9

5920 72022

-

SR & SR-IP user manual

MG_0100

Check and re-lubricate

with waterproof grease

if necessary

IF over 3 mm movement,

Break-away rings must be

replaced

Check annually rubber

element and replace every

2nd year.

(NB: SR300 does not have

a rubber element)

DO NOT apply anti-fouling

DO NOT clean with chemicals,

hot water or high-pressure

water jet in this area. Retract

mechanism

anode

Gear leg anode

(Both sides)

Tunnel anode

(Both sides)

Twist rings

Check these areas for leaks

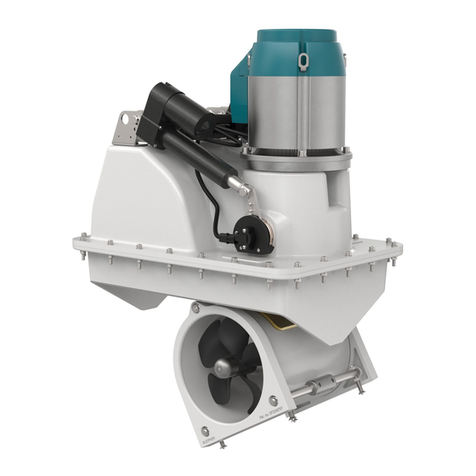

SR(V,L) Maintenance

MC_0013

Basic Troubleshooting

*Not applicable to SX thrusters.

Before seeking assistance from the website help desk from your Sleipner dealer/ distributor, please perform these tests.

(NB: If you are unable to understand or perform these checks, you must consult a Sleipner distributor.)

CHECK SOLUTION

The motor runs, but there is no thrust

Check propellers are fi tted, fastened correctly and there

is no damage to the prop shaft. Re-fasten or replace if necessary

*Check the flexible coupling between the motor and

drive shaft is fi tted correctly and not damaged. Replace if necessary

* Check the gear leg is not damaged. Replace if necessary

The thrusters performance is reduced

Check the propeller, gear house and tunnel are free from

growth/ barnacles or debris and damage.

Remove growth and clean. (NB: If there is obstruction in the tunnel it will disturb/ block

the water flow and signifi cantly reduce performance.)

Check the battery is in a good working condition.

(NB: Keep the main engine(s) running in use to have a continuous charge to the

batteries)

• Check batteries are not worn out or in a bad charged condition

• Check electrical connections/ wiring for damage or wear (corrosion)

• Check cables are the correct size per the product manual

• Tighten/ re-adjust connections

The thruster does not start/ works in only one direction or does not turn off

Check the main switch is active/ on. Open the main switch if it is closed.

Check all battery fuses are in good condition.

• Check batteries

• Check electrical connections/ wiring for damage or wear (corrosion)

• Tighten/ re-adjust and clean connections

The thruster is not shutting off after the Joy Stick/ panel

is disengaged.

Hit the main switch to disengage the thruster. Contact and consult a Sleipner distributor

as the control system has been damaged.

The thruster works in only one direction

Damaged relay. Hit the main switch to disengage the thruster. Contact and consult a Sleipner distributor

as the control system has been damaged.

The thruster runs in a pulsing action

This is a build-in error response.

-Solenoids failure Hit the main switch to disengage the thruster. Contact and consult a Sleipner distributor.

The solenoid might be in a lock-in/ auto stop position. Hit the main switch to disengage the thruster. Contact and consult a Sleipner distributor.

Replace if

necessary

}

MC_0352

Advanced Control Panel Troubleshooting

Control panels operating on the S-link system display all faults via the control panel interface or via other warming methods.

To review any issues of your product refer to the appropriate user manual for a complete list of fault codes and troubleshooting guides.

For additional supporting documentation, we advise you to visit

our website www.sleipnergroup.com