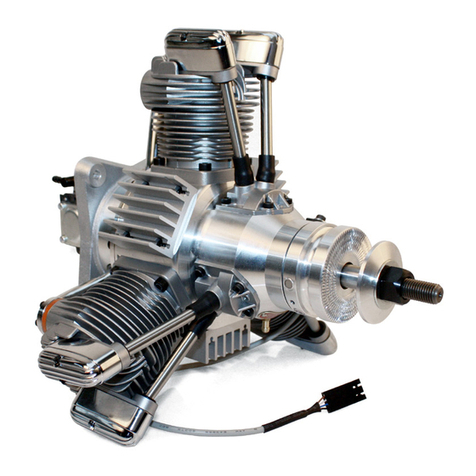

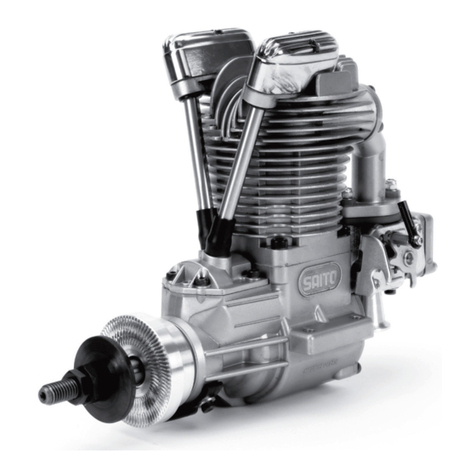

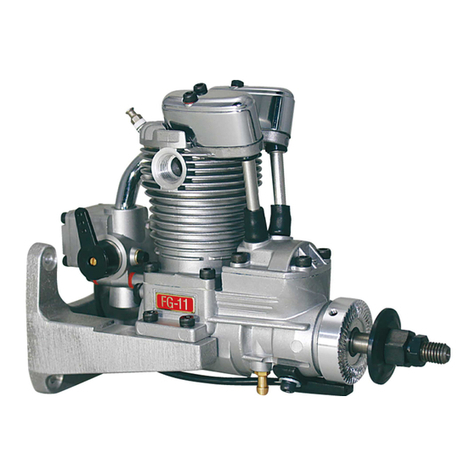

Engine Parts

Identification

It is important to be able to identify the

parts of your Saito engines. Attached

you will find an exploded view of a

Saito 4-stroke engine, as well as charts

that include part numbers and

descriptions. This will assist you in

easily and rapidly identifying the

respective parts of your Saito engine.

Support Equipment

Thefollowingitems,whicharenotincluded

withyourSaitoengine,arenecessaryin

ordertooperatethemodelengine:

1. Fuel. For maximum protection and

longevity of Saitoengines, Saito

recommends a fuelcontaining 20% oil

and 10-15% nitro methane. If this blend is

not readily available, the next best

selection is a high quality 2-cycle glow

fuel,such as Hangar 9Aero-Blend,

Omega,Cool Power, K&B, Power

Master, etc.Use of fuels composed

entirely of castoroil is not recommended.

Amix of synthetic-castor oilis acceptable

and can be found in the various fuels

described above.

2. Propeller. Refer to the "Propeller

Selection" chart, located on page 16, to

determine the best initial propeller for

your particular application. Propellers

should be balanced prior to use.

3. Glow Plug Battery. Your glow

plug may be properly heated by

several different sources. The Hangar 9

Power Panel (HAN106), when

accompanied by a 12-volt Sealed Lead

Acid Battery (HAN102) and a Glow

Plug Locking Socket (HAN120) is an

ideal source of heat for your glow

plug. A conventional 1.5-volt heavy-

duty dry cell battery with a Glow Plug

Locking Socket (HAN120) or alligator

clips may also be used. Additionally,

there are several very good glow-

starters (nickel cadmium-powered

glow plug igniters) that work well.

4. Glow Plug Wrench. Used to

removeand tightenglow plugs.The

Hangar9 Long Reach PlugWrench

(HAN2510) is an excellent wrench to

utilize, as a longer shaft may be necessary

to access the glowplug.This depends

mostlyupon engineinstallation.

5. Manual or Electric Starter. For

manual starts, a “chicken stick” is

highly recommended. Never use

your fingers to start any model engine.

To do so invites injury. There are a

variety of electric starters on the

market. The Hangar 9 12V heavy-duty

Super Starter (HAN110) will work

perfectly on all Saito engines.

6. Tachometer. The use of a

tachometer for setting the high-speed

needle valve prior to flight is

encouraged. It will also be helpful

when setting the idle adjustment of the

carburetor(s).

S U P P O R T E Q U I P M E N T 3

Saito Single Cyl Manual 9-00 9/11/00 10:06 AM Page 5