Slingsby T-37 Skylark User manual

V 1.10 11/14/2018

1

1/3-Scale Slingsby T-37 Skylark ~ by Peter Goldsmith Designs

Wings

•Wings are constructed in four panels. Panels

are joined by laminated plywood joiners with

the inner two panels permanently joined

around a center laminated rib.

•Locate the plywood center wing joiner parts

and the center rib plywood and G10 parts.

Stick T-pins through alignment holes and

epoxy parts together.

•The center and outboard wing joiners are three

pieces of plywood laminated together. The center

rib is three pieces of plywood and two pieces of

G10 laminated together with the G10 added to

the outsides of the lamination.

•Locate all the wing ribs and shear web parts,

break them out of the laser cut sheets, lightly

sand off the nubs, and group them in order.

This helps ensure that you have all the

necessary parts identified and speeds the

build process.

•Peter recommends NOT build the wing

panels over the plans, but rather to use the

plan as a reference. The reason is the paper

plans can change dimension with time and

humidity causing a mismatch between the

parts and the plan. Establish and straight

reference line on your building surface and

scribe a perpendicular reference line at one

end. Align the lower spar with the reference

line running down the worksurface and the

first wing rib with the perpendicular

reference line.

V 1.10 11/14/2018

2

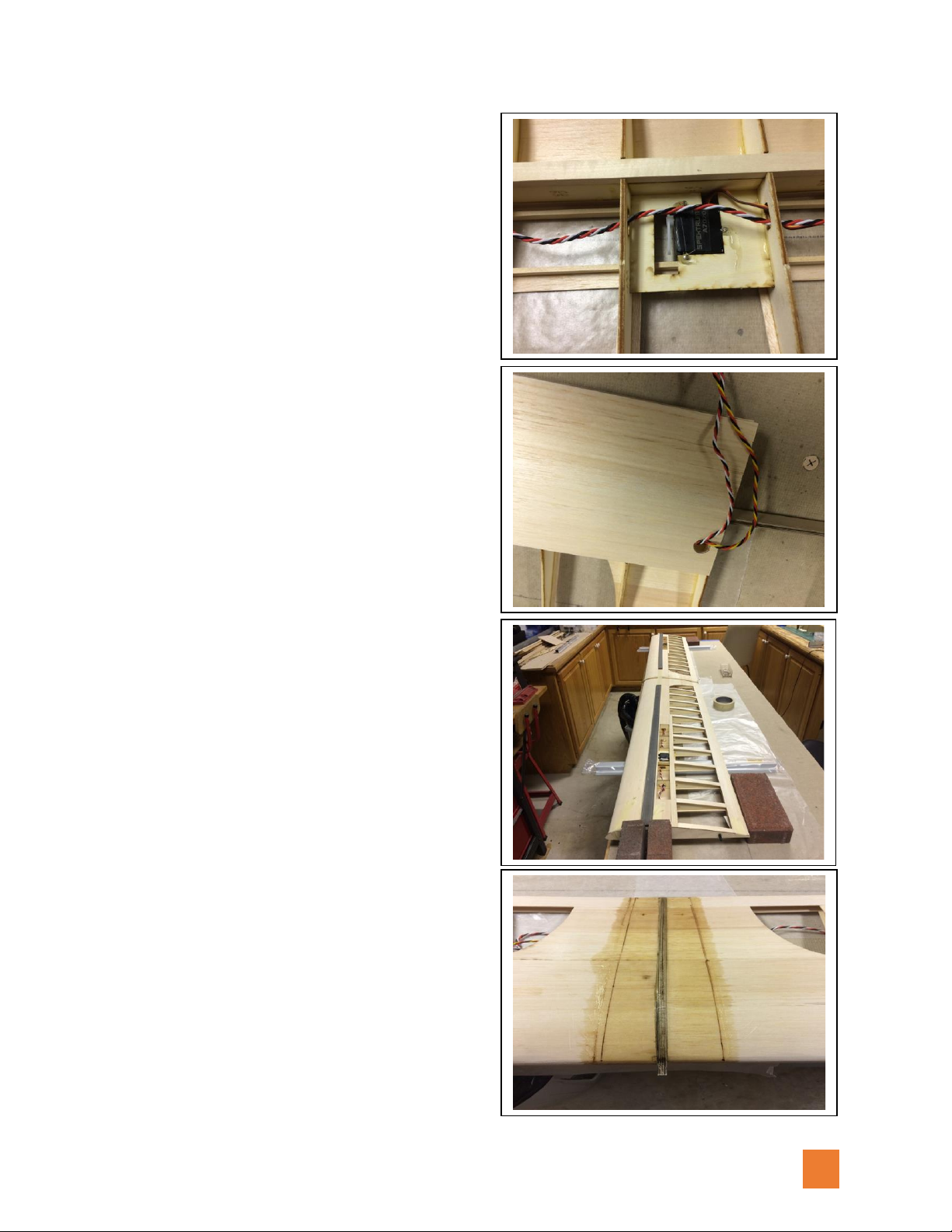

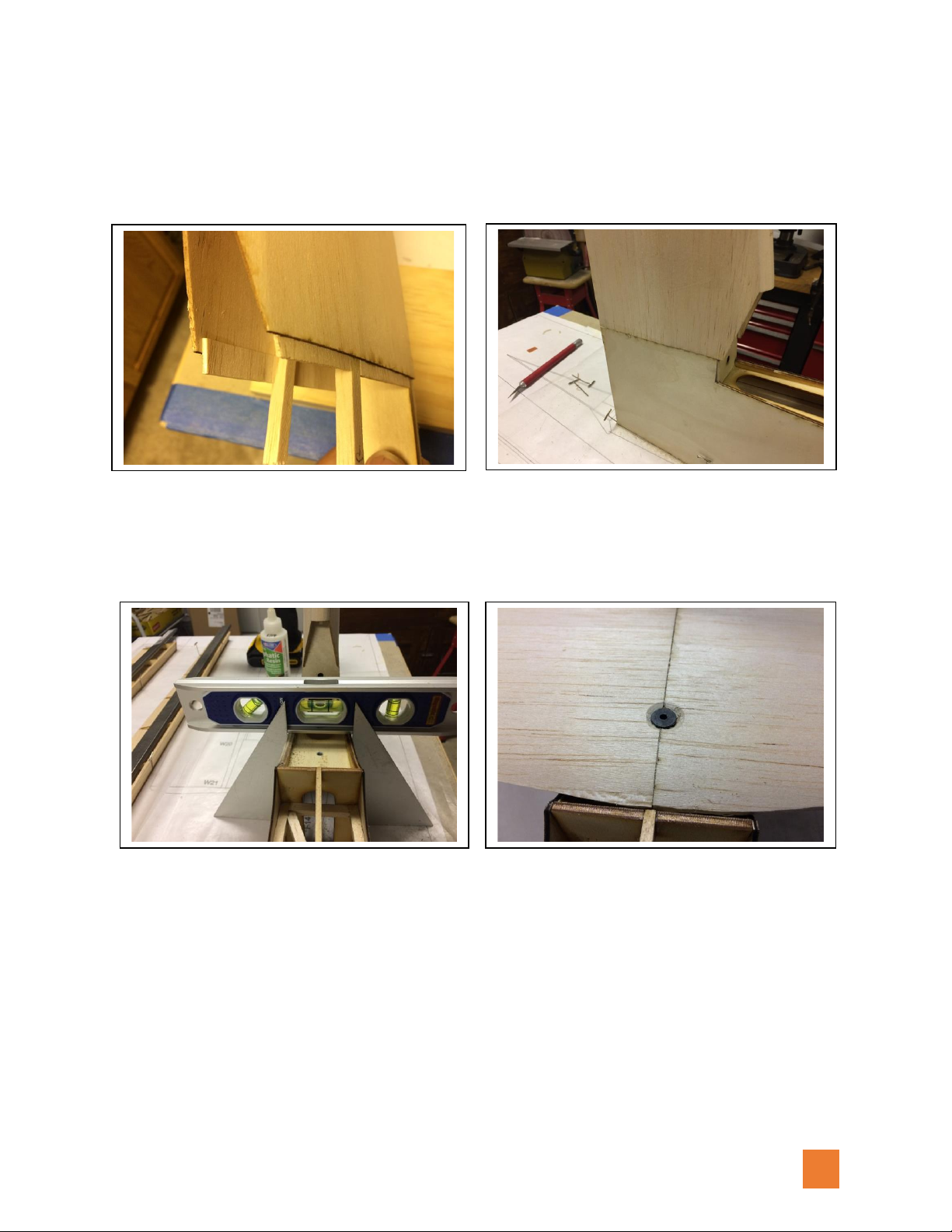

•For many kit builders, building over the plan

is preferred…so we used the plan just to see

how well things would go. First step is to get

the lower spar pinned into place.

•Locate all the ribs and shear webbing for

each wing. Study the plan and arrange the

pieces in order. Note that the shear webs

have a top and bottom as well as a left and

right. Make sure you have these properly

oriented as you glue them in place.

•Note the laser cut dotted lines between the

top and bottom spars on W1 ribs. This area

will get removed at a later step. Note also the

dihedral angle on the root side of shear web

S1. This sets the angle the root ribs of the

center sections.

•The S1 and S2 shear webs set the spacing

between the W1 and W2 ribs. They also form

the “box” that the spar joiner blade will fit

into. You can cover one of the plywood spar

joiners with wax paper and use it as a spacer

when gluing in S1 and S2 parts.

•This same “box” will be created at the

outboard end of the center panels and on the

inboard end of the tip panels. Add the stack

of wing bolt plates (note that it is easier to

laminate these parts together and sand the

top taper before gluing them between the

ribs). These form a hard point for the wing

bolts and need to fill the space between the

top and bottom balsa wing sheeting.

V 1.10 11/14/2018

3

•Continue out board adding a shear web and

then a rib, another shear web and then

another rib. Add the spoiler servo mount

plate being very careful to get the correct

orientation. Add the TE parts along the

trailing edge (they are like mini shear webs).

The servo mounts are made to exactly fit the

Spektrum A7020 or A7050 thin wing servos.

•Glue on the top trailing edge balsa sheeting

strip. We used a piece of steel as a weight to

hold the trailing edge flat on the workbench.

(Various pieces of steel are available at

Lowe’s or Home Depot and make handy tools

for model building.)

•Glue the 3/8” x 3/8” balsa leading edge in

place and sand the top edge so it follows the

contour of the ribs. Top wing sheeting will be

glued down over this edge. One method of

applying the balsa wing sheeting is to use

Deluxe Materials Speed Bond glue and a hot

iron. Glue is applied to both surfaces to be

joined and allowed to dry. Start by ironing

along the spar and work forward over the

ribs and then on to the leading edge.

•Add the 1/8” x 1/4" basswood strips to front

and back edges of spoiler pocket. Balsa wing

sheeting and cap strips can now be added.

Study the plan to see where the sheeting fits

relative to the spoiler pocket, spar line, and

wing root area. Once the glue has set, the

wing panel can be removed from the

workbench and turned over. Fit the spoiler

servo in place and string the servo extensions

through the ribs before going on to complete

the bottom sheeting and cap strips.

V 1.10 11/14/2018

4

•Do not use the rubber grommets on the

servo mounts. Servos are hard mounted

directly to the servo mounting plates. Best to

program your radio, attach the servo arm,

and adjust for the correct travel of the spoiler

servo. Also make sure there is enough

clearance around the servo arm for the

spoiler door stirrup to retract down into the

wing. We applied a dot of Zap Goo to the

points of the servo mounting screws.

•Servo arm needs to be in line with the

midline of the servo case in the retracted

position and at about 70 degrees to the

midline in the fully deployed position. Make

an exit hole for the servo extension in the

bottom wing sheeting at the root end. Add

part W6b to reinforce the alignment pin hole.

•Once both center panels are completed, fit

them together over the center wing joiner

with the laminated center rib in place. The

center rib may need to be sanded to fit flush

with the top and bottom wing skins. Much

easier to do this before the panels are joined!

Prop up both wing tips an equal amount,

align the trailing edges of the two panels

along a reference line, and once satisfied

epoxy wing joiner, center rib, and two panels

together.

•Reinforce the center joint with a wrap of

fiberglass top and bottom. This hardens the

balsa surface and helps prevent crushing of

the balsa sheeting when tightening the wing

bolts.

V 1.10 11/14/2018

5

•We did not build the wing tips over the plan.

Instead, we use the reference lines on our

workbench. Take time to get the spar, first

rib, and shear webs properly aligned. The

wing tip joiner was wrapped in wax paper

and used as a spacer. Building squares were

held in place with weights while glue dried.

•Add the next rib checking that it is square

with the spar.

•Continue out the spar adding a shear web

and then a rib checking that each rib is

square with the spar. Pin the rib trailing edge

of each rib to hold it squarely in place.

•Add the aileron door support between ribs

W13 & W14

•Note that there are no shear webs after rib

W17. Keep the spacing of ribs W18 –W21

uniform with the rib spacing between W6 &

W17.

•The door to the aileron bay is also the servo

mount. Laminate the servo mount parts to

the door being careful to set the correct

orientation.

•Add the 1/8” thick balsa trailing edge to the

back of the ribs in the aileron cut out. Cut this

piece to follow the taper of the wing before

gluing in place. Once secured in place, sand

to top edge to the contour of the ribs.

V 1.10 11/14/2018

6

•Add top spar, top trailing edge sheeting, and

3/8” square leading edge. Shape the top of

the leading edge to follow the contour of the

ribs. Using a razor plane speeds this process.

•Lay the top wing sheeting over the wing and

mark the root and tip overhang. Cut off this

excess sheeting and save it for the next

section to be covered.

•Glue the top front section of sheeting in

place. Add top trailing edge sheeting as

shown on the plans.

•Using the excess piece cut off in the last step,

fit it in place between the top front section of

sheeting and the trailing edge of the aileron

cutout. Scribe a curve on the root end (as per

the plan) and glue in place.

•Cut a curve on another small piece to

complete the top sheeting on rib W10. Add

cap strips to ribs W6 –W9.

•Add part W6b to the inside of rib W6 to

reinforce the alignment pin hole.

V 1.10 11/14/2018

7

•Flip the wing over, install the aileron servo

extension cable and then add sheeting as was

done on the top side. The plywood end cap

rib is added, and the leading edge is sanded

round. After a final sanding to level out any

uneven joins, the wing is now ready to cover.

•Laminate all the parts together for the servo

doors/mounts. This is a good time to

program your radio and set up the servo

travel. Install the servo arm and mount the

servo on the door/mount.

•Aileron ribs are added to the bottom pre-cut

sheeting using the laser etched lines as a

guide. Add the 1/8” balsa leading edge piece

and sand it to the taper of the ribs. Add the

top sheeting and final sand the ailrons.

•The ailerons are top hinged using two strips

of covering material (one on top side and one

on the under side) to make the hinge.

V 1.10 11/14/2018

8

•First, add a strip of covering about 3/4" wide to the top edge of the aileron. Then, holding it

place against the wing in the down position, seal the strip to the wing. Then flip the aileron

over onto the top of the wing and apply a second strip of covering over the bottom side of

the hinge line. Move the aileron back to the neutral position and go over the hinge line with

your iron to seal the top and bottom pieces together. Add the G10 aileron horn in the

precut slot and make an aileron pushrod using 2-56 threaded rod and clevis.

•Bend 1/32” music wire to make the spoiler door stirrup (note sketch of this on the plans).

Stirrup needs to be about 5mm wide and extend down into the wing about 12mm (wire

should be about 17mm tall). Wire is pushed through holes in the spoiler blade, glued in

place with thin CA, and cut off flush with the outside surface.

•Place shims in the spoiler bay to raise the outside of spoiler flush with the top of the wing.

Use shims to hold the spoiler in the center of the opening to allow for friction free opening

and closing. Now you can apply a 3/4” wide strip of covering to form the hinge line. Spoiler

does not require a second strip on the underside. Servo arm pushes the spoiler open and

V 1.10 11/14/2018

9

engages the music wire stirrup to hold the spoiler closed. Springiness of the covering hinge

naturally wants to close the spoiler as will the air pressure against it in flight. There is no

direct connection between the servo arm and the spoiler blade.

Stab/Elevators

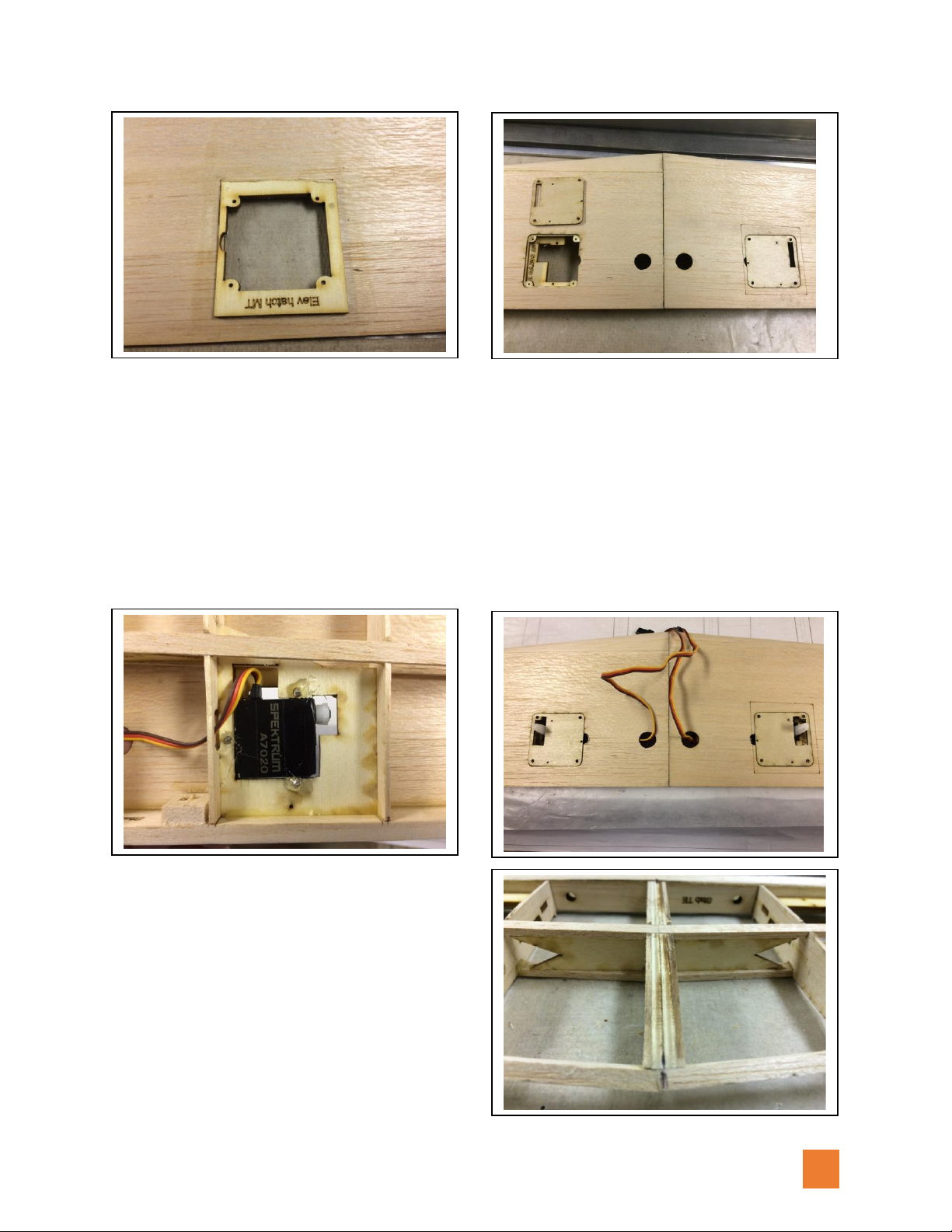

•The horizontal stabilizer and elevator halves

are tapered structures. Peter’s design

provides building tabs on the ribs that allow

these structures to be built on a flat surface.

As the ribs are removed from the carrier

sheets, be cautious to not break off these

tabs.

•Locate all the stab parts and arrange them in

order to start the build.

V 1.10 11/14/2018

10

•Pin the stab TE to a straight reference line on your workbench. Note the predrilled holes for

the hinge points. Also note the tabs that hold the hinge line level with the workbench

surface. Laminate the center S1 & S2 ribs together and glue the elevator servo mounting

plates between ribs S3 & S4. Glue all the ribs to the TE. Next, add the spar and the leading

edge. To orient yourself, the bottom of the stab facing up here.

•Sand the TE to follow the contour of the ribs (be careful about pressing down too hard on

the structure so you don’t break off the leveling tabs on the ribs). Test fit the Elevator Hatch

Mount between ribs S3 and S4. It needs to fit tight against the TE and rib S3. Trim the front

side as needed to achieve this fit.

•Glue the Elevator Hatch Mount to the bottom stab skin using the laser etched outline as a

reference.

•The bottom stab skins are slightly oversize on purpose, so pay attention to this next step!

•Test fit the skin to the stab keeping the Elevator Hatch MT frame tight against rib S3 and the

TE. The center line edge where the two skins meet will need to be trimmed on each half to

make a clean center line joint.

V 1.10 11/14/2018

11

•Install the elevator servo arm and screw it to the servo mount plate. (again, this is a good

time to program your transmitter and to set the servo travel for the elevator servos). Do not

use the rubber grommets, hard mount the servo directly to the plywood plate.

•Recommended elevator servo is Spektrum A7020 thin wing servo. Use the supplied long

double arm with one side removed. Pull the servo leads through the ribs and out through

the holes in the bottom skins. No extension is needed.

•Add the balsa “donut” pieces to the inside

of the TE to extend the holes for the hinge

points. Sand the stab spar joiner to fit

between the top and bottom spars. Then,

add the top spar. Break off the build leveling

tabs and sand the TE and ribs to contour.

Add the top skins, trim off excess, and sand

leading edge round. Add Stab tips and final

sand the stab.

V 1.10 11/14/2018

12

•Elevators are constructed in a similar manner. Use a scrap piece of 1/16” balsa to make a

spacer between the E2 ribs. This forms the slot for the G10 elevator control horns. Once

constructed, add the balsa donuts to the inside of hinge point holes.

Add the LE to the elevator halves and sand it to a V along the center hinge line. Add the tips and

sand to final shape along with the stab.

V 1.10 11/14/2018

13

Fin/Rudder

•Locate all the parts to complete this section. The ribs have build tabs that allow the

structure to be assembled on a flat surface without the need for special shims. The

leading edge of the rudder is like the elevators. There are two pieces with pre-drilled

hinge point holes. One is used in the initial construction of the rudder and the second is

added later and sanded to a V along the hinge line. We used dowel pins to align parts.

•Using the plan as a reference, cut the

fin spars and leading edge to length and

mark the location of the ribs.

V 1.10 11/14/2018

14

•Dry fit the parts together and make sure

the slant of the ribs is correct according to

the plan. Once you are sure, tack together

with thin CA.

•Stand this structure on the fin tail post using the

etch lines to place the ribs and make sure the ribs

are centered over the centerline of the hinge

point holes. Once you are sure everything is

aligned, glue in place.

•Bring the fin and rudder together to check

the alignment of the hinge point holes. Add

the donuts to the inside of the fin hinge

point holes.

•Leading Pre-cut fin sheeting is added to

both sides. Excess sheeting along the

leading edge is trimmed away, leading

edge is flat sanded, and leading-edge

balsa is glued on. Finally, sand the leading

edge to a rounded shape.

V 1.10 11/14/2018

15

Fuselage

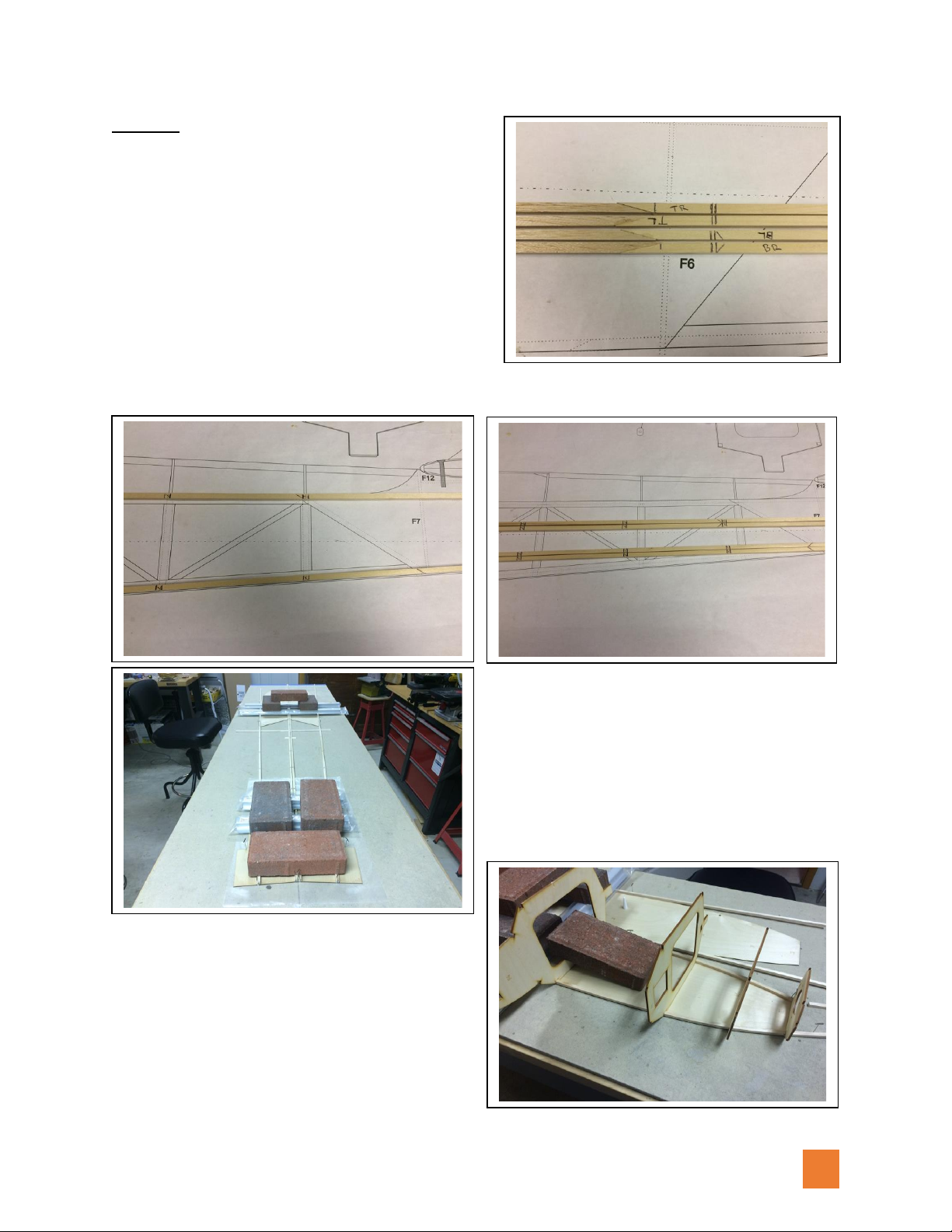

•Fuselage has a top and bottom 1/4"

square longerons that run its length.

These are constructed by scarfing

together 48” balsa and basswood sticks.

•Using the plan as a reference, transfer the

position of the formers onto a pair of the

longerons. Next, copy these marks to the

other pair of longerons. Note that the

balsa half is the front and the basswood half is the rear of the longerons. Since nearly

the entire length of fuselage is flat on the

bottom, the left and right fuselage sides were

aligned along a straight reference line on the

workbench bottom to bottom. This is an easy

way to make the left and right mirror image

fuselage sides. The longerons need to be

supported with 1/8” shims between the front

and rear plywood fuselage side panels.

We used paver bricks as weights to

keep parts flat on the bench while the

glue dries. The front balsa longerons get

bent to follow along the outside edge of

the side panels. The formers can be

used to set the spacing (but don’t glue

them in place).

V 1.10 11/14/2018

16

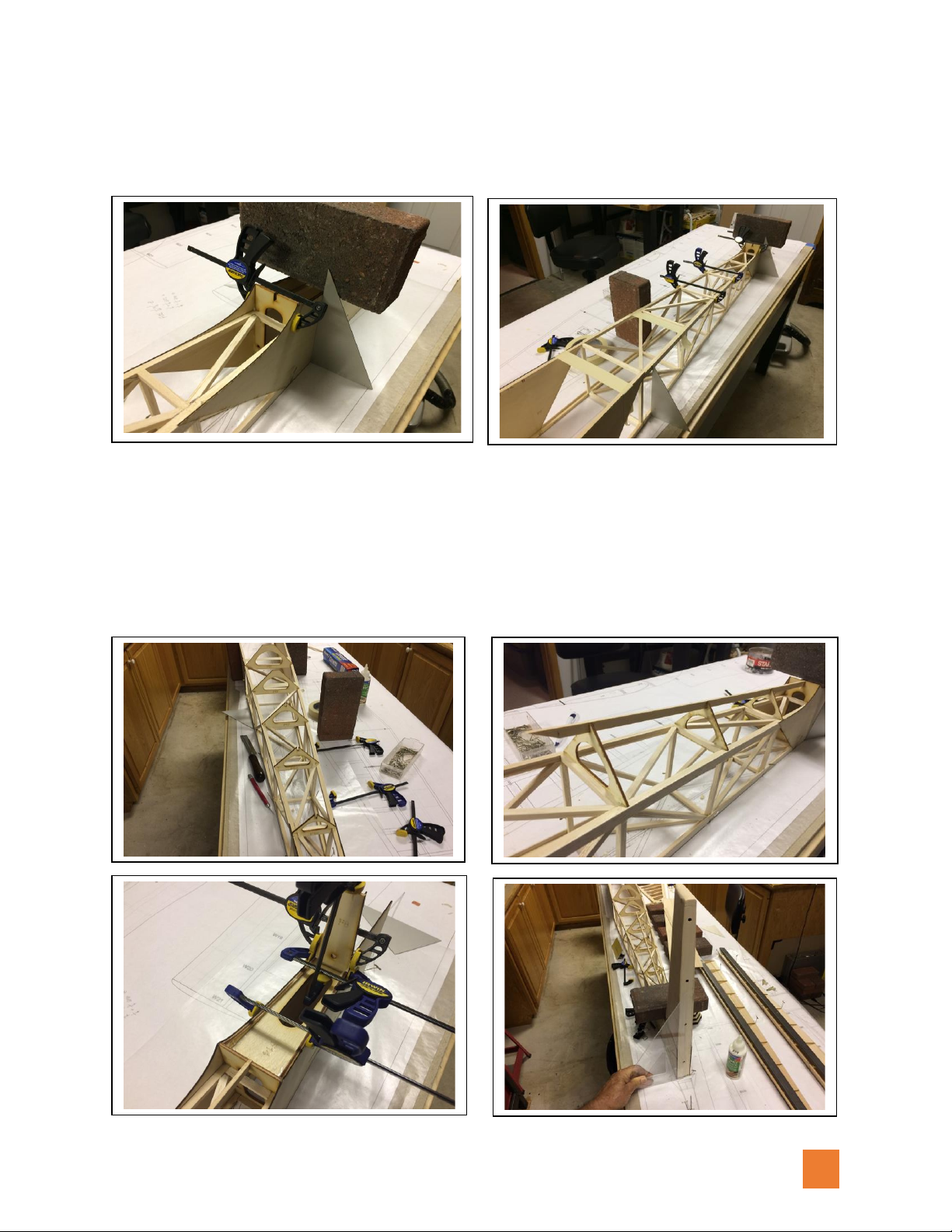

•Once the longerons are set, pins are used to lock the fuselage sides in place on the

workbench surface and 1/16” x 1/2" balsa strips are added to the outside of the 1/4”

square longerons. This creates a lip for the 1/4" square sticks that make the aft fuselage

formers. Add the vertical parts and then the diagonal parts to each side. Make pairs of

cross pieces (that complete the aft fuselage formers) using the plan as a reference.

•Stand the fuselage sides up over the plan. Starting at the rear, add cross pieces and

work forward pinning and clamping while keeping sides flat on the workbench.

V 1.10 11/14/2018

17

•Continue working forward adding the cross pieces and then the diagonals to form the

fuselage truss work. Use weights and builder’s triangles to keep fuselage sides

perpendicular to workbench surface.

•Add the top fuselage formers F15 –F19 and then top 1/8” x 3/8” basswood spine

between F15 and F7. Add F14 and F8. Clamp in place and check that fuselage sides

remain aligned over the plan and perpendicular to the workbench surface. Install the fin

structure into the aft fuselage section and check for fit and alignment, but don’t glue

parts together yet.

V 1.10 11/14/2018

18

•Separate the fin from the fuselage and add pieces of 1/16” scrap balsa to the lower edge

of the fin sheeting. When the fin assembly is reinserted into the fuselage, the lip created

by adding the scrap balsa makes the joint between the plywood fuselage sides and the

fin sheeting sides blend together with a smooth joint.

•Check the stab mount for level and the fuselage sides for square. Position the stab on

the fuselage, drill hole for hold-down bolt, and install blind nut on the underside of F14.

•So far, everything has been done with the fuselage bottom flat on the workbench

surface. Because of the keel tabs on the bottom of formers F2 –F6, the fuselage will

need to be elevated to give them clearance.

•To begin, Use F1 and masking tape to pull the front fuselage sides together. Do not glue

F1 in place. Use enough masking tape that fuselage sides will not separate from F1 as

formers F2 –F6 are friction fit into place. With the fuselage elevated over a straight

reference line, sight down through the fuselage to see if the sides align. Because of the

different density and bending resistance, one side might want to be straighter than the

V 1.10 11/14/2018

19

other and cause the nose to be offset to

one side. If this happens, use a razor saw

to make partial cuts through the 1/4"

longerons on the side resistant to

bended. Make enough cuts to gain

symmetry between the sides.

•Note the lack of symmetry between the

right and left fuselage sides and the angle

of F1 to the centerline.

•Cuts were made in the right side

longerons and the sides were brought

into symmetry and F1 is now square with

the centerline.

•Block the fuselage in place over a straight

reference line and check for alignment

and level before gluing in any of the

formers F1 –F6.

•Sight down the fuselage and check for

symmetry of the sides and that fin is

perpendicular. Once satisfied, use thin CA

to tack the formers in place. Use a good

quality wood glue, like Deluxe Materials

Aliphatic Resin, to reinforce all joints

between the formers and fuselage sides.

V 1.10 11/14/2018

20

•Add the battery box panels, the tow hook

mount plate, and the rudder servo

mount. Make sure servos fit properly in

these mounts before gluing them in

place.

•Motor battery is an E-flite 4S 30C 14.8V

4000mAh LiPo pack.

•Tow release servo is a Spektrum A6320.

•Rudder servo is a Spektrum A5060.

•Add bent wire for the tow release and the

blind nuts for the motor mount (note that

they go on the front side of F1).

Popular Toy manuals by other brands

Lionel

Lionel SD60 owner's manual

LEGO

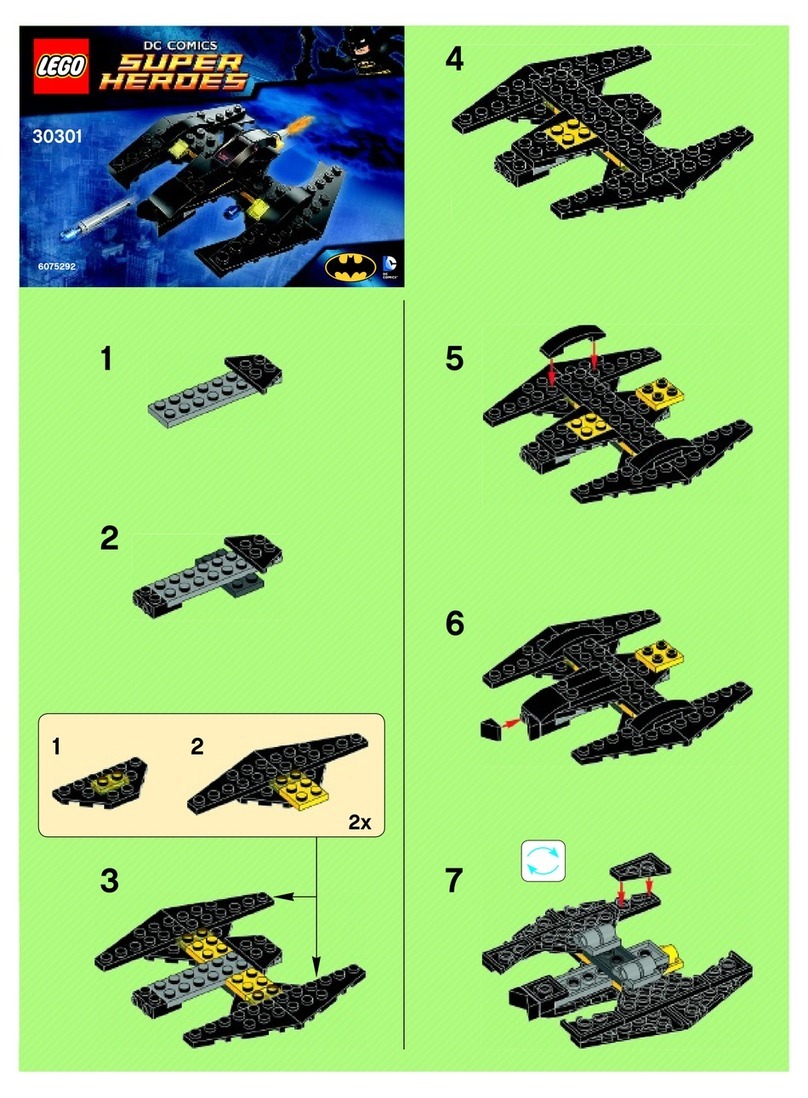

LEGO Super Heroes 30301 Instructions for use

Seagull Models

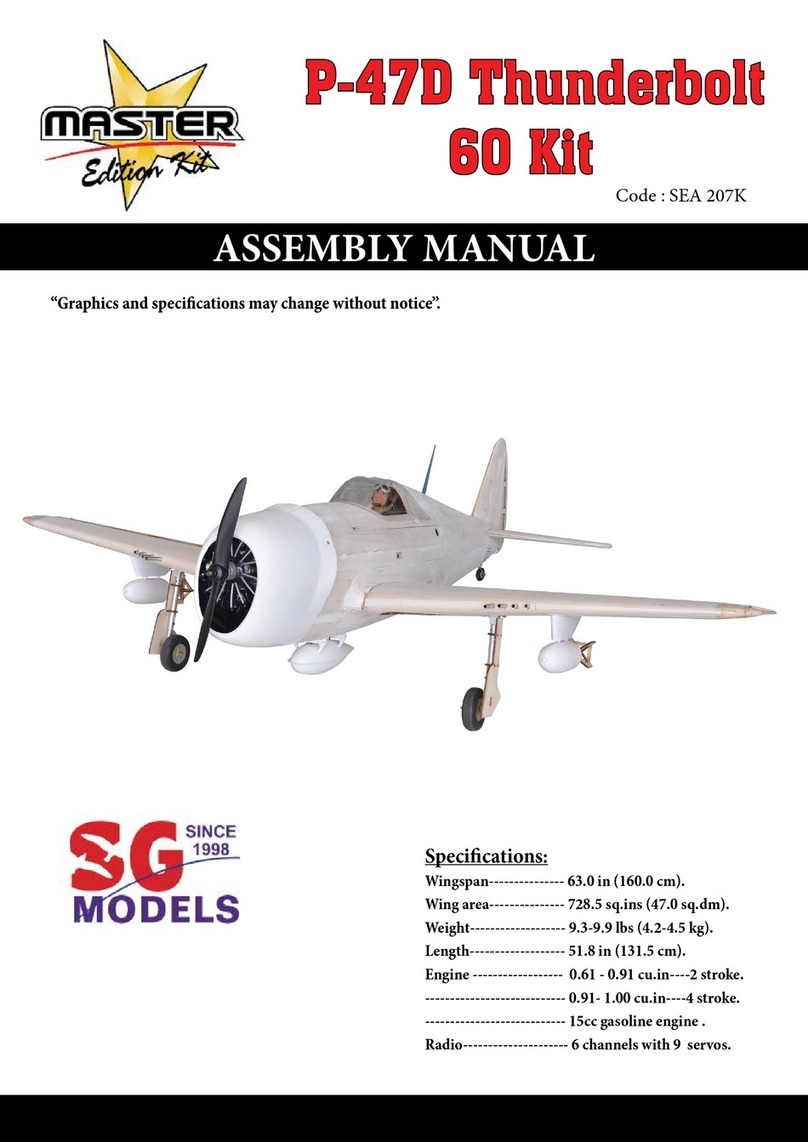

Seagull Models P-47D Thunderbolt 60 Assembly manual

Tamiya

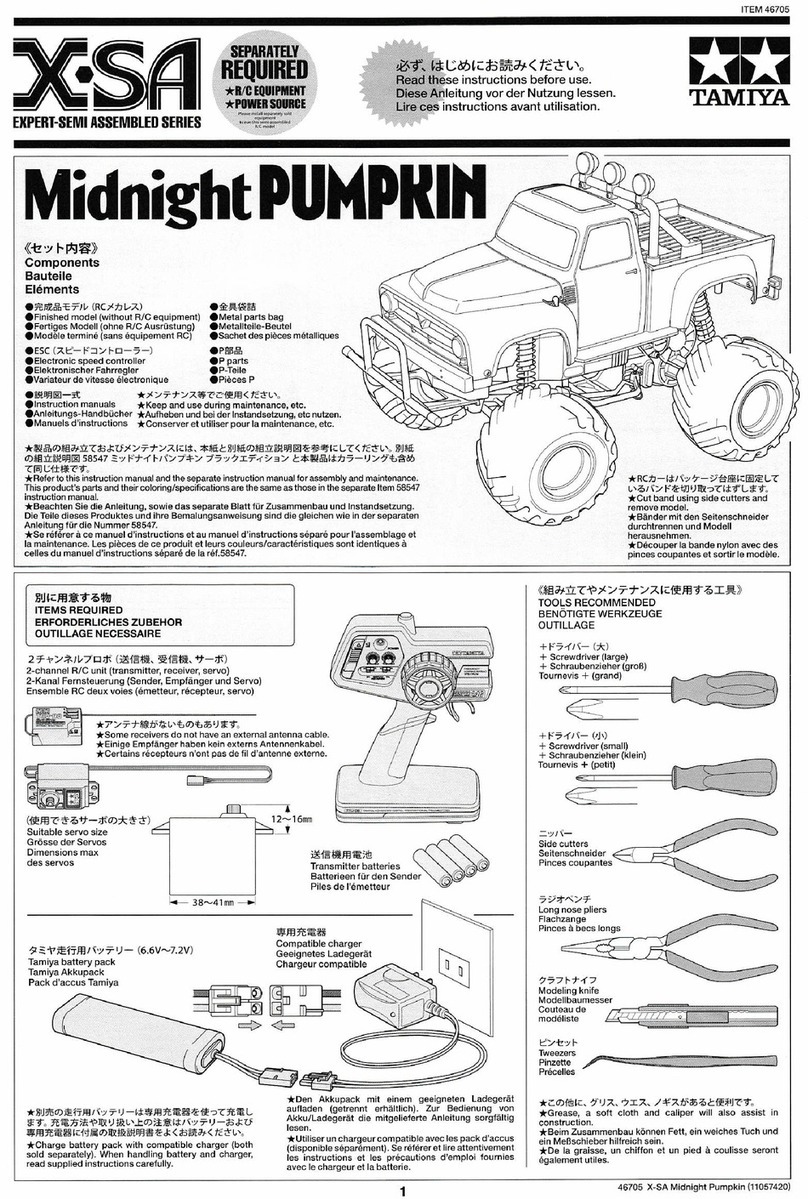

Tamiya X-SA Midnisht PUMPKIN quick start guide

Value Hobby

Value Hobby Easy Stik 15 EPP ARF instruction manual

POLA G

POLA G Round iron stove + accessories manual