CarburetorService

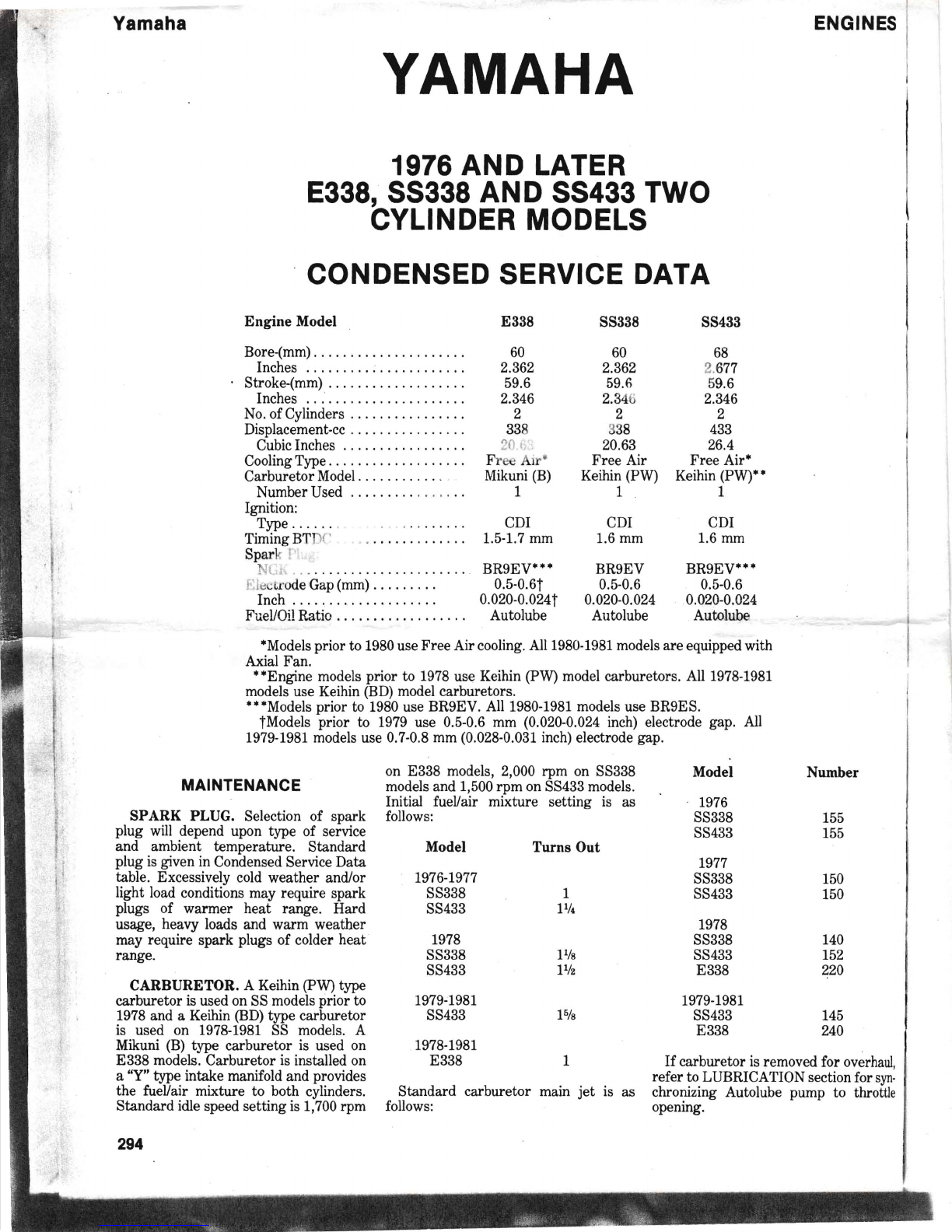

ENGINE~

Fig .

14-Exploded

view

of

operat

ing

diaphragm

(7),

spr ing (8),

spr

ing

seat

(9)

and

regulator

cover

(10).

Upper

end

of

adjusting

stud

is

shown

at (A).

5---,

.......

;--11

16

17

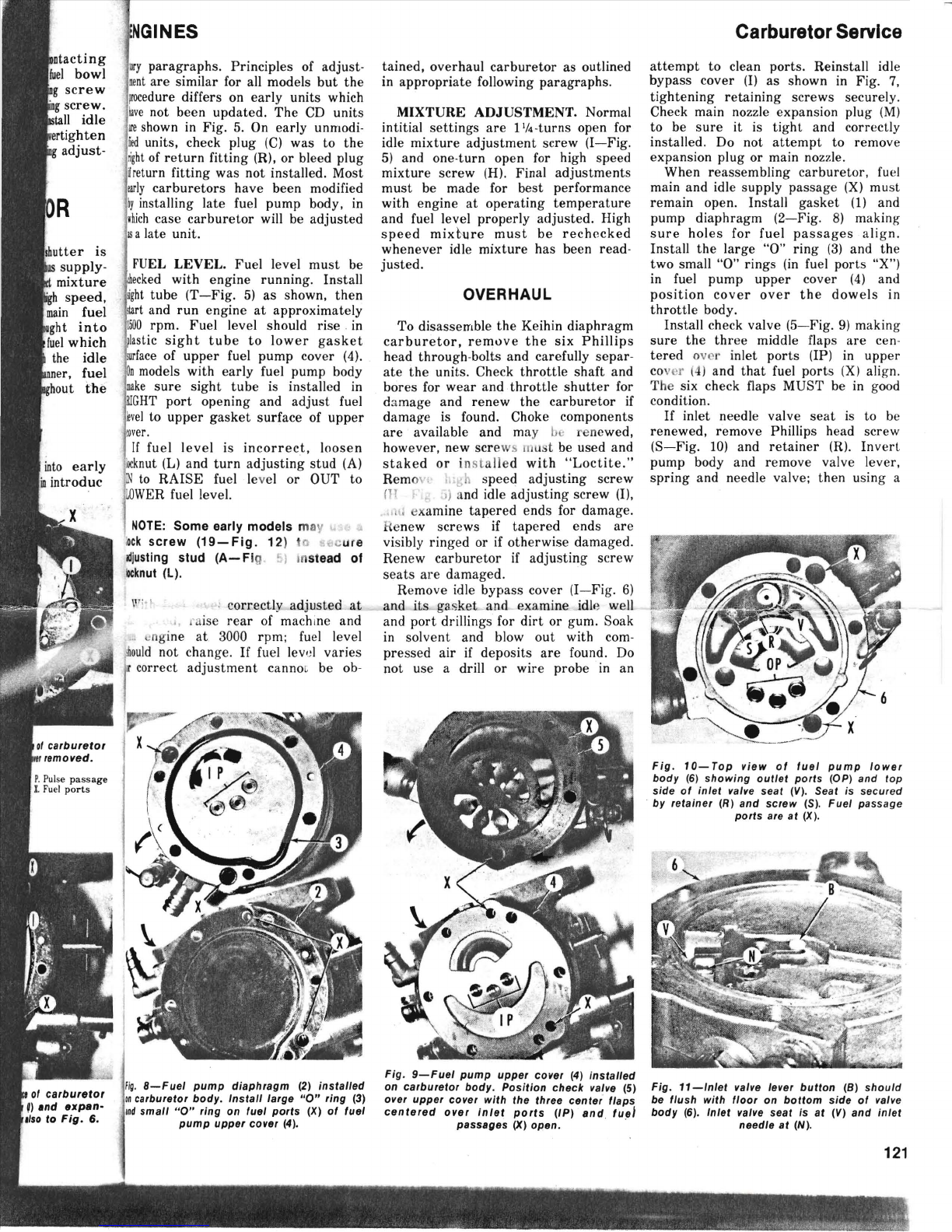

Fig.

12-Exploded

v

iew

of

KEIHIN

d

iaphragm

type

carburetor

showing

component

parts.

S

ight

tube

(21) is

used

to

set

fuel

level

and

. is

not

a

part

of the

carburetor

.

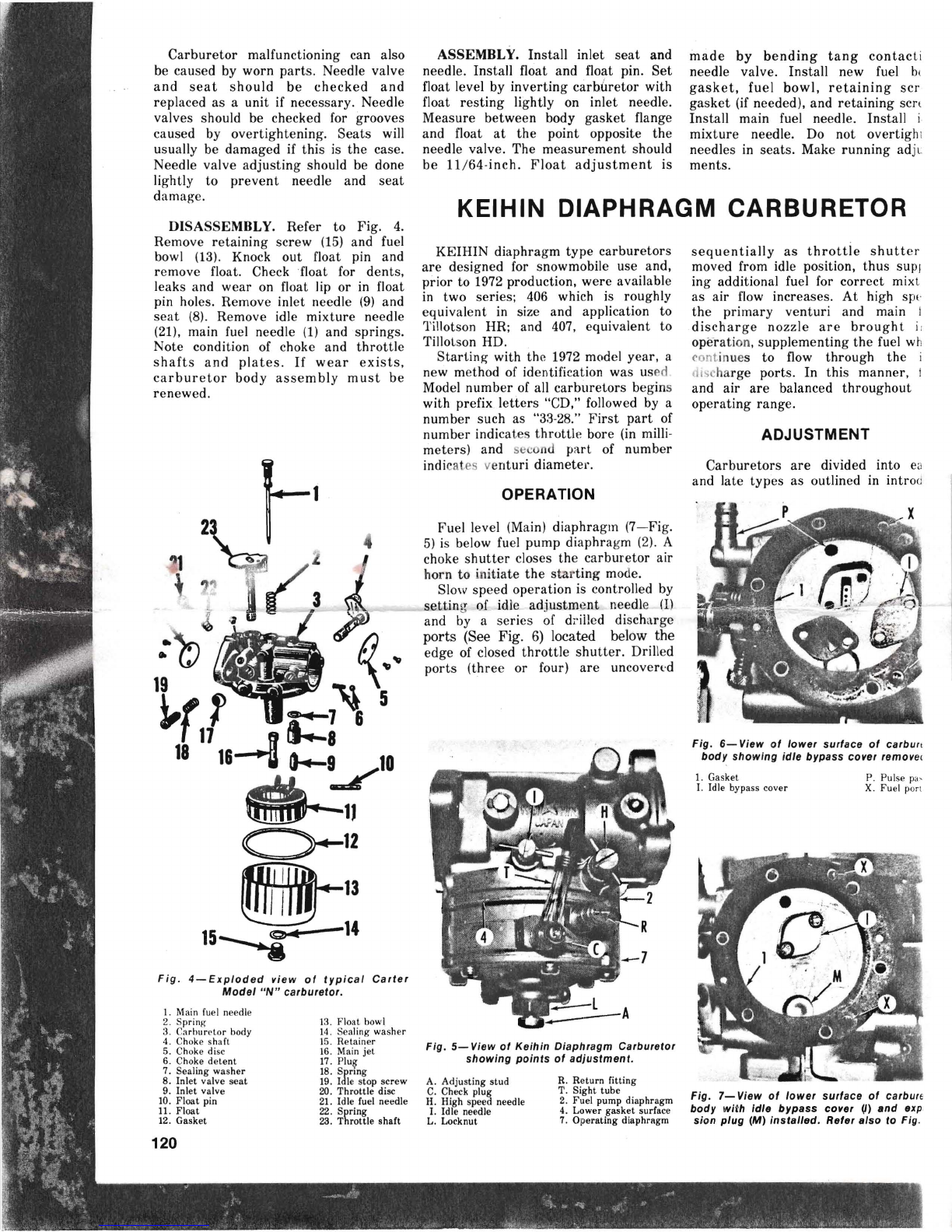

I.

Throttle body

2. Low speed screw 12. Bleed plug

3. High speed needle 13. Spring

4. Low speed needle 14. Pivot shalt

5. Pump diap hragm 15. Valve lever

6. Pump upper cover 16. Regulating diaphrag m

7. Gasket 17. Spring

B. Pump check valves lB. Regulator cover

9. Pump (regulating) body 19. Lock screw

10. Inlet fitti ng 20. Adjust ing screw

11. Inlet needle & seat 21. Sight tube

Fig.13-0perating

diaphragm

(7)

and

associ-

ated

parts

installed

on

lower

side

of

valve

body.

7. Operating diaphr agm

B. Spring P. Pulse fitti ng

9. Spring seat R. R

eturn

fitting

F. Inlet fuel fitting X. Fuel passages

good pin punch of appropriate size,

drive valve seat

(V

) 1I ,V

••

>I out of

valve body. Valve h,ts are available

in standard size and OD oversizes of

0.01 , .d 0.002 mm. Oversize valves

a

"il

t'iied by one or two annular

<J"'

S around outside of body while

standard body is smoot h. Rein

stall

retainer (R

-Fig.

10), needle valve and

lever, then check height of actuating

button

(B-Fi

g. 11) which should be

flush with valve body floor. Adjust if

neces

sary

by b

ending

t

ang

whicl

contacts valve needle (N).

Fig. 13 shows operating diaphragn

(7), spring (8) and spring seat (9

correctly positioned.

Part

s are showr

exploded in proper order in Fig. 14. Ar

initial starting point for adjusting stue

(A) in regulator cover

(1

0) is with

tW

I

threads showing when viewed fron

inside as shown. Adjust the

assem

bled

carburetor after installation as previ

ously outlined.

KEIHIN

TYPE FLOAT CARBURETOR

WITH BUTTERFLY THROTTLE

Carburetors are identified by a model

number which consists of a let

ter

prefix

"BD" followed by a

set

of numb

ers

such

as "44-38". First

par

t of number in-

dicates

thr

ottle bore (in millimeters) and

second p

art

of number indicates venturi

diameter.

ADJUSTMENT

FLOAT

LEVEL.

Float is adjusted by

bending metal

tang

between float body

(16-

Fig. 14A) and float pin (17). As

shown in Fig. 14B, distance (D) should

be 0.48-0.67 inch when carburetor is

tilted

~t

a 20-30 degree angle.

IDLE

SPEED.

Idle speed is adjusted

by turning screw

(8-Fig

. 14A). Idle

speeds vary from model to model, con-

sult respective manufacturer specifica-

tion for recommended speed setting.

IDLE MIXTURE. Idle mix

tur

e ae

justment is done by turning sere.

(6- Fig. 14A).

Start

engine and bring u

to normal operating temperature. Tur

screw either in (lean) or out (rich) to ot

tain an even engine idle. Readjust idl

speed to recommended setting

after

idl

mixture is

set

.

MAIN

JET.

To insure top p

erf

orn

ance of engine, main jet

(13-Fig

. 14

..1

may need to be changed if there is :

2000 feet change in altitude or an

1:

degree F change in temperature. Whe:

altitude or weather temperature if

creases a lower number of

jet

should b

used. Whenever altitude or weathe

temperature decreases a larger numbe

of

jet

should be used. Caution should

b.

taken especially when operating at .

lower altitude, too lean of fuel mixtur.

could shorten engine life.

.

• ..

~

~'I~

' "

......'

h. :

,l

......

,,{.

"'~.

• ..

tj;..~..

.."

\

~

.

122