SLEIPNER MOTOR AS SIDE-POWER S-linkControl Panel 8700 User manual

Made in Norway

©Sleipner Motor AS 2016

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

Tel: +47 69 30 00 60

Fax: +47 69 30 00 70

www.side-power.com

sidepower@sleipner.no

Keep this

manual onboard !

8700

S-linkControl Panel

SIDE-POWER

Thruster Systems

Installation and user’s manual v1.0.5

EN

Control Panel 8700 version 1.0.5 - 2016

2

Product Features .................................................................................................. 3

S-Link overview ................................................................................................... 4

S-Link setup procedure ...................................................................................... 5

General use and alarm indication...................................................................... 6

Alarm codes ......................................................................................................... 7

DO NOT connect any other control equipment to the S-link

controlled products except Side-Power original S-link prod-

ucts or via a Side-Power supplied interface product made

for interfacing with other controls. Any attempt to directly

control or at all connect into the S-link control system with-

out the designated and approved interface, will render

all warranties and responsibilities for the complete line of

Side-Power products connected void and null.

Content

DECLARATION OF CONFORMITY

We, Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad, Norway

declare that this product with accompanying standard remote

control systems complies with the essential health and safety

requirements according to the Directive 89/336/EEC of 23

May 1989 amended by 92/31/EEC and

93/68/EEC.

Control Panel 8700 version 1.0.5 - 2016 3

Important !

This panel will only work with Side-Power electric retractable thrust-

ers with a S-link control system. This panel is waterproof from the

front side when correctly installed. However, you must ensure that

it can never be submerged in water as this might cause a short

circuit and malfunction of the thruster system.

1 243

Ref: Pcs. Parts:

1 1 x Control panel

2 1 x Gasket

3 4 x Screws (A4)

4 4 x Corner clips

STBD

PORT ON 2 OFF

Installation:

Find a comfortable position for the panel where it does not obstruct or are

obstructed by other controls. Use the enclosed cut-out pattern to mark the

area. Cut out the circular area as shown on pattern.

If the front surface around your cut out is jaggered or chipped, use a sealant

to assist the gasket.

A Put the gasket (2) in its designated track in the back face of the panel (1)

B Plug the S-link Spur cable into the connector at the rear of panel.

Twist the locking ring on the connector clockwise to secure connector.

C Put the panel (1) in place and screw in and tighten the four screws (3)

D Press gently each of the four corner clips (4) into their corner slot

Product features

Control Panel 8700 version 1.0.5 - 2016

4

16 SR80/185T - SR100/185T 1.1.0 - 2010

optional

M

+-

12V

5A

red

black

yellow

Terminator

120 ohm

Terminator

120 ohm

Retract

panel

Power supply

cable

Retract

thruster

Controller

6 1242

T-connector T-connector T-connector

Actuator

Draw no:

Drawn:

Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad

Norway

Tel: +47 69 30 00 60

Wiring Retract thruster

W / manual main switch

L.G. 8.6.09

RTS-A00-652-01

Battery

+12V

8730

Foot

Switches

( opt.)

Remote control

(opt.)

Manual main switch

Main fuse

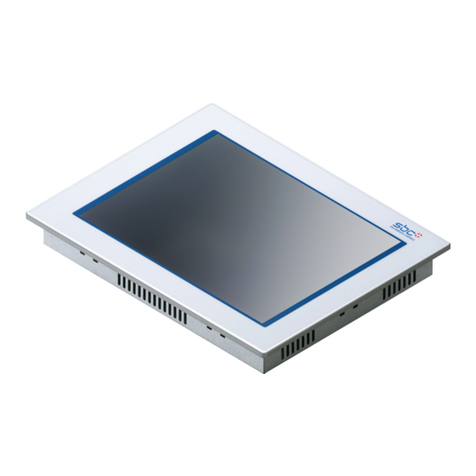

The S-link control system is powered by a dedicated power cable con-

nected to the system backbone as a normal spur cable.

The cable ends connect to battery pos. and battery neg. and the cable

shield connects to battery neg.

The battery pos. must be connected through a 5A fuse.

N

GB

S-link systemeter strømforsynt via en dediker strømkabel som kobles til

systemets “backbone” som en normal “spur”-kabel.

Kabelendene kobles til batteriets pluss- og minuspol og skjermkabelen

kobles til batteriets minuspol.

Ledningen som kobles til batteriets plusspol må sikres med en 5A sikring

M

+-

12V

5A

red

black

yellow

Terminator

120 ohm

Terminator

120 ohm

Retract

panel

Power supply

cable

Retract

thruster

Controller

6 1242

T-connector T-connector T-connector

Actuator

Draw no:

Drawn:

Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad

Norway

Tel: +47 69 30 00 60

Wiring Retract thruster

W / Automatic Main Switch

L.G. 8.6.09

RTS-A00-651-01

Battery

+12V

Automatic

Main Switch

w/S-link

8730

Foot

Switches

( opt.)

Remote control

(opt.)

optional

S-link koblingsskjema

S-link system schematics

Setup with manual main switch

Setup with automatic main switch

S-Link Overview

Control Panel 8700 version 1.0.5 - 2016 5

To control a dual thruster setup on one S-link bus, the panels must be set up

to control one thruster each. As factory default, the panel is setup to control

the bow thruster. The panel controlling the stern thruster must be set up fol-

lowing the procedure described:

1 Disconnect all S-link equipment concerning the bow thruster (Panel,

AMS, Thruster Control Box, Interface etc.) from the S-link bus, and keep

all equipment concerning the stern thruster connected.

2. Make sure panel is turned OFF.

3. Press and hold ON button 2 and PORT button at the same time for

approx. 3 seconds. The yellow status LED will blink and the red OR

green LED turns on (factory default: GREEN - controlling bow thruster).

4. Press STARBOARD button to assign this panel and all connected devic

esasSTERN.REDstatusLEDwilllightuptoconrmsetupasstern

thruster.

5. Turn off panel, and reconnect all S-link equipment.

The same procedure can be used to match all devices for a single thruster

system bow or stern. Just follow steps 2,3,4 and 5. At step 4 press PORT but-

ton to assign all the devices connected as BOW. GREEN status LED will light

uptocomrmsetupasbowthruster.

S-Link Setup Procedure

Control Panel 8700 version 1.0.5 - 2016

6

Note!

THE MAIN SWITCH MUST BE TURNED OFF IMMEDIATELY WHEN AN IPC

ERROR OCCURS TO PREVENT OVERHEATING OF THE MAIN THRUSTER

RELAYS!

THRUSTER WILL NOT RETRACT WHILE REVERSING AT “HIGH” SPEED. THIS

WILL TRIGGER THE “RETRACT OPERATION OBSTRUCTED” ALARM.

IF AN ALARM IS TRIGGERED, REDUCE SPEED AN PRESS BOTH “ON” BUT-

TONS SIMULTANEOUSLY BEFORE RETRYING “OFF” BUTTON

General use and alarm indication

PANEL ON: push both “ON” buttons simultaneously, thruster deploys.

PANEL OFF: push “OFF” button, thruster retracts.

Operate thruster by pushing red and green arrows.

STATUS/ALARM LEDS:

YELLOW LED solid light means panel is on.

GREENLEDashesduringdeployphase,SolidGREENLEDindicates

thruster deployed and ready to operate.

REDLEDashesduringretractphase,allLEDsoutwhenpanel/thruster

is shut down.

If something unexpected happens while deploying/retracting thruster,

theLEDswillashalarmcodesaccordingtoformonnextpage.

The panel will shut off automatically if not operated for approximatly 6-9

minutes.

Control Panel 8700 version 1.0.5 - 2016 7

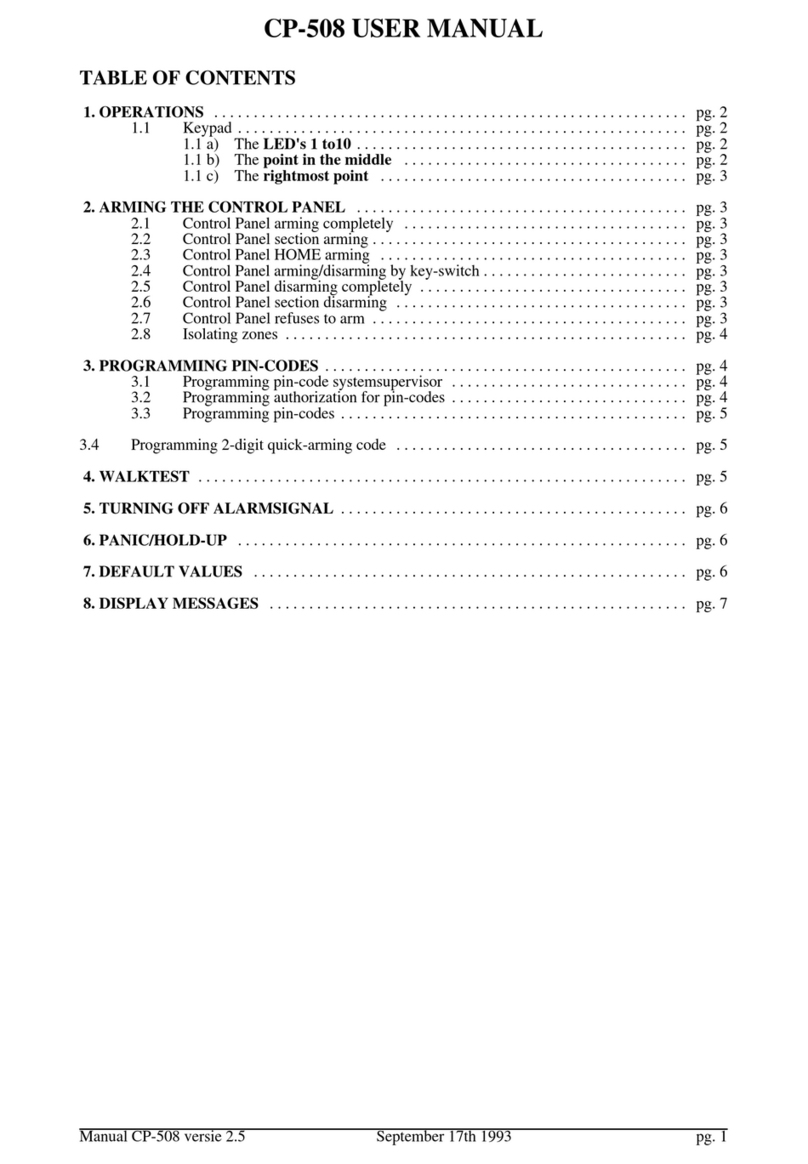

ALARM SPEC. RETRACT

LED Panel alarm indication Failure Thruster reaction User action

1

1 flash YELLOW & GREEN - Pause Thruster, overtemp Retracts Turn off panel, wait for 20 mins.

2

2 flashes YELLOW & GREEN - Pause Thruster, low power Retracts Turn off panel, charge batteries.

3 3 flashes YELLOW & GREEN - Pause Deploy operation obstructed Retracts

Turn off panel. Go for lower speed/deeper

water. Retry.

4

4 flashes YELLOW & GREEN - Pause SR150000 position sensor fail Retracts

Position sensor short or open circuit.

Check wiring and connection.

5 5 flashes YELLOW & GREEN - Pause

SR150000 solenoid output short

circuit, port or starboard.

Retracts

Check solenoid wiring and connection,

and check if solenoid is shorted.

6

6 flashes YELLOW & GREEN - Pause SR150000 motor temp sensor fail Retracts

Check motor temp sensor, wiring and

connection.

1

1 flash YELLOW & RED - Pause Power failure, Actuator System shuts down

Turn off panel. Check actuator

connections . Retry.

2

2 flashes YELLOW & RED - Pause Thruster IPC error Retracts

Turn off panel - thruster must be serviced

by authorized personel.

3 3 flashes YELLOW & RED - Pause Retract operation obstructed

Aborts retract, deploys and retries to

retract 3 times. If operation still is

obstructed, retract stops on

obstruction

Press both ON-buttons to deploy thruster.

Turn Main-Switch off. Remove

obstruction.

1

1 flashes YELLOW, GREEN & RED -

Pause

Automatic Main Switch Power

failure

None Check power to Automatic Main Switch

2

2 flashes YELLOW, GREEN & RED -

Pause

Automatic Main Switch fuse

blown

None

Replace fuse on Automatic Main Switch. If

new instalation, check if input and output

is correct connected.

3

3 flashes YELLOW, GREEN & RED -

Pause

Automatic Main Switch manual

override

None Pull up Automatic Main Switch

4

4 flashes YELLOW, GREEN & RED -

Pause

Panel has no contact with

thruster.

None

Turn off panel. Check main switch, fuse,

cable connections, cables. Retry.

C:\Users\olekr\AppData\Local\Microsoft\Windows\Temporary Internet Files\Content.Outlook\JZ2NO5R1\Panel alarms (3)20.10.2014 Side 1 av 1

Alarm Codes

Note!

Ensure that the dipswitch settings are correct in 150000 control unit. See retract manual for more information.

Worldwide sales and service

www.side-power.com

SLEIPNER MOTOR AS

P.O. Box 519 N-1612 Fredrikstad Norway

Tel: +47 69 30 00 60 Fax:+47 69 30 00 70 www.side-power.com sidepower@sleipner.no

The information given in the document was correct at the time it was published. However, Sleipner Motor AS can not accept liability for any inaccuracies or omissions it

maycontain.Continuousproductimprovementmaychangetheproductspecicationswithoutnotice.Therefore,SleipnerMotorAScannotacceptliabilityforanypos-

sible differences between product and document.

Table of contents

Other SLEIPNER MOTOR AS Control Panel manuals

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER S-linkControl Panel PJC211 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power 8950 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER PJC-322 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS 8700 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER 86-08955 User manual