8Tehničke upute REGULACIJA Cm Pelet-set

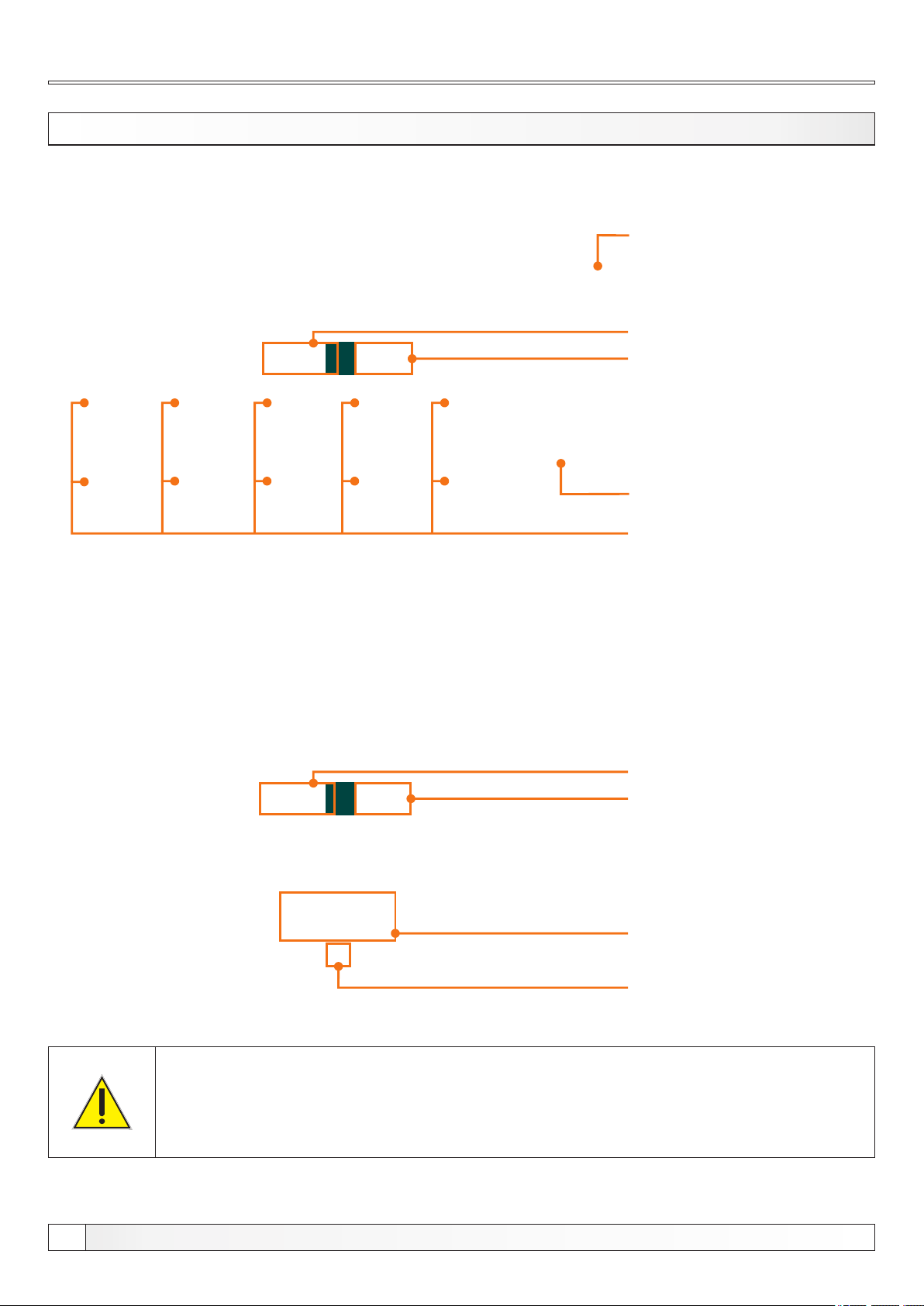

Maintenance, Cleaning

1.0. MAINTENANCE

1.1. CLEANING THE BURNER

Under "CLEANING" menu are two options:

Cleaning: this option is used to start the burner fan on the set RPMs to

clean the burner grate (note: depending of the pellets quality grate will

be more or less clean. After this procedure, burner grate should be

removed and cleaned and the burner head should also be cleaned.)

Burner fan: this option sets the burner fan RPMs during cleaning

Technical instructions REGULATION Cm Pelet-set

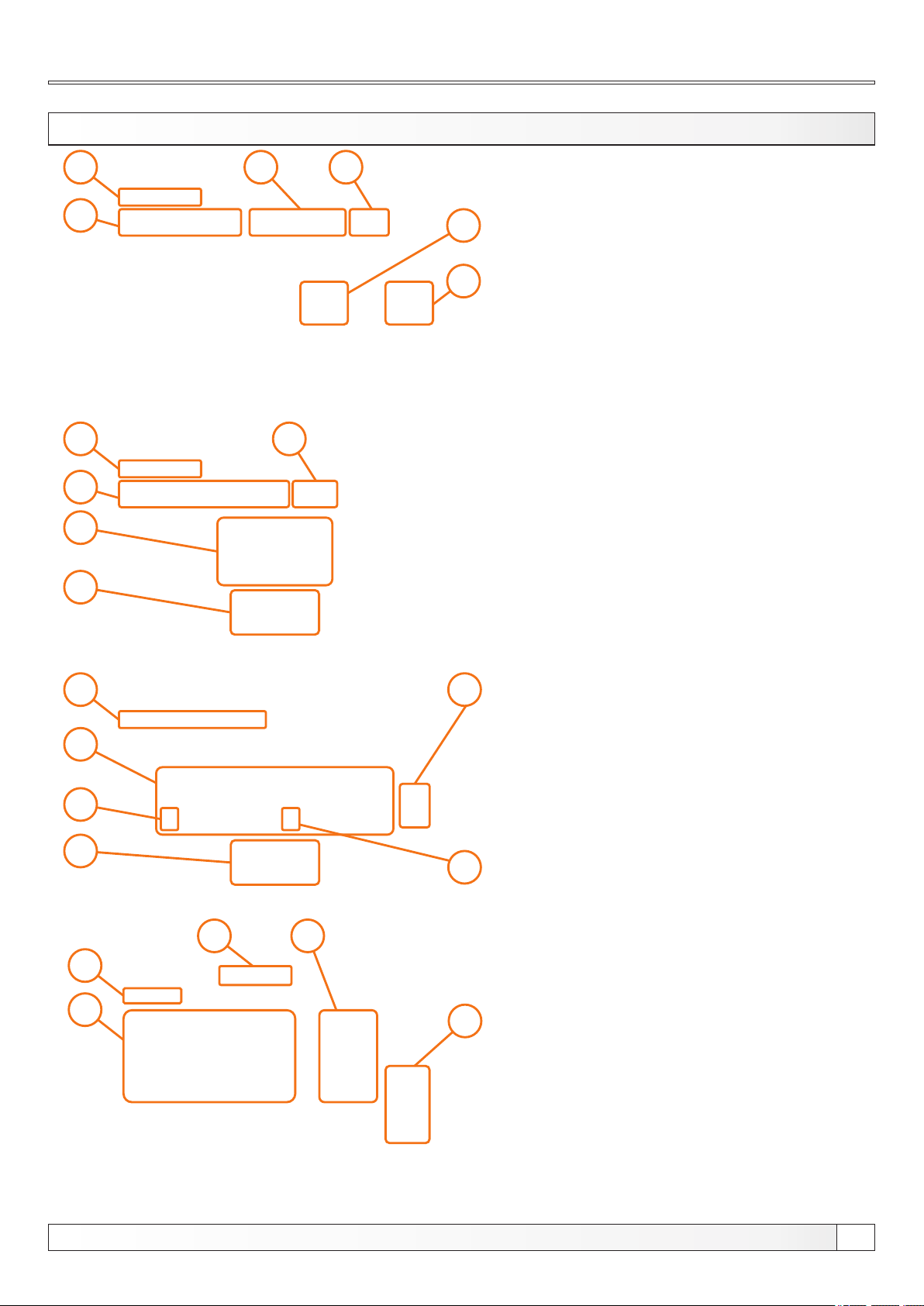

1.1.1. CLEANING

Press the "START" button to start the burner fan for 10 min.

After pressing the "START" button countdown is started for 10 min,

after which burner fan stops automaticaly

Press "AIR VALVE" button to open the electro-magnetic valve and to

clean the burner with compressed air.

After pressing the "AIR VALVE" countdown ist started for 60 sec in

which time "AIR VALVE" button is disabled to alow compressor to fill its

tank.

This option is used to adjust burner fan RPMs during cleaning

procedure

Possible adjustment:

- Factory adjustment: 3000 rpm

- Minimal adjustment value: 500 rpm

- Maximal adjustment value: 3000 rpm

1.1.2. BURNER FAN

NOTE: burner cleaning option is not replacing the need for manual

cleaning of the burner and burner grate. It should be manually cleaned

regulary according to the technical manual.