves the right to modify the written material

without prior notice.

For further information, refer to the CD-ROM and our website http://www.hima.de and

http://www.hima.com.

© Copyright 2011, HIMA Paul Hildebrandt GmbH + Co KG

All rights reserved

Contact

HIMA Address

HIMA Paul Hildebrandt GmbH + Co KG

P.O. Box 1261

68777 Brühl, Germany

Phone: +49 6202 709-0

Fax: +49 6202 709-107

Type of Change

Revision

index

Revisions

technical editorial

4.00 New edition for SILworX V4 X X

X-SB 01 Table of Contents

HI 801 007 E Rev. 4.00 Page 3 of 38

Table of Contents

1Introduction ............................................................ 5

1.1 Structure and Use of this Manual......................................................................... 5

1.2 Target Audience..................................................................................................... 5

1.3 Formatting Conventions ....................................................................................... 6

1.3.1 Safety Notes ............................................................................................................ 6

1.3.2 Operating Tips ......................................................................................................... 7

2Safety...................................................................... 8

2.1 Intended Use .......................................................................................................... 8

2.1.1 Environmental Requirements................................................................................... 8

2.1.2 ESD Protective Measures........................................................................................ 8

2.2 Residual Risk ......................................................................................................... 9

2.3 Safety Precautions................................................................................................. 9

2.4 Emergency Information......................................................................................... 9

3Product Description .............................................. 10

3.1 Safety Function.................................................................................................... 10

3.1.1 Reaction in the Event of a Fault............................................................................. 10

3.2 Scope of Delivery................................................................................................. 10

3.3 Type Label ............................................................................................................ 11

3.4 Structure............................................................................................................... 12

3.4.1 Block Diagram........................................................................................................ 12

3.4.2 Safety-Related Processor System ......................................................................... 12

3.4.3 Interfaces ............................................................................................................... 13

3.4.4 Indicators ............................................................................................................... 14

3.4.5 Module Status Indicators ....................................................................................... 15

3.4.6 Redundancy Indicators .......................................................................................... 16

3.4.7 Rack Connection Indicators................................................................................... 16

3.4.8 Slot Indicators ........................................................................................................ 17

3.4.9 Diagnostic Indicators.............................................................................................. 17

3.4.10 Ethernet Indicators................................................................................................. 17

3.5 Product Data......................................................................................................... 18

3.6 Connector Boards................................................................................................ 19

3.6.1 Pin Assignment...................................................................................................... 19

4Start-up................................................................. 21

4.1 Mounting............................................................................................................... 21

4.2 Mounting and Removing the Module................................................................. 22

4.2.1 Mounting and Removing the Module ..................................................................... 22

4.3 Configuring the Module in SILworX................................................................... 24

4.3.1 Tab: Module........................................................................................................... 24

4.3.2 Tab: Routings......................................................................................................... 26

4.4 Managing the Modules ........................................................................................ 26

Table of Contents X-SB 01

Page 4 of 38 HI 801 007 E Rev. 4.00

5Operation .............................................................. 27

5.1 Handling................................................................................................................27

5.2 Diagnosis ..............................................................................................................27

6Maintenance.......................................................... 28

6.1 Maintenance Measures........................................................................................28

6.1.1 Loading the Operating System...............................................................................28

6.1.2 Proof Test...............................................................................................................28

7Decommissioning.................................................. 29

8Transport .............................................................. 30

9Disposal................................................................ 31

Appendix............................................................... 33

Glossary................................................................................................................33

Index of Figures....................................................................................................34

Index of Tables .....................................................................................................35

Index......................................................................................................................36

X-SB 01 1 Introduction

HI 801 007 E Rev. 4.00 Page 5 of 38

1 Introduction

The present manual describes the technical characteristics of the module and its use. It

provides information on how to install, start up and configure the module in SILworX.

1.1 Structure and Use of this Manual

The content of this manual is part of the hardware description of the HIMax programmable

electronic system.

This manual is organized in the following main chapters:

Introduction

Safety

Product Description

Start-up

Operation

Maintenance

Decommissioning

Transport

Disposal

Additionally, the following documents must be taken into account:

Name Content Document no.

HIMax

System manual

Hardware description of the

HIMax system

HI 801 001 E

HIMax

Safety manual

Safety functions of the HIMax

system

HI 801 003 E

HIMax

Communication manual

Description of communication

and protocols

HI 801 101 E

SILworX Online Help

(OLH)

Instructions on how to use

SILworX

-

First Steps Introduction to SILworX HI 801 103 E

Table 1: Additional Relevant Manuals

The latest manuals can be downloaded from the HIMA website at www.hima.com. The

revision index on the footer can be used to compare the current version of existing manuals

with the Internet edition.

1.2 Target Audience

This document addresses system planners, configuration engineers, programmers of

automation devices and personnel authorized to implement, operate and maintain the

devices and systems. Specialized knowledge of safety-related automation systems is

required.

1 Introduction X-SB 01

Page 6 of 38 HI 801 007 E Rev. 4.00

1.3 Formatting Conventions

To ensure improved readability and comprehensibility, the following fonts are used in this

document:

Bold: To highlight important parts

Names of buttons, menu functions and tabs that can be clicked and

used in SILworX.

Italics: System parameter and variables

Courier Literal user inputs

RUN Operating state are designated by capitals

Chapter 1.2.3 Cross references are hyperlinks even though they are not

particularly marked. When the cursor hovers over a hyperlink, it

changes its shape. Click the hyperlink to jump to the corresponding

position.

Safety notes and operating tips are particularly marked.

1.3.1 Safety Notes

The safety notes are represented as described below.

These notes must absolutely be observed to reduce the risk to a minimum. The content is

structured as follows:

Signal word: danger, warning, caution, notice

Type and source of danger

Consequences arising from the danger

Danger prevention

The signal words have the following meanings:

Danger indicates hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates hazardous situation which, if not avoided, could result in death or

serious injury.

Warning indicates hazardous situation which, if not avoided, could result in minor or

modest injury.

Notice indicates a hazardous situation which, if not avoided, could result in property

damage.

NOTICE

Type and source of damage!

Damage prevention

SIGNAL WORD

Type and source of danger!

Consequences arising from the danger

Danger prevention

X-SB 01 1 Introduction

HI 801 007 E Rev. 4.00 Page 7 of 38

1.3.2 Operating Tips

Additional information is structured as presented in the following example:

iThe text corresponding to the additional information is located here.

Useful tips and tricks appear as follows:

TIP The tip text is located here.

2 Safety X-SB 01

Page 8 of 38 HI 801 007 E Rev. 4.00

2 Safety

All safety information, notes and instructions specified in this manual must be strictly

observed. The product may only be used if all guidelines and safety instructions are

adhered to.

This product is operated in accordance with SELV or PELV. No imminent danger results

from the module itself. The use in Ex-Zone is permitted if additional measures are taken.

2.1 Intended Use

HIMax components are designed for assembling safety-related controller systems.

When using the components in the HIMax system, comply with the following general

requirements

2.1.1 Environmental Requirements

Requirement type Range of values

Protection class Protection class III in accordance with IEC/EN 61131-2

Ambient temperature 0...+60 °C

Storage temperature -40...+85 °C

Pollution Pollution degree II in accordance with IEC/EN 61131-2

Altitude < 2000 m

Housing Standard: IP20

Supply voltage 24 VDC

Table 2: Environmental Requirements

Exposing the HIMax system to environmental conditions other than those specified in this

manual can cause the HIMax system to malfunction.

2.1.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the

system or replace modules.

NOTE

Device damage due to electrostatic discharge!

When performing the work, make sure that the working area is free of static and

wear an ESD wrist strap.

If not used, ensure that the device is protected from electrostatic discharge, e.g.,

by storing it in its packaging.

X-SB 01 2 Safety

HI 801 007 E Rev. 4.00 Page 9 of 38

2.2 Residual Risk

No imminent danger results from a HIMax module itself.

Residual risk may result from:

Faults in the engineering

Faults in the user program

Faults in the wiring

2.3 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.4 Emergency Information

A HIMax controller is a part of the safety equipment of a system. If the controller fails, the

system adopts the safe state.

In case of emergency, no action that may prevent the HIMax systems from operating safely

is permitted.

3 Product Description X-SB 01

Page 10 of 38 HI 801 007 E Rev. 4.00

3 Product Description

The X-SB 01 system bus module is intended for use in the programmable electronic

systems (PES) HIMax. The module can only be inserted into base plate's slots 1 and 2.

If the base plate only contains one module, the HIMax system operates with only one

system bus (mono operation). If the base plate contains two modules, the HIMax system

operates with two redundant system busses (redundant operation).

HIMA recommends using redundant operation (default) to exploit the HIMax system

availability.

The module has the following functions:

To establish connections between the modules.

To establish connections to other base plates.

Manage the rack ID and SRS of the modules.

Further, the module provides an interface to the programming and debugging tool (PADT).

The module has been certified by the TÜV for safety-related applications up to SIL 3

(IEC 61508, IEC 61511 and IEC 62061), Cat. 4 (EN 954-1) and PL e (EN ISO 13849-1).

Refer to the HIMax Safety Manual (HI 801 003 E) for more information on the standards

used to test and certify the module and the HIMax system.

3.1 Safety Function

The module transfer the data via a safety-related protocol.

3.1.1 Reaction in the Event of a Fault

If a failure occurs on a system bus, the bus connection is ensured via the redundant system

bus, provided that both system busses have been previously configured.

3.2 Scope of Delivery

The module must be installed on a suitable connector board to be able to operate. The

connector boards for the system bus module are integrated into the base plate and are

contained within the scope of delivery, see Chapter 3.6.

X-SB 01 3 Product Description

HI 801 007 E Rev. 4.00 Page 11 of 38

3.3 Type Label

The type label specifies the following important details:

Product name

Mark of conformity

Bar code (2D or 1D code)

Part number (Part-No.)

Hardware revision index (HW Rev.)

Software revision index (SW Rev.)

Operating voltage (Power)

Ex specifications (if applicable)

Production year (Prod-Year:)

Figure 1: Sample Type Label

3 Product Description X-SB 01

Page 12 of 38 HI 801 007 E Rev. 4.00

3.4 Structure

The module consists of:

Safety-related processor system

Service and system bus interfaces

The module is equipped with LEDs to indicate the status, see Chapter 3.4.4.

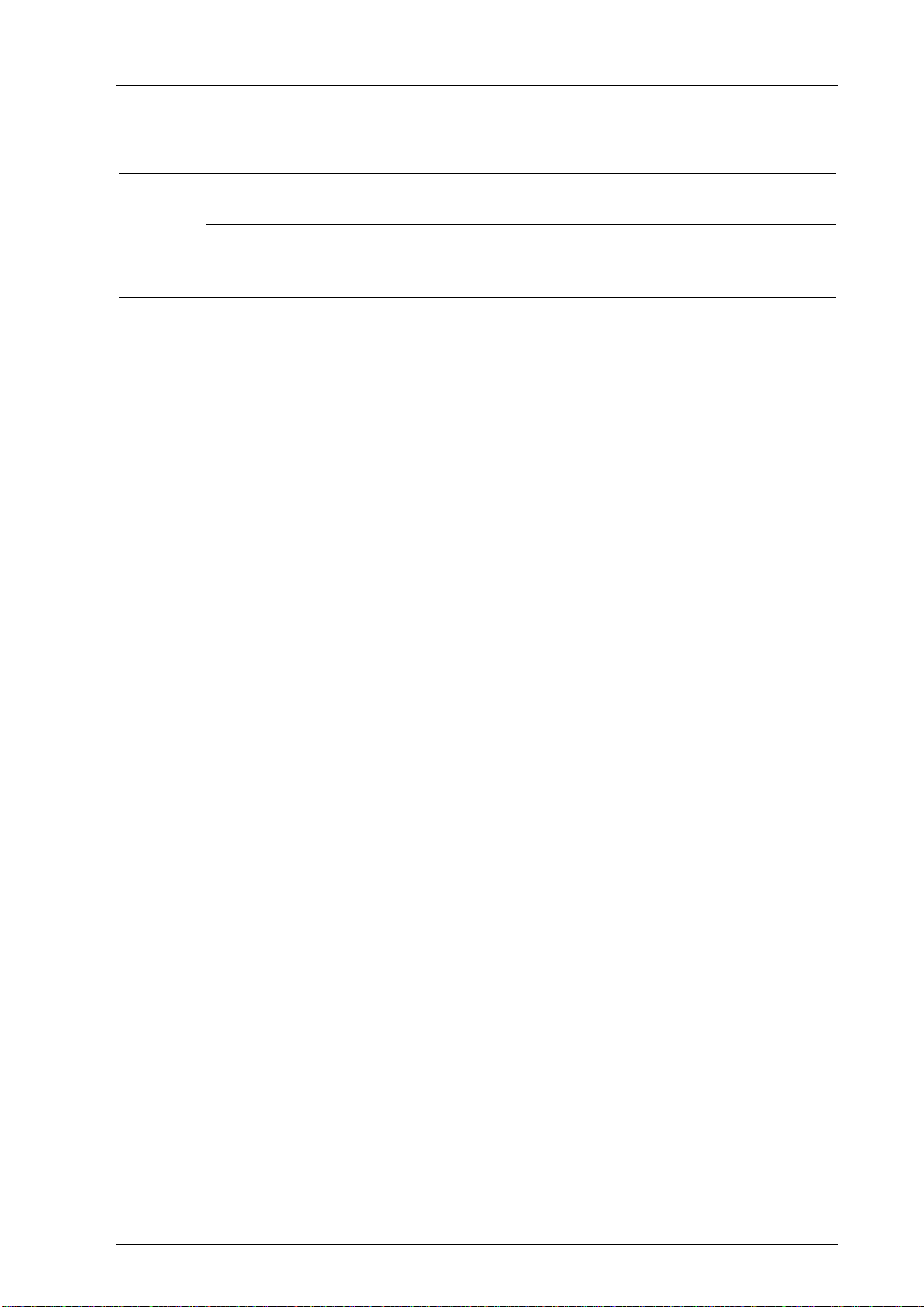

3.4.1 Block Diagram

The following block diagram illustrates the structure of the module.

Safety-Related Processor System

System Bus Controller

System Bus A or System Bus B

Figure 2: Block Diagram

3.4.2 Safety-Related Processor System

The safety-related 1oo2 processor system controls and monitors one system bus of the

HIMax system. The X-SB 01 module in slot 1 controls and monitors the system bus A and

the module in slot 2 controls and monitors the system bus B.

Operating system and error code history are stored in a non-volatile memory which can be

read in SILworX via the diagnosis.

X-SB 01 3 Product Description

HI 801 007 E Rev. 4.00 Page 13 of 38

3.4.3 Interfaces

The connector board associated with the module is equipped with the following interfaces:

One service interface (PADT)

Two system bus interfaces (UP, DOWN)

One diagnostic interface (DIAG), for future applications

Service Interface PADT

The service interface allows the user to connect to the PADT. The service interface can be

used to load both the user program into the processor module and the operating system

into the individual modules.

Service interface PADT

Number 1

Transfer standard 10/100 Base-T, half and full duplex

Auto Negotiation Yes

Auto Crossover No

Connection socket RJ-45

IP Address Freely configurable

Subnet Mask Freely configurable

Table 3: Specifications for the Service Interface

iThe service interface does not support auto crossover. A crossover cable must be used for

point-to-point connections.

System Bus Interface UP, DOWN

The system bus interfaces are used to connect to additional base plates in the HIMax

system and are configured with the SILworX programming tool. To connect the interfaces,

use cables complying with Ethernet megabit standard (at least CAT 5e cable).

System bus interfaces

Number 2

Auto crossover Yes

Connection socket RJ-45

Labeling Up, Down

Table 4: Specifications for the System Bus Interface

Diagnostic Interface DIAG

Diagnostic interface reserved for further applications

3 Product Description X-SB 01

Page 14 of 38 HI 801 007 E Rev. 4.00

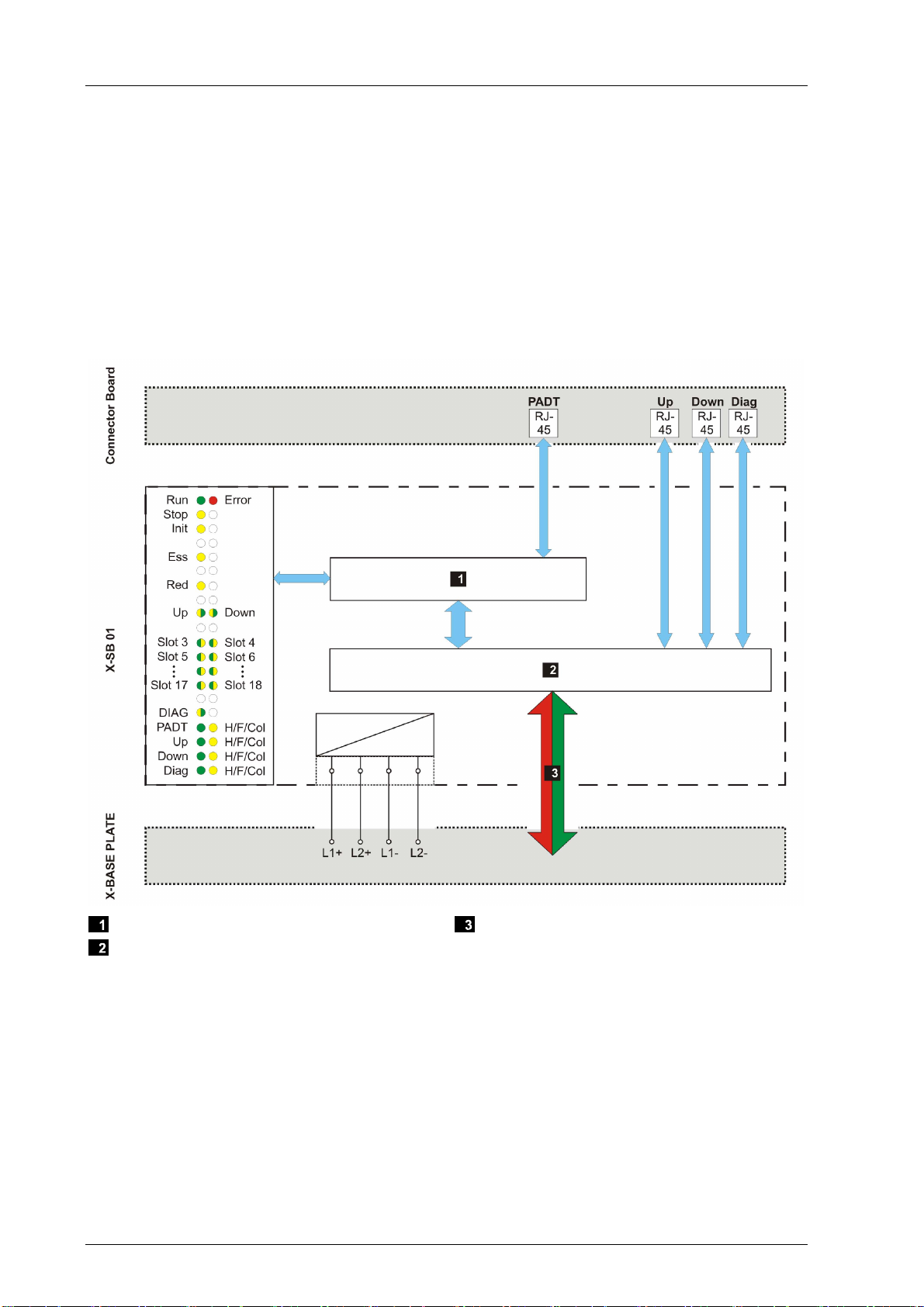

3.4.4 Indicators

The following figure shows the LED indicators for the module.

Figure 3: Indicators

X-SB 01 3 Product Description

HI 801 007 E Rev. 4.00 Page 15 of 38

The LEDs indicate the operating state of the module.

The LEDs on the module are divided into six groups:

Module status indicators (Run, Error, Stop, Init)

Redundancy indicators (Ess, Red)

Rack connection indicators (Up, Down)

Slot indicators (Slot 3…18)

Diagnostic indicators (Diag)

Communication indicators (Ethernet)

When the supply voltage is switched on, a LED test is performed and all LEDs briefly flash

simultaneously.

Definition of Blinking Frequencies

The following table defines the blinking frequencies of the LEDs:

Name Blinking Frequencies

Blinking1 Long (approx. 600 ms) on, long (approx. 600 ms) off

Blinking2 Short (approx. 200 ms) on, short (approx. 200 ms) off, short (approx. 200

ms) on, long (approx. 600 ms) off

Blinking-x Ethernet communication: Flashing in sync with data transfer

Table 5: Blinking Frequencies of LEDs

3.4.5 Module Status Indicators

These LEDs are located on the front plate, on the upper part of the module.

LED Color Status Description

On Module in RUN, normal operation

Blinking1 Module state:

STOP/OS_DOWNLOAD or

OPERATE (only with processor modules)

Run Green

Off Module not in RUN,

observe the other status LEDs

On/Blinking1 Internal module faults detected by self-tests, e.g.,

hardware, software or voltage supply.

Fault while loading the operating system

Error Red

Off Normal operation

On Module state:

STOP / VALID CONFIGURATION

Blinking1 Module state:

STOP / INVALID CONFIGURATION or

STOP / OS_DOWNLOAD

Stop Yellow

Off Module not in STOP, observe the other status LEDs

On Module state: INIT, observe the other status LEDs

Blinking1 Module state: LOCKED, observe to the other status

LEDs

Init Yellow

Off Module state: neither INIT nor LOCKED, observe

the other status LEDs

Table 6: Module Status Indicators

3 Product Description X-SB 01

Page 16 of 38 HI 801 007 E Rev. 4.00

3.4.6 Redundancy Indicators

The LEDs are located below the module status indicators.

LED Color Status Description

On Caution: Removing an operating system bus

module cause the system to fail!

The SB module is

running in mono operation (only 1 system bus active)

configured in SILworX

The module is absolutely required for operating the

HIMax system!

Blinking1 Caution: Removing an operating system bus

module cause the system to fail!

The SB module is inserted and configured for redundant

operation, but the redundant module is not available.

The module is absolutely required for operating the

HIMax system!

Ess Yellow

Off The system bus module is not absolutely required for

operation! Observe the Red LED!

On Redundant operation, the SB module is operating

redundantly.

The redundant SB module periodically allocates

identical system/rack IDs

(the adjustment of the system/rack IDs was successful).

Blinking1 Redundancy setting

Red Yellow

Off No redundant operation!

Table 7: Redundancy Indicators

3.4.7 Rack Connection Indicators

The rack connection and slot LEDs are labeled Sys Bus.

LED Color Status Description

On Physical and logical connection to the system bus module

in another base plate.

Green

Blinking1 Transient disturbances on the system bus

On The modules recognizes additional system bus modules

on the system bus

Yellow

Blinking1 Only a physical connection to the system bus module in

another base plate.

Up

Off Off No connection to another system bus module.

On Physical and logical connection to the system bus module

in another base plate.

Green

Blinking1 Transient disturbances on the system bus

On The modules recognizes additional system bus modules

on the system bus

Yellow

Blinking1 Only a physical connection to the system bus module in

another base plate.

Down

Off Off No connection to another system bus module.

Table 8: Rack Connection Indicators

X-SB 01 3 Product Description

HI 801 007 E Rev. 4.00 Page 17 of 38

3.4.8 Slot Indicators

The slot indicator LEDs are located after the Slot label.

LED Color Status Description

Green On Module inserted in slot X, logical connection established.

Yellow Blinking1

Module inserted in slot X, logical connection not

established.

3...18

Off Off Slot X not used

Table 9: Slot Indicators

3.4.9 Diagnostic Indicators

Diagnostic indicators reserved for future applications!

3.4.10 Ethernet Indicators

The communication LEDs are labeled Ethernet.

LED Color Status Description

Blinking-x Communication detected on interface.

Blinking1 IP address conflict detected.

LEDs adjacent to one another,

PADT and H/F/Col blinking

PADT Green

Off PADT not connected.

On Speed = 100 Mbit/s

Blinking-x not defined!

Blinking1 IP address conflict detected.

LEDs adjacent to one another,

PADT and H/F/Col blinking

H/F/Col

(PADT)

Yellow

Off Speed = 10 Mbit/s or no connection.

On System bus module connected, physical connection

established.

Up Green

Off No system bus module connected.

On System bus module connected, physical connection

established.

Down Green

Off No system bus module connected.

On Diagnostic device connected, physical connection

established

Diag Green

Off No diagnostic device connected.

On Full duplex operation on the F line

Blinking-x Collision detected on the Col line

H/F/Col

(Up,

Down,

Diag)

Yellow

Off Half duplex operation on Hline

Table 10: Communication Indicators

3 Product Description X-SB 01

Page 18 of 38 HI 801 007 E Rev. 4.00

3.5 Product Data

General

Supply voltage 24 VDC, -15 %...+20 %, rP≤5 %,

SELV, PELV

Current input max. 0.65 A

Operating temperature 0…+60 °C

Storage temperature -40…+85 °C

Humidity max. 95 % relative humidity, non-condensing

Type of protection IP20

Dimensions (H x W x D) 310 x 29.2 x 230 mm

Weight approx. 1.2 kg

Table 11: Product Data

Figure 4: Views

X-SB 01 3 Product Description

HI 801 007 E Rev. 4.00 Page 19 of 38

3.6 Connector Boards

The connector boards connect the system modules to the Ethernet interfaces. Two

connector boards are secured to the base plate: one left connector board (L) for slot 1 and

one right connector board (R) for slot 2. The connector boards contain information on the

number of modules (10, 15 or 18) that can be inserted into the base plate and the

corresponding slot IDs.

Slot Left/Right Slot ID

1 Left (L) 62

2 Right (R) 63

Table 12: Connector Boards

3.6.1 Pin Assignment

The interface name is printed on the connector boards.

Figure 5: Connector Boards

3 Product Description X-SB 01

Page 20 of 38 HI 801 007 E Rev. 4.00

Designation Description

External interface

PADT (X1) Connection for the PADT

External system bus interfaces

UP (X2) Connection for additional HIMax base plates

DOWN (X3) Connection for additional HIMax base plates

External diagnostic interface

DIAG (X4) Connection reserved for future applications

Table 13: Description of the Connector Boards

Table of contents

Other HIMA Control Unit manuals

HIMA

HIMA HIMax X-DI 32 51 User manual

HIMA

HIMA HIMax X-CI 24 01 User manual

HIMA

HIMA HIMatrix F60 Installation and operation manual

HIMA

HIMA HIMatrix F60 DI 32 01 User manual

HIMA

HIMA HIMax X-DI 32 05 User manual

HIMA

HIMA HIMax X-MIO 7 01 User manual

HIMA

HIMA DIO 24/16 01 User manual

HIMA

HIMA HIMax X-DO 12 51 User manual

HIMA

HIMA HIMax X-DI 64 01 User manual

HIMA

HIMA HIMax X-HART 32 01 User manual