SLEIPNER MOTOR AS SE 170 User manual

Keep this

manual onboard !

SIDE-

POWER

Thruster systems

Installation and user's manual

GB

NInstallasjons og brukermanual

Made in Norway

©Sleipner Motor AS 2007

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

Tel: +47 69 30 00 60

Fax: +47 69 30 00 70

www.side-power.com

sidepower@sleipner.no

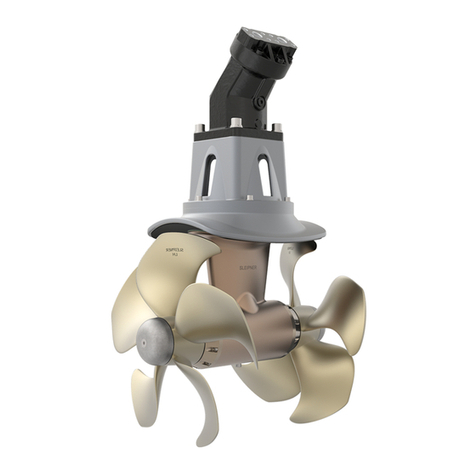

SE 170/250TC

SE210/250TC

2SE 170/250 TC - SE210/250TC 1.0.0- 2008

Innhold

N

SAMSVARS ERKLÆRING

Sleipner Motor AS

Postboks 519

N-1612 Fredrikstad, Norge

Erklærer at dette produktet med tilhørende

standard kontrollsystemer er i samsvar med

helse, og sikkerhetskravene i henhold til Direk-

tiv 89/336/EEC FRA 23 Mai 89, korrigert av

92/31/EEC og 93/68/EEC.

Installasjons instruksjoner

Tekniske spesikasjoner.............................................................3

Planlegning og viktige forbehold.................................................4

Tunnel installasjon

Plassering av tunnel/thruster......................................................5

Utforming av tunnelåpninger ......................................................6

Hvordan unngå turbulens rundt tunnelåpninger .........................7

Forslag til tunnelinstallasjon på seilbåt.......................................8

Tunnel installasjon i glassberbåter ...........................................9

Thruster installasjon

Gearhus og motorbraket...........................................................11

Propeller ...................................................................................12

Elektromotor .............................................................................13

Elektrisk installasjon .................................................................14

Kontrollpanel og kontrollkabler .................................................15

Koblingsskjema elektrisk ..........................................................16

Koblingsskjema ........................................................................17

Sjekkpunktliste for kontroll av installasjon ................................18

Brukermanual

Viktige forbehold.......................................................................19

Hvordan operere Sidepower thrustere .....................................20

Vedlikehold og servise..............................................................21

Problemer og løsninger ............................................................22

Garantierklæring ....................................................................23

Reservedelsliste ....................................................................24

Servicesentere ...................................................................... 28

Installation instructions

Technical specications............................................................. 3

Planning & important precautions.............................................. 4

Tunnel installation

Positioning of the tunnel / thruster ............................................ 5

How to shape the tunnel ends................................................... 6

How to prevent drag from tunnel installation ............................. 7

Possible tunnel installation in sailboats ..................................... 8

Tunnel installation in a GRP boat .............................................. 9

Thruster installation

Gearhouse and motorbracket.................................................. 11

Propeller.................................................................................. 12

Electromotor ............................................................................ 13

Electrical installation ............................................................... 14

Control panel and control-leads............................................... 15

Visual wiring diagram .............................................................. 16

Technical wiring diagram ........................................................ 17

Checklist for control of the installation..................................... 18

User's manual

Important user precautions...................................................... 19

How to use Sidepower thrusters.............................................. 20

Maintenance & service ............................................................ 21

Troubleshooting....................................................................... 22

Warranty statement .............................................................. 23

Spareparts list & drawing .................................................... 24

Service centres ..................................................................... 28

Contents

GB

DECLARATION OF CONFORMITY

We, Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad, Norway

declare that this product with accompanying

standard remote control systems complies with

the essential health and safety requirements

according to the Directive 89/336/EEC of 23

May 1989 amended by 92/31/EEC and

93/68/EEC.

3

SE 170/250 TC - SE210/250TC 1.0.0- 2008

Motor: Spesialutviklet reversibel DC-motor.

Girhus: Sjøvannsbestandig bronsje. Kulelagre på pro-

pellaksel. Kule og glidelager komb. på drivaksel.

Motorbraket: Sjøvannsbestandig aluminium.

Galvanisk isolert fra motor

Tunnel: Kryssvevet glassber.

Aluminium og ståltunnel på forespørsel.

Propell: 5-blads skewback "Q-prop" propell i kompositt-

materiale.

Batterier: Minimum anbefalt batteri størrelse.

(Kaldstart kapasitet etter DIN std.)

SE170/250TC 24V: 560 CCA DIN

SE210/250TC 24V: 700 CCA DIN

Drift tid: S2 = 3 min. Eller gjennomsnittlig 7-10% innen

en begrenset tidsperiode.

Sikkerhet: Elektronisk tidsforsinkelse forhindrer motorskade

ved rask retningsendring.

Motoren stanser automatisk ved overopphetning

(slår seg automatisk på etter nedkjøling).

Brytepinne mellom drivaksel og motor beskytter

gir hvis propell blir blokkert.

Om orginalt Side-Power panel blir brukt så vil

dette slås av automatisk etter 6 minutter etter

siste gang trøsteren ble brukt.

Integrerte microprossessor føler hele tiden på

releet, reduserer slitasje og risk for ”heng” på

relé. Trøsteren vil stoppe automatisk etter 3

minutter om det oppstår ”heng” på relé, eller

Tekniske spesikasjoner

N

Motor: Custom made reversible DC-motor.

Gearhouse: Seawater resistant bronze. Ballbearing at

propellershaft and combination of ballbearing

and slide bearing at driveshaft.

Motor bracket: Seawaterresistant aluminium,

galvanicly insulated from motor

Tunnel: Cross spun with rowing G.R.P tunnel

Steel & aluminum tunnels available at request.

Propeller: 5-blade skewback "Q-prop" propeller, breglass

reinforced composite.

Batteries:

Minimum recommended battery capacity

(cold crank capacity by DIN/SAE standard)

SE170/250TC 24V : 560 CCA DIN/1065 CCA SAE

SE210/250TC 24V : 700 CCA DIN/1330 CCA SAE

Max. use: S2 = 3 min. or appr. 7-10% within a limited time

frame.

Safety

:

Electronic time-lapse device protects against

sudden change of drive direction. Electric thermal

cut-off switch in electromotor protects against

over heating (auto reset when electro motor cools

down).

Flexible coupling between electro-motor and

driveshaft protects electromotor and gearsystem

if propeller gets jammed.

If original Sidepower panel is used, the panel

shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids,

reducing wear and risk of solenoid lock-in. Auto-

stop of thruster in case of accidental solenoid

lock-in or if run signal is continous for more than

3 minutes

Technical specications

GB

SE 170/250 TC SE210/250TC

Thrust [lbs] 341 462

A [in] 9,84 9,84

B [in] 16,6 18,80

Cmin. [in] 9,84 9,84

D [in] 11,81 11,81

D recommended [in] 23,6 23,60

Emin. [in] 0,28 0,24

Emax. [in] 0,39 0,51

Motor output [Hp] 10,7 13,5

Voltage [V] 24 24

Weight [lbs] 97 150

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

SE 170/250 TC SE210/250TC

Thrust [kg] 170 210

A [mm] 250 250

B [mm] 421 478

Cmin. [mm] 250 250

D [mm] 300 300

D recommended [mm] 600 600

Emin. [mm] 7 6

Emax. [mm] 10 13

Motor output [kW] 8 10

Voltage [V] 24 24

Weight [kg] 44 68

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

METRIC

IMPERIAL

4

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Technische Daten

D

C

Waterline

A

F

Motor: Custom made reversible DC-motor.

Gearhouse: Seawater resistant bronze. Ballbearing at

propellershaft and combination of ballbearing

and slide bearing at driveshaft.

Motor bracket: SP 75 Ti / SP 95 Ti / SP 125 Ti:

Seawaterresistant aluminium

Tunnel: Cross spun with rowing G.R.P tunnel

Steel & aluminum tunnels available at request.

Propeller: Symmetrical 4 blade propeller, fibreglass reinforced

composite.

Batteries:

Minimum recommended battery capacity

(cold crank capacity by DIN/SAE standard)

SP75Ti 12V : 550 CCA DIN/1045 CCA SAE

24V : 300 CCA DIN/570 CCA SAE

SP95Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

SP125Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

Max. use: S2 = 3 min. or appr. 7-10% within a limited time

frame.

Safety

:

Electronic time-lapse device protects against

sudden change of drive direction. Electric thermal

cut-off switch in electromotor protects against over

heating (auto reset when electro motor cools down).

Flexible coupling between electro-motor and

driveshaft protects electromotor and gearsystem

if propeller gets jammed.

If original Sidepower panel is used, the panel

shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids,

reducing wear and risk of solenoid lock-in. Auto-

stop of thruster in case of accidental solenoid

lock-in or if run signal is continous for more than

3 minutes

Technical specifications

GB

SP 75 Ti SP 95 Ti SP 125 Ti

Thrust [lbs] 165 209 275

A [in] 7,28 7,28 9,84

B [in] 13,9 15,3 15,7

Cmin. [in] 7,87 7,87 9,0

D [in] 6,7 6,7 11,0

D recommended [in] 13,4 13,4 22,0

Emin. [in] 0,24 0,24 0,28

Emax. [in] 0,31 0,31 0,39

Motor output [Hp] 6 8 8,7

Voltage [V] 12/24 12/24 12/24

Weight [lbs] 44 68 77

Gear oil capacity [fl.oz]2.367 2.367 6,736

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

SP 75 Ti SP 95 Ti SP 125 Ti

Thrust [kg] 75 95 125

A [mm] 185 185 250

B [mm] 352 389 398

Cmin. [mm] 200 200 230

D [mm] 170 170 280

D recommended [mm] 340 340 560

Emin. [mm] 6 6 7

Emax. [mm] 8 8 10

Motor output [kW] 4,4 6 6,5

Voltage [V] 12/24 12/24 12/24

Weight [kg] 20 31 37

Gear oil capacity [ml] 70 70 200

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

METRICMETRIC

METRICMETRIC

METRIC

IMPERIALIMPERIAL

IMPERIALIMPERIAL

IMPERIAL

Motor: Gleichstrommotor

Getriebegeh.: Seewasserbeständige Bronze. Kugellager an

der Propellerachse, Kombination von Kugel-

und Gleitlager an der Antriebsachse.

Motorhalterung: SP 75 Ti / SP 95 Ti / SP 125 Ti:

Seewasserbeständiges Aluminium

Tunnel: Glasfibertunnel (Kreuzgewebe)

Stahl- & Aluminiumtunnel auf Anfrage.

Propeller: Symmetrischer, 4 flügeliger Kaplanpropeller aus

Glasfiberverbundmaterial.

Batterie:

Empfohlene mind. Batteriekapazität

(Kaltstartkapazität nach DIN/SAE)

SP75Ti 12V : 550 CCA DIN/1045 CCA SAE

24V : 300 CCA DIN/570 CCA SAE

SP95Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

SP125Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

Betriebszeit: S2 = 3 min. oder ca. 7-10% innerhalb eines

beliebigen Zeitraumes.

Sicherheit

:

Elektronische Zeitverzögerung zum Schutz des

Getriebes bei plötzlichem Wechsel der Drehrich-

tung. Elektrischer Thermoschalter zum Schutz

des Motors gegen Überhitzung (erneute Betriebs-

bereitschaft nach Abkühlung).

Scherstift zwischen Elektromotor und Getriebe-

achse als Schutz, wenn der Propeller blockiert

ist. Nach der letzten Benutzung schaltet das

Original Side-Power Panel automatisch nach 6

Minuten ab. Der integrierte Mikroprozessor

überwacht das Relais und reduziert sowohl

Verschleiß, als auch Relaisblockade. Das

Bustrahlruder stoppt automatisch bei Relais-

Blockade, oder bei Betrieb des Bugstrahlruders

von mehr als 3 Minuten.

4SE 170/250 TC - SE210/250TC 1.0.0- 2008

Viktige forholdsregler og planlegning

N

Før installasjon må instruksjonsmanualen leses gjennom, og bruker må gjøre seg kjent med produktet.

Thrusteren må ikke installeres i rom som der gnister og høy varme medfører brannfare.

Elektromotoren vil produsere karbon støv fra børstene under drift slik att en lagringsplass må fysisk avskilles fra thrusteren for å unngå att det man

lagrer blir støvete / møkkete.

Elektromotoren er avhengig av god kjøling, sørg derfor for ventilasjon eller god plass rundt motoren ved montering.

Elektromotoren kan monteres i alle vinkeler i fra vertikalt til horisontalt der hvor plassutnyttelsen krever det.

Hvis elektromotoren monteres i en vinkel på mer en 30o, må den støttes opp separat.

Elektromotoren må håndteres forsiktig. Den må ikke bæres etter kontaktpunktene, og motoren må ikke settes ned på drivakselen.

Følg de anbefalte målene som er oppgitt i manualen, propell eller girhus må ikke stikke ut av tunnelen.

Elektromotoren, tilhørende komponenter, kontakter eller åpne ledd i strømkabler må monteres så de ikke utsettes for vann.

Vi anbefaler å male girhuset med bunnstoff. PS sinkanoder, pakninger og propellaksel skal ikke påføres bunnstoff.

Ikke påfør gelcoat / topcoat eller lignende inne i tunellen. Det er bare plasee til ett lag primer og to lag bunnstoff mellom tunellen og propellene.

Når båten ligger på land har ikke elektromotoren den motstanden den har i vann. Motoren bruker derfor ekstremt kort tid før den oppnår ødeleggende

høyt turtall. Med båten på land, unngå hurtig bytte av driftsretning da det kan forårsake skade på truster.

Denne manualen er beregnet som støttemateriell for montører med erfaring / utdanning, og har derfor ikke all informasjon nødvendig for å oppnå en

korrekt installasjoner.

Installer ikke elektromotoren i nærheten av lett brennbart materiale, da motoren oppnår temperaturer over 100oC ved før den stopper automatisk.

Området intill thrusteren må ikke benyttes som lagringsplass da motoren vil bli varm samt att dette vil medføre en fare for att elektriske koblinger blir

løse eller kortslutter

I de tilfeller båter skal godkjennes eller klassiseres i henhold til internasjonal, eller spesielle standarder, er montør ansvarlig for at de gjeldende lover

og regelverk følges. Sleipner Motor AS kan ikke garantere at instruksjonene i denne manualen er i henhold til alle gjeldende regelverk og standarder.

NB ! Ved feilaktig installasjon av panel, thruster eller tunnel frafaller all garanti stilt av Sleipner Motor AS.

Planning and important precautions

GB

Prior to installation, it is important that the installer reads this guide to ensure necessary acquaintance with this product.

The thruster must NOT be installed in compartments that require ignition proof electric equipment. If necessary, make a separate

compartment.

The electromotor will generate some carbon dust so that any storage compartment must be separated from the thruster to prevent the stored items

from becoming dusty/dirty.

If you are installing the Sidepower in a small room /compartment, it should be ventilated to ensure cooling of the electromotor.

If the height in the room you are installing the Sidepower is limited, the Sidepower can be installed horizontally or at any angle in between.

- If the electro motor is positioned more than 30o off vertical, it must be supported separately.

- The electromotor must be handled carefully. Do not lift it by the internal connections/main terminals or put it down on the driveshaft.

- Beware to keep installation within advised measurements. No part of the propeller or gearhouse must be outside the tunnel.

The electromotor, its components, contacts / plugs or other joints in the control cables must be mounted so that they will keep dry at all times.

We advice to paint the gearhouse and propellers with antifouling. PS! Do not paint the zinc anodes, sealings or propellershafts.

Do not nish the inside of the tunnel with a layer of gelcoat / topcoat or similar. It is only room for a thin layer of primer and two layers of

anti-fouling between the tunnel and the props.

With the boat on land, only run the thruster for a fraction of a second, as without resistance it will accelerate very fast to a damaging rpm.

Also, while the thruster is in air, make sure that the propellers have come to a complete stop before performing a directions change of the

thruster, as it might cause damage to the thruster.

This manual is intended to support educated/experienced staff and is therefore not sufcient in all details for the correct installation.

Don’t install the electromotor at close range to easily ammable objects as it will reach over 100°C before the temperature switch is

activated.

Do not store items close to the thruster motor as it gets hot as well as any loose items near the thruster motor can cause problems with electrical wir-

ing coming loose and short-circuiting.

When installed in boats approved or classied according to international or special national rules, the installer is responsible for following the demands

in accordance with these regulations / classication rules. The instructions in this guide can not be guaranteed to comply with all

different regulations/classication rules.

These instructions are only general instruction. If you are not skilled to do this work, please contact professional installers for assistance.

NB! Faulty installation of the tunnel, thruster or panel will render all warranty given by Sleipner Motor AS void.

5

SE 170/250 TC - SE210/250TC 1.0.0- 2008

Plassering av tunnel og thruster

N

Tunnelen bør plasseres lengst mulig frem i baugen (Fig. 1)

For å oppnå mest mulig moment rundt båtens dreiepunkt, er det meget

viktig å plassere tunnelen så langt fremme som mulig. Avstanden fra

båtens dreiepunkt til thruster vil ha stor betydning på thrusterens effekt.

Eks.:

A: 55kg skyvekraft x 11m moment = 605kgm skyvekraft

B: 55kg skyvekraft x 10m moment = 550kgm skyvekraft

Posisjon A vil gi 10% mer skyvekraft til rotasjon.

Tunnelen skal plasseres dypest mulig (Fig. 2)

Tunnelen skal plasseres så dypt som mulig av to grunner:

1. Så luft ikke suges ned i tunnelen å ødelegger skyvekraften.

2. Ved å øke vanntrykket jobber propellen mer effektivt.

Hovedregelen er at tunnelen skal plasseres minimum ½ x tunnelen dia.

under vannlinje. Anbefalt dybde er minst ¾ x dia. under vannlinje (). Når

tunnelen er plassert 33-35 cm under vannlinjen bør andre faktorer vur-

deres som viktigere, d.v.s. å plassere tunnelen lengre frem.

Optimal tunnel lengde

Dersom tunellen blir for lang vil friksjonen i tunellen reduser vannhastig-

heten og derved effekten.

Dersom tunellen blir for kort (normalt bare i nedre del av tunellen) kan det

oppstå kavitasjons problemer da vannet ikke har tid / av-stand til å «rette

opp strømningsretningen» før det treffer propellen (Fig. 3&4). Denne

kavitasjonen vil redusere effekten og lage mye støy.

Den optimale tunell lengden er 2 til 4 ganger tunell diameteren og dersom

tunellen blir så mye som 6 til 7 ganger diameteren i lengde vil effekt tapet

bli klart merkbart.

Positioning of the tunnel / thruster

GB

The Thruster should be as far forward as possible (Fig. 1)

Because of the leverage effect around the boats pivot point, it is very

important for the thrusters actual effect in the boat to get it as far for-ward

as possible. The relative distance change from the boats pivot point to the

thruster will be the change of actual thrust for the boat.

Example:

A: 55kg thrust x 11m leverage = 605kgm torque to rotate the boat

B: 55kg thrust x 10m leverage = 550kgm torque to rotate the boat

In position A you will get 10% more thrust to turn the boat around.

The thruster should be placed as deep as possible (Fig. 2)

The tunnel should be placed as deep as possible for two reasons:

1. So that it does not suck down air from the surface which will

destroy the thrust completely.

2. To get as high as possible a water pressure to get maximum

efciency from the propeller.

Generally the top of the tunnel should be a minimum of ½ x the tunnel

diameter below the waterline. This is an absolute minimum and we rec-

ommend that it is at least ¾ x tunnel diameter () below the waterline.

A really good distance is about 1/1 x tunnel diameter () below the

waterline.

When you get the top of the tunnel 30-35 cm*/1 feet below the surface,

other factors should be considered more important, i.e. moving the thrust-

er further forward.

Optimal tunnel length

If the tunnel gets to long, the friction inside will reduce the water speed

and thereby the thrust.

If the tunnel gets to short (normally only in the bottom section of the tun-

nel) you can get cavitation problems as the water will not have had time to

“straighten” itself before reaching the propeller (Fig. 3&4). This cavitation

will reduce performance as well as creating a lot of noise.

The optimal tunnel length is 2 to 4 x tunnel diameter and you should avoid

tunnels longer than 6 to 7 times the tunnel diameter as the performance

reduction is then clearly noticeable.

10

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Tunnelplazierung soweit vorne wie möglich (Fig. 1)

Um einen möglichst großen Abstand vom Drehpunkt des Schiffes zu

erreichen, ist der Sidepower möglichst weit vorne einzubauen.

Eine Vergrößerung des Abstandes vom Drehpunkt des Schiffes

hat eine direkte Auswirkung auf die verfügbare Schubkraft.

Beispiel :

A: 55kg Schubkraft x 11m = 605kgm zum Wenden des Bootes

B: 55kg Schubkraft x 10m = 550kgm zum Wenden des Bootes

In Beispiel A stehen damit 10% mehr Schubkraft zur Verfügung.

Den Tunnel so tief wie möglich positionieren (Fig. 2)

Den Tunnel aus zwei Gründen so tief wie möglich positionieren:

1. Damit nicht Luft mitangesaugt wird, die die Schubkraft

vollständig herabsetzt.

2. Um einen möglichst hohen Wasserdruck zu erhalten, um die

maximale Effizienz des Propellers erreichen.

Die Oberkante des Tunnels muß mind. einen halben Tunnel-

durchmesser unterhalb der Wasserlinie liegen. Dieser Wert ist ein

absolutes Minimum. Besser ist ein Wert von ca. ¾ des

Tunneldurchmessers (-). Optimal ist eine Abstand von 1/1 x

Tunneldurchmesser (--) zur Wasserlinie.

Liegt die Oberkante des Tunnels 30-35cm* / 1fuß unterhalb der

Wasserlinie, können andere Faktoren berücksichtigt werden.

Optimale Tunnellänge

Bei einem zu langem Tunnel reduziert der Reibungsverlust die

Wassergeschwindigkeit und damit die Schubkraft.

Bei einem zu kurzem Tunnel (häufig im unteren Bereich des

Tunnels) können Kavitationsprobleme entstehen, da sich das

Wasser nicht gerade auszurichten kann (Fig. 3&4). Diese Kavita-

tion ist leistungsreduzierend und kann starken Lärm verursachen.

Die optim. Tunnellänge ist das 2-4 fache des Tunneldurchmessers.

Tunnellängen von mehr als dem 6-7 fachen des Tunneldurch-

messers sollten vermieden werden, da dadurch die Leistung

reduziert wird.

Positionierung von Tunnel / Thruster

D

Positioning of the tunnel / thruster

GB

A = 11,0m

B = 10,0m

A

B

Pivot

point

min.

1/3Ø

Ø

min.

1/3Ø

3/4Ø

-

1/1 Ø

--

30 - 35 cm*

min.

1/2Ø

Fig. 1

Fig. 2

Fig. 3

Fig. 4

The Thruster should be as far forward as possible (Fig. 1)

Because of the leverage effect around the boats pivot point, it is very

important for the thrusters actual effect in the boat to get it as far for-

ward as possible. The relative distance change from the boats pivot

point to the thruster will be the change of actual thrust for the boat.

Example:

A: 55kg thrust x 11m leverage = 605kgm torque to rotate the boat

B: 55kg thrust x 10m leverage = 550kgm torque to rotate the boat

In position A you will get 10% more thrust to turn the boat around.

The thruster should be placed as deep as possible (Fig. 2)

The tunnel should be placed as deep as possible for two reasons:

1. So that it does not suck down air from the surface which will

destroy the thrust completely.

2. To get as high as possible a water pressure to get maximum

efficiency from the propeller.

Generally the top of the tunnel should be a minimum of ½ x the

tunnel diameter below the waterline. This is an absolute minimum

and we recommend that it is at least ¾ x tunnel diameter (-) below

the waterline. A really good distance is about 1/1 x tunnel diameter

(--) below the waterline.

When you get the top of the tunnel 30-35 cm*/1 feet below the

surface, other factors should be considered more important, i.e.

moving the thruster further forward.

Optimal tunnel length

If the tunnel gets to long, the friction inside will reduce the water

speed and thereby the thrust.

If the tunnel gets to short (normally only in the bottom section of the

tunnel) you can get cavitation problems as the water will not have

had time to “straighten” itself before reaching the propeller (Fig. 3&4).

This cavitation will reduce performance as well as creating a lot of

noise.

The optimal tunnel length is 2 to 4 x tunnel diameter and you should

avoid tunnels longer than 6 to 7 times the tunnel diameter as the

performance reduction is then clearly noticeable.

6SE 170/250 TC - SE210/250TC 1.0.0- 2008

Tunnelåpninger

N

Avrundede åpninger vil minke støy, og maksimere effekt.

Vi anbefaler å avrunde tunnelåpningene mest mulig.

Den optimale avrundingen har en radie som er 10% av tunnelens diam-

eter.

Hvorfor er en avrundet tunnelåpning så viktig?

1. En avrundet tunnelåpning vil forhindre at det oppstår turbulens / kavi-

tasjon, noe som vil oppstå ved en installasjon med skarpe kanter.

Turbulensen forårsaker mer støy, og begrenser skyvekraften.

- Turbulensen / kavitasjonen blokkerer tunnelen og svekker skyvekraf-

ten.

- I det kavitasjon og turbulens når propellen påvirkes ytelsen til denne

og øker støyen.

2. En avrundet tunnelåpning gjør også at thrusteren suger vann langs

skroget på båten. Dermed oppstår det et lavtrykk som vil hjelpe å suge

båten i dreieretningen. Med skarpe åpninger klarer ikke thrusteren å

suge vann langs skroget, og lavtrykket uteblir. Så mye som 40% av

skyvekraften har blitt målt til å ligge her på noen installasjoner.

NB! Propellene til Sidepower thrustere kaviterer ikke på arbeids-has-

tighet, så kavitasjon og støy som oppstår som følge av kavitasjon,

skapes av tunnel installasjonen.

NB! Selv der en perfekt avrunding ikke er mulig er det viktig å runde av

kantene så mye som mulig, en tunnelåpning med skråkant vil ha

stor effekt fremfor en med skarpkant (se side 20, ill. 1b & 1d).

Tunnel ends

GB

Rounded tunnel ends will maximize thrust and minimize noise.

We recommend rounding the tunnel connection to the hull-side as

much as possible.

The optimum rounding has a radius of 10% of the tunnels diameter.

Important advantages over sharp tunnel to hull connections are:

1. The rounded tunnel end will prevent creation of turbulence

cavitation that will come from a sharp tunnel end when water

passes by fast, thereby preventing a double negative impact on

the thrust and noise level (Fig. 1 & 2).

- The turbulence / cavitation blocks the outer area of the tunnel

and thereby reduces the effective tunnel diameter and thrust.

- The turbulence / cavitation hits the propeller and thereby reduce

the propellers performance and creates noise.

2. The curved tunnel end makes the thruster take water also from

along the hull-side, creating a vacuum that will suck the boat

sideways and thereby give additional thrust (Fig. 3 & 4).

With a sharp tunnel end, the thruster will be unable to take water

from along the hull-side, and you will not get the desired vacuum

and additional thrust. This “free” additional thrust can in optimal

installations be as much as 30 - 40% of the total thrust.

NB! A Sidepower thruster propeller does not cavitate at working

speed so that all cavitation and cavitation noise in the tunnel will

be caused by the tunnel installation.

NB! Even if it is not possible to make the perfect rounding, it is very

important to round the tunnel end as much as possible. A

angled tunnel to hull connection will also do much of the same

job as a rounded connection (see page 20, Fig. 1b & 1d).

12

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Formgebung der Tunnelenden

--

--

-

//

//

/

Abgerundete Tunnelenden erhöhen die Schubkraft und

reduzieren das Geräuschniveau.

Der Bereich Tunnelende / Außenseite des Rumpfes ist soweit

möglich abzurunden. Der optimale Wert für den Radius dieser

Rundung beträgt 10% des Tunneldurchmessers.

Vorteile gegenüber einer scharfen Tunnel / Rumpfverbindung sind:

1. Abgerundete Tunnelenden verhindern Turbulenzen / Kavitation,

wie sie an scharfenkantigen Tunnelenden auftreten. Damit

werden zwei negative Auswirkungen auf Schubkraft und

Geräuschentwicklung vermieden (Fig. 1 & 2).

- Turbulenz / Kavitation blockieren den äußeren Tunnelbereich.

Dadurch werden effektiver Tunneldurchmesser und Schub-

kraft reduziert.

- Die Turbulenz / Kavitation trifft auf den Propeller und reduziert

dessen Effektivität und führt zu zusätzl. Geräuschentwicklung.

2. Abrundungen ermöglichen, daß Wasser entlang der Rumpf-

außenseite angesaugt werden kann. Dadurch entsteht ein

Vakuum ("zusätzliche" Schubkraft"), das das Schiff seitwärts

bewegt (Fig. 3 & 4). Bei scharfkantigen Enden kann kein

Wasser entlang der Rumpfaußenseite angesaugt werden,

wodurch das benötigte Vakuum nicht zustande kommt.

Diese Schubkraft kann bei optimaler Installation bis zu 30-40%

der absoluten Schubkraft betragen.

NB ! Sidepower Propeller sind so ausgelegt, daß sie nicht

kavitieren, sodaß die Geräuschentwicklung aufgrund von

Kavitation durch die Tunnelinstallation bedingt ist.

NB ! Ist eine optimale Abrundung nicht möglich, so sind die

Tunnelenden soweit möglich abzurunden. Angeschrägte

Tunnel / Rumpfverbindungen sind zu einem gewissen Grad

ebenfalls mit ähnlich positiven Auswirkungen wie eine

Abrundung verbunden (siehe Seite 20, Fig. 1b & 1d).

Tunnel ends

Fig. 2

Fig. 4

Fig. 1

Fig. 3

GB D

R = 0,1 x D (10%)

R = 0,1 x D (10%)

D

Rounded tunnel ends will maximize thrust and minimize

noise.

We recommend rounding the tunnel connection to the hull-side as

much as possible.

The optimum rounding has a radius of 10% of the tunnels diameter.

Important advantages over sharp tunnel to hull connections are:

1. The rounded tunnel end will prevent creation of turbulence

cavitation that will come from a sharp tunnel end when water

passes by fast, thereby preventing a double negative impact on

the thrust and noise level (Fig. 1 & 2).

- The turbulence / cavitation blocks the outer area of the tunnel

and thereby reduces the effective tunnel diameter and thrust.

- The turbulence / cavitation hits the propeller and thereby reduce

the propellers performance and creates noise.

2. The curved tunnel end makes the thruster take water also from

along the hull-side, creating a vacuum that will suck the boat

sideways and thereby give additional thrust (Fig. 3 & 4).

With a sharp tunnel end, the thruster will be unable to take water

from along the hull-side, and you will not get the desired vacuum

and additional thrust. This “free” additional thrust can in optimal

installations be as much as 30 - 40% of the total thrust.

NB! A Sidepower thruster propeller does not cavitate at working

speed so that all cavitation and cavitation noise in the tunnel will

be caused by the tunnel installation.

NB! Even if it is not possible to make the perfect rounding, it is very

important to round the tunnel end as much as possible. A

angled tunnel to hull connection will also do much of the same

job as a rounded connection (see page 20, Fig. 1b & 1d).

7

SE 170/250 TC - SE210/250TC 1.0.0- 2008

Motstand forårsaket av tunnel

Prevent drag from tunnel N

Et mulig problem for seilbåter eller meget hurtiggående båter er motstand

i tunnelen. Aktre ende på tunnelen vil være en liten loddrett ate mot

vannstrømmen som skaper uønsket motstand.

Denne aten kan også forårsake problemer med at vann føres inn i tun-

nelen under seilas, eller kjøring i høy fart og får da propellen til å rotere,

dette skaper uønsket støy.

Det er to mulige løsninger på problemet, avhengig av hva som er enklest

å få til på båten.

1. Den løsningen som vanligvis reduserer motstanden mest er å lage

en fordypning i skroget i aktre ende av tunnelåpningen. Den loddrette

aten vil da forsvinne og dermed motstanden. Hovedregelen å følge

er at bakkanten av tunnelen ikke skal synes når man står rett foran

båten å titter akterover langs båten senterlinje. Dybden, utformingen

og vinkling av fordypningen avhenger av båttypen, og hvordan vannet

følger skroget, men de este båter vil være tjent en fordypning som

vinkler lett nedover (Fig. 2).

2. Motstanden vil også reduseres av en spoiler i forkant av tunnelen.

Spoileren fører det meste av vannstrømmen rundt og forbi tunnelen.

Størrelsen og utformingen på spoileren avhenger av båten. Hove-

dregelen er at bakkanten av tunnelen ikke skal synes når man står

rett foran båten å titter akterover langs båten senterlinje. Den enkleste

måten å lage spoileren på er å la tunnelen stikke ut i forkant av tunne-

len, og forme spoileren opp mot den (Fig. 3).

Det er alltid viktig å avrunde tunnelåpningene mest mulig for å motvirke

støy og for å få mest mulig effekt av thrusteren.

Mer informasjon om dette på side 20.

GB

A possible problem in sailboats or fast powerboats is that they get a

drag from the back face of the tunnel, as this becomes a “at” area

facing the water ow (Fig. 1).

This can also create problems with the thruster spinning (passive)

and making noise while sailing or driving the boat with water being

pushed through the tunnel at high speed.

This can be solved in two different ways, depending on what is

possible or easier to do.

1. The best solution which normally reduces the drag most is to make

a recess in the hull at the back of the tunnel. Thereby the back face

is gone and about all the drag (Fig. 2). The depth and shape of this

recess will depend on the boat. Basically you should not see the back

face of the tunnel when standing directly in front of the tunnel at the

angle of the boats centreline. The angle up or down backwards of the

insert in the hull, depends on the hull shape, but normally it is angled

slightly down because of the water ow on this area of the hull.

2. The drag will also be reduced a lot, especially in fast power boats, by

making a deector / spoiler in front of the tunnel. This will push the

water ow out from the hull so that most of it passes by the back face

of the tunnel (Fig. 3).

The shape and size of this deector will depend on the hull shape.

Basically you should not see the back face of the tunnel when standing

directly in front of the tunnel at the angle of the boats centreline. The

easiest way of making this is to let a part of the tunnel stick out in the

lower forward area of the hole, and use this as a support to mould a

soft curve/spoiler shape.

Remember to still round the tunnel ends as much as possible to get

optimum thruster performance and minimum noise. For more

information on how to practically do this see page 20.

14

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Segelboote und sehr schnelle Booten können gelegentlich durch

auf die rückseitige Fläche des Tunnels auftreffendes Wasser

gebremst werden (Fig. 1).

Dies kann dazu führen, daß sich der Thruster durch den perma-

nenten Wasserdurchfluß hörbar passiv zu drehen beginnt.

Das Problem kann je nach Möglichkeit auf zwei Arten beseitigt

werden.

1. Der störende Effekt wird am deutlichsten reduziert, indem man

im Rumpfbereich hinter dem Tunnel eine Aussparung vornimmt.

Dadurch werden Auftreffläche und störender Effekt eliminiert

(Fig. 2).

Tiefe und Form dieser Aussparung hängen vom Boot ab.

Die Innenseite des Tunnels sollte von vorne prinzipiell nicht

sichtbar sein.

Der mögliche Winkel der Aussparung hängt meist von der

Rumpfform ab. Bedingt durch die Wasserströmung in diesem

Bereich sollte dieser Winkel leicht nach unten gerichtet sein.

2. Der Geschwindigkeitsverlust kann speziell bei schnellen Booten

durch einen Abweiser bzw. Spoiler vor dem Tunnel deutlich

reduziert werden.

Das Wasser wird so beeinflußt, daß es größtenteils an der

frontalen Fläche vorbei geleitet wird (Fig. 3).

Form und Größe des Abweisers hängen von der Rumpfform ab.

Prinzipiell sollte auch hier die Innenseite des Tunnels von vorne

nicht sichtbar, sondern durch den Abweiser verdeckt sein.

Dieser läßt sich einfach realisieren, indem man den Tunnel ein

Stück aus dem Rumpf herausstehen läßt und darauf einen

geschwungenen Abweiser / Spoiler formt.

Die Tunnelenden sind zur vollen Leistung und minimalen

Geräuschentwicklung des Thrusters weitgehend abzurunden.

Weitere Informationen siehe Seite 20.

Optimaler Strömungsverlauf am Rumpf

D

Prevent drag from tunnel

GB

--

--

-

//

//

/

Fig. 2Fig. 1 Fig. 3

--

--

-

A possible problem in sailboats or fast powerboats is that they get a

drag from the back face of the tunnel, as this becomes a “flat” area

facing the water flow (Fig. 1).

This can also create problems with the thruster spinning (passive)

and making noise while sailing or driving the boat with water being

pushed through the tunnel at high speed.

This can be solved in two different ways, depending on what is

possible or easier to do.

1. The best solution which normally reduces the drag most is to

make a recess in the hull at the back of the tunnel. Thereby the

back face is gone and about all the drag (Fig. 2). The depth and

shape of this recess will depend on the boat. Basically you

should not see the back face of the tunnel when standing directly

in front of the tunnel at the angle of the boats centreline. The

angle up or down backwards of the insert in the hull, depends on

the hull shape, but normally it is angled slightly down because of

the water flow on this area of the hull.

2. The drag will also be reduced a lot, especially in fast power

boats, by making a deflector / spoiler in front of the tunnel. This

will push the water flow out from the hull so that most of it passes

by the back face of the tunnel (Fig. 3).

The shape and size of this deflector will depend on the hull

shape. Basically you should not see the back face of the tunnel

when standing directly in front of the tunnel at the angle of the

boats centreline. The easiest way of making this is to let a part of

the tunnel stick out in the lower forward area of the hole, and use

this as a support to mould a soft curve/spoiler shape.

Remember to still round the tunnel ends as much as possible to get

optimum thruster performance and minimum noise. For more

information on how to practically do this see page 20.

8SE 170/250 TC - SE210/250TC 1.0.0- 2008

Tunnel installasjon på seilbåter

N

Mange seilbåtskrog er bygget for å oppnå høy fart. De har brede skrog

som ikke stikker dypt i baugen. Skrogtypen gjør det vanskelig å installere

en thrustertunnel på vanlig måte, spesielt med tanke på å plassere den

langt nok frem (Fig. 1).

Thrustertunneler kan allikevel installeres i de este seilbåter. Dette gjøres

ved å la en del av tunnelen stikke ut i underkant av skroget. Tunnelen er

sterk nok til dette, og thrusteren blir plassert lav nok og langt nok fremme.

Dette gjøres ved at øvre halvdel av tunnelen støpes inn i skroget, tunne-

len styrkes i underkant ved å støpe en kul rundt tunnelen og jevne den ut

mest mulig.

Denne metoden brukes av noen av de helt største seilbåt-produsentene i

verden, de viser til at den ikke gir utslag på fart under normal seilas.

Denne installasjonen kan også være gunstig for båter med ate bunner,

for å unngå ekstremt lange tunneler og store ovale tunnelåpninger.

Tunnel installation in sailboats

GB

Many sailboats have a racing type hull which means that it is very at bot-

tomed and has a very shallow draft in the bow section. It is thereby very

difcult not to say impossible to t a tunnel thruster the usual way, at least

as far forward in the hull as a thruster should be (Fig. 1).

However, it is possible to install a tunnel thruster in most sailboats, even

when the hull does not directly support the tting of a tunnel.

This is done by tting the tunnel halfway into and halfway under-neath the

existing hull and then strengthen it and smoothening the water ow by

moulding a bulb around / underneath the tunnel.

This will allow installation in good position on the boat, maintaining the

reliability and space advantages of a tunnel thruster.

This installation is being used by some of the world’s largest sailboat

builders, and has been proven to give little to no speed loss for normal

cruising.

This can also be a good installation method for at bottomed barges to

avoid extremely long tunnels and huge oval tunnel openings in the hull.

16

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Segelboote weisen häufig einen Rumpf in Rennform auf, was

einen sehr flachen Rumpf im Bugbereich bedeutet. Es ist daher

schwierig oder fast unmöglich, den Tunnel an der gewünschten

(effektivsten) Stelle, also möglichst weit vorne im Bug zu plazieren

(Fig. 1).

Trotzdem ist es vielfach möglich unter diesen Bedingungen eine

Bugschraube einzubauen, auch wenn der Tunnel damit nicht völlig

vom ursprünglichen Rumpf umgeben ist.

Der Tunnel wird zur Hälfte in den bestehenden Rumpf integriert,

die andere Hälfte geht über diesen hinaus. Der Tunnel muß nur

noch verstärkt und strömungsgünstig abgerundet werden.

Dies erlaubt eine Installation in geeigneter Position bei Nutzung

der Zuverlässigkeits- und Platzvorteile einer Tunnelschraube.

Diese Installationsart wird von einigen der weltweit führenden

Segelboothersteller verwendet und führt meistens nur zu einem

äußerst geringen bzw. gar keinem Geschwindigkeitsverlust.

Diese Bauweise ist auch für Barkassen (z.B. Flußboote) mit

flachem Bug geeignet, um einen zu langen Tunnel und große

ovale Tunnelöffnungen im Rumpf zu vermeiden.

Installation in Segelbooten

D

Tunnel installation in sailboats

Fig. 1

GB

Min

//

//

/--

--

-

Pos. B

Pos. A

//

//

/--

--

-

Many sailboats have a racing type hull which means that it is very

flat bottomed and has a very shallow draft in the bow section. It is

thereby very difficult not to say impossible to fit a tunnel thruster the

usual way, at least as far forward in the hull as a thruster should be

(Fig. 1).

However, it is possible to install a tunnel thruster in most sailboats,

even when the hull does not directly support the fitting of a tunnel.

This is done by fitting the tunnel halfway into and halfway under-

neath the existing hull and then strengthen it and smoothening the

water flow by moulding a bulb around / underneath the tunnel.

This will allow installation in good position on the boat, maintaining

the reliability and space advantages of a tunnel thruster.

This installation is being used by some of the world’s largest sailboat

builders, and has been proven to give little to no speed loss for

normal cruising.

This can also be a good installation method for flat bottomed barges

to avoid extremely long tunnels and huge oval tunnel openings in the

hull.

9

SE 170/250 TC - SE210/250TC 1.0.0- 2008

Tunnel installering

N

Sleipner Motor anbefaler at innstøping av glassbertunnelen utføres

av kyndig personell. Denne instruksjons manualen gir ikke detaljerte

opplysninger om glassberstøpning. Problemer som skyldes instal-

lering er installatørens fulle ansvar.

Bestem plassering av tunnelen ut i fra informasjonen gitt tidligere i ma-

nualen, og de angitte mål for thrusteren du skal installere.

Merk av senter på tunnelen på babord og styrbord side. Bor et 6 m.m.

vannrett hull, på begge sider (Fig. 1).

Bøy til og tilpass en 5 m.m. stålstang, som vist på g. 2 der den tilbake-

bøyde enden skal markere tunnelens radius. Stikk enden inn å marker

tunnelens ytre diameter, skjær ut hullet med en stikksag (Fig. 2).

Puss av gelcoat og polyester så glassberen ligger bar i et 12 cm stort

område rundt tunnel hullet. Dette må gjøres på innsiden og utsiden av

skroget, før tunnelen støpes fast i skroget (Fig. 3).

Sett inn tunnelen å marker hvor det skal kappes for å passe i skroget

(Fig. 4). Hvis det skal støpes en spoiler i forkant av tunnelen bør en del av

tunnelen stikke ut i for og underkant av skroget for å støpe spoileren mot

(Side 20, Fig. 2). Kapp tunnelen i ønsket størrelse. Slip lett med slipepa-

pir, og vask med aceton der hvor det skal støpes med glassber.

NB ! Det må ikke støpes der hvor thrusteren skal monteres.

Støp fast tunnelen først på innsiden av skroget, bruk minst 8 lag med 300

g Glassbermatte, og polyester. Ved bruk av alternative materialer, glass-

ber matter eller rovingtyper (Se s. 20, Fig. 1). Hvis tunnelåpningene

avrundes til den optimale 10% radius må ofte legge ekstra lag med polyes-

ter glassbermatte på innersiden av tunnelen, for å oppnå riktig tykkelse i

forhold til skrogtykkelsen.

NB ! Forsikre deg om at overgangene mellom tunel og skrog er nøye

sammenstøpt. På steder en ikke kommer til med vanlige lag med polyes-

ter/glassber matte, sørg for og lage en blanding av polyester og glass-

ber, som fylles i dette.

Tunnel installation

R

D

Fig. 1

Fig. 3 Fig. 4

Fig. 2

GB

We recommend that a professional does the breglass tting of the

tunnel. These instructions are only general, and do not explain in

any way the details of breglass work. Problems caused by faulty

installation of the tunnel, are the installers full responsibility.

Find the position in the boat considering the information given earlier in

this manual and the applicable measurements for the thruster model you

are installing.

Mark the centre of the tunnel on both sides. Drill a 6mm hole horizontally

in these marks (Fig. 1).

Bend a ø 5mm steel bar as shown with the “tip” bent back at the tunnel

radius and mark the circle for the tunnel opening (outside diameter of the

tunnel). Cut the hole with a jigsaw (Fig. 2).

Grind off the gelcoat and polyester so that you are down in the “real bre-

glass” in an area of 12cm around the hole both inside and outside in the

hull to cast the tunnel to the hull (Fig. 3).

Insert the tunnel and mark its shape to t the hull (Fig. 4). (if you are in-

stalling with a deector/spoiler, leave a part or the tunnel of the front- and

underside of the tunnel to have a base for this (see page 20, Fig. 2). Cut

the tunnel ends to the desired shape and lightly sand its surface and

clean with acetone or similar where you are going to apply breglass.

NB! Do not cast/glass on the area were the thruster will be placed.

Then cast the tunnel to the inside of the hull, use at least 8 layers of 300 g

glass and resin, preferably alternating mat and rowing types of breglass

(see page 20, Fig. 1). If you are rounding the tunnel ends to the perfect

10% radius you may in some cases have to make further layers inside to

preserve the desired hull thickness.

NB! Make sure that any gap between the tunnel and the hull are com-

pletely lled with resin/breglass. In areas where you can not access to

make normal layers of resin/breglass, a resin/ breglass mixture must be

lled in that area.

10 SE 170/250 TC - SE210/250TC 1.0.0- 2008

Tunnel installering

Tunnel installation N

Rund av tunnelendene med en radius 10% av tunneldiameter (Fig. 1a),

eller lag en skråkant 10-15% av tunneldiameter (Fig. 1c). Der dette ikke er

mulig skal tunnel kantene rundes av mest mulig.

Vi anbefaler å støpe to lag utenpå tunnellavrundingen og over et område

på 6-8cm (Fig. 1c & 1d).

Gelcoat eller lignende må påføres på områdene der det har blitt pusset

eller støpt for å gjøre glassberen vanntett.

NB ! Alle originale Sidepower tunneler er vanntette ved levering!

Så fremt man ikke ønsker en annen farge er det ikke nødvendig å påføre

Gelkoat, Topkoat og ere lag med primer for å gjøre tunnelen vanntett.

Puss tunnelen med nt slipepapir og påfør et lag primer for å få bunnstoff

til å sitte.

Sidepowertunnelen er helt vanntett uten behandling med unntak av de

områder det som er støpt fast i skroget.

Påfør Gelcoat/Topcoat/epoxy og primer på de områder som er pusset ned

eller støpt. Vann skal ikke ha direkte kontakt med glassberen i skroget

fordi dette normalt ikke er vanntett.

PS ! Det må ikke støpes der brakketen til thrusteren skal stå. Pass-

formen er nøyaktig tilpasset, og en feilplassert braket kan forår-

sake svikt i girhus.

GB

Fig. 1a

Fig. 3

Fig. 2

Fig. 1b

Fig. 1c

Fig. 1d

Fig. 1

Soften the edges with a radius of 10% of the tunnel diameter (Fig. 1a) or

make a slope with a length of 10-15% of the tunnel diameter (Fig. 1c). If

this is not possible, at least round the tunnel end as much as possible.

We advice to also cast two layers on the outside of the tunnel/hull for an

6-8cm area (Fig. 1c & 1d).

You must apply topcoat/epoxy on the areas outside where you have

grounded or moulded to again make these waterproof.

NB! All original Sidepower tunnels are fully waterproof when

they are delivered.

This means that unless you want, because of special reasons, to have an-

other colour on it, you do not have to apply topcoat or the several layers

of primer that is necessary on the boats’ hull to make it water-resistant.

Sand it very lightly and apply one layer of primer to make the antifouling

sit.

The original Sidepower tube itself is fully water-resistant without treatment

except in the areas where you have bonded it to the hull.

Apply topcoat/epoxy paint and primer on the areas where you have

grounded or moulded as these areas give the water access to the hull

which normally is not waterproof without these applications outside.

PS! Avoid all casting where the motor-bracket is to be placed,

as this will cause mist and possible failure of the

gearhouse.

11

SE 170/250 TC - SE210/250TC 1.0.0- 2008

Fig. 2

1. Marker båtens og tunnelens senterlinje på tunnelen.

Girhuset må plasseres med enden merket P mot babord og enden

merket S mot styrbord (Fig. 4) for at skyveretning skal korrespondere

med merkingen på kontrollpanelene.

2. Bruk girhuspakningen for å sjekke målene (7). Thrusteren skal plas-

seres på styrbord side av senterlinjen med boltehullet i midten av

båten (Fig. 1). Alle hull må være på båtens eller tunnelens senterlinje

for å får til en presis installasjon. Dette skyldes at det er meget liten

klaring mellom tunnelveggen og propellen.

3. Tunnelen må ha en jevn overate der braketen skal festes, all støp,

evt glassber eller epoxy rester må pusses ned så braketen passer

jevnt på tunnelen. Ujevnheter her vil resultere i svikt i girhuset.

4. Bor senterhullet Ø 46 mm, og de to boltehullene Ø 11 mm

5. Prøv girhuset i tunnelen sammen med pakning 1m.m. Monter propell

å sjekk at den er i midten av tunnelen. Hvis propellen ikke er i midten

av tunnelen, forsøk å bruk den endre pakningen, eller begge to sam-

tidig. Hvis tunnelen ikke har en jevn overate så kan et tetningsmate-

riale brukes for å sikre mot lekkasje.

6. Før girhuset gjennom hovedhullet i tunnelen og monter braketten og

girhuset forsiktig sammen.

7. Skru sammen motorbraketten og girhuset med orginalbolter (Fig. 3).

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

33 Nm (24 lb/ft)

Montering av girhus og brakett

N

Fitting gearhouse and motor bracket

GB

Fig. 1

PORT STARBOARD

S

P

Fig. 4

Fig. 3

1. Mark the centreline of the tunnel and the boats centreline.

The gearleg must be tted with the P-mark facing port and S-mark

facing starboard (Fig. 4) for the thrust direction to correspond with the

control panel

2. Use the gearhouse gasket (7) to mark the centre of the holes and

double check the measurements. Place the thruster in the boats

centreline with the bolt hole as the centre (Fig. 1). It is absolutely

necessary that all holes are in-line with the tunnels’ centreline to

ensure precise installation, as the clearance between the

propellers and the tunnel is minimal to ensure best possible

performance.

3. There must be no casting where the motor bracket is to be placed,

as this will cause possible failure of the gearhouse. The motor

bracket must t steady on the tunnel, if the tunnel is not smooth,

all bumps or uneven parts must be grinded smooth.

4. Drill the centre-hole ø 46mm and then the two screw-holes ø 11mm.

5 Try the lower-unit in the tunnel (without the zinc anodes and the

lower part of the exible coupling) by using the gasket inside the

tunnel. Try on the propellers to make sure they are in the middle of

the tunnel and turn freely with the same clearing from each blade to

the tunnel. Use appropriate sealant to ensure that no leakages

occur.

6. Push the gearhouse through the main hole in the tunnel and push

the gearhouse and motor-bracket gently together.

7. Screw the lower unit and the motor-bracket together with the two

provided bolts (Fig. 3).

22

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Fig. 3

7

1. Die Mittellinie von Tunnel und Boot markieren.

SP 75 Ti / SP 95 Ti: Damit Schubrichtung und Kontrollpanel

über-einstimmen, das Getriebegehäuse so einbauen, daß der

Ver-schluß des Getriebegehäuses (der verschraubte Verschluß

hinter einem der beiden Propeller) Richtung Steuerbord zeigt

(Fig. 5).

SP 125 Ti: Fig. 6

2. Die Löcher mit der Dichtung (7) markieren. Maße überprüfen!

Den Thruster schiffssmittig plazieren (Fig. 1). Da der Abstand

zwischen Propellern und Tunnel wegen größtmöglicher

Performance minimal konstruiert ist, müssen für eine präzise

Installation alle Löcher auf der Tunnelmittellinie liegen.

3. Im Bereich der Motorhalterung darf kein Laminat auf dem

Tunnel sein, da dies zu einem Getriebeschaden führen kann.

Liegt die Motorhalterung nicht eben auf dem Tunnel auf, so

sind sämtliche Unebenheiten in diesem Bereich abzuschleifen.

4. Bohren Sie das Zentrumsloch (ø 32 mm) und dann die

beiden Schraubenlöcher (ø 9 mm).

5. Das Getriebegehäuse mit Getriebeöl EP90 durch die Öffnung

der Ölablaßschraube (4) befüllen. Kupferdichtung (3) einsetzen.

6. Das Getriebegehäuse (ohne Zinkanoden und unteren Teil der

elastischen Kupplung) unter Verwendung der Dichtung in den

Tunnel einpassen. Den Propeller auf die Achse stecken; dieser

muß sich frei bewegen lassen und jedes Propellerblatt muß

den gleichen Abstand zum Tunnel aufweisen. Ist die Tunnel-

innenseite ungleichmäßig, etwas Sikaflex o.ä. auftragen,

damit keine undichte Stelle auftritt.

PS ! Die Durchgänge für das Öl (2) von Dichtmasse freihalten.

7. Etwas Öl oder Fett auf die O-ringe der Motorhalterung geben,

da diese sonst beim Montieren beschädigt werden können.

8. Das Getriebegehäuse durch das Hauptloch im Tunnel führen

und vorsichtig mit der Motorhalterung zusammenschieben.

9. Das Getriebegehäuse und die Motorhalterung mit Hilfe der bei-

den Bolzen verschrauben (Fig. 7).

GEAROIL

EP 90

3

4

12

Fig. 4

PORT STARBOARD

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

SP 75 Ti / SP 95 Ti: 17 Nm (12,4 lb/ft)

SP 125 Ti: 33 Nm (24 lb/ft)

Getriebe und Motorhalterung

D

Fitting gearhouse and motor bracket

GB

40,0mm

1,57"

Ø 11,00mm

7/16"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 46,00mm

1,81"

Fig. 1

SP 75 Ti

SP 95 Ti

28,0mm

1,1"

Ø 9mm

0,35"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 32mm

1,26"

Fig. 2

SP125Ti

PORT STARBOARD

SP

Fig. 5

SP 75 Ti

SP 95 Ti

Fig. 6

SP125Ti

Fig. 7

1. Mark the centreline of the tunnel and the boats centreline. SP75Ti

/SP95Ti: The gearhouse must be fitted with the gearhouse lid (the

screwed in lid behind one of the propellers) on the starboard side of

the boat for the thrust direction to correspond with the control panel

(Fig. 5). SP 125 Ti: Fig. 6

2. Use the gearhouse gasket (7) to mark the centre of the holes and

double check the measurements. Place the thruster in the boats

centreline with the bolt hole as the centre (Fig. 1). It is absolutely

necessary that all holes are in-line with the tunnels’ centreline to

ensure precise installation, as the clearance between the

propellers and the tunnel is minimal to ensure best possible

performance.

3. There must be no casting where the motor bracket is to be placed,

as this will cause possible failure of the gearhouse. The motor

bracket must fit steady on the tunnel, if the tunnel is not smooth,

all bumps or uneven parts must be grinded smooth.

4. Drill the centre-hole ø 32mm and then the two screw-holes ø 9mm.

5. Pre-fill the gearhouse with gear oil type EP90 through the oil drain

screw (4). Make sure to get the copper gasket (3) on again.

6. Try the lower-unit in the tunnel (without the zinc anodes and the

lower part of the flexible coupling) by using the gasket inside the

tunnel. Try on the propellers to make sure they are in the middle of

the tunnel and turn freely with the same clearing from each blade to

the tunnel. Use sealant e.g. Sikaflex to ensure that no leakages

occur.

PS! Make sure that no sealant gets in to the oil-holes (2).

7. Make sure that there is some oil or grease on the O-rings in the

motor bracket before mounting it together with the gearhouse.

8. Push the gearhouse through the main hole in the tunnel and push

the gearhouse and motor-bracket gently together.

9. Screw the lower unit and the motor-bracket together with the two

provided bolts (Fig. 7).

22

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Fig. 3

7

1. Die Mittellinie von Tunnel und Boot markieren.

SP 75 Ti / SP 95 Ti: Damit Schubrichtung und Kontrollpanel

über-einstimmen, das Getriebegehäuse so einbauen, daß der

Ver-schluß des Getriebegehäuses (der verschraubte Verschluß

hinter einem der beiden Propeller) Richtung Steuerbord zeigt

(Fig. 5).

SP 125 Ti: Fig. 6

2. Die Löcher mit der Dichtung (7) markieren. Maße überprüfen!

Den Thruster schiffssmittig plazieren (Fig. 1). Da der Abstand

zwischen Propellern und Tunnel wegen größtmöglicher

Performance minimal konstruiert ist, müssen für eine präzise

Installation alle Löcher auf der Tunnelmittellinie liegen.

3. Im Bereich der Motorhalterung darf kein Laminat auf dem

Tunnel sein, da dies zu einem Getriebeschaden führen kann.

Liegt die Motorhalterung nicht eben auf dem Tunnel auf, so

sind sämtliche Unebenheiten in diesem Bereich abzuschleifen.

4. Bohren Sie das Zentrumsloch (ø 32 mm) und dann die

beiden Schraubenlöcher (ø 9 mm).

5. Das Getriebegehäuse mit Getriebeöl EP90 durch die Öffnung

der Ölablaßschraube (4) befüllen. Kupferdichtung (3) einsetzen.

6. Das Getriebegehäuse (ohne Zinkanoden und unteren Teil der

elastischen Kupplung) unter Verwendung der Dichtung in den

Tunnel einpassen. Den Propeller auf die Achse stecken; dieser

muß sich frei bewegen lassen und jedes Propellerblatt muß

den gleichen Abstand zum Tunnel aufweisen. Ist die Tunnel-

innenseite ungleichmäßig, etwas Sikaflex o.ä. auftragen,

damit keine undichte Stelle auftritt.

PS ! Die Durchgänge für das Öl (2) von Dichtmasse freihalten.

7. Etwas Öl oder Fett auf die O-ringe der Motorhalterung geben,

da diese sonst beim Montieren beschädigt werden können.

8. Das Getriebegehäuse durch das Hauptloch im Tunnel führen

und vorsichtig mit der Motorhalterung zusammenschieben.

9. Das Getriebegehäuse und die Motorhalterung mit Hilfe der bei-

den Bolzen verschrauben (Fig. 7).

GEAROIL

EP 90

3

4

12

Fig. 4

PORT STARBOARD

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

SP 75 Ti / SP 95 Ti: 17 Nm (12,4 lb/ft)

SP 125 Ti: 33 Nm (24 lb/ft)

Getriebe und Motorhalterung

D

Fitting gearhouse and motor bracket

GB

40,0mm

1,57"

Ø 11,00mm

7/16"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 46,00mm

1,81"

Fig. 1

SP 75 Ti

SP 95 Ti

28,0mm

1,1"

Ø 9mm

0,35"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 32mm

1,26"

Fig. 2

SP125Ti

PORT STARBOARD

SP

Fig. 5

SP 75 Ti

SP 95 Ti

Fig. 6

SP125Ti

Fig. 7

1. Mark the centreline of the tunnel and the boats centreline. SP75Ti

/SP95Ti: The gearhouse must be fitted with the gearhouse lid (the

screwed in lid behind one of the propellers) on the starboard side of

the boat for the thrust direction to correspond with the control panel

(Fig. 5). SP 125 Ti: Fig. 6

2. Use the gearhouse gasket (7) to mark the centre of the holes and

double check the measurements. Place the thruster in the boats

centreline with the bolt hole as the centre (Fig. 1). It is absolutely

necessary that all holes are in-line with the tunnels’ centreline to

ensure precise installation, as the clearance between the

propellers and the tunnel is minimal to ensure best possible

performance.

3. There must be no casting where the motor bracket is to be placed,

as this will cause possible failure of the gearhouse. The motor

bracket must fit steady on the tunnel, if the tunnel is not smooth,

all bumps or uneven parts must be grinded smooth.

4. Drill the centre-hole ø 32mm and then the two screw-holes ø 9mm.

5. Pre-fill the gearhouse with gear oil type EP90 through the oil drain

screw (4). Make sure to get the copper gasket (3) on again.

6. Try the lower-unit in the tunnel (without the zinc anodes and the

lower part of the flexible coupling) by using the gasket inside the

tunnel. Try on the propellers to make sure they are in the middle of

the tunnel and turn freely with the same clearing from each blade to

the tunnel. Use sealant e.g. Sikaflex to ensure that no leakages

occur.

PS! Make sure that no sealant gets in to the oil-holes (2).

7. Make sure that there is some oil or grease on the O-rings in the

motor bracket before mounting it together with the gearhouse.

8. Push the gearhouse through the main hole in the tunnel and push

the gearhouse and motor-bracket gently together.

9. Screw the lower unit and the motor-bracket together with the two

provided bolts (Fig. 7).

12 SE 170/250 TC - SE210/250TC 1.0.0- 2008

Montering av propeller

N

1. Vri propellakselen så drivpinnen (5) står loddrett. Pinnen må stå midt i

propellakselen.

2. Vri propellen så sporet for driv pinnen er loddrett, eller i lik vinkel som

du har stilt drivpinnen. Skyv propellen inn på propellakselen. Det skal

nesten ikke være klaring mellom propellen og girhuset.

3. Sett på skiven (4) på propellakselen, deretter strammes låsemutteren

(3).

4. Plasser sinkanoden (2) i sporet sitt. Fest den med skruen til sinkan-

oden (1). Bruk locktight eller lignende for at skruen ikke skal skrus ut

av propellrotasjonen.

5. Monter propell merket LH på babord side og propellen merket RH

på styrbord side. Sjekk at propellene roterer fritt og at de er sentrert i

tunellen

Delebeskrivelse:

1: Skrue til sinkanode

2: Sinkanode

3: Låsemutter til propell

4: Skive til propell

5: Drivpinne for propell

Fitting propeller(s)

GB

1. Push the propeller onto the shaft, carefully rotate the propeller

until the drive pin aligns and moves into the slot/grove in the

propeller hub. There should be almost no gap (approximately

1mm) between the propeller hub and the gear house.

2. Place the washer (4) on the propeller shaft and then tighten the

lock-nut (3) on the propeller shaft.

3. Place the zinkanode (2) in its designated position and tighten the

zincanodes holding screw (1). Apply a thread glue (Locktite or

similar) to ensure that the zincanodes holding screw does not un-

screw itself from the propellers rotation.

4. Fit the propellers to the shafts with the LH marked propeller on

the port side and the RH marked propeller on the starboard

side. Turn them to again make sure they move freely and as

much in the centre of the tunnel as you have managed.

Parts description:

1: Screw for zincanode

2: Zincanode

3: Propeller lock nut

4: Washer

5: Drive pin for propeller

5

3

2

14

Locktite

13

SE 170/250 TC - SE210/250TC 1.0.0- 2008

1. Fjern de 4 boltene i i motorbraketten.

2. Plasser motoren på braketten. Plasser motoren slik at de releene er

tilgjengelige for tilkobling senere. Ta hensyn til at motoren er tung når

den bæres og håndteres.

3. Fest motoren til braketten med de re boltene (Fig. 1).

4. SE170: Hvis motoren monteres i en vinkel på mer enn 30ofra loddrett,

trenger den separat/ekstra støtte. Jamfør tekniske tegninger.

SE210: Monter motorstøtten som beskrevet i instruksjonene over.

5. Sjekk at børstefjærene sitter korrekt på børstene (gjøres ved å se

gjennom gitteret på siden av motoren).

I visse tilfeller (ved grunne installasjoner, ske / arbeidsfartøy fartøy)

anbefaler vi å beskytte propell og girhus ved å montere et gitter foran

tunnelåpningene (Fig. 2). Det er da meget viktig å beholde strømlinjefor-

men, og å begrense gitteret til et minimum. Feil installasjon kan begrense

skyvekraften med 10%

NB ! Påfør bunnstoff på girhus og propell for å unngå vekst som kan virke

sterkt hemmende på thrusterens effekt. Sinkanoder propellaksling og

tetninger skal ikke stoffes.

NB ! Thrusteren må kun kjøres i meget korte perioder når den ligger på

land.

NB ! Hvis båten fortsatt er under bygging når thrusteren blir montert må

motoren dekkes til for å unngå at støv og lignende trenger inn i girhus og

elektromotor. Dekket må fjernes før motoren tas i bruk.

Fig. 2

Montering av elektromotor

N

Fitting the electromotor

GB

1. Remove the 4 bolts in the motor bracket.

2. Turn the driveshaft in the gearhouse and the motorshaft so that the

key/keyway are aligned

3. Place the motor gently on the motor bracket. Be careful, the motor

is heavy!

Ensure that you are placing the motor so that the cable terminals on

it are available for electric installation later.

4. Fasten the motor to the bracket with the 4 bolts and tighten them.

5. SE170:If you are installing the motor in an angle of more than 30

degrees off a vertical position, the electromotor needs a separate/

additional support. See illustration in the measurements drawings.

SE210: Install motor support according to instructions on top of page

6. Check the drive system by turning the propeller, it will be a little

hard to turn (because of the gear reduction and the motor), but you

should easily be able to turn it by hand.

In some cases (shallow installation or workboat/shingboat only) we recom-

mend to protect the propeller by mounting a grid in the tunnel opening (Fig.

2). It is important to keep a grid to a minimum and as streamlined for the

thruster’s waterow as possible, as it will decrease the effect of the thruster.

Do not use Circular prole steel as it will decrease thrust signicantly.

NB! Paint the gearhouse and propeller with antifouling for propellers to

prevent growth of barnacles or similar which would reduce the perform-

ance dramatically. Do not paint the propeller shaft, the zincanodes or the

end face of the gearhouse.

NB! Do not run the thruster for more than very short bursts without being

in the water.

NB! If the boat is still being built when the electromotor is installed, it

must be covered up to avoid dust from the building going into the motor

and the solenoids. This cover must be removed before the thruster is

being used.

14

SP 155 TCi / SP 200 TCi / SP 240 TCi / SP 285 TCi

2.5 - 2006

Einbau des Elektromotors

D

1. Die 4 Bolzen in der Motorhalterung enfernen.

2. Die Antriebsachse im Getriebegehäuse und die Motorachse so

drehen, daß die elastische Kupplung dazwischen paßt.

3. Den Motor vorsichtig auf die Motorhalterung aufsetzen. Der

Motor ist sehr schwer!

4. Mit den 4 Bolzen Motor und Motorhalterung lose verschrauben.

5. Abmessen und die beiliegende Motorabstützung so anbringen,

daß der Motor anliegt. Die Abstützung muß gut am Boot be-

festigt werden. Die beiliegende Gummiplatte vor dem fest-

ziehen zwischen Motor und Abstützung bringen.

6. Mit den 4 Bolzen Motor und -halterung miteinander verschrauben.

7. Die Befestigungsschraube im unteren Teil der elastischen

Kupplung festziehen.

8. Überprüfen, ob sich die Propeller frei im Tunnel drehen lassen.

Aufgrund der Getriebeübersetzung und des Motors sollte das

Systemdies etwas schwergängig sein.

In manchen Fällen, z.B. bei flachem Rumpf oder im gerwerblichen

Einsatz (z.B. Fischfang) empfehlen wir, den Propeller durch ein

Gitter vor der Tunnelöffnung zu schützen (Fig. 3). Dieses sollte auf

ein Minimum beschränkt und so stromlinienförmig wie möglich sein,

da ansonsten die Leistung des Thrusters reduziert wird.

NB ! Wir empfehlen, auf das Getriebegehäuse Anti-Fouling

aufzutragen. Nicht auf die Propellerachse, Zinkanoden oder

den Verschluß des Getriebegehäuses auftragen.

NB ! Den Thruster nur für den Bruchteil einer Sekunde betätigen

wenn dieser nicht im Wasser ist.

NB ! Wird der Elektromotor eingebaut, falls das Boot noch in Bau

ist, so muß dieser abgedeckt werden, um eine Verschmutzung

von Relais und Motor zu verhindern. Diese Abdeckung muß

vor Benutzung des Thrusters entfernt werden.

1. Remove the 4 bolts in the motorbracket.

2. Turn the driveshaft in the gearhouse and the motorshaft so the

key in the shaft and the keyway in the flexible coupling are in-line.

3. Place the motor gently onto the driveshaft and the motor

bracket. Be careful, the motor is very heavy!

4. Fasten the motor loosely to the bracket with the provided bolts.

5. Measure up and fit the provided motor support so that the

motor sits tightly in it. The support must be sturdily fastened to

the boat. Make sure to put the provided rubber between the

support and the motor before tightening the strap.

6. Tighten the 4 bolts holding the motor to the motorbracket.

7. Tighten the set-screw in the lower part of the flexible coupling.

8. Check the system by turning the propeller, it will be a little hard

to turn (because of the gear reduction and the motor), but you

should be able to turn it by hand.

In some cases (shallow installation or workboat / fishingboat only) we

recommend to protect the propeller by mounting a grid in the tunnel

opening (Fig. 3). It is important to keep a grid to a minimum and as

streamlined for the thrusters waterflow as possible, as it will

decrease the effect of the thruster.

NB ! Paint the gearhouse and propeller with antifouling for pro-

pellers to prevent growth of barnacles or similar which would

reduce the performance dramatically. Do not paint the pro-

peller shaft, the zincanodes or the end face of the gearhouse.

NB! Do not run the thruster for more than very short bursts with-

out being in the water.

NB ! If the boat is still being built when the electromotor is installed, it

must be covered up to avoid dust from the building going into

the motor and the solenoids. This cover must be removed

before the thruster is being used.

Fitting the electromotor

GB

Fig. 3

Fig. 1

Ke

y

in driveshaf

t

Driveshaft from

gearhouse

Keyway in

flexible-

coupling

Flexible-coupling

Set screw

Fig. 2

SP 200 TCi

SP 240 TCi

SP 285 TCi

SP 200 TCi

SP 240 TCi

SP 285 TCi

For safety the motor of the Sidepower SP200TCi / SP240TCi / SP285TCi must

be fastened in all installation positions with the included motor-support.

1. Fit the motor to the already fitted motorbracket on the tunnel.

2. Fasten the support to a bulkhead / the boat in a correct position to support the

motor firmly. The support can be fastened anywere on the motor as long as it