SLEIPNER MOTOR AS Side-Power 8950 User manual

Made in Norway

©Sleipner Motor AS 2018

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

www.side-power.com

Keep this

manual onboard !

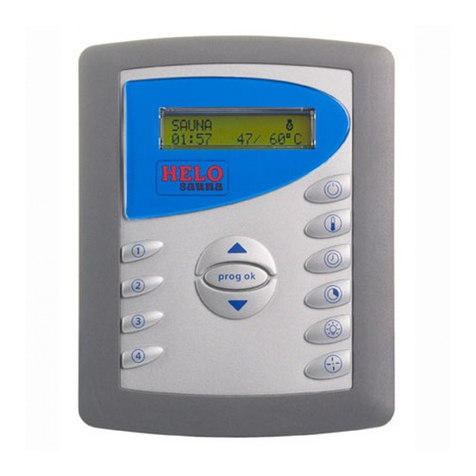

8950/8955/8960/8965

8940/8909C

Control panel

SIDE-POWER

Thruster Systems

Installation and user’s manual

EN

Installasjon og brukermanual

NO

Installationsanleitung

DE

8940 8909C

8955 8965

8950 8960

Document id: 3023

Revision: 6

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018

2

Product Features .................................................................................................. 3

Cut-out dimensions ............................................................................................. 3

Installation ............................................................................................................ 4

Visual wiring diagram.......................................................................................... 6

General use .......................................................................................................... 8

IMPORTANT!

This panel will only work with Side-Power electric thrusters with a built in electronic control box

and a 4/5 lead control cable system. These panels are waterproof from the front end when

correctly installed. However, you must ensure that they can never be submerged in water as this

might cause a shortcircuit and thereby causing the thruster to start unintededly.

Content

VIKTIG!

Dette kontrollpanelet fungerer bare med Side-Power elektriske trustere med integrert

elektronisk kontrollboks og 4/5 leders kontrollkabel system. Disse panelene er vantette fra

fronten når de er korrekt installert. Men, de må aldri stå slik att de er under vann da dette kan gi

en kortslutning som kan føre til selvstarting av trusteren.

WICHTIG!

Das Panel funktioniert nur mit elektrischen Side-Power Systemen mit integrierter elektronischer

Kontrolleinheit und einem Kabelstrang mit 4/5 Leitungen, und ist bei korrektem Einbau an der

Vorderseite wasserdicht. Trotzdem muß sichergestellt sein, daß das Panel nicht unter Wasser

kommt, da dies zu einem Kurzschluß führen kann. Hierdurch kann es zu einem unbeabsichtigten

Start des Thrusters kommen.

SAMSVARSERKLÆRING

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

Erklærer at dette produktet med tilhørende

standard kontrollsystemer er i samsvar med

helse, og sikkerhetskravene i henhold til:

DIRECTIVE 2013/53/EU

DIRECTIVE 2014/30/EU

DIRECTIVE 2014/35/EU

DECLARATION OF CONFORMITY

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

Declare that this product with accompany-

ing standard control systems complies with

the essential health and safety requirements

according to:

DIRECTIVE 2013/53/EU

DIRECTIVE 2014/30/EU

DIRECTIVE 2014/35/EU

FREDRIKSTAD, 20th of January 2018

Arne K Skauen

Managing Director, Sleipner Motor AS

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018 3

Page 2 Installation guide for Sidepower single control panels. Issue 4. © Sleipner Motor AS 2003

SIDEPOWER

Thrusters

Installation:

Für das Panel eine geeignete Position finden; diese Position muß gut zugänglich sein. Das Panel darf nicht

von anderen Teilen blockiert werden. Benutzen Sie die beiliegende Schablone und schneiden Sie das Loch

ent-sprechend der Vorlage aus. Sollte die Schnittkante beschädigt oder uneben sein, bitte zusätzlich zur

Dichtung noch Dichtmasse verwenden.

ADie Dichtung (2) in die dafür vorgesehene Vertiefung in der Rückseite des Panels einlegen (1).

BDen Stecker des Panels mit dem vom Sidepower kommenden Kontrollkabel verbinden.

CFalls ein automatischer Hauptschalter installiert ist(optional), diesen mit dem Stecker des Panels verbinden.

DDas Panel einsetzen (1) und die vier Schrauben eindrehen (3).

EDie vier Eckstücke (4) vorsichtig einsetzen und festpressen.

Achtung ! Sollte der Sidepower entgegengesetzt zur Panelvorgabe laufen, so sind das graue und das

blaue Kabel gegeneinander zu vertauschen; entweder am Sidepower oder am Panel.

Installation:

Find a comfortable position for the panel where it does not obstruct or are obstructed by other controls. Use

the enclosed cut-out pattern to mark the area. Cut out the circular area as shown on pattern.

If the front surface around your cut out is jaggered or chipped, use a sealant to assist the gasket.

APut the gasket (2) in its designated track in the back face of the panel (1).

BConnect the contact with the control cable from the thruster.

CConnect the control output to the Sidepower automatic main switch if installed.

DPut the panel (1) in place and screw in and tighten the four screws (3).

EPress gently each of the four corner clips (4) into their corner slot.

NB ! If the thruster runs the opposite way of the panel, swap positions of the grey and the blue

control cables in one contact, either by the thruster or by the panel.

E

Installasjon:

Finn en god posisjon for panelet hvor det er lett tilgjengelig og ikke blokkerer andre kontroll enheter. Bruk den

medsendte malen til å merke av området, og skjær ut det merkede området. Dersom kantene rundt utskjæringen blir

skadet/ujevne på fremsiden må det benyttes en tetningsmasse sammen med pakningen for å sikre god tetning.

ASett inn pakingen (2) i sporet på baksiden av panelet (1).

BKoble kontakten sammen med kontroll kabelen fra trusteren.

CKoble kontroll signalet til Sidepower automatisk hovedstrømsbryter dersom installert.

DSett panelet (1) inn og skru inn de fire skruene (3).

EPress forsiktig inn hver av de fire hjørne klipsene (4) i hvert sitt hjørne.

NB ! Dersom trusteren skulle gå motsatt vei av panelet, bytt plassering på den grå og den blå

kontroll ledning i en kontakt, enten ved trusteren eller ved panelet.

Product features

Page 2 Installation guide for Sidepower dual joystick control panel. Issue 2. © Sleipner Motor AS 2007

SIDEPOWER

Thrusters

Installation:

Für das Panel eine geeignete Position finden; diese Position muß gut zugänglich sein. Das Panel darf nicht von

anderen Teilen blockiert werden. Benutzen Sie die beiliegende Schablone und schneiden Sie das Loch ent-

sprechend der Vorlage aus. Sollte die Schnittkante beschädigt oder uneben sein, bitte zusätzlich zur Dichtung

noch Dichtmasse verwenden.

ADie Dichtung (2) in die dafür vorgesehene Vertiefung in der Rückseite des Panels einlegen (1).

BDen Stecker des Panels mit dem vom Sidepower kommenden Kontrollkabel verbinden.

CFalls ein automatischer Hauptschalter installiert ist (optional), diesen mit dem Stecker des Panels verbinden.

DDas Panel einsetzen (1) und die vier Schrauben eindrehen (3).

EDie vier Eckstücke (4) vorsichtig einsetzen und festpressen.

Achtung ! Sollte der Sidepower entgegengesetzt zur Panelvorgabe laufen, so sind das graue und das blaue

Kabel gegeneinander zu vertauschen; entweder am Sidepower oder am Panel.

Installation:

Find a comfortable position for the panel where it does not obstruct or are obstructed by other controls. Use the

enclosed cut-out pattern to mark the area. Cut out the circular area as shown on pattern.

If the front surface around your cut out is jaggered or chipped, use a sealant to assist the gasket.

APut the gasket (2) in its designated track in the back face of the panel (1).

BConnect the contact with the control cable from the thruster.

CConnect the control output to the Sidepower automatic main switch if installed.

DPut the panel (1) in place and screw in and tighten the four screws (3).

EPress gently each of the four corner clips (4) into their corner slot.

NB ! If the thruster runs the opposite way of the panel, swap positions of the grey and the blue

control cables in one contact, either by the thruster or by the panel.

E

Installasjon:

Finn en god posisjon for panelet hvor det er lett tilgjengelig og ikke blokkerer andre kontroll enheter. Bruk den medsendte

malen til å merke av området, og skjær ut det merkede området. Dersom kantene rundt utskjæringen blir skadet/ujevne på

fremsiden må det benyttes en tetningsmasse sammen med pakningen for å sikre god tetning.

ASett inn pakningen (2) i sporet på baksiden av panelet (1).

BKoble kontakten sammen med kontroll kabelen fra trusteren.

CKoble kontroll signalet til Sidepower automatisk hovedstrømsbryter dersom installert.

DSett panelet (1) inn og skru inn de fire skruene (3).

EPress forsiktig inn hver av de fire hjørne klipsene (4) i hvert sitt hjørne.

NB ! Dersom trusteren skulle gå motsatt vei av panelet, bytt plassering på den grå og den blå

kontroll ledning i en kontakt, enten ved trusteren eller ved panelet.

1

2

34

P:\PRODUKT\SIDEPOWE\Trykk_internt – pan mal double joystick 2004

23/9/2004 – Mette Olafsen

50,5mm

38,4mm

Ø52

Ø52

61,1mm

111,1mm

This way Up!

Cut-Out Template

double joystick panel - 8940

Cut-out dimensions

IMPORTANT!

Use only attached template!

WICHTIG!

Verwenden Sie nur beigefügten Vorlage!

VIKTIG!

Bare bruk vedlagt utskjæringsmal!

Page 2 Installation guide for SidePower single control panels. Issue 5. © Sleipner Motor AS 2004

Installation:

Für das Panel eine geeignete Position finden; diese Position muß gut zugänglich sein. Das Panel darf

nicht von anderen Teilen blockiert werden. Benutzen Sie die beiliegende Schablone und schneiden Sie

das Loch ent-sprechend der Vorlage aus. Sollte die Schnittkante beschädigt oder uneben sein, bitte

zusätzlich zur Dichtung noch Dichtmasse verwenden.

AÜberprüfen Sie, ob die Dichtung (2) in der Rückseite des Panels eingelegt ist (1).

BDen Stecker des Panels mit dem vom Sidepower kommenden Kontrollkabel verbinden.

CFalls ein automatischer Hauptschalter installiert ist, diesen mit dem Stecker des Panels verbinden.

DDas Panel (1) einstecken und mit den vier Schrauben befestigen.

EDen Blendenring im Uhrzeigesinn festdrehen.

Achtung ! Sollte der SidePower entgegengesetzt zur Panelvorgabe laufen, so sind das graue und das

blaue Kabel gegeneinander zu vertauschen; entweder am Sidepower oder am Panel.

Installation:

Find a comfortable position for the panel where it does not obstruct or is obstructed by other

controls. Use the enclosed cut-out pattern to mark the area. Cut out the circular area as shown on

pattern. If the front surface around your cut out is jaggered or chipped, use a sealant to assist the

gasket.

ACheck that the gasket (2), in its designated track in the back face of the panel (1), is mounted.

BConnect the contact with the control cable from the thruster.

CConnect the control output to the Sidepower automatic main switch if installed.

DPut the panel (1) in place and screw in and tighten the four screws (3).

EGently twist on the decor-/front ring (4) clockwise.

NB ! If the thruster runs the opposite way of the panel, swap positions of the grey and the blue

control cables in one contact, either by the thruster or by the panel.

E

Installasjon:

Finn en god posisjon for panelet hvor det er lett tilgjengelig og ikke blokkerer andre kontroll enheter.

Bruk den medsendte malen til å merke av området, og skjær ut det merkede området. Dersom kantene

rundt utskjæringen blir skadet/ujevne på fremsiden må det benyttes en tetningsmasse sammen med

pakningen for å sikre god tetning.

ASjekk at pakningen (2) på baksiden av panelet (1) er montert.

BKoble kontakten sammen med kontroll kabelen fra trusteren.

CKoble kontroll signalet til SidePower automatisk hovedstrømsbryter dersom installert.

DSett panelet (1) inn og skru inn de fire skruene (3).

EVri på den medleverte frontringen (4) medurs.

NB ! Dersom trusteren skulle gå motsatt vei av panelet, bytt plassering på den grå og den blå

kontroll ledning i en kontakt, enten ved trusteren eller ved panelet.

SIDE-POWER ®

Thruster systems

4 3 12

For control panels

8955/8965/8990

Ø 2,5 mm / 0,10"

53,0 mm / 2,09"

53,0 mm / 2,09"

Cut out area:

Ø 51,8 mm / 2"

Cut out area:

Ø 51,8 mm / 2"

61,0 mm / 2,4"

61,0 mm / 2,4"

For control panels 8950 / 8960

Ø 3,0 mm / 0,12"

Pos: Pcs. Parts Deler Teile

11 Control panel Kontrolpanel Steuerpanel

21 Gasket Pakning Dichtung

34 Screws (A4) Skruer (A4) Schraube (A4)

44 Corner clips Hjørneklips Eckstück

4b 1 Front ring Frontring Blendenring

b

For control panels

8955/8965/8990

Ø 2,5 mm / 0,10"

53,0 mm / 2,09"

53,0 mm / 2,09"

Cut out area:

Ø 51,8 mm / 2"

Cut out area:

Ø 51,8 mm / 2"

61,0 mm / 2,4"

61,0 mm / 2,4"

For control panels 8950 / 8960

Ø 3,0 mm / 0,12"

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018

4

Installation

Find a comfortable position for the panel where it does not obstruct or are

obstructed by other controls. Use the enclosed cut-out pattern to mark the

area. Cut out the circular area as shown on pattern.

If the front surface around your cut out is jaggered or chipped, use a sealant

to assist the gasket.

A Put the gasket (2) in its designated track in the back face of the panel (1)

B Plug the S-link Spur cable into the connector at the rear of panel.

Twist the locking ring on the connector clockwise to secure connector.

C Put the panel (1) in place and screw in and tighten the four screws (3)

D Press gently each of the four corner clips (4) into their corner slot

Note! If the thruster runs the opposite way of the panel, swap positions of

the grey and the blue control cables in one contact, either by the thruster or

by the panel.

EN

Installation

Installasjon

Finn en god posisjon for panelet hvor det er lett tilgjengelig og ikke blok-

kerer andre kontroll enheter. Bruk den medsendte malen til å merke av

området, og skjær ut det merkede området.

Dersom kantene rundt utskjæringen blir skadet/ujevne på fremsiden må det

benyttes en tetningsmasse sammen med pakningen for å sikre god tetning.

A Sett inn pakningen (2) i sporet på baksiden av panelet (1).

B Koble kontakten sammen med kontroll kabelen fra trusteren.

C Koble kontroll signalet til Side-Power automatisk hovedstrømsbryter

dersom installert.

D Settpanelet(1)innogskruinndereskruene(3).

E Pressforsiktiginnhveravderehjørneklipsene(4)ihvertsitthjørne.

NB! Dersom trusteren skulle gå motsatt vei av panelet, bytt plassering på

den grå og den blå kontroll ledning i en kontakt, enten ved trusteren eller

ved panelet.

NO

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018 5

Installation

Installation

FürdasPaneleinegeeignetePositionnden;diesePositionmußgut

zugänglich sein. Das Panel darf nicht von anderen Teilen blockiert werden.

Benutzen Sie die beiliegende Schablone und schneiden Sie das Loch ent-

sprechend der Vorlage aus.

Sollte die Schnittkante beschädigt oder uneben sein, bitte zusätzlich zur

Dichtung noch Dichtmasse verwenden.

A Die Dichtung (2) in die dafür vorgesehene Vertiefung in der Rückseite

des Panels einlegen (1).

B Den Stecker des Panels mit dem vom Side-Power kommenden

Kontrollkabel verbinden.

C Falls ein automatischer Hauptschalter installiert ist (optional), diesen mit

dem Stecker des Panels verbinden.

D Das Panel einsetzen (1) und die vier Schrauben eindrehen (3).

E Die vier Eckstücke (4) vorsichtig einsetzen und festpressen.

Achtung! Sollte der Side-Power entgegengesetzt zur Panelvorgabe laufen,

sosinddasgraueunddasblaueKabelgegeneinanderzuvertauschen;

entweder am Side-Power oder am Panel.

DE

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018

6

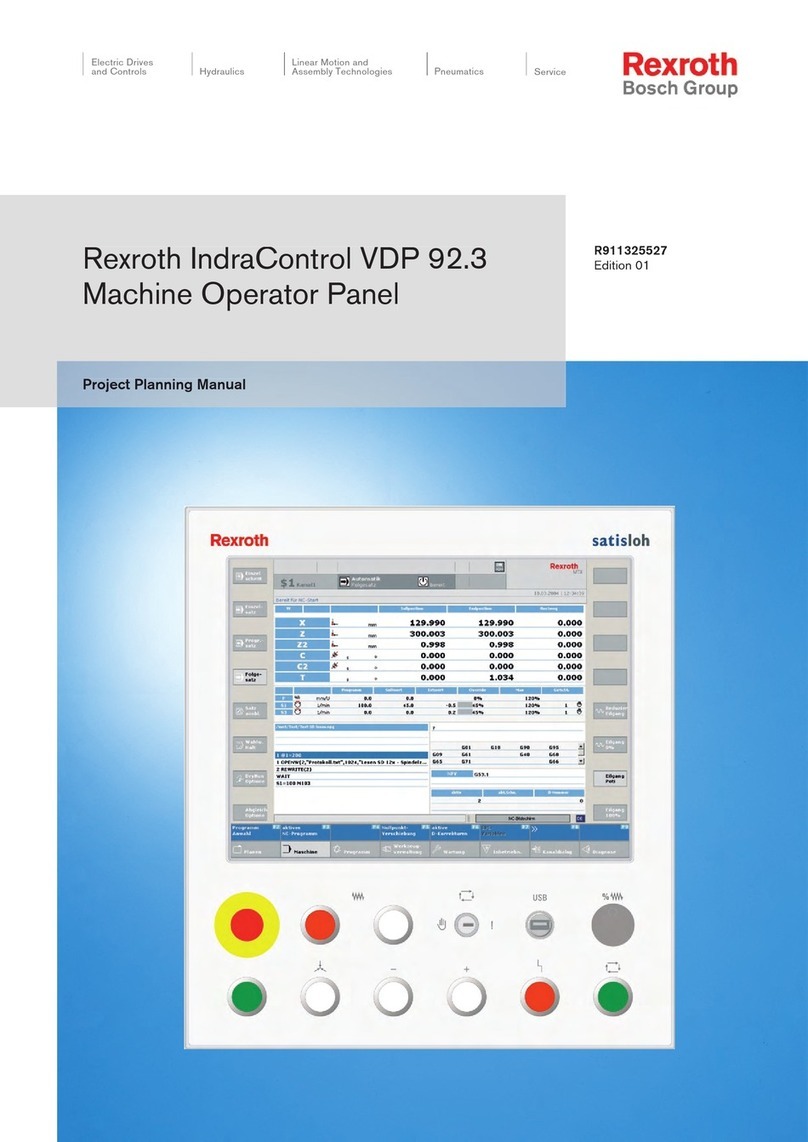

Visual wiring diagram

IMPORTANT! Very important to check the following with main switch in off position:

After all electrical connections have been completed check with an ohm meter that there is no electrical connection between electro

motor body and positive terminal on the motor and between the electro motor body and the negative (A1) terminal on the motor. If you

feel unsure on how to perform this check, contact skilled personnel for guidance.

"Visual" wiring diagram

EN NVisuelt Koblingsskjema

6 1265 5-LEAD

Y-CONNECTOR

6 1265 5-LEAD

Y-CONNECTOR

6 1278-xxM 5-LEAD

CONTROL CABLE

6 1278-xxM 5-LEAD

CONTROL CABLE

6 1278-xxM 5-LEAD

CONTROL CABLE

6 1277-xxM 4-LEAD

CONTROL CABLE

6 1277-xxM 4-LEAD

CONTROL CABLE

STERN BOW

STERN

BOW

STERN

6 1278-xxM 5-LEAD

CONTROL CABLE

Switch

5A fuse

Switch

5A fuse

Common negative

10A fuse

+

-

+

-

IMPORTANT!

Common negatvie MUST be wired when using control panel 8940 and 8909C

if separate battery banks are installed. (Bow and Stern thtrusters combined)

6 1274 4-LEAD

Y-CONNECTOR

STERN BOW

STERN

BOW

STERN

xA fuse

6 1277-xxM 4-LEAD

CONTROL CABLE

6 1277-xxM 4-LEAD

CONTROL CABLE

6 1277-xxM 4-LEAD

CONTROL CABLE

6 1277-xxM 4-LEAD

CONTROL CABLE

6 1274 4-LEAD

Y-CONNECTOR

xA fuse

Common negative

10A fuse

++

- -

IMPORTANT!

Common negatvie MUST be wired when using control panel 8940 and 8909C

if separate battery banks are installed. (Bow and Stern thtrusters combined)

With Automatic Main Switch:

With Manual Main Switch:

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018 7

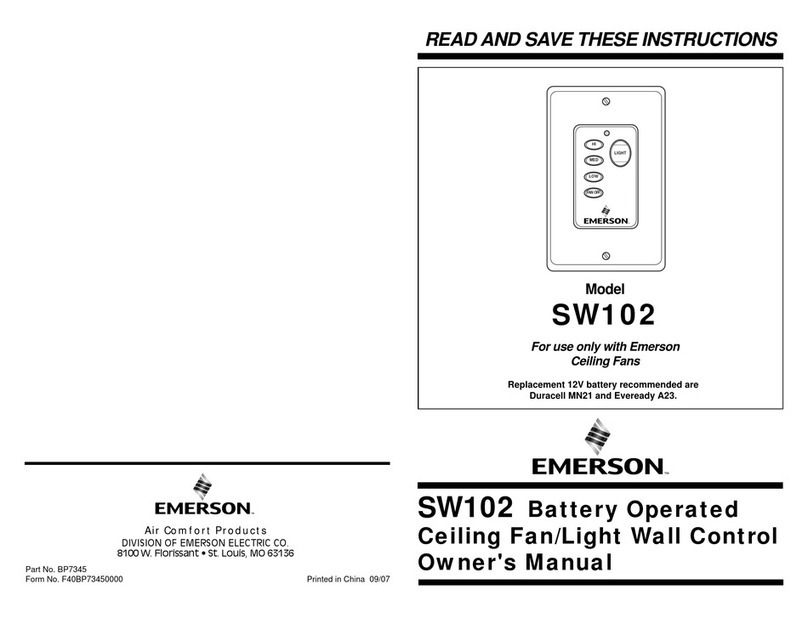

General use

Turn boat to port

Turn boat to starboardTo turn panel OFF

To turn panel ON

Bow+Stern

Thruster

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018

8

How to use Side-Power thrusters

EN

1. Turn main power switch for the bowthruster on. (Always turn off the main

power switch when not onboard.)

2. Please take some time to exercise thruster usage in open water to avoid

damages to your boat.

3. Turn the control panel on by pushing both “ON” buttons on the original

Side-Power panel simultaneously. If another type of control is installed,

engage the On/Off switch for the bowthruster.

4. Turn the bow in the desired direction by pushing the red button for port

movement or the green button for starboard movement. If you have a

joystick control, move it in the direction you wish the bow to move. Other

controls like footswitches or toggle-switches on the throttle can be

used. These are normally logically installed, so by engaging the port con-

trol,thebowgoesportetc.Incaseofanydoubts,tryinopenwatersrst.

5. Depending on the sideways speed of the bow, you must disengage the

control device shortly before the bow is in the desired direction, as the

boat will continue to move after stopping the bowthruster.

How to use a single stern thruster

Some boats might however have installed a single stern thruster because of

space limitation in the bow. In this case the stern thruster is used in the same

way as a single bow thruster (see above) for moving the boat’s stern.

How to use a bow and stern thruster combined

The combination of a bow and stern thruster offers total manoeuvrability to

the boat and the opportunity to move the bow and the stern separately from

each other. This enables you to move the boat sideways in both directions

and to turn the boat around its own axis staying at the same place.

• Again,ifindoubt,tryinopenwaterrst!

• If original Side-Power panel is used, the panel shuts off automatically

approx 6-9 minutes after last use.

Hvordan bruke Side-Power thruster

NO

1. Skru på hovedstrømmen (skru alltid av hovedstrømmen når du ikke er

om bord i båten).

2. Det er fordel om de prøver baugthrusteren på åpent vann den første gangen.

3. Skru på kontrollpanelet ved å trykke inn begge ”on” knappene på

Side-Power panelet. Hvis annet en originalt panel brukes må dette skrus på.

4. Snu baugen i ønsket retning ved å trykke rød knapp for babord, og grønn

knapp for styrbord. Hvis du har joystickpanel så må stikka dyttes i den ret-

ning baugen skal vendes. Andre kontrollenheter som fotbrytere, eller bry-

tere på gass hendel kan også brukes. Disse er vanligvis logisk installert og

lette og operere. Ved tvil lønner det seg og prøve på åpent vann først.

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018 9

5. Avhengig av hvor stor fart baugen får sideveis må thrusteren stoppes før

baugen er i riktig posisjon, dette fordi baugen vil fortsette sideveis litt

etter thrusteren skruses av.

Hvordan bruke en enkel hekkthruster

Enkelte båter vil av plassmessige, eller andre hensyn bare installere en

hekkthruster. I disse tilfeller brukes hekkthrusteren på samme måte som

baugthrusteren.

Hvordan bruke hekk og baugthruster kombinert

Kombinasjonen av baug og hekkthruster gir en total kontroll over båtens

bevegelser p.g.a. muligheten til å bevege hakken og baugen uavhengig

av hverandre. Båten kan skyves sidelengs og dreies rundt sin egen akse.

• Det er også her fordel å prøve ut systemet på åpent vann.

• Om orginalt Side-Power panel blir brukt så vil dette slås av automatisk

etter ca. 6-9 minutter etter siste gang thrusteren ble brukt.

Benutzung von Side-Power Thrustern

DE

1. Die Bugschraube über deren Hauptschalter einschalten. Den Hauptschalter

immer ausschalten, wenn niemand an Bord ist.

2. Nehmen Sie sich etwas Zeit, um sich auf offenem Gewässer mit der

Steuerung de Bugschraube vertraut zu machen.

3. Original Side-Power Panels durch gleichzeitiges Drücken der “ON” Knöp-

fe einschalten. Falls eine anderes Panel verwendet wird, den On/Off

Schalter für die Bugschraube einschalten.

4.DenBugindiegewünschteRichtungbewegen;rot/BackbordKnopf

für Richtung Backbord, grün / Steuerbord Knopf für Richtung Steuer-

bord. Bei Verwendung eines Joystick Panels, dieses in die gewünschte

Richtung bewegen. Kontrollpanels wie Fuß- und Kippschalter können

ebenfalls verwendet werden. Diese sind normalerweise logisch installiert,

d.h. der Bug folgt der entsprechenden Panelvorgabe. Bei Unklarheit, zu-

nächst auf offenem Gewässer ausprobieren.

5. Abhängig von der Geschwindigkeit, mit der sich der Bug seitwärts bewe-

gt, muß die Steuerung bereits vor Erreichen des Endpunktes aufhören,

da sich der Bug noch etwas in die entsprechende Richtung “nachbewegt”.

Benutzung einer Heckschraube

Einige Schiffe haben aufgrund von Platzmangel im Bug stattdessen eine

Heckschraube installiert. In diesem Fall ist die Heckschraube wie eine

Bugschraube (siehe oben) zu verwenden, um das Heck zu bewegen.

Gemeinsame Benutzung von Bug- und Heckschraube

Die Kombination von Bug- und Heckschraube bietet die unabhängige

Manövrierbarkeit von Bug und Heck. Dies eröffnet die Möglichkeit, das

Boot seitwärts in beiden Richtungen oder auf der Stelle um die eigene

Achse zu bewegen.

• Bei Unklarheit, zunächst auf offenem Gewässer ausprobieren.

• Nach der letzten Benutzung schaltet das Original Side-Power Panel au-

tomatisch nach ca. 6-9 Minuten ab.

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018

10

Warranty Statement

EN

Warranty statement

EN

1. The equipment manufactured by Sleipner Motor AS (The “Warrantor”) is warranted to be free from defects in workmanship and materials under normal

use and service.

2. This Warranty is in eff ect for of two years (Leisure Use) or one year (Commercial use) from the date of purchase by the user. Proof of purchase must be

included, to establish that it is inside the warranty period.

3. This Warranty is transferable and covers the product for the specifi ed time period.

4. In case any part of the equipment proves to be defective, other than those parts excluded in paragraph 5 below, the owner should do the following:

(a) Prepare a detailed written statement of the nature and circumstances of the defect, to the best of the Owner’s knowledge, including the date of

purchase, the place of purchase, the name and address of the installer, and the Purchaser’s name, address and telephone number;

(b) The Owner should return the defective part or unit along with the statement referenced in the preceding paragraph to the warrantor,

Sleipner Motor AS or an authorized Service Centre, postage/shipping prepaid and at the expense of the Purchaser;

(c) If upon the Warrantor’s or Authorized Service Centre’s examination, the defect is determined to result from defective material or workmanship, the

equipment will be repaired or replaced at the Warrantor’s option without charge, and returned to the Purchaser at the Warrantor’s expense;

(d) no refund of the purchase price will be granted to the Purchaser, unless the Warrantor is unable to remedy the defect after having a reasonable

number of opportunities to do so. Prior to refund of the purchase price, Purchaser must submit a statement in writing from a professional boating

equipment supplier that the installation instructions of the Installation and Operation Manual have been complied with and that the defect remains;

(e) warranty service shall be performed only by the Warrantor, or an authorized Service Centre, and any attempt to remedy the defect by anyone else

shall render this warranty void.

5. There shall be no warranty for defects or damages caused by faulty installation or hook-up, abuse or misuse of the equipment including exposure to

excessive heat, salt or fresh water spray, or water immersion except for equipment specifi cally designed as waterproof.

6. No other express warranty is hereby given and there are no warranties which extend beyond those described in section 4 above. This Warranty is

expressly in lieu of any other expressed or implied warranties, including any implied warranty of merchantability, fi tness for the ordinary purposes for

which such goods are used, or fi tness for a particular purpose, and any other obligations on the part of the Warrantor or its employees and

representatives.

7. There shall be no responsibility or liability whatsoever on the part of the Warrantor or its employees and representatives for injury to any person or

persons, or damage to property, loss of income or profi t, or any other consequential or resulting damage or cost which may be claimed to have been

incurred through the use or sale of the equipment, including any possible failure or malfunction of the equipment, or part thereof.

8. The Warrantor assumes no liability for incidental or consequential damages of any kind including damages arising from collision with other vessels

or objects.

9. This warranty gives you specifi c legal rights, and you may also have other rights which vary from country to country.

Control Panel 8950, 8955, 8960, 8965, 8940, 8909C version 3023-6 - 2018 11

Warranty statement

EN

1. The equipment manufactured by Sleipner Motor AS (The “Warrantor”) is warranted to be free from defects in workmanship and materials under normal

use and service.

2. This Warranty is in eff ect for of two years (Leisure Use) or one year (Commercial use) from the date of purchase by the user. Proof of purchase must be

included, to establish that it is inside the warranty period.

3. This Warranty is transferable and covers the product for the specifi ed time period.

4. In case any part of the equipment proves to be defective, other than those parts excluded in paragraph 5 below, the owner should do the following:

(a) Prepare a detailed written statement of the nature and circumstances of the defect, to the best of the Owner’s knowledge, including the date of

purchase, the place of purchase, the name and address of the installer, and the Purchaser’s name, address and telephone number;

(b) The Owner should return the defective part or unit along with the statement referenced in the preceding paragraph to the warrantor,

Sleipner Motor AS or an authorized Service Centre, postage/shipping prepaid and at the expense of the Purchaser;

(c) If upon the Warrantor’s or Authorized Service Centre’s examination, the defect is determined to result from defective material or workmanship, the

equipment will be repaired or replaced at the Warrantor’s option without charge, and returned to the Purchaser at the Warrantor’s expense;

(d) no refund of the purchase price will be granted to the Purchaser, unless the Warrantor is unable to remedy the defect after having a reasonable

number of opportunities to do so. Prior to refund of the purchase price, Purchaser must submit a statement in writing from a professional boating

equipment supplier that the installation instructions of the Installation and Operation Manual have been complied with and that the defect remains;

(e) warranty service shall be performed only by the Warrantor, or an authorized Service Centre, and any attempt to remedy the defect by anyone else

shall render this warranty void.

5. There shall be no warranty for defects or damages caused by faulty installation or hook-up, abuse or misuse of the equipment including exposure to

excessive heat, salt or fresh water spray, or water immersion except for equipment specifi cally designed as waterproof.

6. No other express warranty is hereby given and there are no warranties which extend beyond those described in section 4 above. This Warranty is

expressly in lieu of any other expressed or implied warranties, including any implied warranty of merchantability, fi tness for the ordinary purposes for

which such goods are used, or fi tness for a particular purpose, and any other obligations on the part of the Warrantor or its employees and

representatives.

7. There shall be no responsibility or liability whatsoever on the part of the Warrantor or its employees and representatives for injury to any person or

persons, or damage to property, loss of income or profi t, or any other consequential or resulting damage or cost which may be claimed to have been

incurred through the use or sale of the equipment, including any possible failure or malfunction of the equipment, or part thereof.

8. The Warrantor assumes no liability for incidental or consequential damages of any kind including damages arising from collision with other vessels

or objects.

9. This warranty gives you specifi c legal rights, and you may also have other rights which vary from country to country.

Worldwide sales and service

www.side-power.com

SLEIPNER MOTOR AS

P.O. Box 519 N-1612 Fredrikstad Norway

The information given in the document was correct at the time it was published. However, Sleipner Motor AS can not accept liability for any inaccuracies or omissions it

maycontain.Continuousproductimprovementmaychangetheproductspecicationswithoutnotice.Therefore,SleipnerMotorAScannotacceptliabilityforanypos-

sible differences between product and document.

This manual suits for next models

5

Table of contents

Other SLEIPNER MOTOR AS Control Panel manuals

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER PJC-322 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER S-linkControl Panel 8700 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS 8700 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER 86-08955 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER S-linkControl Panel PJC211 User manual